Chancellor’s University Safety Committee (CUSC) Meeting

advertisement

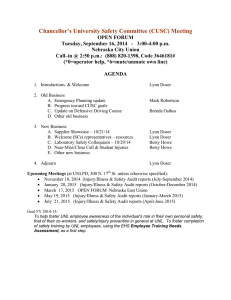

Chancellor’s University Safety Committee (CUSC) Meeting Tuesday, July 15, 2014 3:00-4:00 p.m. UNLPD 300 N. 17th Call–in @ 2:50 p.m.: (888) 820-1398, Code 3646181# (*0=operator help, *6=mute/unmute own line) AGENDA 1. Introductions & Welcome Lynn Doser 2. Fiscal Year 2013-14 (4th Qtr.) Injury/Illness Yoko Smith 3. Fiscal Year 2013-14 (4th Qtr.) Safety Audit Brenda Osthus 4. Old Business A. Emergency Planning update B. Progress toward CUSC goals C. Interest in Defensive Driving Course D. Other old business Mark Robertson Brenda Osthus 5. New Business A. Welcome (SCs) representatives B. Other new business Lynn Doser 6. Adjourn Lynn Doser Upcoming Meetings (at UNLPD, 300 N. 17th St. unless otherwise specified): September 16, 2014 OPEN FORUM Nebraska City Union November 18, 2014 (Injury/Illness & Safety Audit reports (July-September 2014) January 20, 2015 (Injury/Illness & Safety Audit reports (October-December 2014) March 17, 2015 OPEN FORUM Nebraska East Union May 19, 2015 (Injury/Illness & Safety Audit reports (January-March 2015) July 21, 2015 (Injury/Illness & Safety Audit reports (April-June 2015) Goal FY 2013-14: To help foster UNL employee awareness of the individual’s role in their own personal safety, that of their co-workers, and safety/injury prevention in general at UNL. To foster completion of safety training by UNL employees, using the EHS Employee Training Needs Assessment, as a first step. Chancellor’s University Safety Committee Meeting Meeting Minutes July 15, 2014 3:00 - 4:00 p.m. UNLPD Conference Room The meeting was convened by Chair, Lynn Doser (Sheldon Museum of Art). Attendees introduced themselves. Members: Greg Maguire (Housing), Mark Robertson (UNLPD), Beth Whitaker (School of Biological Sciences), Chanell Carpenter (UHC), Deb Pearson (Libraries), Jolene Deinert (Custodial Services), Allan Henrichs (Shared Services), Kyle Hansen (Campus Rec), Brenda Osthus (EHS), Yoko Smith (EHS support). Safety Committee Chairs: Raul Barletta (VBS). SC Chair Attending Remotely: Tamra Jackson-Ziems (Plant Pathology). FY 2013-2014 (4th Quarter) INJURY INCIDENT REPORT Forty-two (42) First Reports of Injury (FRIs) were received by EHS for injuries occurring between April 1 and June 30, 2014. Twenty-six (26) or 62% were classified as OSHA-Recordable, considered potentially more serious. All reports were sent to members for review prior to the meeting. Brenda Osthus stressed awareness of two categories of incidents: falls and overexertion. These types of injuries occur across all worker classifications, tend to be serious, and tend to be high dollar claims. Often injuries from overexertion can be avoided simply by using the correct mechanical assistance, e.g., carts for moving heavy items rather than hand carrying. Falls often can be avoided with a few simple strategies, e.g., avoid hand-carrying items while traversing steps, maintain awareness of terrain, avoid rushing, wear sturdy footwear, be sure to clean up spills/liquids, etc. There were a number of animal-related injuries. Osthus explained that occupational safety is one portion of the AALAC (Association for Assessment and Accreditation of Laboratory Animal Care) accreditation that UNL is currently seeking in the animal care program. To assist in evaluating their occupational safety program, EHS provides regular reports of animal-related injuries to the IACUC (Institutional Animal Care & Use Committee) so that they can evaluate if different handling techniques or additional training is necessary to minimize the risk of injury in the future. FY 2013-2014 (4th Quarter) SAFETY AUDIT OVERVIEW Safety Audits are conducted of all spaces at UNL on a schedule, based on identified hazards and regulatory requirements. The quarterly safety audit report was sent to members for review prior to the meeting. Brenda Osthus highlighted selected deficiencies: (1) Machine guarding in shops which poses a high risk of injury and (2) Electrical safety (particularly extension cords and power strips), which continues to be a area of deficiency noted over and over again. Osthus encouraged members to stress safety in these particular areas within their reporting units. Osthus also reported EHS's emphasis on establishment of a safety manual (Virtual Manual) and completion of training by faculty and staff. EHS emphasis on these items complements the goal established by the committee. Osthus reported that when a safety manual is a cited deficiency, EHS staff creates a basic manual for the user and advises them to review the content. Lynn Doser asked about the deficiency cited by EHS related to leaving a helium cylinder on a cart. Osthus explained that compressed gas cylinders not in use are to be secured to an immobile structure with the valve cap in place. Carts are intended only for transport. OLD BUSINESS Emergency Planning & Preparedness Update In his report, Mark Robertson noted that UNL’s emergency alert system is moving to a new vendor (Rave Mobile Alert). The new vendor will provide enhanced features, such as the ability to send alerts to UNL’s web page, Twitter, Facebook, and other social media. It also provides the ability to send “pop up” messages to computers, and will support digital signage (“Alert Us”). Details of what