MRCIVES 2013 MAR 2 6

Masterbuilders: A Gallery for Making at the Edge of the Mockup by

Andrew James Manto

MRCIVES

'MASSACHUSETS INS1M E

OF TECHNOLOGY

MAR 2

6

2013

B.S. Architectural Studies

University of Wisconsin-Milwaukee, 2008 LiBRARIES

Submitted to the Department of Architecture in Partial Fulfillment of the Requirements for the Degree of

Master of Architecture at the

Massachusetts Institute of Technology

February 2014

© 2014 Andrew James Manto. All rights reserved.

The author hereby grants to MIT permission to reproduce and to distribute publicly paper and electronic copies of this thesisjocument in _pole or in part in any medium now known or hereafter created.

Signature of Author:

...

Department of Architecture

January 5, 2014

C e rtifie d b y ..........

Joel Lamere

Assistant Professor of Architecture

Thesis Supervisor

....................................................................

A cce pted by................

Takehiko Nagakura

Chair of the Department Committee on Graduate Students

.....................................................

1

Thesis Readers

John E. Fernandez

Associate Professor of Building Technology

Azra Ak'amija

Assistant Professor of Art, Culture + Technology

2

Masterbuilders: A Gallery for Making at the Edge of the Mockup by

Andrew James Manto

Submitted to the Department of Architecture on February 03, 2014 in partial fulfillment of the requirements for the Degree of Master of Architecture

ABSTRACT

The term "master-builder" defines an individual who encompasses the skills to conceptually conceive of and physically manifest a piece of architecture. These individuals are as much interested in the formal and social outcomes of a design as they are in the materials and construction techniques that make them real. Despite this, contemporary architectural practice has veered away from the concept of masterbuilder, and into more limiting and bracketed professional roles. The rise in project complexity and evolving legal frameworks mean that architects now work as part of a much larger and divided design and construction team.

This thesis insists that designing and making are not two separate acts, but are rather one holistic process.

It builds off of the contemporary momentum created by digital fabrication, rapid prototyping, and the maker movement but goes one step further. While it recognizes that the testing of design ideas through the construction of small scale models and mockups is important to the design process, this thesis argues that the 1 to 1 construction of buildings are an essential part of future architectural practice.

Thesis Supervisor: Joel Lamere

Title: Assistant Professor of Architecture

3

oll

'C4

A

4

masterbuilder

LJ

a gallery for making at the edge of the mockup

5

6

masterbuilder[s] proposes a new type of architectural design methodology through the design and fabrication of a small building.

+

~<

Past

At its core, it challenges the separation between architects and builders described first by Leon Alberti, and later codified professionally by Sir John Soane.

Alberti believed that architects should not take part in the building process. Rather, he described a clear point at which design work ended, and building began. To transfer design information to builders, Alberti developed a system of two dimensional scaled drawings.

7

Unlike contemporary drawings, Alberti's were free of dimensional annotation. Rather, they were understood relationally, with objects was drawn as a multiple of an established base unit. In certain cases, such as his walking map of Rome, instructions were given as a series of polar coordinates which could be plotted out.

8

S SEBASTIANO

-------------------- -------------------

--------- ---------

---------- ----------

------

--------- --------- --------- --------

El ES ED E3

V now j

27 Snmxblowr modkik spwn: pka dnd emwownm r IM W bin?

VI-JI'L

-

7 t4ipw', wu~he&' WN0CI 3 p41 (?UU4f(l*.IdI

me

42

He designed buildings such that features were geometrically related to one another. The proportions between essential units were used rather than explicit measurements.

9

I

I,

)k

Architects

Structural Engineers

Electrical Engineers

Landscape Architects

Interior Designers

Mechanical Engineers

In the 18th century, Soane further cemented the split between design and building through the professionalization of the discipline via regulated building contracts.

10

Xkii

A

Under these circumstances, architects began to work with other professional "design" disciplines, while contractors interfaced more directly with their "maker" counterparts.

11

12

Present

More recently, there has been an erosion to this formula prompted by a renewed interest in making as an act in which designers actively participate. Commonly, this is known as craft, which actually takes form around a distinct set of sub-themes.

13

/

/

/7/,

A

/1

Ii

II

/

I:

Methodology: Digital Fabrication

Digital fabrication dissolves the barrier between digital design work and physical realization.

14

Environment: Fabrication Lab

The fablab offers a new space type that combines design and fabrication into a single space.

15

ii i~

I

Means: Material Experimentation

Material experimentation offers a way of discovering novel forms, but at the expense of a premeditated plan.

16

Testing Platform: Installation

Installations have traditionally been the testing ground for design projects in the fablab.

17

Culture: Maker Movement

The culture of making and craft has fed a growing number of ad-hoc makers.

18

19

20

Future

Design methodology needs to leverage contemporary materials, tools, and culture. This is where premeditated architectural design meets a serendipitous process of making. More specifically, this thesis explores expanded polystyrene as design medium.

