Filter Technology BEARINGS ENGINEERING THAT MOVES THE WORLD

advertisement

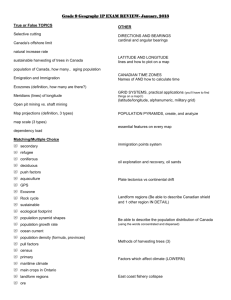

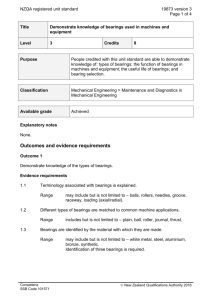

THINK Filter Technology BEARINGS ENGINEERING THAT MOVES THE WORLD Bearings Since 1759 250 years of exceptional engineering GKN Sinter Metals Filters, the leading manufacturer of porous sinter metal products, offers a variety of solutions to fulfil customer requirements. We are familiar with various applications in almost every industrial branch. Our products are applied in gas- and liquid filtration, dampening, sparging, sensor protection, bulk handling and many more. We offer solutions for high temperature and corrosive environments. Sintered filter elements made of stainless steels, bronze, nickel based alloys, titanium and several special alloys can be manufactured seamless up to 1,600 mm length and 320 mm OD. Larger elements will be assembled in our certified in-house welding shop. Our most innovative product for the chemical industry is the patented metallic membrane SIKA-R…AS. The filter cartridges equipped with this state-of-the-art technology offer a flow rate up to 4 times higher compared to conventional sinter metal filter cartridges. Furthermore an excellent back flush performance is guaranteed. The filter active membrane layer with filter grades down to 0.1 µm absolute has a thickness of only 200 µm and is made of the same alloy as the coarse support material. The membrane is sinter bonded to the support and therefore cannot peel off. Another innovation introduced by GKN is the sinter bonded joint of porous parts with solid fittings in order to avoid welding seams – the weak spot of all sintered cartridges of our competitors. All sintered materials of GKN offer a self-supporting structure with high mechanical strength. We manufacture various filter grades with specified pore sizes and flow rates in order to have the appropriate solution for your requirements. 2 Bearings Properties of self-lubricating sintered bearings The properties of self lubricating bearings are determined by the defined density of the bearing material. produced which forms a lubricating film on thecontact surface and helps to circulate the lubricant. The resulting number of pores acts as a reservoir for the lubricant. In running condition, within a short time an equilibrium is established in the circulation of the lubricant. Through linking of the pores, a canal system is Function schematic Inactive condition Running condition 3 Bearings Applications Various domestic appliances and hand workshop tools… … as well as usage in bigger machine elements Sintered self-lubricating sliding bearings are the ideal solution for applications where lubrication is problematic or even impossible. The pores in the surface layer of a sintered self-lubricating bearing are filled with lubricating oil making any further lubrication unnecessary. The pore structure forms a labyrinth of interconnected pores of controlled size and volume, thus allowing uniform lubrication over the entire bearing surface. The oil volume dispensed increases automatically with the service temperature rising as a result of the increasing rotational speed. 