Innovative solutions for chassis systems and structural assemblies

advertisement

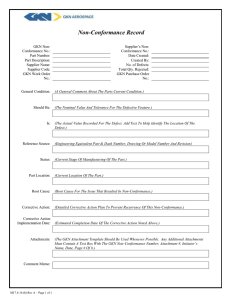

Innovative solutions for chassis systems and structural assemblies Welcome to the world A leading global engineering group, with over 250 years heritage of quality and innovation, operating in more than 30 countries. Technology and engineering from GKN is at the heart of the vehicles and aircraft produced by the world's leading automotive, off highway, defence and aerospace manufacturers. More than 40,000 people work in GKN companies and joint ventures in more than 30 countries. “Every day we harness our considerable technology and manufacturing resources to supply the highest quality systems, structures, components and services.” GKN operate in four key business areas: GKN Automotive GKN Land Systems GKN Aerospace GKN Powder Metallurgy Supplying driveshafts, geared components, torque management devices to vehicle manufacturers in the global car and light vehicle markets. Design, manufacture and supply wheels, driveline products, tractor attachment systems, clutches, gearboxes, structural assemblies and chassis systems for the mining, agricultural, construction, automotive, defence, rail and industrial machinery markets. Activities are concentrated on the production of airframe and engine structures, components and assemblies for both military and civil aerospace markets. Producing powdered metal and sintered components for automotive and other industrial customers. Power Management Wheels & Structures Aftermarket & Services GKN Land Systems comprises three specialist businesses: Power Management - world leader in the design, manufacture and supply of PTO driveshaft, drive line components, gearboxes, clutches and tractor attachment systems for the global off highway markets. Wheels & Structures - world leader in design, development and manufacture of wheels for off highway applications and automotive wheels in Asia, and pressed steel, structural assemblies, modules and chassis systems for the automotive, off highway, defence and rail sectors. Aftermarket & Services - a global aftermarket distribution and service business serving the automotive and off highway industry. 2| d of GKN GKN Structures – engineering excellence and high performance GKN Land Systems is renowned for engineering excellence and has expanded its global presence significantly over recent years with manufacturing, service and distribution facilities worldwide. Whilst GKN Structures’ growing range of non automotive customers benefit from the automotive derived facilities, such as site compliance to TS16949 and safe launch procedures for all new work. Within the GKN Land Systems group, GKN Structures is a specialist chassis and sub assembly supplier to a number of key sectors including automotive, off highway and defence. Automotive customers include Land Rover, Toyota, Ford, Bentley, Aston Martin and Leyland Truck. GKN Structures is investing heavily in its Telford Headquarters facilities with a new shotblast, top coat, large area laser and press brake. This investment will not only complement our existing extensive facilities, but also ensure that we maintain our leading role and reputation for engineering excellence, innovation and high performance. Rockford Nagbøl Telford Armstrong, Estherville Ribemont Woodridge: PM, W&S Wichita Auburn Hills Lohmar Carcastillo Sohland Offenbach Bruneck Carpenedolo Tokyo Liuzhou GKN Land Systems Manufacturing locations: Wheels & Structures Power Management Multi-business Porto Alegre Montevideo AMS Remanufacturing Engineering centres: Auburn Hills & Offenbach Bruneck Lohmar Rockford Carpenedolo Woodridge 3| Your automotive and non autom Automotive modules and systems GKN Structures has built an outstanding reputation for excellence and reliability in the design, development and manufacture of automotive chassis, suspension, body and structural systems for the major automotive OEMs including Land Rover, Toyota, Ford, Bentley, Aston Martin and Leyland Truck. Similarly, we have extensive expertise in delivering complete modular systems in sequence directly to a customers’ production line: Full ladder frame chassis Cross members and suspension arms Front and rear suspension components Complex sub-frames for high and low volume applications Process capabilities Multi stage press lines Blanking line Robotic welding CMM/Faro/laser inspection Access to specialist pressing technologies E-coat paint process Full TS16949 compliance Control arms Rear non driven axles Automotive 4x4 Ladder Chassis Frame 4| motive partner Non automotive lower volume processing Non automotive customers are able to take advantage of the automotive derived high quality facilities, these include automotive standard process control and full TS16949 compliance across our entire site. Further, site expertise in automation for both press and robotic welding means we are equipped to apply this technology to your work. With our substantial investment in lower volume processing equipment including laser, press brake and paint finishing, together with our commitment to lean manufacturing excellence, GKN Structures is ideally placed to support and successfully exploit opportunities to improve efficiency through value engineering and value added activities. Laser cutting Up to 4 x 2 Press brake 4.2 Mtrs 400 tonnes Robotic welding Resistance, spot and projection In particular, our E-coat paint process is capable of treating a wide range of components from small car speaker grilles right up to full chassis. This environmentally friendly process ensures both high corrosion resistance and excellent surface finish suitable for top coating where required. Arc, Mig and Tig Dedicated robotic cells and flow Comprehensive prototype facility Flexible robot cell developments Manual welding Agricultural Vehicle Ladder Chassis Frame Full in-house training facility High number of coded welders Shotblast Booth capable of full chassis blasting E-coat processing 5.8m x 1.5m x height 2m Top coat Wet coat and powder coat processing up to full chassis 5| Aluminium Structures Squeezeforming The drive towards weight reduction and increasingly stringent emissions creates a wide range of engineering opportunities for aluminium technologies. GKN Structures is committed to developing new components for a wide range of target sectors including defence, automotive, motor sport and rail. Aluminium Structures employs a unique Squeezeforming process, with closely controlled cooling and solidification of molten aluminium under pressure, giving excellent mechanical properties. This process enables the use of a wide range of heat-treatable alloys to give forged material properties and cast-in inserts for locally improved wear resistance or strength. As an example of our high performance aluminium engineering technology, Aluminium Structures has been supplying road