DOE/ET-51013-209 UC20,a,b,df,g

advertisement

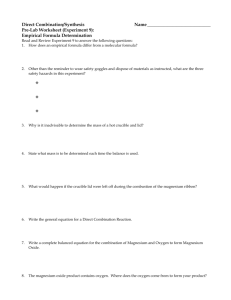

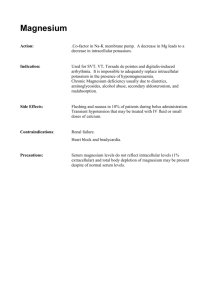

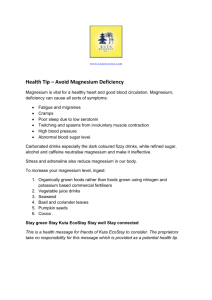

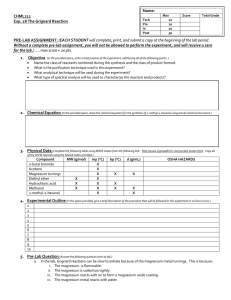

DOE/ET-51013-209 UC20,a,b,df,g PFC/RR-87-1 Pumping Effectiveness of a Magnesium Vapor Jet in the Presence of a High Power Neutral Beam Source T. J. Farish and R. S. Post January 1987 Plasma Fusion Center Massachusetts Institute of Technology Cambridge, Massachusetts 02139 USA This work was supported by the U. S. Department of Energy Contract No. DE-AC02-78ET51013. -2- Abstract An experimental study of a supersonic magnesium vapor jet neutralizer has established the effectiveness of the jet in reducing cold streaming gas from a high current neutral beam source. The removal of molecular hydrogen gas by a magnesium jet neutralizer provides a means of simplifying jet beamline design by improved pumping characteristics of the compared with conventional technology while simultaneously improving performance. -3- An experimental study of a supersonic magnesium vapor jet neutralizer has established the effectiveness of the jet in reducing cold streaming gas from a high current neutral beam source. The removal of molecular hydrogen gas by a magnesium jet neutralizer provides a means of simplifying jet beamline design by improved pumping characteristics of the compared with conventional technology while simultaneously improving performance. In the ion a source is used as the charge-exchange target. prevented plasma from ions escaping pumping up conventional neutralizer system, hydrogen gas issuing from flowing from from to the undergoing the machine. target mirror machines, plasma in order to prevent hot charge-exchange reactions in the gas and Excess gas is limited by baffling and large speeds of the beamlines. in This gas must be but Present methods allow plasmas to build the plasma lifetime is still limited by charge-exchange. The present experiment tests an improved version of the magnesium with a full-scale ion beam source capable of 55 amperes extracted at jet 16.9 kV. a cold The data shows that the magnesium jet is capable of maintaining gas pressure differential in excess of three orders of magnitude over the full range of beam source operating conditions. neutral the study particle fraction Measurements of obtainable with the magnesium jet and a of possible magnesium plasma formation in the beam-jet interaction region are underway. The valve, is vapor conduit and supersonic nozzle. heated point magnesium vapor jet consists of four main components: oven, Magnesium metal in the oven to an operating temperature of 8000 C, well above the melting of 6540 C. When the valve is opened, magnesium vapor flows out of -4- the oven through the conduit to the supersonic nozzle. The vapor stream exits the nozzle at supersonic velocities and intercepts the ion beam/gas stream. as The 20 kV beam particles are neutralized by the magnesium vapor in a gas charge-exchange cell. From the point of view of the energetic beam atoms, the magnesium molecules are almost stationary. For the hydrogen cold magnesium stream molecules are the an system mass flow and gas was found formidable the barrier. beam, however, the Since the magnesium by of raising the oven temperature and increasing the the limited evaporated material. In a real-world system, by temperature effects on reliability of components leakage around the pumping region. that In an arbitrarily large amount of gas can be pumped with simply rate is a with jet acts like a diffusion pump to sweep away the gas. system, this pumping presents traveling moving quite fast compared to the hydrogen gas molecules, magnesium ideal molecules reliability of the In previous experiments, heating units it deteriorated for 1 shows the magnesium oven, valve and heating units. The operating temperatures above 9000 C. Figure oven, conduit components. and heating units are made from commercially available The electromagnetically operated valve, which consists of a molybdenum shaft