WSDP: MODULE 2 TOPIC 6: OPERATION AND MAINTENANCE PLAN

advertisement

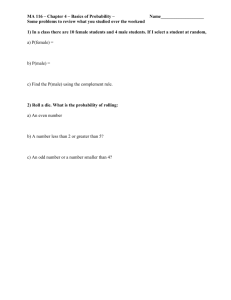

WSDP: MODULE 2 TOPIC 6: OPERATION AND MAINTENANCE PLAN 6. OPERATION AND MAINTENANCE PLAN The focus on improvement of levels of service through creating new infrastructure at great cost results often in overlooking the importance of the development and implementation of sound asset management practices. Through the assessment of this important function WSAs are enabled to identify areas of concern and it should form the base for the development of an Asset Management Plan. Neglecting the implementation of best practice operational and maintenance procedures would result in ineffective service delivery and shortened life span expectancy of assets. Additional capital expenditure for refurbishment or replacement will eventually be unavoidable. The two important aspects of asset management under consideration are: Operations Maintenance 6.1. OPERATION AND MAINTENANCE 6.1.1. Water Network Performance Water network performance is monitored by recording bursts on particular lengths of pipework. Lengths of pipework have been relayed in past financial years yet other sections continue to age and exhibit increased burst frequencies. An examination of burst main statistics indicates that the predominant pipe size and type prone to failure are pipe sections made up of fibre-cement in the sizes of 100 mm and below. Noteworthy observations are that in the South Peninsula and Tygerberg areas, the failing pipework is 100 mm fibre-cement. Both of these districts have similar lengths of pipework and ages (approximately 50 years). Helderberg and Blaauwberg Districts experience failure both with 100 mm fibre-cement pipe and fibre-cement pipe of less than 100 mm nominal diameter. In the old Cape Town municipal area the water reticulation performance has benefitted from past infrastructural renewal and therefore has fewer sections of pipe approaching the unserviceability condition. 2.95 Khayelitsha is a relatively new network and does not have pipe sections that require replacement. A breakdown of suggested pipe replacement to achieve a nominal reduction in burst water mains is as indicated in the following table: Table 1: Water Pipework to be replaced in 2012/13 District Proposed relay Length (m) 2012/13 District 1 35 560 District 2 4 570 District 3 - District 4 16 131 District 5 29 012 District 6/7 and 8 15 599 Total 100 872 (±100km) Source: Five Year Water Replacement Programme (per District) obtained from Reticulation District officials, 2012/13 Khayelitsha District has the best performance, well within the target of 20 bursts per 100 km per year. This is because this network is, on the whole, the newest in the Metro. The network of the Cape Town district, whilst being the oldest, has a fairly stable performance but lies above the target performance. The reason for this is that it has benefitted from sustained investment and optimal operations over the years (albeit reduced investment due to diversion of funds to other Metro areas with poorer infrastructural performance). Table 2: Reticulation Statistics (USPC 2012/06 (v08) WATER NETWORKS Repair to Burst Water Mains Water Mains Replaced (m) 2011/12 YEAR STATS AS AT END JUNE 2012 BLAAUWCAPE HELDERKHAYEBERG TOWN BERG LITSHA SOUTH PEN. TYGERBERG YTD - ANNUAL COMPARISON YTDYTDYTD2011/12 2010/11 2009/10 790 594 784 30 794 965 3 957 6 523 6 169 39 049 13 456 5 745 5 28 448 3 272 89 975 57 419 53 104 2.96 For the 2011/12 financial year it was suggested that ±150km (Five Year Replacement Programme for Reticulation Networks, Inclusive of Operational Improvement Proposals, February 2012) of the water network be replaced. Approximately 60% of the recommended pipe replacement has taken place. This suggested that the burst frequency could have been reduced even further. Over the first 6 months of the 2012 calendar year the burst main rate was 35 bursts/100km/year. 6.1.2. Sewer Network Performance Whilst reported sewer blockages are quickly attended to and the cause of the blockages are recorded, there is only a minimum of inspections of the sewers to determine if underlying causes