ET 367 – CNC Programming & Machining Western Illinois University

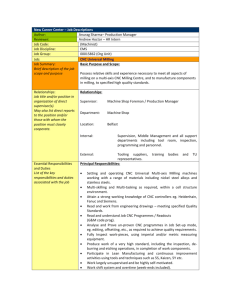

advertisement

ET 367 – CNC Programming & Machining Western Illinois University Department of Engineering Technology Spring Semester 2012 Class Time: Location: Tuesday, 6:00pm - 8:30pm Room 220, WIU-QC Riverfront campus Instructor: Joe Keitel Contact Info: cell phone: 563-554-4352, Email: JD-Keitel@wiu.edu Office Hours: Tuesday, 5:30pm – 6:00pm and 8:30pm – 9:00pm Catalog Description: ET 367 – Introductory and advanced applications of numerically controlled machines. Textbook: CNC Programming Handbook-3rd Edition, Smid, Peter Objectives: Upon completion of the course, students will be able to: • Know and identify the various types of CNC machining operations. • Understand the terminology, basic principles, equipment and techniques used in CNC manufacturing. • Correctly apply CNC machine code to create desired machine output. • Develop programming and machining skills which allow application of CNC knowledge to production situations. Evaluation: • Attendance & Participation (400 points: 12.5%): Each student is expected to complete several reading or research assignments prior to the class period. Class discussions, quizzes, exams, presentations or written reports could be used to evaluate the fulfillment of this task. • Assignments (1700 points: 53.1%): Approximately 14 weekly assignments will be issued during the semester. Each one is worth 80-150 points. Due dates will be set for each given assignment, but are usually the beginning of the next class period. There will be one project report worth 100 points, due date to be established and PROBABLY one class exercise worth 200 points. • Quizzes (400 points: 12.5%): Four quizzes will be given during the semester. Each quiz will consist of 15-20 questions worth 3-10 points each (100 points per quiz). • Mid-Term Exam (300 points: 11.5%): The mid-term exam will consist 40-50 questions worth 3-10 points. • Final Exam (400 points: 12.5%): The final exam will consist 50-60 questions worth 3-10 points. • Extra Credit: Several extra credit assignments will be presented during the semester. Students are NOT required to fulfill these activities, but each assignment completed correctly could help raise a final grade. A grade of 80% or higher is required to receive the extra assignment credit. Grading Information: All assignments, tests and projects will be graded according to the following scale (based on 3200 pts): 93% - 100% = A (2960 - 3200 points) 90% - 93% = A- (2868 - 2959 points) 87% - 90% = B+ (2772 - 2867 points) 83% - 87% = B (2640 - 2771 points) 80% - 83% = B- (2548 - 2639 points) 77% - 80% = C+ (2452 - 2547 points) 73% - 77% = C (2320 - 2451 points) 70% - 73% = C- (2228 - 2319 points) 67% - 70% = D+ (2132 - 2227 points) 63% - 67% = D (2000 - 2131 points) 60% - 63% = D- (1908 - 1999 points) Less than 60% = F (1907 or less points) Course Policies: It is expected that students will behave properly in class. Students who disrupt class, or deface equipment or property will be removed from the classroom and penalized in the current assignment/project, and in extreme cases with a failing final grade. Cheating will result in FAILING the course automatically. Attendance: Do NOT miss classes, attendance and participation are required. Lectures and demonstrations will occur at varying times during the class period. Attendance will be recorded and may affect your final grade. Five (5) or more absences will result in a 10% penalty applied to a final grade. Students Rights and Responsibilities: It is essential that all students know what is required of them in order to complete a course satisfactorily. To that end, the Office of the Provost and Academic Vice President recommends that students become familiar with the guideline concerning their rights and responsibilities. The guidelines are available online at: http://www.wiu.edu/provost/policies.php Students with Disabilities: In accordance with University policy and the Americans with Disabilities Act (ADA), academic accommodations may be made for any student who notifies the instructor of the need for an accommodation. For the instructor to provide the proper accommodation(s) you must obtain documentation of the need for an accommodation