4 Bearings Manufucturing of self-lubricating sintered bearings Blending Compaction Sintering Sizing Impregnation with lubricants 5 Bearings Standard materials GKN Sinter Metals Filters manufacture bearings from the following materials: Bronze Bronze / MoS2 Iron Special materials on request. Our technicians will be pleased to help you choosing the best suitable material for your application. 6 Bearings Standard geometries of self-lubricating sintered bearings Cylindrical bearing Having the most economical bearing shape, cylindrical bearings, for the most part, are pressfitted into a premachined housing with the help of a fitting pin. A B A A C IT8 Flange bearing Flange bearings differ from cylindrical bearings due to the flange at one end. E The flange serves as a stop gauge in assembly and, in certain cases, as an enlarged shoulder for axial load. This shape of bearing also requires the help of a fitting pin when press-fitted. A C F A R B IT8 A 7 Bearings Piece price in € Self-lubricating sintered bearings (bronze) Larger quantities on request Dimensions 51-200 201-500 501-999 6G7x10r6x6 0.208 0.54 0.38 0.26 0.19 6G7x10r6x10 0.347 0.62 0.46 0.34 0.27 8G7x12r6x8 0.347 0.59 0.43 0.34 0.28 8G7x12r6x12 0.520 0.80 0.64 0.51 0.41 10G7x14r6x10 0.520 0.82 0.57 0.40 0.28 10G7x14r6x20 1.040 0.95 0.67 0.47 0.33 10G7x16r6x10 0.845 0.82 0.66 0.52 0.42 10G7x16r6x12 1.014 0.94 0.75 0.60 0.48 10G7x16r6x16 1.352 1.09 0.87 0.70 0.56 10G7x16r6x20 1.690 1.24 0.99 0.80 0.64 12G7x18r6x8 0.780 0.82 0.66 0.52 0.42 12G7x18r6x12 1.170 0.93 0.74 0.60 0.48 12G7x18r6x16 1.560 1.19 0.94 0.74 0.59 12G7x18r6x20 1.950 1.45 1.15 0.91 0.72 14G7x20r6x14 1.547 1.24 0.99 0.79 0.63 14G7x20r6x20 2.210 1.71 1.37 1.09 0.88 15G7x21r6x20 2.340 1.79 1.43 1.15 0.92 15G7x22r6x25 3.507 2.36 1.89 1.51 1.21 16G7x20r6x16 1.248 1.22 0.98 0.78 0.62 16G7x20r6x20 1.560 1.24 1.00 0.80 0.65 16G7x22r6x16 1.976 1.47 1.18 0.94 0.75 16G7x22r6x20 2.470 1.75 1.40 1.12 0.90 16G7x22r6x25 3.087 2.23 1.78 1.43 1.14 18G7x24r6x18 2.457 1.85 1.48 1.18 0.95 20G7x26r6x16 2.392 1.94 1.55 1.24 0.99 20G7x26r6x20 2.990 2.25 1.80 1.44 1.15 d2 20G7x26r6x25 3.737 2.73 2.18 1.75 1.40 A d1 20G7x26r6x30 4.485 2.97 2.38 1.90 1.52 20G7x28r6x20 4.160 2.29 1.83 1.47 1.17 22G7x28r6x22 3.575 2.68 2.14 1.72 1.37 25G7x32r6x20 4.322 2.79 2.23 1.79 1.43 25G7x32r6x25 5.403 3.51 2.81 2.25 1.80 25G7x32r6x32 6.916 4.49 3.59 2.87 2.30 30G7x35r6x20 3.521 3.12 2.50 2.00 1.60 30G7x35r6x30 5.281 3.50 2.98 2.53 2.15 30G7x38r6x20 5.893 3.93 3.14 2.52 2.01 30G7x38r6x30 8.840 4.21 3.37 2.69 2.16 30G7x38r6x40 11.786 5.87 4.70 3.76 3.01 Tolerances d1 = G7 ( after fitting H7) d2 = r6 8 