of blockages are related to infrastructural defects. There is a dire need for technical staff to carry out this function. Predominant infrastructural failures are related to the use of pitch fibre pipe, joint failure in clay pipework and corrosion of cement bulk pipework that carries sewage that is releasing aggressive gases. Accordingly, sewer replacement is premised on the replacement of 420 km pitch fibre sewers and clay sewers over a five year period. The condition of bulk sewer pipework is also of concern. Collapses in this pipework indicate that there is an urgent need to determine its condition and thereafter carry out any required rehabilitation before the condition deteriorates to the extent where these sewers have to be reconstructed at double the cost. GIS records indicate the following: Table 3: Estimated Sewer Rehabilitation Lengths Material Length (m) Pitch fibre 128 260 Clay sewers 291 260 Bulk sewers 359 186 Source: Budget Plan (Vol 4), Reticulation, Five year replacement programme 2.97 6.1.3. Water Process Control, Maintenance and Management Skill The current classification of the WTW’s, is according to Section 26 of the National Water Act (Act No.36 of 1998). Monitoring Process The quality of water produced at the CCT’s water treatment plants is strictly monitored on a continual basis to ensure compliance with the South African National Standard 241:2006 on drinking water quality. The Scientific Services Branch conducts routine sampling and analysis of potable water produced at all water treatment plants, as well as inspection of treatment processes. Scientific services have acquired SANS 17025 certification for laboratory quality testing. Expansion of the laboratory is a necessity for improving its capability to undertake a wide spectrum of tests. The water quality report below indicates the analytical data and approximate distribution for Cape Town drinking water as at the end of June 2012. The South African National Standards (SANS 241:2006) Specification for a Class I and II water is also stipulated on this report. This report indicates the quality of the drinking water leaving each of the major water treatment plants and the approximate distribution areas they service. Table 4: Class 1: Drinking Water Quality for June 2012 (SANS 241 requirements per population size; 1 sample: 20 000 population) Water Supply Outlets Sample Points Per Water Supply Outlet Sample Points Sampled Number of Samples Taken for June Chemi cal Microbio logical % Compliance SANS 241 May Month Chemi cal Microbio logical 12 Month Rolling Average Chemi Micro cal biological Water Treatment Plants 10 9 32 28 99 100 99 99 Reservoir * 26 23 76 86 100 100 98 99 Distribution * 107 90 333 352 100 100 98 100 Informal Settlements * 43 35 67 64 100 98 98 98 186 157 508 530 100 100 98 99 Total 2.98 REMARKS: Chemical Results: Most of the distribution sampling points that fail can be attributed to high Turbidity results. OBW 09, SPW 11, BBW 06, TBW 02 and Informal Settlement 32 fail due to high pH values. Sample points Atlantis Clinic, Atlantis Pella 40 and BBW 01 fail due to high Iron values. Informal Settlement has 29 fails due to high Iron and Lead values. Overall the water is safe to drink. The determinants at the Water Treatment Plants that do not comply with SANS 241 are Aluminium and Turbidity. *Please note: Chemical Analyses: pH, Conductivity, Turbidity and Alkalinity were done weekly. Aluminium, Chloride, Calcium, Iron, Manganese, Potassium, Sodium, Sulphate, Nitrate/Nitrite and TDS were done every 8 to 9 weeks. Microbiology Results: In the month of November the following sample exceeded the SANS 241 guideline for Bacteriological quality of drinking water: On 2011-11-14 MBW 04, Newlands Reservoir outlet to Wynberg had an Escherichia coli (E. coli) count of 1 CFU/100ml. On 2011-11-15 it had an E.coli count of 3 CFU’s/ml. On 2011-11-16 the result was <1 CFU/100ml and hence complied with the guideline. The informal settlement results that exceeded the guideline are not included. Please see the comments below Informal Settlements: The non-compliance of the informal settlements to the South African National Drinking Water Standard (SANS 241) can be attributable to the following: Plastic communal taps are being used for sampling. Because of plastic material taps are not flamed prior to samples collection. Taps are not dedicated for sampling only; and are used by the community. Location of sample taps in close proximity to or just behind the communal toilets can introduce cross contamination to the tap as users wash, touch and drink directly from the taps. Taps are often dirty and leaking. 