through Disability Resource Center (DRC) and provide it to the instructor. It is imperative that you take the initiative to bring such needs to the instructor's attention, as he/she is not legally permitted to inquire about such particular needs of students. Students who may require special assistance in emergency evacuations (i.e. fire, tornado, etc.) should contact the instructor as to the most appropriate procedures to follow in such an emergency. Contact Disability Resource Center (DRC) at 298-2512 for additional services. Late Assignment Policy: • • Assignments that are turned in one class late will be penalized by the loss of up to ten (10) percent plus any deductions for incorrect answers. Assignments that are submitted two classes late will lose up to twenty (20) percent in addition to the incorrect answer deductions. Test Schedule: Test schedule is tentatively set as below but is subject to change. All tests will be announced in advance. Quiz 1: Tuesday, January 31, 2012 Quiz 2: Tuesday, February 21, 2012 Mid-Term Exam: Tuesday, March 6, 2012 Quiz 3: Tuesday, April 3, 2012 Quiz 4: Tuesday, April 24, 2012 Final Exam: Tuesday, May 8, 2012 Tentative Topic Schedule: • • • • • • • • • • • • • • • • Wk 1-Jan 17: Ch 1,2,3,4: Overview of CNC equipment and function Wk 2-Jan 24: Ch 6,7,8,9,15: Planning & writing programs, G & M codes, machine zero Wk 3-Jan 31: Ch 10,11,12,13,20: dimensions, block sequence, feed & speed rates, rapid travel Wk 4-Feb 7: Ch 14,16,18,19,21: tools, work/machine coordinates, machine zero return Wk 5-Feb 14: Ch 22,25,27,28,30: linear move, cycles, patterns, milling, cutter comp Wk 6-Feb 21: Ch 29,31,32,33: arc/circular movement, planes, contour milling, slots & pockets Wk 7-Feb 28: Ch 34,35,36,37: turning, lathe cycles, grooving, cutoff Wk 8-Mar 6: MID-TERM EXAM over weeks 1-7; HNI tour? Wk 9-Mar 20: Ch 39,40,41: sub-programs, datum shift, mirror Wk 10-Mar 27: Ch 42,43: coordinate rotate, scaling Wk 11-Apr 3: Ch 46,47: horizontal milling, live lathe tooling Wk 12-Apr 10: Macro call out, variables Wk 13-Apr 17: Wk 14-Apr 24: Macomb Trip? Wk 15-May 1: Wk 16-May 8: FINAL EXAM over weeks 1-15 Syllabus subject to change upon notice. Informational and educational websites: There are MANY helpful videos on You Tube for CNC programming and machining: www.youtube.com etprof has a couple of videos on CNC programming including Coordinates: http://www.youtube.com/watch?v=AKwlzIJG5lo&list=UUkvmOc1DyINyqezAyxg0sA&index=2&feature=plcp G54 – G58: http://www.youtube.com/watch?v=EI2inCb0Wfs Wikipedia has a very good entry on CNC: http://en.wikipedia.org/wiki/G-code CNC websites http://www.cncinformation.com/ http://www.editcnc.com/index.shtml http://www.cncezpro.com/index.cfm http://machmotion.com/cnc-info.html http://www.machsupport.com/ http://www.cnczone.com/ http://www.custompartnet.com/wu/milling http://www.hougen.com/tech_tips/speeds/speed.html (Feed & Speed calculator) http://www.daycounter.com/Calculators/GCode/Feed-Rate-Calculator.phtml (Feed & Speed calculator) Websites catered to hobbyists and homemade CNC routers http://www.routoutcnc.com/downloads.html http://www.hobbycncsoftware.com/ http://www.diycnc.co.uk/index.html Instructor provided reference and support material: Support materials for CNC Programming Handbook, 3rd Edition, Smid, Peter 7 Easy Steps to CNC Programming, Software: CNC-Simulation: machine tool simulation software (30-90 day free trial periods) CNC Simulation software: free to download and use but must register and re-visit website http://www.cncsimulator.com/ Cutviewer Mill: CNC milling machine code verification software ($250) Cutviewer Turn: CNC lathe machine code verification software (with milling) http://www.cutviewer.com/ Mach3 Mill: CNC milling software ($175) Mach3 Turn: CNC turning software (with milling) http://machmotion.com/ G-Zero Conversational CAM CNC Milling Simulation software – CCAM4 ($219) http://www.g-zero.com/ and http://www.legacycncwoodworking.com/software-selection/ Basic Viewer: CNC code output viewer-use with Discriminator (from cnc Edit) (free to download & use) Discriminator: CNC code verification software (from cnc Edit) (free to download & use) http://www.cncedit.com/ Various simplified software programs for CNC programming http://cncsimple.wordpress.com/