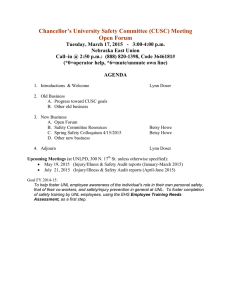

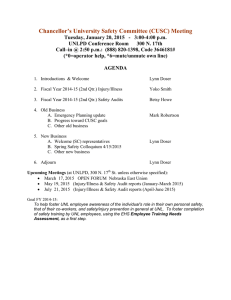

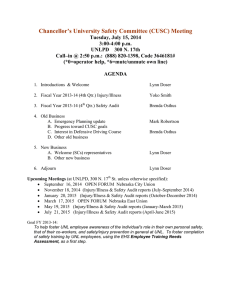

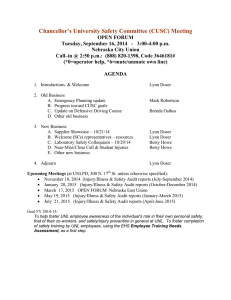

Chancellor’s University Safety Committee (CUSC) Meeting

Chancellor’s University Safety Committee (CUSC) Meeting

Tuesday, November 18, 2014 - 3:00-4:00 p.m.

UNLPD Conference Room 300 N. 17th

Call–in @ 2:50 p.m.: (888) 820-1398, Code 3646181#

(*0=operator help, *6=mute/unmute own line)

AGENDA

1.

Introductions & Welcome

2.

Fiscal Year 2014-15 (1st Qtr.) Injury/Illness

3.

Fiscal Year 2014-15 (1st Qtr.) Safety Audit

Lynn Doser

Yoko Smith

Betsy Howe

4.

Old Business

A.

Emergency Planning update

B.

Progress toward CUSC goals

C.

Update on Defensive Driving Course

D.

Supplier Showcase – 10/21/14

E.

Laboratory Safety Colloquium – 10/29/14

F.

Other old business

Mark Robertson

Brenda Osthus

Lynn Doser

Betsy Howe

5.

New Business

A.

Welcome (SC) representatives – resources? Lynn Doser

B.

Other new business

6.

Adjourn Lynn Doser

Upcoming Meetings (at UNLPD, 300 N. 17 th

St. unless otherwise specified):

January 20, 2015 (Injury/Illness & Safety Audit reports (October-December 2014)

March 17, 2015 OPEN FORUM Nebraska East Union

May 19, 2015 (Injury/Illness & Safety Audit reports (January-March 2015)

July 21, 2015 (Injury/Illness & Safety Audit reports (April-June 2015)

Goal FY 2014-15:

To help foster UNL employee awareness of the individual’s role in their own personal safety, that of their co-workers, and safety/injury prevention in general at UNL. To foster completion of safety training by UNL employees, using the EHS Employee Training Needs

Assessment, as a first step.

Chancellor’s University Safety Committee Meeting

Meeting Minutes

November 18, 2014 3:00 - 4:00 p.m.

UNLPD Conference Room

The meeting was convened by Chair, Lynn Doser (Sheldon Museum of Art).

Attendees introduced themselves.

Members: Greg Turner (BSM), Eileen Bergt (Landscape Services), Beth Whitaker

(School of Biological Sciences), Chanell Carpenter (UHC), Deb Pearson (Libraries),

Jolene Deinert (Custodial Services), Pat Dussault (Chemistry), Tracy Grauer (ITS),

Kim Phelps (University Services), Karen Helberg (PHREC attending remotely), Yoko

Smith (EHS support), Betsy Howe (EHS support).

Safety Committee Chairs: Alan Boldt (Biological Systems Engineering), Andy

Suyker (School of Natural Resources).

FY 2014-2015 (1st Quarter) INJURY INCIDENT REPORT

Forty-nine (49) First Reports of Injury (FRIs) were received by EHS for injuries occurring between July 1 and September 30, 2014. Twenty-eight (28) or 57% were classified as OSHA-Recordable, considered potentially more serious. All reports were sent to members for review prior to the meeting.

Yoko Smith noted that there were an unusual number of hornet or wasp injuries this year, but only two were OSHA-Recordable. There was some discussion on prevention. One of the main areas of occurrence was nests in hollow portions of gates/fencing at extension centers. Each facility dealt with all identified hornet nest locations as identified, but due to the large quantity of potential nesting sites did not pre-treat all potential areas.

The majority of injury incidents this quarter were caused by factors within the control of the worker: deviation from protocol, PPE available but not used/used improperly, inattention, engineering controls available but not used, improper tool or usage of tool. CUSC members were reminded to share this information within their spheres of influence.

FY 2014-2015 (1st Quarter) SAFETY AUDIT OVERVIEW

Safety Audits are conducted of all spaces at UNL on a schedule, based on identified hazards and regulatory requirements. The quarterly safety audit overview was sent to members for review prior to the meeting.

Betsy Howe highlighted selected deficiencies:

In both laboratory and shop spaces where hazardous chemicals are used, a number of entrances were not identified with a door placard or the placard was illegible or inaccurate. EHS conducts a hazard reassessment as part of a safety audit but will reassess and revise door placards upon request of a room occupant when hazards within change.