2.99 6.1.4. Waste Water Operations (Process Control), Maintenance and Management Skill An Operational and Compliance Monitoring Programme that meets the requirements of DWA as stipulated in the Green Drop Criteria was drawn up by CCT and is implemented by the Municipality. Operational samples are taken on a daily basis at all the WWTWs. The compliance samples that are taken on a monthly basis at all the WWTWs are analysed at CoCT accredited Scientific Services laboratories and monthly monitoring and inspection reports are compiled. Table 5: Waste Water Treatment Non-Compliance as at June 2012 WWTW Bellville PROBLEM DEFINITION No sample complying on COD, Ammonia and E.Coli. One sample complying on TSS. CAUSES REMEDIAL ACTIONS Broken diffusers in North and Centre biological reactors are causing poor aeration of the biomass. Experienced belt press mechanical breakdowns which have reduced the mass of sludge to be wasted per day. The UV disinfection system is not in operation due to the poor settling pond effluent. Construction of the new Membrane Works(20Ml/d) is in progress(long-term plan).A task group comprising Operations and EAM electrical and mechanical sections has been formed to focus on improving the reliability of the dewatering equipment. The settlement ponds are in the process of being cleaned out. The by-pass pipeline to the UV lights is in progress – this will allow the SST effluent to flow directly to the UV disinfection unit. The maturation ponds and bypass channel are being cleaned. At the end of June 2012 the bypass pipeline was brought into operation. Borcherds Quarry Non-compliance on all the parameters Maturation ponds are full of sludge which is contamination the secondary settling tank effluent which is generally compliant with the General Standard. Klipheuwe l Non-complying TSS, COD and Ammonia The septic tank is being cleaned out This Process was completed and the plant is recovering Gordons Bay Non-compliance on COD Foaming in the reactor Dosing of chlorine Maturation Ponds contaminated with sludge due to failure of Archimedean Screw Pumps at Intermediate Pump station. Removing sludge from maturation ponds. The plant effluent compliant before entering maturation ponds. Mitchells Plain Non-compliance on ammonia and E.Coli 2.100 6.1.5. Status of Equipment and Plant on Wastewater Treatment Works (as at January 2012) Table 6: Status of Equipment and Plant on Wastewater Treatment Works WWTW 1 Athlone 2 Description Primary Tanks, 3 new tanks being installed Grit removal unit appears unsatisfactory. 3 Gravity thickener - inadequate 4 5 Required required. This is in not applicable at this stage – investigation new thickener required refurbishment – this Holder leaking has been refurbishment – Retic Demolish Mixed Liquor & RAS Pumps 9 10 Replacement may be required sludge Cleaning not completed yet Sludge Beds are a fire hazard Require cleaning Blower #1: faulty Interstage screw pump Bellville external contractor Internal costs. Job Requires completion Part of the capital project Part of the capital project Repair vs replacement being investigated Repair vs replace In progress Inlet screen 2 out of Repair chain and Part of future upgrade commission placed in auto mode plan gearbox 13 obtained Refurbishment/ incomplete 12 Quotations to be Maturation Ponds full of Outer Perimeter Fence 11 R 0.5 million An appointment of an years of age) 8 R 10 million to confirm require demolishing require replacement (over 20 to be determined Requires Redundant tanks and 7 to be determined is in progress sand, gas lines corroded, Gas pipelines and buildings R 5 million progress Replacement or partially blocked Estimated Cost One further tank Anaerobic