and tungsten plug, was designed for a previous prototype and used with magnesium jet temperature ceramic modification neutralizer of 8000 C. fiber operation, no the system is the current oven design. The designed to operate with an oven The oven and conduit are surrounded by layers of insulation valve with is and a opened single for 0.5 steel to heat shield. During 2 seconds per shot, with -5- approximately shows the ion grams experimental ragnesium conduit 0.1 oven and beam nozzle is transversely actual experiment Tara evaporated per second. Figure 2 The in its own vacuum chamber) is mated to a long inside the test stand vacuum chamber. also A full-scale mounted on the test stand, with the ion beam through delineate the chambers P1, the magnesium setup used in the gas pumping experiments. (residing source directed of the magnesium jet. The baffles which P2 and P3 have been designed so as to simulate relative volumes and conductances in the Tara Tandem Mirror beamline. In this experiment, chamber P1 corresponds to the source tank, chamber P2 corresponds to the plug region (which is to b-e screened by the jet) and chamber P3 represents a jet blow-down region. The magnesium vapor is collected on a liquid nitrogen-cooled surface used as part of the milliseconds, module. vacuum and the jet is nilliseconds. The ion beam source is fired for 50 the pressures in the chambers are recorded by a CAMAC After magnesium system. system turned has on returned and the to its source base pressure, the fired again for 50 The results are shown in Figures 3, 4 and 5 which compare the pressure in the simulated plug region for low and high beam power and low and high temperature jet can brought case be up magnesium temperature. Figure 3 shows a low (oven at 7500 C) in which some gas leakage through the seen. to oven As shown in Figure 4, when the oven temperature is its operating value of 8000 C, the pressure pulse is virtually eliminated from ion source at full operating power of 55 amperes extracted at beam is the simulated plug region. 16.9 kV, and the oven is at 8000 C. In Figure 5, the -6- This reducing the data cold presence demonstrates of also in a magnesium jet is capable of full scale ion beam developed for use with the Tara Such a gas reduction would allow a substantial plasma lifetime. to work the hydrogen gas flow by three to four orders of magnitude in Tandem Mirror experiment. increase that reduce cold In addition, a magnesium jet system would gas flow from a beam dump into the plasma region. The oven heaters and valve operated very reliably with an oven temperature of 8000 C. When the vacuum chamber was opened, all magnesium deposits magnesium the were found to scavenger. beamline was reside on the liquid nitrogen panel used as a Although no evidence of magnesium migration down seen, magnesium flow is underway. a more sensitive experiment to detect stray -7- Acknowledgment Grateful F. Yarworth, with this work. acknowledgment is extended to Richard P. Torti, George Vitaly J. Berkman and Marcel P. J. Gaudreau for their help -8- EL VALVE 000 HEATERS -*) O O O 0 0 O0 CONDUIT 0 0 0000 00 00 0 0 0 HEATERS 7 0 MG OVEN o 0 0 MAGNESIUM OVEN Figure 1. 0 0 0 0 lo 0 0 0 0 0 0 0l 0 0 c-9 U)t Ui r-V I I 4 0 4 4I ) I rl 4 ro I PL4 1-41- 9 I I I C I M' 101 Figure 2. -10- PRESSURE RISE DURING SHOT - LOW BEAM POWER 10 I I I Mg jet ON, T-a750 cc : i 0 C 10-7 UAAAIL r U-) cc , 41 1 i~i'UkW""I 1 V)U~YWF.~YlW.YP - Oa. rCj . VV~~~T'U*V* VV*~* - pvf~.~w ~-1~-14iU1I I CL .1 -1.0 .6 2.2 . 3.8 5.4 TIME (SEC) -~ 7.0 10 Ig I F I -- a- Lii a:U, (n' LLi cc a- 0'7 cv, CL to-, -1.0 .6 2.2 3.8 ThiuE (SEC) Figure 3. 5. 4 (.U -11- PRESSURE RISE DURING SHOT - LOW BEAM POWER 10 g cc jet ON, T-800 C ff a U' \0 fir nA - 10 -1 .0 10 .6 2.2 3.8 TIME (SEC) 7.0 5.4 7.0 I. 1g cc C 5.4 jet OFF lo's cc n~ cc 10-1 10-1 -1 .0 .6 2.2 TIME (SEC) Figure 4. 3.8 -12- PRESSURE RISE DURING SHOT - HIGH BEAM POWER 10 Mg jet ON, T=800 r C lo-s cc 4D a- r-- -1.0 .6 2.2 TIME (SEC) 3.8 5.4 7.0 5.4 7.0 10' jet OFF rMm t7i a: cc C- 1 -I. 0 .6 2.2 3.8 TIME (SEC) Figure 5.