Des Moines Register 05-10-07

Des Moines Register

05-10-07

Project hopes to generate new use for corn product

Distillers grains, left over from ethanol production, would be turned into pellets and used to make electricity

By JASON CLAYWORTH

REGISTER STAFF WRITER

Iowa is the focus of a new advancement that could help the state convert ethanol production leftovers into electricity.

If the project is successful, a byproduct from ethanol plants across the state would be processed into pellets that would be used at electricity plants to reduce the use of coal and cut greenhouse gas emissions.

The technology is among the first that could tap into a $100 million program approved by the Iowa Legislature last month.

That program, known as the Iowa Power Fund, would grant financial assistance for renewable fuel advancements as a way to catapult the state's world standing in energy production.

"It just seems the Power Fund would make a lot of sense" to help the cornpowered electricity pellet idea, said Bruce Hansen, a spokesman for the Iowa

Area Development Group.

Hansen's group, which helps businesses expand or locate within many of Iowa's electric service areas, helped coordinate the pellet project.

Brad Anderson, a spokesman for Iowa Gov. Chet Culver, has reviewed some of the information about the pellet product and said it would probably be given consideration by state officials.

"The project does seem like the type of project the Power Fund board would be interested in looking at," Anderson said.

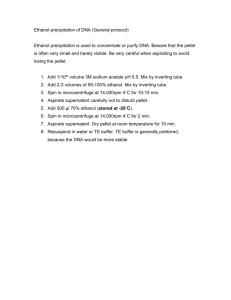

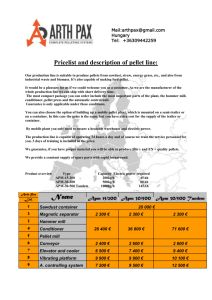

Developers of the corn pellet estimate that an ethanol plant that produces 100 million gallons a year has enough dried distillers grains, a byproduct that is now fed to livestock, to make 600 tons of pellets a day. That level of production, given the dozens of ethanol plants across the state, has the potential for a massive reduction in the use of coal across the United States, they say.

Before now, ethanol producers have had a tough time forming the corn material into pellets because of its high natural oil content. Converting the material to pellet form is an important advancement because it makes transportation and loading easier and less costly, Hansen said.

The new pellet is made of 100 percent dried distillers grains. It is a product created by Ag Pellet Energy, based in Carmel, Ind., and Landers Machine Co., located in Fort Worth, Texas.

The group is filing for patent protection and has not divulged how the pellets are made.

"In a nutshell, we just took the normal pellet process and went beyond the conventional way of thinking," said Scott Landers, president of Landers Machine.

In addition to the energy generation potential, researchers at Iowa State

University plan to conduct a cattle feeding test this spring using the pellets.

Livestock already consume much of the distillers grains produced by the ethanol plants. The study will help determine whether it's easier to feed the cattle using the pellet form.

A test run in March at a power plant in Spencer showed reductions in pollution emissions. Specifically, officials conducting the test run noted a decrease in opacity, which means that smoke leaving the stacks of the power plant was clearer.

But there are drawbacks. The test burn used a mix of 10 percent pellets and 90 percent coal. The energy output dropped by roughly 8.5 percent.

There's also a cost factor. The pellets are 20 percent to 30 percent costlier than coal. It's possible the cost difference will decrease if corn prices drop, Landers said.

Additionally, reduction of pollution should be considered as part of the overall value of the product, Landers said.

"We hope they see that value," Landers said.

Power plants fueled by coal and other fossil fuels produce about 40 percent of the U.S. emissions of carbon dioxide, according to the Environmental Protection

Agency. Carbon dioxide is the primary greenhouse gas contributing to climate change.

Environmentalists often discourage the use of coal, noting studies that show a higher likelihood of mercury exposure as well as lung and heart disease caused from its pollution.

Neila Seaman, director of the Iowa chapter of the Sierra Club, said the group would probably embrace the pellet technology "if it can substitute (for) coal and assuming it doesn't do any further harm to the environment."

One concern of Seaman's is that more coal-powered electric plants could be built as a way to maximize the use of the pellets.

"We are trying to downsize the coal use in this state," Seaman said. "We wouldn't want them to facilitate bringing in more coal-fired plants."

The Power Fund could help ethanol producers set up the added processing needed to create the pellets, Hansen said. His group has sent information to the governor's office about the pellet technology.

The fund would create a new Office of Energy Independence, which would take applications and examine proposals from renewable energy projects seeking assistance.

A seven-member committee would review the feasibility of the projects, and the

18-member Iowa Power Fund board would decide whether to provide financial incentives.

The program is one of Culver's priorities. He is expected to sign the legislation this month.

Reporter Jason Clayworth can be reached at (515) 699-7058 or jclayworth@dmreg.com