Asset Management Using Failure Forecasting and Statistical Assessment of Diagnostic Testing

advertisement

Asset Management Using Failure

Forecasting and Statistical

Assessment of Diagnostic Testing

Miroslav M. Begovic

School of ECE, Georgia Institute of Technology

Fourth Annual Carnegie Mellon Conference on the Electricity Industry

FUTURE ENERGY SYSTEMS: EFFICIENCY, SECURITY, CONTROL

Pittsburgh, March 10-11, 2008

1

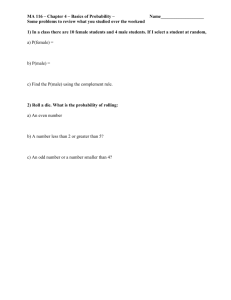

Background/Problem Statement

Most utilities have incomplete failure data on

various components, such as cables, switchgear,

etc.

Framework: a software-based algorithm to

estimate future failures based on data obtained

from incomplete failure information.

The optimal replacement rate needed to maintain

failures at a specified failure rate is sought.

Optimal failure rate estimation will yield the lowest

replacement and maintenance budget required to

meet the desired failure performance

2

Effect of Replacements on

Failure Rates

FAILURES

FAILURE

REDUCTION

INSTALLATION TIME

PARTIAL REPLACEMENT

TIME

3

Estimation and Control of Failures

in Composite Populations

ESTIMATED FAILURES

UPPER BOUND

(CONFIDENCE RANGE)

LOWER BOUND

INSTALLATION EVENTS

TIME

PARTIAL REPLACEMENT EVENTS

PROPOSE TO DEVELOP

SCHEDULE FOR

REPLACEMENT

EVENTS

4

Preliminaries

If p(t) is the pdf of the time to failure t of a single

component, the probability of that component failing

before time t is given by

P (t ) =

∫

t

0

p (u ) du

Assuming Weibull distribution for p(t) and population of N

identical components, the pdf of a component of that

population failing before time t is given by

−β

p0 (t ) = N βα t

β −1 − ( t / α ) N

β

e

,

t ≥ 0.

5

Preliminaries (cont.)

The expected value of T (the time to failure of a

single component) is

⎛1 ⎞

E (T ) = αΓ ⎜ + 1 ⎟

⎝β ⎠

The expected value of T (the time to failure of a

single component) in a population of N identical

components is

E (T0 ) =

α

N

1/ β

⎛1 ⎞

Γ ⎜ + 1⎟

⎝β ⎠

6

Failure Rates

The overall failure rate will be

f 0 (t ) =

p0 (t )

1 − P0 (t )

t≥0

,

In terms of the original α and N

f N (t ) = N βα t

−β

β −1

t≥0

,

Which will produce linear growth compared to the aging of

a single component

β

−β

p (t ) = Wei (α , β ) = βα t

f (t ) = βα t

−β

β −1

β −1

,

(

)

e

,

−

t

α

t≥0

t≥0

7

Formulation of the Failure

Model

f (t ) = X ⋅ K ⋅ (t − g )

b

Parameters K,b,g represent the description (model) of the failures

for population X (or N, if we deal with the discrete components)

When there are multiple populations Xi installed in years i = 0, 1, 2, …, k,

the cumulative failure model F(t,g,b,K) becomes a sum:

k

F (t , g , b, K ) = ∑ X i ⋅ K ⋅ (t − g − i )

b

i =0

8

Methodology for Identification of

Statistical Coefficients

160

140

140

120

120

number of failures

number of failures

Actual Failures and Curve Fit

Actual Failures

160

100

80

60

100

80

60

40

40

20

20

0

1960

1965

1970

1975

1980

year

1985

1990

1995

IDENTIFICATION OF {g,b,K}

STATISTICAL PARAMETERS

ESTIMATED FAILURES CURVE

0

1960

1965

1970

1975

1980

1985

1990

1995

year

CALCULATION OF ESTIMATED

FAILURES USING {g,b,K}

9

Failure Estimation

FAILURES

PAST

PRESENT

FUTURE

PROBABILITY OF

FAILURE ESTIMATE

…

t-1

t

t+1

YEAR

10

Test Data Set: New

Installation and Replacement

New Miles Installed and Replaced

600

installed

replaced

500

miles

400

300

200

100

0

1960

1965

1970

1975

1980

year

1985

1990

1995

2000

11

Distribution of Estimated Failures

Year 1 Projection of Frequency versus Number of Failures

25

Frequency

20

15

10

5

0

0

50

100

150

200

Number of Failures

250

300

350

400

300

350

400

300

350

400

Year 2 Projection of Frequency versus Number of Failures

25

Frequency

20

15

10

5

0

0

50

100

150

200

Number of Failures

250

Year 3 Projection of Frequency versus Number of Failures

25

Frequency

20

15

10

5

0

0

50

100

150

200

Number of Failures

250

Three year projection histograms for 1000 simulations.

