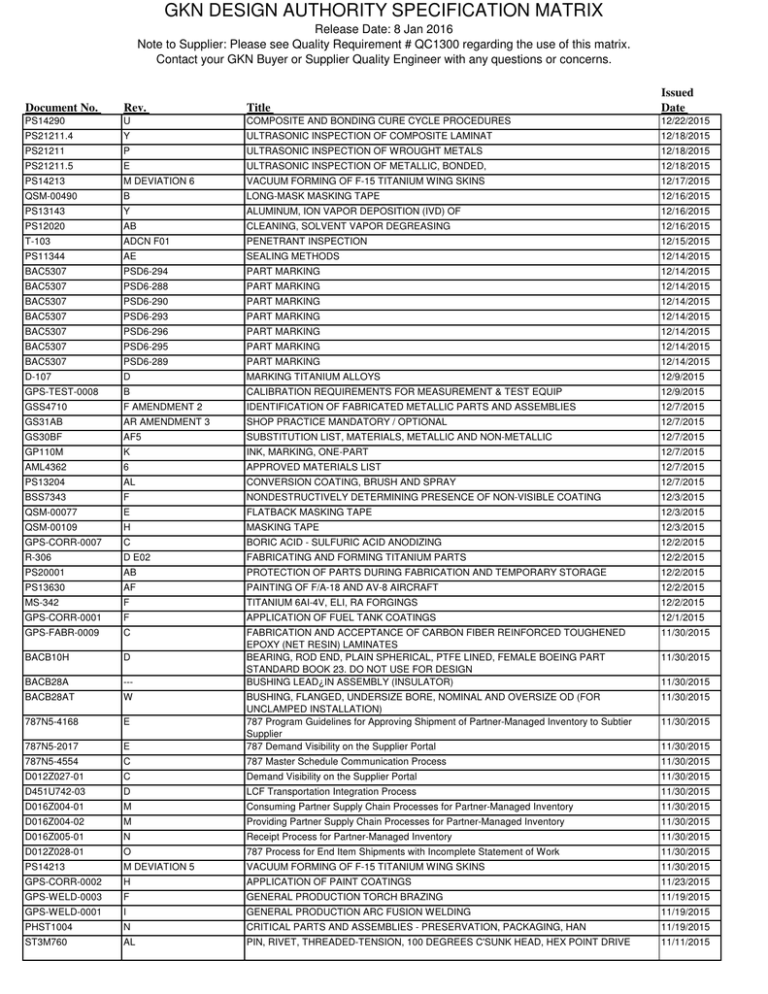

GKN DESIGN AUTHORITY SPECIFICATION MATRIX

advertisement