Parameters that Affect the Digging of a BiologicallyInspired Underwater Borrowing Robot

ARC-HVE

MAssACHU TTF ISTITI IToE

by

OF TECHNULOLGY

JUN 2 4 2015

Steven Paul Guitron

Submitted to the Department of Mechanical Engineering

in Partial Fulfillment of the Requirements for the Degree of

Bachelor of Science in Mechanical Engineering

LIBRARIES

at the

MASSACHUSETTS INSTITUTE OF TECHNOLOGY

June 2015

0 2015 Massachusetts Institute of Technology. All Rights Reserved.

redacted

Author..................Signature

Department

Mechanical Engineering

May 18, 2015

Certified by ................

Signature redacted

Daniel S. Dorsch

Ph.D. Student in Mechanical Engineering

Certified by .........

Signature redacted.

Amos oi Wider, V

Assistant Professor of Mechanical Engineering

Accepted by .........

Signature redacted

Anette Hosoi

Professor of Mechanical Engineering

Undergraduate Officer

MITLibraries

77 Massachusetts Avenue

Cambridge, MA 02139

http://Iibraries.mit.edu/ask

DISCLAIMER NOTICE

Due to the condition of the original material, there are unavoidable

flaws in this reproduction. We have made every effort possible to

provide you with the best copy available.

Thank you.

The images contained in this document are of the

best quality available.

Parameters that Affect the Digging of a Biologically-Inspired

Underwater Borrowing Robot

by

Steven Paul Guitron

Submitted to the Department of Mechanical Engineering

on May 18, 2015 in Partial Fulfillment of the

Requirements for the Degree of

Bachelor of Science in Mechanical Engineering

Abstract

RoboClam 2 is a device that burrows based on the movement of the Atlantic razor clam. A functional

RoboClam 2 has been built. Testing was conducted in a controlled laboratory environment to

determine what parameters of the device and its operation affect its ability to dig both speedily,

deeply, and efficiently. Smaller contraction and dilation volume, heavier device weight, and longer

contractions above a theoretically calculated minimum fluidizing velocity were all found to correlate

with faster digging speed. Future work will involve experimentally determining the minimum

fluidizing velocity and the effect of contraction speed on digging ability.

Thesis Supervisor: Daniel S. Dorsch

Title: Ph.D. Student in Mechanical Engineering

Thesis Supervisor: Amos G. Winter, V

Title: Assistant Professor of Mechanical Engineering

3

4

Contents

1

Introduction

11

2

Modeling RoboClam 2

12

3

2.1

Dynamics of Digging . . . . . . . . . . . . . . . . . . . . .

12

2.2

Minimum Fluidization Velocity . . . . . . . . . . . . . . . .

14

2.3

Energy Consumption. . . . . . . . . . . . . . . . . . . . .

17

Device

17

3.1

Device Specifications . . . . . . . . . . . . . . . . . . . . .

17

3.2

Control Method . . . . . . . . . . . . . . . . . . . . . . .

18

4

Testing Environment

18

5

Experimental Procedure

20

6

Problems during Testing

21

7

Results and Discussion

22

7.1

Contraction Distances and Diameters . . . . . . . . . . . . .

22

7.2

Large versus Small Contraction Diameters . . . . . . . . . . .

23

7.3

Fluidization Time and Digging Speed . . . . . . . . . . . . .

24

7.4

Effect of Downward Force . . . . . . . . . . .. . . . . . . .

26

8

Conclusions

27

9

Future Work

27

5

6

List of Figures

1-1

ROBOCLAM 2. RoboClam 2 is a robot designed to dig through sand in the

ocean by fluidizing the surrounding sand. By fluidizing the soil, RoboClam 2

can save an order of magnitude of energy versus conventional methods of

digging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1

CONTROL VOLUME IN FLUIDIZED ZONE. Ergun's equation can be used

on a small control volume in the fluidized region of RoboClam 2 as its radius

contracts. By solving for the minimum contraction velocity needed to induce

fluidization, we can determine how fast we need to contract to dig

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

effectively.