12

Failure Estimation and

Confidence Intervals

95% Confidence Interval

50% Confidence Interval

250

180

160

200

140

No. of Failures

No. of Failures

120

100

80

150

100

60

40

50

20

0

1970

1975

1980

1985

Year

25% Confidence Interval.

1990

1995

0

1980

1985

1990

1995

Year

95% confidence interval .

13

Bottom Line: 1-Year Replacement

Upper Bound

Future Year 1 Replacement Confidence

600

replacement (miles)

550

500

450

400

350

300

50

55

60

65

70

75

80

confidence (%)

85

90

95

100

14

Asset Management

Objectives

Objectives

Follow-Up

Follow-Up

Maintenance

Maintenance

Scheduling

Scheduling

Planning

Planning

Asset

Asset

Management

Management

Analysis

Analysis

Budgeting

Budgeting

Data

DataLogging

Logging

Source: Joshua Perkel, NEETRAC

15

Cost Analysis

LOAD VOLTAGE

Refurbishment

Repair

Preventive Replacement

Diagnostic Testing

Replacement on Failure

Cost of Outage

DURATION OF

OUTAGE

OCCURRENCE

OF OUTAGE

TIME

COST OF OUTAGE

COST OF ENERGY

NOT SERVED

INITIAL COST OF

OUTAGE

Hard to Assess the Cost of

Reliability for Utilities

16

Motivation

Diagnostic tests look for symptoms of

degradation, not failures.

Symptoms are difficult to relate to future failures

unless they are in the extremes.

Probability

“Good”

?

“Bad”

No Failure

Failure

Diagnostic Measurement

17

Diagnostics – where to look

FRACTION OF CABLE

FRACTION OF CABLE

POPULATION TESTED

POPULATION TESTED

POSITIVE FOR

POSITIVE FOR

REPLACEMENT

REPLACEMENT

TESTED CABLE

TESTED CABLE

POPULATION

POPULATION

TOTAL CABLE

TOTAL CABLE

POPULATION

POPULATION

18

Passive Approach – do nothing

Cost Parameters:

A = Failure rates [failures/miles/year]

B = Average length of segment [ft]

C = Average cost of replacement cable [$/ft]

D = Average cost of repair [$/ft]

E = Length of population [miles]

F = Average Momentary Cost of Outage [$/failure]

G = Average Cost of Energy Not Served [$/min/failure]

TF = Average Duration of Outage [min]

Cost = A ⋅ E ⋅ [ (C + D ) ⋅ B + F + G ⋅ TF ] [$ / yr ]

19

Passive Cost

AVOIDABLE COST

Cost = A ⋅ E ⋅ [ (C + D) ⋅ B + F + G ⋅ TF ] [$ / yr ]

AVERAGE COST OF

ENERGY NOT SERVED

PER FAILURE

TOTAL NUMBER OF

FAILURES PER YEAR

COST OF REPLACEMENT

(CABLE + WORK)

AVERAGE COST OF

MOMENTARY

INTERRUPTION

20

SoE1

Failure Management

Avoidable cost can be reduced by replacing

suspect cable segments in an efficient way

before they fail

Need to know how many

failures are anticipated –

failure forecasting

Need to know

which segments to replace

how accurate the identification

21

Slide 21

SoE1

Figure Hard to read

School of ECE, 1/29/2007

Failure Management

Cost Parameters:

B = Average length of segment [ft]

C = Average cost of replacement [$/ft]

D = Average cost of repair [$/ft]

I = Total number of tested segments [ ]

J = Cost of diagnostic test per day [$/day]

K = Number of segments tested per day [day-1]

ξ = Fraction of the tested segments to be replaced – ratio

red to green areas

Cost = (C + D) ⋅ B ⋅ ξ ⋅ I + I ⋅ J / K [$ / yr ]

22

Cost of Failure Management

Cost = (C + D) ⋅ B ⋅ ξ ⋅ I + I ⋅ J / K [$ / yr ]

COST OF CABLE

(REPLACEMENT AND

WORK) PER SEGMENT

NUMBER OF SEGMENTS

NEEDING REPLACEMENT

COST OF DIAGNOSTIC

TEST PER SEGMENT

TOTAL NUMBER OF

TESTED SEGMENTS

23

Observations

Savings are achieved from small ξ

values (only segments correctly

diagnosed as bad are replaced)

Diagnostic tests add to the cost

It is not practical to test every segment

every year (cost would be too high)

How to determine which segments to

test?