Most traditional building materials are actually quite old.

[wood, concrete, and metals] experienced a transformation revolution. EPS foam represents a new starting point: a truly

Discovered by generations past, these materials into the forms we see today during the industrial modern material.

21

Wood

Ancient p

22

Wood Framing

North America

1830's

23

Iron

Gerzah, Egypt

3500 BC

Ste

Luristan,

el

Iran

1000 3C

24

4

-0

Cast Iron

Abraham Darby

1709

Steel

Henry Bessemer

1856

------

25

~Kj

Concrete

Tiryns, Greece

1400 BC

26

Concrete

John Smeaton

1750

Stet

27

EPS Foam

Koppers Company

1954

29

/

N

~iIIII Th

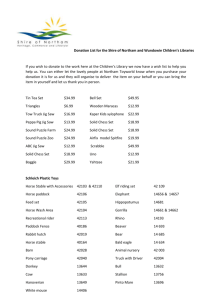

Expanded Polystyrene Foam

$3 per cubic foot

1 pound per cubic foot

Lumber

$7 per cubic foot

25 pounds per cubic foot

Material Analysis

As compared to other contemporary materials, Expanded Polystyrene holds advantages in weight and cost per cubic foot.

30

ii~;~ ~$;

K

A

Concrete

$7 per cubic foot

150 pounds per cubic foot

Steel

$175 per cubic foot

490 pounds per cubic foot

31

Concrete Block

8" x16" x 8"

37 Pounds

16"

8"0

4

II

Ii

Ii

II

I,

(I

II

-~

__/

-.~1

I

-7

1

/

-Fl gI

I

/

I

Lightweight

EPS foam contains 52x volume at roughly the same weight as concrete. This allows components to be fabricated much larger, with no weight penalty.

32

EPS Foam Block

I

1-f

0'

AU

.

I

32 Poui ids

96"

I

I

I

I

I

I

I

I

I

I

I

I

I

I I

I

I I

I

I

I

I

I

I

I

I

I

I

I

I

I

I I

I I

Il

Ill

Ill i/

I'

I

Il-

-

~---*--- -

I j

Ii

I,

I

I j

II lj

I

I j

I

1

4809

-- I

I

I

I

I

I

I

I

I j

/

33

Foam Form Factor

Foam's lightweight yet fragile nature suggest that it be traditional 'stick' and 'sheet' typologies, which rely on forces, foam is best used as large, monolithic blocks.

used differently than other building materials. Unlike the ability of materials to resist tensile and buckling

34

F F

Stereotomic Operations

The large scale size of foam blocks are tooled stereotomically via methods of varying precision and expediency

[Robotic Hot Wire Cutting, Computer Controlled Milling, and Hand Carving]

35

Contemporary EPS Usage

EPS foam is commonly used in construction, but most typically as faux-ornamental architectural elements.

36

Projective EPS Usage

The lightweight and inexpensive nature of EPS foam makes it a candidate for whole building construction.

37

OI

Working methodology as placetype

The thesis positions three distinct placetypes next to one another: the workshop, the gallery, and the studio.

38

39

F~

2'' 2 ii

V.'

I

V

K-il.

~'Iii

K'

G Studio

Th e Fin ch Gallery\

Studio Hammer-

T

Hungry Man Ga r

Turn Collaborative

Gorham Metalworkso AnySquaretSotudioC

I

K

/

4

'I

N

11

\

V

N

*KLLM Architects

\

.4

4,

4.

AF inkI Foundary

Dreambox Gallery

Coyne Archtects a

Creative LoungeChiCagO

Ern Varndell Gallery

Steel Point

Prop Art Gallery Gallery 20 3

Studio Gan g

-N

\

1

V

N., i.i~Ii

.1

IN.

Site

The prospective site is in inter-city Chicago, along the Milwaukee Avenue corridor. This strip is home to a collection of shops, galleries, and architectural offices.

40

F 7771

LJ

1-7

X

N)

The wedge-shaped site is part of an open brown-field, and directly adjacent to an abandoned freight railroad corridor being transformed into an elevated linear park.

41

42

43

'N

V t, .e

voo T

44

I

7-

45

Material

The primary material used was EPS foam. It was transported to the MIT shop via container truck, stored outdoors under secured tarps, and brought inside to be processed.

46

Jigs

A series of 3 jigs were used to cut out the vaulted blocks. They were constructed from a series of MDF pieces and clamped to the sides of a foam blank before cutting by hand.

47

Block 01

Side 01: Jig A

Side 02: Jig B

Block 02

Side 01: Jig B

Side 02: Jig C Flipped

50

Block 03

Side 01: Jig C Flipped

Side 02: Jig B Flipped

Block 03

Side 01: Jig B Flipped

Side 02: Jig A

51

Block 05

Side 01: Jig A

Side 02: Jig C Flipped

Block 06

Side 01: Jig C Flipped

Side 02: Jig A

52

Block 07

Side 01: Jig A

Side 02: Jig C

7

Ni

1%~

/

Block 08

Side 01: Jig C

Side 02: Jig A

53

h

Nesting

Final parts were cut from the drop pieces of previous cuts, ensuring that material did not go to waste.