A large number of laboratories and shops did not have an accurate list of hazardous chemicals stored/used in the area. Betsy explained this type of list need not include quantities unless the area so desires for their own controls. The purpose of the chemical inventory list is so workers can review such lists to become aware of hazardous chemicals in their area but which they personally may not be using.

A predominant finding in audits of General areas (offices/conference rooms/storage areas/lounges/break rooms, etc.) was use of power strips for higher power applications such as microwaves, refrigerator/freezers, coffeepots, etc. Higher power items should be plugged directly into a permanently installed outlet.

OLD BUSINESS

Emergency Planning & Preparedness Update

Mark Robertson was at an international conference and unable to attend.

Three major preparedness exercises were held on the week of the 10th. This drills tested the readiness of the UNL Emergency Operations Center, UNL Family

Assistance Center and the UNL Joint Information Center. These exercises simulated the response to an anhydrous ammonia release in a lab.

Progress toward the CUSC Goal

To help foster UNL employee awareness of the individual’s role in their own personal safety, that of their co-workers, and safety/injury prevention in general at UNL. To foster completion of safety training by UNL employees, using the EHS Employee Training Needs

Assessment, as a first step.

Betsy Howe has been working with Information Technology Services. Facilitated by

Colleen Huls, this department is planning to require all department staff to successfully complete the Injury and Illness Prevention Plan and Emergency

Preparedness web-based training by the end of calendar year 2014.

Chanell Carpenter, University Health Center (UHC), said their department could not attend the Supplier Showcase as that day they had UHC all-area training, including emergency preparedness as it specifically relates to the UHC facility/operations.

Defensive Driving Course

Brenda Osthus sent word to the committee that Patrick Barrett has been provided information on what defensive driving resources are available through the Nebraska Safety Council. No decision has been made on the next steps.

Supplier Showcase

Lynn Doser reported that the CUSC booth reached at least 178 UNL personnel, the number of “Speak Out for Safety” stickers distributed. Those members staffing the booth highlighted the “Report An Accident or Near-Miss” section of the EHS web site, reinforcing their message with a screen shot handout indicating this area’s location on the updated EHS web site.

Attendees shared a few campus safety concerns which Lynn followed up on.

Laboratory Safety Colloquium

Betsy Howe reported that the emphasis of the last colloquium held on October 29 th and of the next colloquium to be held April 15, 2015 is more generally applicable rather than targeted specifically toward laboratories. The recent colloquium,

“DISASTER! Protect Yourself and Your Research,” reviewed a number of scenarios toward the goal of inspiring attendees to think about how to protect their individual research components, including data, in addition to the personal safety considerations usually considered, for example in the Emergency Preparedne ss web-based training. The colloquium is now online through the EHS web site under the “Training” section.

Other

Eileen Bergt reported that some shrubs near the Sheldon Museum of Art causing issues with pedestrian visibility were removed. The Architecture Hall lighting situation discussed at the last CUSC meeting is being addressed. Additionally, bushes near the 50/50 Housing unit were trimmed as there were issues related to visibility by those using the 17 th

& R Parking Garage.

A question was posed as to where the responsibility for sidewalk snow removal lies for areas in front of fraternities and sororities. Eileen said fraternities and sororities are responsible for their own snow removal. It was reported that these groups have routinely been shoveling only their steps and their own walkway leading to the sidewalk. This results in treacherous walking conditions for UNL faculty, staff and students in front of sororities and fraternities. Eileen will make sure sororities and fraternities are aware they must clear the public walkways in front of their buildings.

NEW BUSINESS

The two Safety Committee attendees were welcomed. There was no other new business.

CLOSING REMARKS

The next meeting will be held on January 20, 2015, from 3:00 – 4:00 p.m. at the UNL

Police Department Conference Room. The meeting was adjourned by Chair Lynn

Doser at 3:45 p.m.

CUSC

Workers

Compensation

Incident

Report

(July

‐

September

2014)

As of September 30, 2014, forty ‐ nine (49) FRIs were received for injuries occurring between July 1 and September 30, 2014.

Three (3) or 6 % were “report only” (no medical treatment sought).

Eighteen (18) or 37 % were not OSHA ‐ recordable, meaning they were minor in nature (requiring only one visit to clinic without prescription medication).

Twenty ‐ eight (28) or 57 % were classified as recordable, and are considered potentially more serious.

Of those recordable incidents, seven (7) or

14 % were lost time incidents that required the employees to be off work, to be transferred to a different job or to be under restricted duties.

Trailing Reports:

Six (6) FRIs were received for injuries occurring prior to July 1, 2014.

One (1) did not require medical treatment.

Two (2) were not OSHA ‐ recordable,

meaning they were minor in nature.

Three (3) were classified as OSHA ‐ recordable, and are considered potentially more serious.

Animal Science (Animal Handler).

Date of Accident (DOA): June 12, 2014.

Struck head on the building structure while standing on a pickup in a shop.

Location.

ARDC (Agriculture worker).

DOA: June 13, 2014.

Strained right knee after walking on very muddy fields.