15

MINIMUM CONTRACTION VELOCITY VS DEPTH. RoboClam 2 must

contract its exterior plates at a minimum velocity to attain fluidization. Using

Ergun's equation, minimum contraction velocity for fluidization can be

calculated from the depth of RoboClam 2 beneath the surface of the

sand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16

TESTING ENVIRONMENT. To ensure repeatability and ease of testing, a

laboratory-based testing environment was made. The blue barrel is filled with

sand and water; the sand is able to be fluidized using a pump attached to the

barrel. The end of the piston was attached to RoboClam 2 and was used to

both impart downward force and, using a string potentiometer, record the depth

of RoboClam 2 over time . . . . . . . . . . . . . . . . . . . . . . . . . .

19

DEPTH VS CYCLE FOR DIFFERENT CONTRACTION DIAMETERS. The

large diameter test involved RoboClam 2 cycling between diameters of 62.3 mm

and 66.4 mm. The small diameter test cycled between 58.2 mm and 61.2 mm.

The small diameter test resulted in faster digging because the same weight of

the device is concentrated on a smaller area. Since RoboClamn 2's digging is

primarily inhibited by the sand below the device (when the exterior of the device

is fluidized), a more concentrated force results in more penetration of the sand.

It is currently unknown why the data is so noisy . . . . . . . . . . . . . . .

24

.11

2-2

4-1

7-1

7

7-2

7-3

7-4

DIGGING SPEED VS TIME FLUIDIZED. "Time fluidized" represents the

time that the plates spent moving above the minimal fluidization velocity, which

in our calculation was found to be 15 mm/s. This graph shows that RoboClam

2 needs to move its plate past the minimal fluidization velocity and for a certain

amount of time (around 0.02 s) for the digging speed to be anything

m eaningful. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25

TOTAL ENERGY EXPENDED UP TO DEPTH VS DEPTH. From the shape

of the graph, as RoboClam 2 digs to deeper depths, it needs exponentially more

energy to continue digging. While this is not a problem with current testing, it

will become a problem when a future iteration of RoboClam is tested at far

greater depths due to the looming energy requirement . . . . . . . . . . . . .

25

DEPTH PER CYCLE AT DIFFERENT DOWNWARD FORCES. Imparting

downward force increased the chance of device failure, which is why the trial

length was shortened as the force was increased. Each trial required around the

same energy per cycle. . . . . . . . . . . . . . . . . . . . . . . . . . . .

26

8

7.1

Examination of Speed to Energy Ratio . . . . . . . . . . . . .

9

.

List of Tables

22

10

1

Introduction

The Atlantic razor clam (Ensis directus) has been studied extensively due to its

ability to dig into soil with an order of magnitude less energy than conventional

methods of digging. This ability comes from the razor clam's ability to fluidize the

soil around it, and as a result, it can dig deeper and more efficiently than if it were

to dig through packed soil [1].

A device that takes advantage of the Atlantic razor clam's method of digging

would be useful in applications such as laying cables or anchoring vessels to the

seafloor. Because of the efficiency of this natural design, this type of device would

be especially useful as an anchor in energy-strapped autonomous underwater vehicles

(AUVs) due to their reliance on batteries and their small size.

The breadth of applications and practicality of the design inspired the biomimetic

devices "RoboClam" and its second iteration "RoboClam 2," which were made to

take advantage of the Atlantic razor clam's energy efficient digging ability. Much

of the theory behind the mechanics of RoboClam has been devised [1]. Using the

current RoboClam 2 model, this theory will be validated through testing in the

laboratory within a controlled sand bed. The goal is to adjust operation parameters

to maximize real life performance of RoboClam 2.

Figure 1-1: ROBOCLAM 2. RoboClam 2 is a robot designed to dig through sand in the ocean by

fluidizing the surrounding sand. By fluidizing the soil, RoboClam 2 can dig with an order of

magnitude less energy versus conventional methods of digging.

11

2

Modeling RoboClam 2

While RoboClam 2's abilities can be tested and verified experimentally, it is still

beneficial to consider different models that describe RoboClam 2's dynamics. If we

find the models to be practically useful after comparing them with experimentally

obtained data, then the models can be used to predict behavior in situations that

were possibly not tested, such as situations that may allow for maximum

performance.

