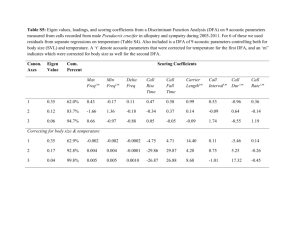

(DFA)

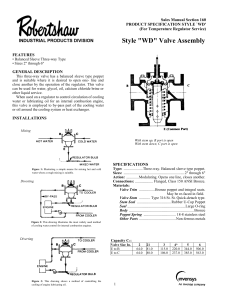

advertisement