µ δ − 384

advertisement

IE 361 Hwk #3 Key

3.18

f. To make 1% of the sheets produced below nominal in length,

z = [(0 – µ) / 1.88] < -2.33

=> µ ≈ 4.38

UCL x = µ + 3

LCL x = µ − 3

δ

n

δ

= 5.64 + 3

= 5.64 − 3

n

1.88

3

1.88

3

= 8.896

= 2.384

q = P[ x < LCLx ] = P[ x < 2.384] = P[

ARL = 1 /0.0329 ≈ 30

x−µ

δ/ n

<

2.384 − µ

1.88 / n

] = P[Z < −1.84] = 0.0329

Therefore, 30 samples are needed to detect this.

For np chart, p=0.01

UCL x = np + 3 np (1 − p ) = 0.547

UCL x = np − 3 np (1 − p ) < 0

q = P[ x > UCLx ] = P[ x > 0.547] = P[ x > 1] = 0.0297

ARL = 1/ 0.0297 = 33.67 ≈ 34

Using np chart we need 34 samples to detect this.

By comparison, we can detect 1% of the sheets produced below nominal in length more

quickly by using x chart.

3.22

b. x = 1.18097

δ = 0.0001964

x ± 3δ = 1.18097 ± 3 ∗ 0.0001964 = (1.18038,1.18156)

3 δ Control Limits

#8 violates 3 δ Control Limits rule;

x ± 2δ = 1.18097 ± 2 ∗ 0.0001964 = (1.18058,1.18136)

2 δ Control Limits

#5, 6, 24, 8, 15 violate 2 δ Control Limits rule;

x ± δ = 1.18097 ± 0.0001964 = (1.18077,1.18117)

1 δ Control Limits

#4, 5, 6, 7, 24, 8, 13, 14, 22 violate 1 δ Control Limits rule.

f. δ = 0.0001964

n=4

µ = 1.1809

UCL x = µ + 3

LCL x = µ − 3

Z1 =

Z2 =

δ

n

δ

n

= 1.1809 + 3

= 1.1809 − 3

UCL x − 1.1810

δ/ 4

LCL x − 1.1810

δ/ 4

0.0001964

4

0.0001964

4

= 1.1812

= 1.1806

= 2.06

= −4.12

q = P[Z<-4.12 or Z>2.06] = 1- 0.9803 = 0.0197

ARL = 1 / 0.0197 = 50.8 ≈ 51

Therefore, 51 subgroups are required to detect such change in mean diameter.

4.2

c.

#

x

1

2

3

4

5

6

7

8

9

10

Average

.5

4.5

2.0

2.0

3.0

3.0

2.0

4.5

3.0

0

2.45

MR

4

2.5

0

1

0

1

2.5

1.5

3

1.722

δ = MR / 1.128 = 1.722 / 1.128 = 1.527

µ = 2.8

ARL=370

UCLx = µ + M δ = 2.8 + 3.2 * 1.527 = 7.686

LCL x = µ − M δ = 2.8 − 3.2 * 1.527 < 0

UCLMR = Rδ = 4.40 * 1.527 = 6.719

According to these limits, the milling process was operating at standard values of process

parameters over the production of the 10 screen fixture mountings.

IE 361

Homework #3

3-27

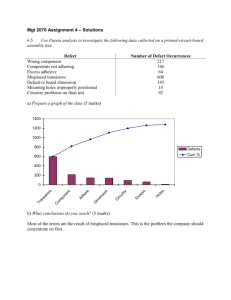

a. This data is attribute data because we are taking counts

b. A subgroup is a final assembly of a jet engine inspected each day

c. This would be the Poisson distribution because we are measuring nonconformities per

inspection unit. There is no upper bound with a minimum count of 0. This nonconforming

probability will be very small in the overall assembly process.

d.

λ = 636 / 30 = 21.20

λ = var

σ (hat ) = 21.20 = 4.6043

c. CL = λ = 21.20

UCLx = λ + 3 λ = 35.01

LCLx = λ - 3 λ = 7.39

This process was not stable, too many plotting outside of limits!

d. The calibration of devices used by each inspector must be the same and they must agree on

the definition of conforming and nonconforming.