Weather condition.

FMP Facilities & Planning.

DOA: June 17, 2014.

Went up the stairs to 8 th

floor and tore left meniscus.

Fatigue/stress.

Breakdown of OSHA Recordable Incidents (Events and Causes) 07/01/2014 – 09/30/2014

Bending, climbing, crawling, reaching, twisting

Overexertion in Lifting

Food Service

1

(Inadequate procedure)

Laboratory

1

(Deviation from protocol)

Custodial Maintenance/

Utilities

Agriculture/ landscape

1

(Location problem)

2

(Inadequate procedure, engineering control available but not used)

Animal Handler

Overexertion in holding, carrying, etc.

Struck against or by

Fall

4

(Location problem, PPE available but not used)

1

(Inattention)

1

(Improper tool usage)

2

(Housekeeping, improper tool usage)

1

(Deviation from protocol)

2

(Improper tool usage, PPE needed but not available)

Office

Slip, trip, loss of balance without fall

1

(Uneven terrain)

1

(Uneven terrain)

4

(Uneven terrain,

Equipment failure, deviation from protocol, inattention)

1

(Uneven terrain)

Public Safety Totals

2

3

6

3

1

8

Exposure to harmful substance or environment

Assaults & Violent Acts

(Animals or humans)

1

(PPE available but not used)

Repetitive motion 1

(Fatigue/strain)

1

(Environment –

Other)

1

(Environment –

Other)

2

1

(Environment

– Other)

2

1

Totals

8 1 1 5 6 1 5 1 28

Age (OSHA Recordable)

July ‐ Sept.

2014

18 ‐ 25

26 ‐ 40

41 ‐ 55

56 ‐ 65

0 1 2 3 4 5 6 7 8 9 10

Safety Audit Overview (July 1 – September 30, 2014)

Safety Audits are conducted of all spaces at UNL on a schedule, based on identified hazards and regulatory requirements. A ‘space’ is defined as an area on the official IRP map with a number and/or word designation and includes areas such as secondary rooms, corridors, storage areas, etc.

684

874

Laboratory spaces

General spaces

(Office/Common/Classroom/Storage)

Shop/Custodial & Utility spaces

Areas audited (within 36 buildings) :

102

Ag Hort Greenhouse 2

Ag Hort Greenhouse 4

Animal Sciences Complex

Biochemistry Hall

Beadle Center

Bioscience Greenhouses – Beadle Center

Bus Garage

Chase Hall

East Stadium

Elliott Facility

Facilities Implement Building

Hamilton Hall

Hardin Hall

Hawks Championship Center

Insecticide Storage Building

Keim Hall

Landscape Services East

Landscape Services – City Campus

Deficiency Recap

Landscape Services Metal Building

Landscape Services Metal Canopy

Leverton Hall

Lied Center for Performing Arts

Manter Hall

Morrison Life Science Research Center

Osborne Athletic Complex

Plant Pathology Greenhouse

Plant Sciences Hall

Scott Engineering Center

Service Building

Stewart Seed Lab

Temple Building

Theodore Jorgensen Hall

Transportation Services

University Health Center

Veterinary Basic Science Building

Watson Building

One ‘lab/office/shop’ may consist of multiple, connected spaces with the same use/same room owner. Most prevalent deficiencies for each space type are listed in order of predominance.

Deficiencies in Laboratories

Entrances to areas where hazardous chemicals are stored are not identified with a laboratory door placard, or the placard is illegible or inaccurate.

Emergency shower and/or eyewash were not immediately available, accessible, and/or operable in areas where any material can have an adverse effect on the health and safety of humans is used. Eyewashes and showers have not been tested regularly.

Written safety procedures are lacking or incomplete (e.g., Virtual Manual/Chemical

Hygiene Plan and lab-specific written protocols as appropriate/applicable).

Required training has not been completed.

An accurate inventory or hazardous chemicals stored/used in the area is not available.

Deficiencies in General Areas (office, classroom, storage, break room/lounge, etc.)

Power strips are not used solely for low power applications, rather are being used to power microwaves, refrigerator/freezers, coffeepots, and other items not considered “low power.”

Re-locatable power taps, power strips or extension cords are not plugged directly into a permanently installed electrical outlet.

Extension cords are not restricted to temporary use, or multi-plug adaptors are used as a substitute for permanent wiring or receptacles.

Deficiencies in Shops

Administrative controls are lacking, ineffective or ineffectual (safety training, Virtual

Manual or equivalent Hazard Control Plan and shop-specific written protocols as appropriate/applicable)

Entrances to areas where hazardous chemicals are stored are not identified with a nonlaboratory/NFPA door placard, or the placard is ineligible or inaccurate.

Improper adjustment (e.g., Work rests must be adjusted to the abrasive wheel with a maximum opening of 1/8” to prevent the work from being jammed between the wheel and rest; distance between the adjustable tongue & the grinding wheel periphery exceeds

¼”)

An accurate inventory or hazardous chemicals stored/used in the area is not available.

Audit statistics reviewed are Occupational Safety findings and do not include specific program audits, such as Radiation Safety or Biosafety.