Digesters, full of Cape Flats Sewer ex Athlone, 6 Intervention 2.101 14 Belt press 2&3 are out of commission for repairs. are in the process of being repaired to improve sludge dewatering Repair and align with automation system In progress and removal 15 Blower # 3 is out of commission 16 Requires repairs Sludge cake pumps cannot PLC needs to be set accommodate full cake to accommodate cake volume volumes produced 17 Pond 2 is out of commission 18 Needs to be lined with clay or plastic In progress done R 3 – 5 million – part of current upgrade project Installation of Med/fine screen pre-UV to UV disinfection unit cannot perform reliably – taken out of prevent damage to UV lights. use R 10 million – part of current upgrade project Improvement in effluent quality. 19 20 SSTs cannot accommodate SST modification to high flows. improve settling Standby generator not on auto 21 22 Borcherds Quarry 23 24 Re-use pumps not operational Being replaced Unable to separate dewatered Need to automate primary and secondary centrifuge – being sludges. investigated Blower 3 out of commission Refurbish blower due to vibration motor – in progress Ponds are full of sludge 25 PST 1 requires repairs to scrapers and rope pulley 26 Ponds cleaning plan for summer months. In progress Inlet Screw Pumps, Screws and trough Screws inefficient require refurbishment Cape Flats 27 Requires repair Odour Control System requires upgrading Being planned R 7 million – will be part of future upgrade project In progress R 1 million R 350 000 - ongoing In progress done R 5 million To be determined 2.102 28 29 30 Primary Tank Bridges Bridge Replacement corroded required Aeration System requires Aeration System constant repair requires replacement R 10 million R 0.5 million Anaerobic Mixers inefficient because of age and Require replacement R 0.4 million Require replacement R 8 million breakdowns 31 Clarifier Bridges corroded 32 Costs to be Aerobic Blowers are 30 years old. Have been repaired but established once the Require replacement will require replacement contractor has assessed the problems 33 Blower #1 gearbox vibration In progress 34 Boilers damaged Needs repair Being investigated 35 Green Point Pumps require replacement Currently underway Part of capital project 36 Gordons Bay Electrical Panels To be replaced In progress 37 Hout Bay 38 Macerator system inadequate requires upgrading Coarse and fine screen and grit removal 39 Kraaifontein Install fine screenings and grit removal. This R 2 million will be planned In planning Anaerobic digester not in use. Refurbish digesters. Activated sludge plant is on Will form part of a extended aeration general contract. 40 R 5 million R 5 million Pipeline is part of By-pass pipeline and pump station to be Ponds are full of sludge upgrade contract (in progress). constructed. Completion date in early 2012. R 5 million for cleaning – being planned. 41 42 43 44 Macassar Melkbosstrand Mitchells Plain Standby Generator beyond Replacement. In repair planning Degritter gearbox Requires repairs done Require replacement R 5 million Require replacement To be investigated Coarse Screen outdated and inadequate. Inlet Screws, in poor R2-3 million 2.103 mechanical condition. 45 Mechanical Screens, old screen requires replacement Requires replacement R 200 million for the and screening removal is – Retic to plan 3rd Cape Flats sewer inefficient 46 2 Screw Pumps irreparable. One Inter stage Pump Station Screw being replaced. Tender being repaired R 10 million to replace other with submersible. 47 Reactors in bad repair 48 Aeration Blowers leak oil, and breakdown require refurbishment R 0.5 million Require replacement R 0.2 million 49 An appointment of an Clarifier, one floor has lifted Need to be repaired external contractor may be required 50 Anaerobic Digesters off line: require cleaning and pipework Refurbishment Internal costs. Job required not completed yet and Belt Press breakdown Replacement/ Part of the capital problems with inclined Refurbishment project Require refurbishment done Maturation Pond Fencing (2 Require fencing for Part of future upgrade km) safety reason plan Demolish R 0.3 million and pumps require refurbishment. Boilers need overhaul. 