features will be used/costs to departments, etc. are pending. UNL’s Emergency Planning & Preparedness web site is in the process of being upgraded and re-formatted. The building emergency plan template should be available on this web site after the upgrade. There are also efforts occurring to establish methods of stressing emergency preparedness using social media. Robertson has received the standard template for tornado posters from University Communications and will now be the keeper of this information. He is transitioning the posters from specifying a particular room to be more generic (e.g., lower level, interior room). Mark will complete a poster for any building upon request and email the poster to the requester as a pdf file. Generally, requests are placed through the BMR and posters are placed near elevators and stairs. The EOC (Emergency Operations Center) has been involved in a number of tabletop exercises, the most recent being a simulated release of anhydrous ammonia in Walter Scott Engineering (WSEC). One interesting outcome of this most recent exercise was the “interconnectedness” of several UNL buildings. In this case, the simulated event impacted WSEC, the Link, Othmer Hall, and Nebraska Hall since all are physically connected. It was also noted, that steam tunnels can serve as a conduit for “interconnectedness” of UNL buildings. This is a consideration in emergency planning. Progress Toward the CUSC Goal To help foster UNL employee awareness of the individual’s role in their own personal safety, that of their co-workers, and safety/injury prevention in general at UNL. To foster completion of safety training by UNL employees, using the EHS Employee Training Needs Assessment, as a first step. Several members reported on their department’s activities relative to the CUSC goal: Beth Whitaker reported that annual training for the TAs in Arts & Sciences has been scheduled with EHS. Doser reported emergency preparedness training for their tour guides, who are responsible for the safety of their tour groups. Kyle Hansen reported that Campus Rec has reinitiated their efforts to conduct self-audits throughout all Campus Rec departments. It is time-consuming, but valuable. Deb Pearson reported that the Libraries has reestablished their New Employee Orientation and have incorporated completion of safety training into that program. Yoko Smith reported that Museums and Business Services have requested training records to determine who has not completed training, and are reviewing the EHS Training Needs Assessment. Jolene Deinert reported that Custodial Services has adopted a monthly theme for focusing on safety. This month’s topic is building evacuation and fire extinguisher training. Interest in Defensive Driving Course Members confirmed their continued interest in driver safety training, expressing their interest in both web-based and hands-on. There was also interest in focused training, e.g., high profile vehicles, vans, trucks. Campus Rec reported that their drivers are required to take driver training, which they currently do through Southeast Community College. Campus Rec would be very interested in a similar training program through UNL. Doser offered two ideas that would encourage departments to participate: discounted rental rates and no charge for the class. Other Jolene Deinert introduced herself as the Custodial Services representative and was welcomed to the committee. NEW BUSINESS There was no new business. CLOSING REMARKS The next meeting will be held on September 16, 2014, from 3:00 – 4:00 p.m. at the Nebraska City Union. The meeting was adjourned by Chair Lynn Doser. CUSC Workers Compensation Incident Report (April – June 2014) As of June 30, 2014, forty‐two (42) FRIs were received for injuries occurring between April 1 and June 30, 2014. Seven (7) or 17 % were “report only” (no medical treatment sought). Nine (9) or 21 % were not OSHA‐recordable, meaning they were minor in nature (requiring only one visit to clinic without prescription medication). Twenty‐six (26) or 62 % were classified as recordable, and are considered potentially more serious. Of those recordable incidents, ten (10) or 24 % were lost time incidents that required the employees to be off work, to be transferred to a different job or to be under restricted duties. Trailing Reports: Five (5) FRIs were received for injuries occurring prior to April 1, 2014. One (1) did not require medical treatment. One (1) was not OSHA‐recordable, meaning it was minor in nature. Three (3) were classified as OSHA‐recordable, and are considered potentially more serious. Building Service Maintenance. Date of Accident (DOA): October 17, 2013. Strained left shoulder while lifting a motor in a tight spot. Engineering control not used. Education Media. DOA: January 1, 2014. Left tennis elbow due to repetitive nature of work with computers. Fatigue/stress. Campus Recreation. DOA: March 26, 2014. Strained lower back while lifting cabinet. Housekeeping. Breakdown of OSHA Recordable Incidents (Events and Causes) 04/01/2014 – 06/30/2014 Food Service Construction Custodial Fall 1 (Improper tool usage) Bending, climbing, crawling, reaching, twisting Overexertion in Lifting 1 (Deviation from protocol) 2 (Fatigue/stress, deviation from protocol) Caught in/crashed by Other contact with objects or equipment 1 (PPE not