24

Diagnostics: Issues

UNEXPECTED

FAILURES

FRACTION OF CABLE

FRACTION OF CABLE

POPULATION TESTED

POPULATION TESTED

POSITIVE FOR

POSITIVE FOR

REPLACEMENT

REPLACEMENT

TESTED CABLE

TESTED CABLE

POPULATION

POPULATION

TOTAL CABLE

TOTAL CABLE

POPULATION

POPULATION

If number of replaced segments is smaller than

failure forecast, unexpected failures will likely occur

Even if the number of replaced segments is equal to

the failure forecast, there may (and probably will) be

unexpected failures in the untested population

25

Diagnostics: Issues (2)

UNEXPECTED

FAILURES

FRACTION OF CABLE

FRACTION OF CABLE

POPULATION TESTED

POPULATION TESTED

POSITIVE FOR

POSITIVE FOR

REPLACEMENT

REPLACEMENT

TESTED CABLE

TESTED CABLE

POPULATION

POPULATION

TOTAL CABLE

TOTAL CABLE

POPULATION

POPULATION

If population to be tested is poorly chosen,

the benefits of the diagnostic test are lost

26

Diagnostic Accuracy

UNEXPECTED

FAILURES

FRACTION OF CABLE

FRACTION OF CABLE

POPULATION TESTED

POPULATION TESTED

POSITIVE FOR

POSITIVE FOR

REPLACEMENT

REPLACEMENT

TESTED CABLE

TESTED CABLE

POPULATION

POPULATION

TOTAL CABLE

TOTAL CABLE

POPULATION

POPULATION

P (T < 0 G ) = 1 − ε

P (T > 0 G ) = ε

P (T > 0 B ) = 1 − ε

P (T < 0 B ) = ε

27

Diagnostic Accuracy (2)

P(G T < 0) =

P(T < 0 G ) P(G )

P(T < 0 G ) P(G ) + P(T < 0 B) P( B)

=

1⋅ P(G )

P(G )

=

=

=1

1 ⋅ P(G ) + 0 ⋅ P( B) P(G )

If diagnostic accuracy is perfect, testing will identify

all the good (G) and bad (B) tested components

28

Diagnostic Accuracy (3)

P(T < 0 G ) P(G )

=

P(G T < 0) =

P(T < 0 G ) P(G ) + P(T < 0 B ) P ( B)

0.5 ⋅ P(G )

0.5 ⋅ P(G )

=

=

= P(G )

0.5 ⋅ P(G ) + 0.5 ⋅ P( B)

0.5

If diagnostic accuracy is bad, testing will identify

all the good (G) and bad (B) tested components only

as their proportions in the tested population

29

Replacement Cost

Population: 100 miles

Diagnostic Cost: $6k/mile

Cycle: 6 years

Cost per annum: $100k/yr

Failure rate: 30 failures/100 mi/yr

Replacement on failure:

uniformly distributed [$5k, $10k]

Replacement on failure:

uniformly distributed [$5k, $10k]

Cable cost: uniformly distributed

between [$27,$33]

Diagnostic accuracy: uniformly

distributed in [80%,100%]

Forecast: Total Cost {$/yr]

100,000 Trials

Frequency Chart

100,000 Displayed

.072

7192

.054

.036

.018

Mean =493,884.48

.000

100,000.00

375,000.00

650,000.00

$/yr

0

925,000.00

1,200,000.00

30

Replacement Cost

DISTRIBUTION

DISTRIBUTIONOF

OFTOTAL

TOTALCOST

COST

1.2E+06

1.2E+06

1.0E+06

1.0E+06

$/YEAR

$/YEAR

8.0E+05

8.0E+05

6.0E+05

6.0E+05

4.0E+05

4.0E+05

2.0E+05

2.0E+05

0.0E+00

0.0E+00

[80%

[80%,100%

,100%] ]

0%

0%

[90%

[95%

[90%,100%

,100%] ]

[95%,100%

,100%] ]

DIAGNOSTIC

DIAGNOSTICACCURACY

ACCURACYDISTRIBUTION

DISTRIBUTION

10%

10%

25%

25%

50%

50%

75%

75%

90%

90%

[100%

[100%,100%

,100%] ]

100%

100%

31

Cost Benefit of Diagnostics

Cost [$]

BENEFIT

Consequence

LOSS

Alternate

Program 1

Maintenance

Alternate

Program 2

Diagnostic

Selection

Source: Joshua Perkel, NEETRAC

32

Conclusions

Failure Forecasting algorithm provides some guidance

under the assumption that oldest population of equipment is

the most prone to failures

Diagnostic testing may provide better targeting of the

candidates for replacement, but at a cost (both due to the

procedure and its limited accuracy)

Analysis of different scenarios of desired failure

performance assist in formulating optimal strategies

Circumstances may significantly influence the cost of

diagnostic testing

33