This proves especially useful before testing RoboClam 2 in risky

situations, such as digging so deep that it would be difficult to pull the device out of

the sand without fluidization.

The actual device can be simplified in our model. RoboClam 2 is essentially a

weighted cylinder with an adjustable diameter.

This adjustment is accomplished

using curved plates that conform to the shape of the device.

These plates can be

pulled into or pushed out of the device maintaining a relatively cylindrical profile.

2.1

Dynamics of Digging

As RoboClam 2's radius contracts, a fluidized zone is created around the device,

allowing RoboClam 2 to sink through the fluidized sand like the device would sink

through a liquid. However, RoboClam 2 stops sinking once it reaches a certain depth

in the packed sand below. The depth to which it sinks per contraction is governed

by the weight of the device, the area impacting the sand, the velocity when it hits

the surface of the sand, and the amount of fluidization around the device.

The drag force FD in the fluidized liquid determines the velocity v at which

RoboClam 2 falls into the packed sand and is given as

F IpAC~2

FD

(2.1)

where pP is the density of the water-bead mixture upon fluidization (with an

estimated void fraction of between 40% and 45%), A is the circular cross-sectional

area of RoboClam 2, and CD is the coefficient of drag for the water-bead mixture.

12

The drag coefficient for these types of beads at various void fractions has been

determined experimentally [2].

Conducting a force balance of RoboClam 2 sinking through the medium gives us

M

dv

= (m -

Vp,)g - F

(2.2)

where m is the mass of RoboClam 2 and V is its volume.

Combining (2.1) and (2.2) and solving the differential equation for v allows us to

find the depth the device would fall given complete fluidization of the medium. Using

the parameters of the setup and RoboClam 2, the device would sink about 50 mm

in 0.1 seconds (which is about the time a contraction takes) if fluidized sand was the

only thing hampering RoboClam 2's digging speed.

From this calculation, we can see that the drag force is not the limiting factor in

digging speed (RoboClam 2 digs at about an order of magnitude slower than this

speed). RoboClam 2's digging speed is instead likely governed by the properties of

the packed soil beneath it. The soil at the tip of RoboClam 2 is like the soil at the

surface when RoboClam 2 fluidizes the surrounding soil. The device sinks into the

soil, but once in the packed soil, the device is greatly slowed.

If the cross-sectional area of RoboClam 2 is smaller, then the force from its weight

is more concentrated, resulting in greater stress on the sand below it. This will cause

the sand to fail until a deeper depth, resulting in a greater digging speed. Likewise,

a heavier RoboClam 2 with the same cross sectional area as a lighter RoboClam 2

would be expected to dig faster because of the greater stress imparted on the sand.

This greater stress will cause the device to sink further below in the sand each cycle

based on its own weight.

Theoretically, a heavy RoboClam with a small diameter that could create a

certain minimum plate contraction velocity for the longest possible time would be

ideal.

13

2.2

Minimum Fluidizing Velocity

To dig as efficiently as possible, RoboClam 2 needs to contract its radius within a

specific range of velocities.

If the radius is contracted too quickly, the water and

particles will not have time to move.

If the radius is contracted too slowly, the

fluidized zone will not be created [1].

RoboClam 2 moves down when the sand

around it is fluidized. Therefore, it is necessary to maximize the time that the soil

is fluidized. To do this, the radius of RoboClam 2 would have to be contracted at

the slowest speed that would allow fluidization. This would also allow the device to

use lower power accelerating and decelerating the plates during a contraction. The

speed that RoboClam 2 digs is governed by the time that fluidization is allowed to

occur during each contraction cycle as well as the properties of the sand around and

beneath RoboClam 2.

When RoboClam 2's radius contracts, water is pulled through the beads creating

a void fraction just around the device of about 40% to 45%. Ergun's equation [5]

E3,+ DP

E

23)

AP =

150ov,9AX (1 -

_)2

0

1.75pv, 2 AX (1

+1

2

_

)

describes both laminar and turbulent flow behavior of fluids through packed beds

0

where AP is the pressure drop across the fluidized bed, p is the dynamic

viscosity, V. is the superficial velocity, Ax is the length of the bed, p is the density

of the fluid, DP is the equivalent spherical diameter of the beads, and E is the void

fraction of the bed. Ergun's equation is specified for a tube, but we can describe a

control volume, as in Figure 2-1, and use Ergun's equation as an approximation of

the fluid flow through it.

