Statistics 496, Applied Statistics for Industry II Name: _________________ Exam

advertisement

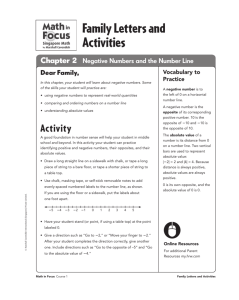

Statistics 496, Applied Statistics for Industry II Name: _________________ Exam 1, Spring 2009 Site: ___________________ INSTRUCTIONS: You will have 1 hour and 30 minutes to complete the exam. There are 5 questions worth a total of 100 points. Not all questions have the same point value so gauge your time appropriately. Read the questions carefully and completely. Answer each question and show work in the space provided on the exam. Turn in the entire exam when you are done or when time is up. For essay questions, think before you write. 1. [30 pts] As part of the quality assurance program a customer service call center monitors the response time, the time between the first ring until a service representative answers the call. The target time is 30 seconds with upper and lower specification limits of 0 seconds and 60 seconds, respectively. Six response times are selected, at random, from each of 50 shifts. Refer to the JMP output “Call Pickup Time.” a) [6] Looking at the control charts on page 1 of the output, comment on the stability of the response time process. Use all points within control limits as your definition of statistical control. Be specific and be sure to comment on both charts. b) [4] Special causes were identified and removed from the response time process. Looking at the control charts on page 2 of the output, comment on the stability of the response time process. Use all points within control limits as your definition of statistical control. Be specific and be sure to comment on both charts. c) [3] Compute an estimate of the process standard deviation from the value of R given on page 2 of the output. 1 d) [5] Capability analysis is run on the 282 response times remaining after special causes have been removed. Explain how the comparison of the overall standard deviation given in this analysis to the estimate you obtained in c) support the notion that special causes have been removed. e) [2] How many of the response times fall outside the specification limits? f) [2] What is the value of the process potential index? g) [2] What is the value of the process capability index? h) [2] According to the output, what percentage of response times would we expect to see outside of specification limits? i) [4] Do you believe that the percentage in h) is an accurate representation of the processes capability? Explain briefly. 2 2. [25 pts] An important quality characteristic in the manufacture of pulp used in paper is the pulp brightness. Pulp brightness is measured with a reflectance meter. Each of four shift operators makes five pulp hand-sheets from unbleached pulp. Reflectance is measured for each of the hand-sheets using the reflectance meter. Each operator measures the hand-sheets she/he has made. The data are given below. Mean, Yi Variance, si2 O1 60.3 60.0 60.1 60.2 59.8 60.08 Operator O2 O3 59.8 60.7 60.2 60.7 60.4 60.5 59.9 60.9 60.0 60.3 60.06 60.62 O4 61.0 60.8 60.6 60.5 60.5 60.68 0.037 0.058 0.047 0.052 a) [5] Is this an experiment or an observational study, explain briefly. b) [6] Compute the value of the Least Significant Difference (LSD) using t=3. c) [4] Using the value of the LSD in b), which, if any, of the operators have statistically significant mean brightness measurements? 3 Because the operators made the hand-sheets and measured the brightness we can’t be sure if differences are due to how the operators make the hand-sheets or how they measure the hand-sheets. d) [5] If we were interested in looking at differences due to the way the operators make the hand-sheets, how would you change the data collection to investigate this? e) [5] If we were interested in looking at differences due to the way the operators measure the hand-sheets, how would you change the data collection to investigate this? 3. [10 pts] Discuss briefly the enumerative and analytic purposes of a designed experiment. 4 4. [25 pts] The manufacturer of video tape runs an experiment to investigate the relationship between the video tape manufacturing line speed and the number of flaws in an 800 meter roll of video tape. There are four line speeds (10, 20, 30 and 40 decimeters per second). Only one manufacturing line is used in the experiment. There is one operator for the line. All the raw material comes from the same batch. The flaws on each video tape will be counted by the quality engineer using a detailed operational definition of what a flaw is. Six video tapes are manufactured for each line speed. The order of the 24 runs will be completely randomized. The data are given below. Y s2 10 10 5 12 8 14 8 9.5 10.3 Line Speed (dcm/sec) 20 30 14 13 12 18 16 10 13 13 9 15 8 18 12.0 14.5 9.2 9.9 40 17 16 12 15 22 14 16.0 11.6 a) [6] Comment on the control of outside variables, randomization and replication within the experiment. • Control • Randomization • Replication 5 25 20 Flaws 15 10 5 0 0 10 20 30 40 50 Line Speed b) [2] Comment on the general trend in the plot of tape flaws versus line speed. c) [8] Give the least squares regression equation that relates tape flaws to coded line speed. d) [2] Predict the number of tape flaws for a line speed of 25. e) [7] Is there a statistically significant linear relationship between tape flaws and the coded line speed? Support your answer with the appropriate test of hypothesis. Use t=3 as your critical value. 6 5. [10 pts] The purpose of replication in an experiment is to provide an estimate of within group, or replication error, variability. Two scenarios for an experiment involving chocolate chip cookies are given below. The response is an overall evaluation of the cookie based on scores for moistness, texture, flavor, greasiness and appearance. Higher scores indicate a better evaluation. • Scenario 1: One batch of cookie dough is made with vegetable margarine, one batch with reduced fat vegetable margarine, one batch with butter and one batch with vegetable shortening (Crisco). Five cookies are baked from each batch of dough. • Scenario 2: Five batches of cookie dough are made with vegetable margarine, five batches with reduced fat vegetable margarine, five batches with butter and five batches with vegetable shortening (Crisco). One cookie is baked from each batch of dough. a) [4] Describe in words the experimental (replication error) variability that exists in each scenario. • Scenario 1: • Scenario 2: b) [6] If cookies made with butter are found to have a mean score higher than those made with vegetable products and that difference is statistically significant, what sort of generalization can be made? • Scenario 1: • Scenario 2: 7