used properly) Exposure to harmful substance or environment Totals 2 1 Overexertion in pushing/ pulling Struck against or by Maintenance/ Utilities Agriculture/ landscape 2 (Uneven terrain) Animal Handler 1 (Deviation from procedure) 1 (Location) 1 (Inadequate procedure) Office Shop/ Mechanic Other Totals 4 (Inattention, material failure, location, housekeeping) 1 (Location) 8 1 (Engineering control not used) 4 3 1 (Fatigue/stress) 1 1 (Location problem) 1 (Engineering control not used) 1 (Inattention) 1 (Personal – other) 2 (Location) 2 1 (PPE not used properly) 1 (Unable to determine causes) 3 1 (Location) 3 2 4 4 1 5 7 1 1 26 Age (OSHA Recordable) Apr. ‐ June 2014 18 ‐ 25 26 ‐ 40 41 ‐ 55 56 ‐ 65 +65 0 1 2 3 4 5 6 7 8 9 10 Safety Audit Overview (April 1 – June 30, 2014) Safety Audits are conducted of all spaces at UNL on a schedule, based on identified hazards and regulatory requirements. A ‘space’ is defined as an area on the official IRP map with a number and/or word designation and includes areas such as secondary rooms, corridors, storage areas, etc. Laboratory spaces Kitchen spaces General spaces (Office/Common/Classroom/Storage) Shop/Custodial & Utility spaces 477 24 392 203 Areas audited (within 41 buildings): Agronomy/Horticulture Physiology Agricultural Warehouse No. 1 Agricultural Warehouse No. 2 Animal Sciences Complex Architecture Hall West Ag Implement Outstate Test Shed Beadle Center Bessey Hall Cather/Pound Food Service Chase Hall East Stadium East Thermal Energy Storage Entomology Food Industry Building Filley Hall Henzlik Hall Harper Dining Center Harper Residence Hall Insectary Building Kauffman Academic Residential Center Kiesselbach Crops Research Laboratory Manter Hall Morrison Life Science Research Center Natural Resources Research Annex Plant Science Hall Poultry Building F Pound Residence Hall Schramm Residence Hall Selleck Food Service Bldg. Selleck Quadrangle Smith Residence Hall Splinter Labs Teacher’s College The Village Theodore Jorgensen Hall Transportation Services University Health Center Utility Plant – City Campus Utility Plant – East Campus Veterinary Basic Science Building Water Sciences Laboratory Deficiency Recap One ‘lab/office/shop’ may consist of multiple, connected spaces with the same use/same room owner. Most prevalent deficiencies for each space type are listed in order of predominance. Deficiencies in Laboratories Written safety procedures are lacking or incomplete (e.g., Virtual Manual/Chemical Hygiene Plan and lab-specific written protocols as appropriate/applicable). Required training has not been completed. Emergency shower and/or eyewash were not immediately available, accessible, and/or operable in areas where any material can have an adverse effect on the health and safety of humans is used. Eyewashes and showers have not been tested regularly. An accurate inventory or hazardous chemicals stored/used in the area is not available. Chemicals were not stored in a safe and proper manner, e.g. segregated by compatibility; unnecessary compressed gas cylinders were being stored in the laboratory; compressed gas cylinders were not properly restrained; flammables were stored outside of rated cabinets/stored in household refrigerators; etc. Deficiencies in Kitchens Three feet of clearance is not maintained in front of electrical panels or breaker boxes; or emergency shut-off controls to equipment are blocked/inaccessible. Entrances to areas where hazardous chemicals are used/stored are not identified with a door placard. Compressed gas cylinders (helium) are stored on carts; uncapped. Fire doors are propped open with a door stop. Deficiencies in General Areas (office, classroom, storage, break room/lounge, etc.) Extension cords are not restricted to temporary use, or multi-plug adaptors are used as a substitute for permanent wiring or receptacles. Re-locatable power taps or similar devices are not UL or FM approved, or are not used solely for low power applications. Re-locatable power taps, power strips or extension cords are not plugged directly into a permanently installed electrical outlet. A guard was missing on a portable fan. Deficiencies in Shops There is no Virtual Manual/Hazard Communication plan. Workers have not completed required training such as the basic safety training required (e.g. Core-Emergency Preparedness, Core-Injury and Illness Prevention Plan, Chemical Safety) or other training required based on their job tasks (e.g. Lockout/Tagout). Three feet of clearance is not maintained in front of electrical panels or breaker boxes; or emergency shut-off controls to equipment are blocked/inaccessible. Chemical containers are not adequately labeled (labels missing, illegible, or incomplete). Chemicals were not stored in a safe and proper manner, e.g. segregated by compatibility; compressed gas cylinders were not properly restrained; flammables were stored outside of rated cabinets; etc. Other: Welding cart cylinder valves gauges showed pressure on the gauge; There is a torch set-up on a wooden bench; Soldering occurring w/o waste being properly collected for disposal through EHS; No handrails on steps; Grounding cable on MIG welder left attached to the work table when not in use. Audit statistics reviewed are Occupational Safety findings and do not include specific program audits, such as Radiation Safety or Biosafety.