51 Centrifuge out of commission conveyor bearing failing. 52 Sludge Beds & Maturation Ponds full of sludge 53 54 Redundant Equipment and Building 55 Investigate the various electronic problems. Potsdam UV disinfection performance Place on automatic. is erratic when on automatic The maintenance mode tender is in progress but there is a delay at SCM. R 0.3 million short term The maintenance contract is expected to be to the value of R4 m 2.104 56 Install coarse screens Inlet screens upstream to remove excessive rags 57 Simons Town 58 Low pH chemical dosing Dosing plant being equipment required purchased. Sludge Beds require replacement with mechanical Dewatering 59 Capital Projects – to be investigated R 8 million – in rpogress R 3 – 5 million R 10 million Replace blowers. Interim repair to Wesfleur Domestic blowers gearbox to reduce R 7 million for replacement vibration was completed. 60 61 62 63 Air pipeline corroded Wildevoelvlei Anaerobic Mixers are unreliable No standby Belt Press Maturation Pond contain sludge 64 Emergency repairs R1.4m Has been required. repaired temporarily Requires investigation R 1 million Standby Unit required R 10 million Require refurbishment and/ or Disinfection Part of capital project Plant Install coarse screens Inlet screens upstream to remove R 5 million excessive rags 2.105 6.1.6. Status of Equipment and Plant at Bulk Water Installations (January 2012) Table 7: Status of Equipment and Plant at Bulk Water Installations Item no WTP Description Intervention Required Estimated Cost 1 Faure WTP (BW) Obsolete and aging SCADA equipment Replacement of all PLCs R 6 million 2 Blackheath WTP (BW) PAC Dosing System Complete existing contract – Commissioning and operational acceptance period completed. R 1 million remaining of R7,7 million Contract amount 3 Blackheath WTP (BW) Treatment Residue Water Recovery PS Replace pump motor and associated equipment – Contract in progress R 950 000 4 Steenbras WTP (BW) Lime Storage and Transfer system Complete existing contract – Contractor to address items as per snag list [Completed] [Completed] 5 Voёlvlei WTP (BW) Pump System Surge Vessels Phased refurbishment of 4 large pressure vessels R 1,5 million 6 Voёlvlei WTP (BW) Air-scour Blowers Phased replacement of 2 blowers. One blower replaced during 2010/11. Second blower on order. R 250 000 7 Witzands WTP (BW) Acid Regeneration System Refurbish Acid System R 2 million 8 Firlands PS (BW) Obsolete and aging Variable Frequency Drives (VFD) Replacement of 4 off VSD’s R 25 million 9 Kildare PS (BW) Obsolete motors and electrical control equipment Replace pump motors and control equipment – Contract in progress. R 1 988 000 10 Molteno Reservoir PS No. 2 (BW) Obsolete and aging pump starter panel Replace pump starter panel – Contract in progress. R 415 000 2.106 6.1.7. Status of Equipment and Plant on Pump Stations (as at January 2012) Table 8: Status of Equipment and Plant on Pump Stations Item no Pump Stations Description Intervention Required Estimated Cost 1 Gordon’s Bay 4 No 1 pump o/c No 2 Pump blocked with Rags Pump 1 removed for repairs and pump 2 unblocked R6 000.00 2 Simons Town 12 Heavy rain Cleaned where possible R1 000.00 3 Simonstown 1 Heavy rain Cleaned where possible R1 000.00 4 Simonstown 2 Heavy rain Cleaned where possible R1 000.00 5 Fleur Park Pumps tripped due to rags Reset pumps R1 000.00 6 Lourens River Pump # 3 tripped on over temparature and 2nd pump out for repair Cleaned where possible All 3 pumps tripped Pumps reset (investigation into cause of simultaneous trip) R2 000.00 7 Helderberg R2 000.00 8 Summer Greens Blocked rising main Unblocked the main with jet machine R4 000.00 9 SarelCilliers Electrical Panels Replace R 100 000 10 Serepta Installation of diesel genset Installation of diesel genset R900 000 11 All Pump Stations Telemetry upgrade Upgrade (currently underway) 3.3Kv starters Replace with standard 400v Tender documents been prepared 12 Karl Bremmer R 10 000 000 R 1 800 000 13 HendonPark Electrical Panels Replace R 100 000 14 Naomi Street Electrical Panels Replace R 100 000 (Note: Include equipment and plant with problems only.) 2.107