Contracting the radius faster than the water can accelerate will result in

cavitation [1]. The fluid's maximum velocity is bounded by the contraction velocity

of the radius.

14

Fluidized Zone

Flow direction

P

tdz

d~P

dO

= pgh

Figure 2-1: CONTROL VOLUME IN FLUIDIZED ZONE. Ergun's equation can be used on a

small control volume in the fluidized region of RoboClam 2 as its radius contracts. By solving for

the minimum contraction velocity needed to induce fluidization, we can determine how fast we need

to contract to dig effectively.

The pressure drop across the fluidized bed can be found by examining a control

volume drawn around RoboClam 2, as seen in Figure 2-1. By approximating the

pressure on the plates of RoboClam 2 as negligible during its contraction (a limit

case in which cavitation is just on the verge of happening), the pressure drop would

be the hydrostatic pressure exerted on a segment of the boundary of the control

volume, the surface of the large cylinder that represents the extent of the fluidized

zone around RoboClam 2

d AP = pgh dA = pgz dO dz

(2.4)

where h is the depth of the segment of the control volume. Integrating over z

from the submerged depth of the top of RoboClam 2 to the depth of its bottom

would give the pressure profile for a vertical slice of RoboClam 2; integrating again

around the device would give the total pressure drop needed to solve Ergun's

equation.

15

Alternatively, Ergun's equation can be used on a small segment at the very

bottom of the fluidized region around RoboClam 2.

Since pressure is greatest on

this segment, the most minimal contraction velocity needed for complete fluidization

around RoboClam 2 can be found.

The pressure drop across this small segment is

AP = pgh

(2.5)

Solving Ergun's equation [3] at a depth of 0.05 m gives a minimum velocity for

fluidization of 0.015 m/s.

140

r120

i100

80

RoboClam 2

60

Maximum

Achievable

40

Depth:

323 nun

20

0

100

200

300

400

500

Depth (mm)

Figure 2-2: MINIMUM CONTRACTION VELOCITY VS DEPTH. RoboClam 2 must contract

its exterior plates at a minimum velocity to attain fluidization. Using Ergun's equation, minimum

contraction velocity for fluidization can be calculated from the depth of RoboClam 2 beneath the

surface of the sand.

16

Energy Consumption

2.3

Considering the environments where RoboClam 2 would be used, energy efficiency

is of great importance.

The goal would be to maximize speed and minimize the

energy required to attain that speed, for a period of time it takes to get to a sufficient

depth.

Examining

the

needed

energy,

we

calculate

the

force

during

a

contraction/dilation cycle, given as

F = IKt

(2.6)

where F is the force applied by the actuator, I is the instantaneous current

flowing to the device, and Kt is the motor constant.

Recorded position data was

used to calculate a velocity profile over time for the actuator.

Multiplying the

instantaneous velocity v by (2.6) at the corresponding instantaneous current gives

an expression for the instantaneous power, given as

P = IKtv

(2.7)

We can then integrate the total power curve over time to get the total energy

used to run the trial.

3

Device

3.1

Device Specifications

RoboClam 2 is a cylindrically-shaped device with an adjustable radius.

An interior

Linmot electric linear actuator adjusts the diameter using a wedge system that

translates lateral movement of the actuator to radial movement of the three outer

plates.

When the plates are contracted at a certain speed, the sand is fluidized

around RoboClam 2. The plates conform to the cylindrical shape of the device, and

the gaps between the plates are sealed with silicone.

relatively even fluidization on all sides of the device.

17

This ensures that there is

The device is capable of contracting to a diameter of 55.9 mil and dilating to a

diameter of 68.6 mm. The device contracts at a maximum rate of 54 mm/s. It has

a dry weight of 3.6 kg and a wet weight of 2.4 kg. The device is 0.38 m long.

