THE ROLE FOR FEDERAL R&D ON ALTERNATIVE AUTOMOTIVE POWER SYSTEMS

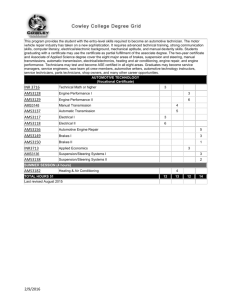

advertisement