3-30

a. ppooled = total nonconforming/total of the sample sizes = 270/2500 = .108

b. This would best be modeled as binomial because we are looking at number of failed, or

success probability

c. CLx = np = 100(.108) = 10.8

UCLx = np + 3 np(1 − p ) = 10.8 + 3 10.8(1 − .108)

LCLx = np - 3 np(1 − p ) = 10.8 - 3 10.8(1 − .108)

d. This plot monitors the number of switches that are nonconforming in each sample..

e. This plot indicates that on average we have 10.8% of each sample nonconforming give or

take 9.311%. For samples 5 and 20 we plot outside of this range telling us that these

particular samples had more nonconforming switches than normal, which is cause for alarm.

f. Shewhart np chart

g. Remove samples 5 and 20

p = 227/2300 = .0987

n = 100

CLx = np = 100(.0987) = 9.87

UCLx = np + 3 np(1 − p ) = 18.82

LCLx = np - 3 np(1 − p ) = .9222

None plot outside limits!

h. p = .0987

n = 75

n = 75

CL = np = .0987(75) = 7.4025

UCL = 7.4025 + 3 7.4025(1 − .0987) = 15.1515

LCL = 7.4025 - 3 7.4025(1 − .0987) = None

n = 144

CL = .0987(144) = 14.2128

UCL = 14.2128 + 3 14.2128(1 − .0987) = 24.95

LCL = 14.2128 - 3 14.2128(1 − .0987) = 3.477

n = 90

CL = .0987(90) = 8.883

UCL = 8.883 + 3 8.883(1 − .0987) = 17.37

LCL = 8.883 - 3 8.883(1 − .0987) = .3944

These three are not the same because we are working with different n values

4-31

5,4

a. V =

4,5

µx1 = 20

µx2 = 20

n=4

UCL x1 = 20 + 3(2.236 / 2) = 23.354

LCL x1 = 20 − 3(2.236 / 2) = 16.646

These control limits will be the same for x 2 because they have the same µ, σ and n

Both the 4th points of x1 and x 2 plot outside of the lower control limit.

b. CLx2 = p = 2 (2 variables, 2 degrees of freedom)

UCLx2 = p + 3 2 p = 8

Subgroup

X^2

1

0

2

3.56

3

8.89

Points 3,4,6 and 7 are out of control

4

10.89

5

0

6

8

7

32

8

3.56

c. Subgroups 3,6 and 7 have means that are related to µ1 and µ2 differently than described by

the positive correlation given in V.

Problem #2

a. For this “stable process” behavior my σ = 1.1426392 which is close to the process short-term

σ = 1.

b. MR / 1.128 = 1.27 / 1.128 = 1.126

This serves as a good estimate of the process short-term standard deviation

c. For column 2 the standard deviation is 29.02705. This does not serve as a short-term

estimate for σ = 1.

d. MR / 1.128 = 1.53 / 1.128 = 1.36

This estimate is much better than the on found in part c

e. Use MR / 1.128 for a short-term estimate of a short-term process standard deviation,

especially when the mean is changing.

Problem #3

a. σ(hat) = MR / 1.128

MR = (1 / r − 1)ΣMRi = 1 /(10 − 1)ΣMRi = (1 / 9) *15.5 = 1.722

σ (hat ) = 1.722 / 1.128 = 1.53

b. σ = 1.722/1.128 = 1.53

UCLMR = R6 = 6(1.527)

CL = 2.6

If x’s fall within control limits then the process is stable

5-2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

(i-.5)/25

0.02

0.06

0.1

0.14

0.18

0.22

0.26

0.3

0.34

0.38

0.42

0.46

0.5

0.54

0.58

0.62

0.66

0.7

0.74

0.78

0.82

0.86

0.9

0.94

0.98

Q(Pi)

989

1020

1022

1105

1129

1135

1157

1195

1220

1288

1313

1368

1502

1531

1629

1643

1666

1703

1706

1764

1764

1792

1946

1952

2004

b. i = np + .5 = 25(.1) + .5 = 3

Q = 1022

Q = 1151.5

Q = 1502

Q = 1946

c. These would not be exact because part b is based on sample data and not the whole

population

d.

Qz ( p) = 4.9[ p ^.14 − (1 − p)^.14]

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

Qz

-2.05

-1.55

-1.27

-1.08

-0.912

-0.7685

-0.6399

-0.521

-0.409

-0.304

-0.201

-0.0998

0

0.0998

0.201

0.304

0.409

0.521

0.6399

0.7685

0.912

1.08

1.27

1.55

2.05

e. This plot is not linear so it does not seem to fit a normal distribution

f.

ln Q(Pi)

1

2

3

4

5

6

7

8

9

10

11

12

13

ln Q(Pi)

6.897

6.928

6.93

7.008

7.029

7.034

7.054

7.086

7.107

7.161

7.18

7.221

7.315

13

14

15

16

17

18

19

20

21

22

23

24

25

7.315

7.334

7.396

7.404

7.418

7.44

7.442

7.475

7.475

7.491

7.574

7.577

7.603

g. This plot is not linear so it does not seem to fit a normal distribution

5-3

a.