3.2

Control Method

A MATLAB

script was written to control the linear actuator using serial

commands sent to the motor driver from the computer. The same script was used

to collect data from both the linear actuator

and a Celesco SP2-50

string

potentiometer so that actuator data could be compared with depth data. The end

of the string potentiometer was attached to the posterior of RoboClam 2.

As

RoboClam 2 dug into the sand, the string would extend from the potentiometer,

allowing us to record RoboClam 2's vertical position. The position of the actuator,

the force imposed, as well as the current drawn from the actuator was collected.

Power and logic (such as commanded position) were sent to the actuator via a

waterproof serial cable.

4

Testing Environment

RoboClam 2 would most likely be used in large bodies of water such as lakes or

oceans. Because of the difficulty of finding human-accessible spots where RoboClam

2 can dig repeatedly, a testing environment was constructed to test different

RoboClam models under controlled parameters [4].

A 96 gallon barrel filled with small beads and tap water was used to simulate the

type of environment where RoboClam 2 would be used.

The beads were each

between 0.595 and 0.841 mm in diameter and filled the barrel to a level deep enough

for RoboClam 2 to dig a complete body length without obstruction from the base of

the barrel [1]. The water level was set about a body length above the surface of the

sand, allowing RoboClam 2's exhaust vents to be completely submerged within the

water.

RoboClam 2 was kept vertically upright via a metal rod connected to a piston,

which was used to impart force downward (to aid in digging) as well as upward (to

18

aid in removing RoboClam 2 after a digging test was completed).

The pressure to

the piston was controlled by a pressure regulator, and this allowed us to test

RoboClam 2 under different downward loads.

As RoboClam 2 dug, the piston would extend.

Using a string potentiometer

attached to the piston, the vertical position of RoboClam 2 could be measured.

String

Piston

Potentiometer

Pressure

Regulators

Drain

Cable to

RoboClam 2

Pipes (to

fluidization

system)

Barrel

Figure 4-1: TESTING ENVIRONMENT. To ensure repeatability and ease of testing, a laboratorybased testing environment was made. The blue barrel is filled with beads and water; the sand is able

to be fluidized using a pump attached to the barrel. The end of the piston was attached to RoboClam

2 and was used to both impart downward force and, using a string potentiometer, record the depth

of RoboClam 2 over time.

19

To ensure repeatability of tests and to simulate an ocean environment to a greater

degree, the beads were fluidized and the barrel was vibrated before another test was

conducted. Fluidization was done via a pump that accelerated water into the bottom

of the barrel.

The pump was turned on for 30 seconds after each test.

The water

flows through the sand particles, eliminating previous cavities imparted from digging.

Excess water was released through a side drain, located at the top of the barrel, into

a reservoir where the pump circulated it back into the barrel for fluidization.

A

vibration motor was fixed to a frame attached to the base of the barrel. The motor

was activated during fluidization and for at least 30 seconds after the pump was shut

off to further ensure that the beads would be evenly dispersed before a new test could

be conducted.

5

Experimental Procedure

RoboClam 2 was controlled by changing various parameters within a MATLAB

script that communicated with the linear actuator. The parameters "cycles", "speed",

"acceleration", "inward position", and "outward position" were set prior to testing.

The "cycles" parameter defines how many times RoboClam 2 would dilate and

contract; a dilation and contraction each count for one cycle each, so that a

contraction followed by a dilation counts as two cycles. During a cycle, RoboClam

2 dilates to an "outward position" or contracts to an "inward position." The "speed"

parameter

represents

how

fast the dilation and contraction

occur,

and

the

"acceleration" parameter sets the time it takes to get to the defined "speed."

The sand was fluidized for 30 seconds, with the vibration motor remaining on for

another 30 seconds to allow the sand to settle more evenly. RoboClamn 2 was then

lowered slowly until it rested on the sand bed.

RoboClam 2's own weight and

possibly the downward force from lowering the device as well as from the piston

caused RoboClam 2 to rest slightly below the surface of the sand.

The testing procedure was activated, allowing RoboClam 2 to automatically dig.

