APersonal Color Proofing Goddard College 1981

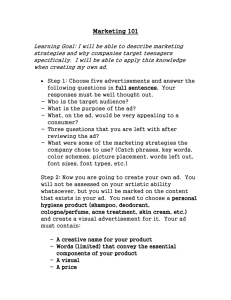

advertisement