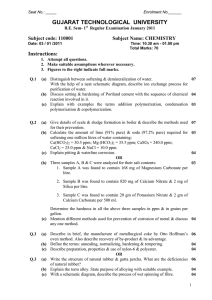

CHEMICAL HYGIENE PLAN

advertisement