When the procedure was finished, the piston and rod (attached to RoboClam 2)

20

pulled the device from the sand and water.

The cycle continued as different

parameters were changed and tested.

6

Problems during Testing

While RoboClam 2 operated well without any force imparted upon it, RoboClam 2

faced problems when the downward forces were too great. During a test with 83 N

of force applied to RoboClam 2, the device suddenly stopped operating.

Upon

removal from the sand (during a test, when RoboClam 2 was still receiving

commands from the computer), RoboClam 2 failed to resume.

However, upon

squeezing the side shells of the device, RoboClam 2 suddenly resumed its operation.

Removing the pressure after RoboClam 2 had failed (while RoboClam 2 was still

partially submerged in the sand) did not cause RoboClam 2 to resume.

However,

squeezing the panels of the device again (while it was partially submerged) caused

the device to resume operation.

RoboClam 2 would always fail after an inward stroke (the diameter going from

large to small). In fact, squeezing the device suddenly after failure would cause the

device to resume, no matter what depth RoboClam 2 was submerged.

The most likely reason for this failure is a problem with the actuator controller.

With extra downward force, the controller may not compensate enough for the

current that the actuator may need to get to the commanded "inward position."

Previous calculations based on the capabilities of the actuator estimate the maximum

depth that RoboClam 2 can dig at 0.323 meters [1].

This is not that deep, and in

fact RoboClam may fail if more force is imparted from the top (as this calculation

was made given the weight of RoboClam 2 exclusively). Nevertheless, more analysis

will need to be conducted to figure out what is causing this problem.

If RoboClam 2 failed during a test, resuming the test was attempted so that

digging at deeper depths could be conducted. For some tests, the graph of depth vs.

time has gaps in otherwise sound data.

The recorded data also seemed to be more noisy than expected.

This could be

due to the small distances that the string was being extended during actual tests.

21

Results and Discussion

7

Contraction Distances and Diameters

7.1

Since RoboClam 2 can contract through a large range of diameters, several tests

were conducted to determine the similarities and differences when contracting to a

small diameter versus contracting to a large diameter. It was also of interest to learn

if the difference between the contraction and dilation diameters affected digging

speed or energy efficiency.

All of these tests were conducted with the same

contraction speed and acceleration.

The fastest digging speed, 0.06 mm/s, was obtained by contracting to 56.5 mm

from 62.1 mm. Its speed to energy ratio was only surpassed by trials where there

was less than a 2 mm difference in contraction and dilation diameters. It was also

interesting that contracting to 58.1 mm from 64.5 mm resulted in a third of the

digging speed and energy efficiency. Another trial with about a 6 mm difference in

the contraction and dilation diameters (62.5 mm and 68.4 mm) achieved only two

thirds the speed as the smallest diameter case.

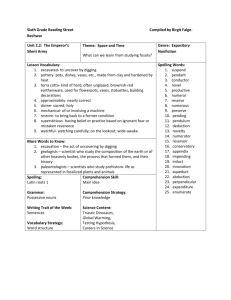

Table 7.1: Examination of Speed to Energy Ratio

Contraction

Diameter

Dilation

Diameter

Contracted

Distance

(mm)

(mm)

56.5

57.8

58.1

58.2

60.4

60.5

62.5

62.6

65.1

66.1

67.3

62.1

59.5

64.5

62.0

68.2

68.4

68.4

68.3

68.2

68.4

68.4

(mm)

Average

Downward

Speed

Average

Energy

Used

Speed to

Energy

Ratio

5.6

1.7

6.4

3.8

7.8

7.9

5.9

5.7

3.1

2.3

1.1

(mm/s)

0.06

0.01

0.02

0.02

0.04

0.05

0.04

0.03

0.006

0.02

0.006

(J/cycle)

0.50

0.15

0.54

0.34

0.65

0.63

0.41

0.41

0.17

0.07

0.02

0.11

0.09

0.04

0.07

0.06

0.07

0.10

0.07

0.03

0.26

0.38

22

Considering the variety of results obtained in these diameter tests, the 56.5 mm

contraction diameter test may have been an outlier in terms of speed and energy

efficiency.