wheels for the Warrior armoured personnel carrier for over 15 years, offering a 50% weight saving over an equivalent steel wheel. Tracked Military Vehicle Wheel 6| Aluminium processing Direct casting process High strength, low weight products Low porosity, fine microstructure Heat-treatable, weldable alloys Proven in service for over 15 years Dedicated, highly-skilled Engineering & Development team E-coat world class paint Customers today demand both higher quality and durability from the products they buy. Not only do they expect these products to perform well, but they want the finish to look good and resist corrosion for a much longer period of time. The E-coat world class paint process offered by GKN Structures is designed to do just that. Cathodic epoxy electro-coat is designed to be compatible with a wide range of liquid and powder top coat materials and, in addition, the excellent surface finish can allow the E-coat to be applied as a single coat where UV resistance is not required. Processing E-coat Cathodic epoxy electro deposition coating 17 tank process, pre-treatment, electro-coat, post rinse and bake oven Tank size: length 5.8m x width up to 1.5m x height 2m. Pre-treatment including phosphate coating Suitable as base coat for A class panels Salt spray resistance testing up 1000 hours against customer specifications Advantages Environmentally friendly: water based paint system Corrosion protection: the paint film is intrinsically bonded with the base metal product Electro-deposition allows coating of intricate and hard to reach areas of parts Transfer efficiencies of better than 95% resulting in reduced paint waste Fewer defects: E-coat gives a better quality product with an even film build During baking, the E-coat will not sag nor will the vapours cause the paint to wash off Highly repeatable process E-Coated Control Arm 7| From concept and design to pro Design, development and testing GKN Structures has proven capability to support a model program from concept to production, assuring client confidentiality at all times. Design A comprehensive suite of CAD analysis tools are used, together with value engineering and competitive benchmarking, to ensure performance targets are met at minimum cost and weight. Design capability from concept to production, finite element analysis used to optimise components With its broad based skills and expertise in automotive, defence and rail markets, GKN Structures offers customers in all sectors a highly developed and professional design, development and testing capability along side its firm commitment to lean excellence. CAD systems include CATIA / SDRC IDEAS / Pro Eng FSS status since 1997 Testing Single axis cyclic Static stiffness/strength Multi-axis cyclic GKN Structures Design & Test Facility Full vehicle/full axle Full corner testing on 150 t seismic mass Remote Parameter Control (RPC) Road load data acquisition on customer vehicles Road simulation Road load data analysis. Component strain data analysis. Access to test track real life conditions 8| oduction World class quality As you would expect from a business that embraces excellence and innovation, quality assurance is one of the cornerstones of GKN Structures’ philosophy. The process begins in quality planning simultaneously with engineering, further supported by full feasibility analysis and continues through process control where we implement a range of tests and checks. Testing and inspection Multi axis CMM machines up to 5 x 3.5 Faro arm inspection These checks include CMM inspection, macro weld tests, ultrasonic weld inspection and, for our paint process, salt spray resistance testing. TS16949 - Site Compliance ISO9001 ISO14001 OHSAS18001 GKN is certified to ISO14001 and is committed to protecting the environment in which we live and work. Destructive testing, Macro Etch Non destructive testing, ultrasonic weld test Safe launch procedure State of the art laser inspection for high volumes 9| Lean enterprise Case study Continuous Improvement - The Land Rover Defender Chassis Before 2009 assembling the Land Rover Defender was almost entirely a manual operation; some sub assembly automation had taken place prior to 2009, but the bulk remained manual and extremely labour intensive. The Defender value stream historically used a large manufacturing footprint, in doing so the cost of heating and lighting was not optimised, work in progress was high and the working environment was not ideal. All Defender chassis are now robot welded, with positive feedback from our customer on the improved reliability and quality. The costs of bringing in outside contractors to design, install, commission and automate a system for final assembly was deemed prohibitive, so the creativity and skills of our in house resources were put to good effect. GKN Structures already had a high level of automation for handling and welding, so the drive to implement change was already in the business. …Land Rover benefited from the quality and reliability improvements this project provided. In January 2009 a maintenance and production team from GKN Telford began designing and then constructing the new assembly line, including all robotic welding equipment software and programs. To reduce obsolescence costs, production robotic cells were refurbished into a prototype assembly and welding cell. …the creativity and skills of our in house resources were put to good effect. The main challenge of the new installation for the in house team was that the new cell needed to be installed on the existing site, without disrupting the supply of chassis to Land Rover. To eliminate some of the risk, the line was put through mass production trials in advance of the line change in August 2009. Working to a strict deadline, the final phase of this project was completed by the removal of the old line and the installation and commissioning of the new automated facility during a two week shutdown in 2009. The benefits of such a major project were numerous, not least a reduction of floor space by 60% which, in turn, meant a huge reduction in heating and lighting costs. Most importantly in all of this, our customer Land Rover benefited from the quality and reliability improvements this project provided. Our operators benefited from a significant enhancement to their working environment. Today, our Telford plant has more than 200 robots on site involved in handling and welding in the various value streams. What started out as a continuous improvement study, turned into a global GKN award for innovation based on the automation of the final welding process here at GKN Structures. GKN Vision Production Excellence Business Process Excellence People Excellence Business Excellence 10 | 11 | GKN Structures Headquarters PO Box 85 Hadley Castle Works Telford TF1 6TE United Kingdom © GKN Land Systems 10/11 1M www.iconnet.co.uk Tel: +44 (0) 1952 428053 www.gknlandsystems.com