55

CLII ii if

-

Variable Draft Angle Cutting

Zero-waste cutting requires that all parts from a cut are usable. Sliding foam pieces apart requires that conic draft angles are used so that blocks can be easily separated.

58

----------rx

59

I A

V 4

VV

A

V fV

,4 VV

Zigzag Cutting

A ruled surface cut between two guide curves creates a pattern with a deep texture and no undercuts.

60

61

XV

1

63

64

A

View looking through gallery.

66

View of front entrance from street.

67

View from Bloomingdale embankment.

68

/

ill ~

I

/

I

I

2

/

K

View looking into gallery from Bloomingdale embankment.

69

View into studio.

70

.. ........

View looking from gallery into workshop

71

View inside of workshop.

72

73

Works Referenced

Allen, Sam. Wood Joiner's Handbook. New York: Sterling Pub., 1990. Print.

Barkow, Frank, and Regine Leibinger. Barkow Leibinger: An Atlas of Fabrication. London: Architectural

Association, 2009. Print.

Bechthold, Martin. New Technologies in Architecture: Digital Design and Manufacturing Techniques. Cambridge:

Harvard University Graduate School of Design, 2001. Print.

Burry, Mark. Scripting Cultures: Architectural Design and Programming. Chichester, UK: Wiley, 2011. Print.

Callicott, Nick. Computer-aided Manufacture in Architecture: The Pursuit of Novelty. Oxford: Architectural,

2001. Print.

Corser, Robert. Fabricating Architecture: Selected Readings in Digital Design and Manufacturing. New York:

Princeton Architectural, 2010. Print.

Deamer, Peggy, and Phillip Bernstein. Building (in) the Future: Recasting Labor in Architecture. New Haven:

Yale School of Architecture, 2010. Print.

Dunn, Nick. Digital Fabrication in Architecture. London: Laurence King, 2012. Print.

"Fabrication: The Designers Guide." Fabrication: The Designers Guide. N.p., n.d. Web. 03 May 2013.

Freyer, Conny, Sebastien Noel, and Eva Rucki. Digital by Design: Crafting Technology for Products and

Environments. London: Thames & Hudson, 2008. Print.

Grobman, Yasha, and Eran Neuman. Performalism: Form and Performance in Digital Architecture. London:

Routledge, 2012. Print.

Kedan, Elite, Jon Dreyfous, and Craig Mutter. Provisional: Emerging Modes of Architectural Practice USA. New

York: Princeton Architectural, 2010. Print.

Kolarevic, Branko. Architecture in the Digital Age: Design and Manufacturing. New York, NY: Spon, 2003. Print.

Leach, Neil, David Turnbull, and Chris Williams. Digital Tectonics. Chichester: Wiley-Academy, 2004. Print.

Lefteri, Chris. Making It: Manufacturing Techniques for Product Design. London: Laurence King Pub., 2007.

Print.

Lynn, Greg. Animate Form. New York: Princeton Architectural, 1999. Print.

Lynn, Greg. Folding in Architecture. Chichester, West Sussex: Wiley-Academy, 2004. Print.

74

Lynn, Greg. Folds, Bodies & Blobs: Collected Essays. [Bruxelles]: La Lettre Volee, 1998. Print.

Oxman, Rivka, and Robert Oxman. The New Structuralism: Design, Engineering and Architectural Technologies.

Hoboken, NJ: Wiley, 2010. Print.

Picon, Antoine. Digital Culture in Architecture: An Introduction for the Design Professions. Basel: Birkhauser,

2010. Print.

Schrdpfer, Thomas, and James Carpenter. Material Design: Informing Architecture by Materiality. Basel:

Birkhauser, 2011. Print.

Self, Charles R. Joinery: Methods of Fastening Wood. Pownal, VT Storey Communications, 1991. Print.

Sheil, Bob. Protoarchitecture: Analogue and Digital Hybrids. London: John Wiley, 2008. Print.

Spence, William Perkins. Residential Framing: A Homebuilder's Construction Guide. New York: Sterling Pub.,

1993. Print.

Thompson, Rob. Manufacturing Processes for Design Professionals. New York: Thames & Hudson, 2007. Print.

Wagner, George, Frank Barkow, Regine Leibinger, and Mohsen Mostafavi. Barkow Leibinger: Werkbericht

1993-2001 = Work Report. Basel:

Birkhauser, 2001. Print.

Zwerger, Klaus. Wood and Wood Joints: Building Traditions of Europe and Japan. Basel: Birkhauser, 1997. Print.

75

76