While the energy calculations seem to stay constant with respect to the

difference in contraction and dilation diameters, the recorded digging speeds seem to

differ more than they should.

This could be due to the impreciseness of the string

potentiometer or to imperfections in attaining similar conditions for each test.

As the difference between contraction and dilation diameter got smaller, the

amount of energy used per cycle fell quite quickly.

If energy efficiency is the top

concern (with little regard for digging speed), then it would be best to operate

RoboClam 2 at the minimum speed in which fluidization is induced. If digging speed

is a top priority, then contracting to a small diameter from a comparatively larger

one seems to be the best choice.

Contracting 6 mm actually resulted in greater

digging speed and less energy used than both trials that contracted 8 mm.

It's

possible that contracting for any greater distance than 6 mm to 7 mm may actually

use more energy than it's worth.

Large versus Small Contraction Diameters

7.2

The large diameter test involved RoboClam 2 cycling between diameters of 62.3 mm

and 66.4 mm. The small diameter test cycled between 58.2 mm and 61.2 mm. The

data was quite noisy, and among the many trials, only a slight advantage was found

with a small diameter versus a larger diameter.

Both trials had roughly the same

energy usage.

The small advantage may be accentuated if the difference between the small and

large diameter tests was more extreme.

23

0

-Small

5

Diameter

-15

-20

-30

-35

-40

0

20

40

60

80

100 120

140 160

180 200 220 240

Figure 7-1: DEPTH VS CYCLE FOR DIFFERENT CONTRACTION DIAMETERS. The large

diameter test involved RoboClam 2 cycling between diameters of 62.3 mm and 66.4 mm. The small

diameter test cycled between 58.2 mm and 61.2 mm. The small diameter test resulted in faster

digging because the same weight of the device is concentrated on a smaller area. Since RoboClam

2's digging is primarily inhibited by the sand below the device (when the exterior of the device is

fluidized), a more concentrated force results in more penetration of the sand. Only two tests are

shown, but other tests produced comparable data. It is currently unknown why the data is so noisy.

7.3

Fluidization Time and Digging Speed

During a contraction, the plates accelerate to a constant speed and then decelerate

to a stop. Using the calculated minimum fluidization velocity from section 2.2, the

digging speed was plotted against the time that the plates were moving above the

minimum fluidization velocity during an average contraction cycle.

A linear

relationship was found between the two parameters, and by extrapolating a linear

fit, the minimum time that the plates must be moving past the minimum fluidization

velocity was found to be approximately 0.02 s.

24

0.07

0

0.06

.0.05

~0.04

@~@

r0.03

6

0.02

9

0,01

0

0

0.04

0.12

0.08

0.2 1

0.16

Time Fluidized (s)

Figure 7-2: DIGGING SPEED VS TIME FLUIDIZED. "Time fluidized" represents the time that

the plates spent moving above the minimal fluidization velocity, which in our calculation was found

to be 15 mm/s. This graph shows that RoboClam 2 needs to move its plate past the minimal

fluidization velocity and for a certain amount of time (around 0.02 s) for the digging speed to be

anything meaningful.

70

60

a

50

40

.~

a

30

20

a,

ii

'S

5.10

0

0

'30

15

45

Depth (mi)

Figure 7-3: TOTAL ENERGY EXPENDED UP TO DEPTH VS DEPTH. The energy cycle

required per cycle should be constant with depth, and therefore a graph of total energy expended vs

depth should be a line with constant positive slope. From the shape of the graph, as RoboClam 2

digs to deeper depths, it needs exponentially more energy to continue digging. This discrepancy could

be caused by a number of things. For example, the starting position during this test was when

RoboClam 2 was sitting on the surface of the sand, and so as RoboClam 2 digs, more of the device

becomes surrounded by sand (and energy use increases since the plates move against sand rather than

water).

25

0

-15

-30

-45

-0

N

-60

-47

N

-83

N

-90

0

20

60

40

80

100

Cycle

Imparting

Figure 7-4: DEPTH PER CYCLE AT DIFFERENT DOWNWARD FORCES.

as

shortened

was

length

trial

the

why

is

which

failure,

device

downward force increased the chance of

J/cycle.