Machine 1: Q(.25) = 1151.5

Q(.75) = 1720.5

Med = 1502

IQR = 569

Q(.25) – 1.5(IQR) = 298

Q(.75) + 1.5(IQR) = 2574

Machine 2: Q(.25) = 1306.50

Q(.75) = 1831.25

Med = 1498

IQR = 524.75

Q(.25) – 1.5(IQR) = 2618.38

Q(.75) + 1.5(IQR) = 519.38

b. Machine 2 has less variation so it is better!

5-17

a.

3-inch saddles:

x ± Τ2 s

3.038 + (.06)(2.319) = 3.178

3.038 − (.06)(2.319) = 2.8972

(2.8972, 3.178) has a 95% chance of including diameters from 90% of the 3-inch saddles

produced

4-inch saddles:

4.224 + (.13)(2.319) = 4.53

4.224 − (.13)(2.319) = 3.923

(3.923, 4.53) has a 95% chance of including diameters from 90% of the 4-inch saddles produced

6.5-inch saddles:

6.4658 + (.0824)(2.319) = 6.657

6.4658 − (.0824)(2.319) = 6.2747

(6.2747, 6.657) has a 95% chance of including diameters from 90% of the 6.5-inch saddles

produced

b.

95% prediction interval for 3-inch saddles

x ± ts 1 + (1 / n)

3.038 − (2.093)(.06)( 1 + (1 / 20) ) = 2.909

3.038 + (2.093)(.06)( 1 + (1 / 20) ) = 3.167

95% prediction interval for 4-inch saddles

4.224 − (2.093)(.13)( 1 + (1 / 20) ) = 3.945

4.224 + (2.093)(.13)( 1 + (1 / 20) ) = 4.503

95% prediction interval for 6.5-inch saddles

6.4658 − (2.093)(.0824)( 1 + (1 / 20) ) = 6.289

6.4658 + (2.093)(..0824)( 1 + (1 / 20) ) = 6.6425

5-18

a.

b.

c.

d.

1 − p ^ n − n(1 − p ) p ^ n − 1 = .8784233 − .27017 = .60825 = 60.83%

(n-1)/(n+1) = 19/21 = .90476 = 90.48%

1-pn = .8784 = 87.84%

n/(n+1) = 20/21 = .9524 = 95.24%

5-28

a. n = 30, x = 44.97938 = µ, s = .0024, target diameter = 44.9825

LC for Cpk = Cpk - z (1 / 9n) + Cpk ^ 2 / 2n − 2

Cpk = min{(44.99-44.97938)/(3*.0024), (.6082)/(30*2 – 2)}= .608

.608 – 1.645 (1 / 9.3) + (.608^ 2 / 58) = .443 (95% lower bound for Cpk)

((44.99 – 44.975)/(6*.0024)) 17.708 / 29 = .81398 (95% lower bound for Cp)

b.

c.

d.

e.

Cp gives potential performance while Cpk gives current performance.

Both would increase

To compare values, both specifications must remain constant

x ± ts 1 + (1 / n)

44.97938 − (.0024)(3.659) 1 + (1 / 30) = 44.9727

44.97938 + (.0024)(3.659) 1 + (1 / 30) = 44.9861

This is a 99% prediction interval for the next diameter. This is valid because of the linear normal

probability plot and stability of aim and short-term variability.

f.

x ± Τ1s

44.97938 − (.0024)(3.064) = 44.972

44.97938 + (.0024)(3.064) = 44.9874

This is a 95% CI that contains 99% of all measured journal diameters.

5-31

a.

µx = 20

µy = 15

µz = 12

σ x = .5

σy = .25

σ z = .3

µarea = µx * µy = 300 inches2

b.

σ ^ 2area = (15^ 2(.5^ 2)) + (20^ 2(.25^ 2) = 81.25

σarea = 9.014

c.

µvolume = µx * µy * µz = 3600 inches3

d.

σ ^ 2volume = (20.15^ 2)(.3^ 2) + (15.12^ 2)(.5^ 2) + (20.15^ 2)(.25^ 2) = 19800

σvolume = 140.7125

5-37

a.

σ ^ 2 = 1.097

σ = .0033056

b.

C = 6.291%

L = 36.24%

T 1 = .3626%

T 2 = .3624%

Τ=0

D = 56.77%

The diameter of the bar contributes most to the variation.