0.65

of

6.6%

within

requirements,

energy

similar

had

trial

Each

the force was increased.

7.4

Effect of Downward Force

Applying a downward force caused the digging speed to increase proportionally.

With the weight of RoboClam 2 and the piston, the digging speed was 0.057".

With a downward force of 47 N, the speed increased to 0.1182". At 83 N of force,

the speed increased to 0.269"n. The average energy used per cycle by RoboClam

2 also stayed about the same, meaning pressing down on the device doesn't make it

work harder. This also means that a heavier RoboClam should dig faster than a

lighter RoboClam given the same body shape and actuator movement parameters.

This response was expected; increasing the downward force causes the device to

impart more force on the soil below, which causes more stress and subsequently

quicker failure throughout the granular medium. As was observed, energy is not

expected to be affected with varying downward force since the direction of the force

is not in the same direction as the radial contraction and dilation of the plates.

26

8

Conclusions

Based on the results, and considering the energy limited environment that a future

RoboClam would be used in, there are a number of recommendations that can be

made to optimize the performance of the device.

For fast digging, a heavier device with a small full contraction radius is

encouraged.

The weight of the device is the primary driver for pushing the device

through the soil once it is fluidized around RoboClam. The small contraction radius

allows more of the weight to be concentrated in a smaller area on the soil. This will

impart more stress on the soil and make the soil fail to a greater depth in the vertical

direction below the tip of the device. RoboClam 2 sinks to the depth of soil failure.

Breaking the failure stress of the packed sand below RoboClam is essential to digging.

Contraction speed of the device is not so important so long as it is above the

minimum fluidizing velocity for the surrounding medium. However, the plates should

contract at this speed for as long as possible, which means the plates must accelerate

to this speed as fast as possible.

The optimum difference between contraction and dilation diameter for RoboClam

2 was found to be around 6 mm. Contracting over a larger difference actually worked

to hinder the device's speed and cost much more energy than what was needed for

that particular digging speed.

While lower differences between contraction and

dilation diameters were found to have greater digging speed to energy expended

ratios, the speed was too low for any sort of practical purpose.

9

Future Work

Modeling RoboClam showed us that RoboClam 2's plates need to be contracted at

a higher speed as it digs to greater depths.

It would be interesting to design a

program that takes data from the depth sensor and uses it as feedback to increase

the contraction speed.

Depth data was taken only once per contraction (right after the contraction was

completed). It would be interesting to record depth data at a much higher frequency

27

and during the contraction cycle so that we can derive a better model for RoboClai

2's digging.

From this model, we can determine what aspects of RoboClam 2's

digging routine need to be accentuated and what aspects offer little importance.

Without vertical force or some kind of propellant, RoboClam 2's maximum speed

is the speed at which it can fall through fluidized sand before the vertical stress in

the soil matches the weight of the device.

One way to increase the digging speed

closer to this maximum speed is to shorten the pause time between contraction and

dilation and to decrease dilation time (increase dilation speed). The objective would

be to increase total contraction time, increasing the time that RoboClam 2 fluidizes

the soil around itself and actively digs.

RoboClam

2

should

also be tested

at far

lower

experimentally determine the minimum fluidization velocity.

28

contraction

speeds

to

Bibliography

[1] Dorsch, Daniel S.

Robot

with

"Design of a Biologically-Inspired Underwater Borrowing

On-Board

Actuation."

Thesis.

Massachusetts

Institute

of

Technology, 2015.

[2] Becker,

Christopher R. "Drag Coefficients on Razor Clams in Slightly

Fluidized Granular Media." Thesis. Massachusetts Institute of Technology,

2008.

[3] Maycock, Andrew. Minimum Fluidizing Velocities for Various Bed Packings,

2006.

[4] Dorsch, Daniel S. "The Design of a Fluidized Bed for Testing of a Robotic

Burrowing Device which Mimics Razor Clams." Thesis.

Massachusetts

Institute of Technology, 2012.

[5] Jia, Yuan, Yan Li, and David Hlavka. "Flow through Packed Beds." 2009.

29