1-50 A b1 IT8 Weight kg/100 pieces Bearings Dimensions Weight kg/100 pieces 1-50 51-200 201-500 501-999 30G7x40r6x30 14.630 5.75 4.60 3.68 2.94 30G7x40r6x40 Auslaufartikel 19.500 7.62 6.10 4.88 3.90 32G7x40r6x32 9.984 4.53 3.62 2.90 2.32 35G7x44r6x36 13.864 6.06 5.45 4.91 4.42 40G7x50r6x30 14.625 7.58 6.82 40G7x50r6x40 19.499 9.43 8.49 40G7x50r6x50 24.374 10.80 9.72 45G7x55r6x50 27.083 12.77 11.49 50G7x60r6x40 23.833 12.33 11.10 50G7x60r6x50 29.791 13.80 12.42 50G7x60r6x63 37.536 18.00 16.20 55G7x66r6x56 40.372 20.69 18.62 60G7x72r6x63 54.052 25.19 22.67 65G7x77r6x63 58.147 26.48 70G7x82r6x63 62.242 34.13 75G7x90r6x63 84.457 40.25 80G7x95r6x63 89.575 43.33 100G7x120r6x100 238.326 76.44 Larger quantities on request Piece price in € A d2 A d1 b1 IT8 Tolerances d1 = G7 ( after fitting H7) d2 = r6 Self-lubricating sintered bearings (bronze) - special dimensions Dimensions Weight kg/100 pieces Special Dimensions 1-50 51-200 201-500 10H7x20r6x20 3.250 3.30 2.64 2.11 12H7x21r6x25 4.022 4.93 3.94 3.16 16H7x23r6x30 4.436 4.30 3.44 2.75 18H7x25r6x20 3.261 3.70 2.96 2.37 20H7x28r6x25 5.200 5.30 4.24 3.39 20H7x30,2x35 9.707 8.65 6.92 5.54 22H7x30,2x40 9.274 8.72 6.98 5.58 25H7x35,2x30 9.978 8.99 7.19 5.75 25H7x35,2x40 13.304 9.35 7.48 5.98 30H7x40,2x30 11.635 9.60 7.68 6.14 30H7x40,2x40 11.514 11.63 9.30 7.44 35H7x45,2x40 17.724 12.81 11.53 10.38 40H7x50,2x60 29.900 22.17 19.95 17.96 501-999 Special dimensions according to drawing Beside our DIN-bearing program – delivery from stock – we also produce customized dimensions up to outer diameters of 225 mm – starting at 1 piece – according to customers drawings or specifications. 9 Bearings Larger quantities on request Cylindrical bearings (bronze MOS2) A d2 A d1 b1 IT8 Tolerances d1 = G7 ( after fitting H7) d2 = r6 10 Piece price in € Dimensions Weight kg/100 pieces 6G7x10r6x10 0.352 0.71 0.53 0.39 0.31 8G7x12r6x12 0.528 0.92 0.74 0.59 0.47 8G7x12r6x16 0.703 0.96 0.78 0.63 0.51 10G7x16r6x10 0.857 0.94 0.76 0.60 0.48 10G7x16r6x16 1.372 1.25 1.00 0.81 0.64 10G7x16r6x20 1.714 1.42 1.14 0.92 0.74 12G7x18r6x20 1.978 1.67 1.32 1.05 0.83 14G7x20r6x14 1.569 1.43 1.14 0.91 0.72 14G7x20r6x20 2.242 1.97 1.58 1.25 1.01 15G7x21r6x20 2.374 2.06 1.64 1.32 1.06 16G7x20r6x20 1.583 1.43 1.15 0.92 0.75 16G7x22r6x16 2.005 1.69 1.36 1.08 0.86 16G7x22r6x20 2.506 2.01 1.47 1.29 1.04 18G7x24r6x18 2.493 2.13 1.70 1.36 1.09 18G7x24r6x25 3.462 2.26 1.83 1.39 1.22 20G7x26r6x25 3.792 3.14 2.51 2.01 1.61 20G7x28r6x20 4.220 2.63 2.10 1.69 1.35 22G7x28r6x22 3.627 3.08 2.46 1.98 1.58 22G7x28r6x28 4.616 3.19 2.57 2.09 1.69 25G7x32r6x25 5.481 4.04 3.23 2.59 2.07 28G7x36r6x28 7.878 6.77 5.43 4.34 3.48 30G7x38r6x30 8.968 4.84 3.88 3.09 2.48 30G7x38r6x40 11.957 6.75 5.41 4.32 3.46 35G7x44r6x36 14.065 6.96 6.27 5.65 5.08 36G7x45r6x36 14.421 7.16 6.47 5.85 5.28 40G7x50r6x30 14.837 8.72 7.84 40G7x50r6x40 19.782 10.84 8.92 50G7x60r6x50 30.223 15.87 14.28 55G7x66r6x56 40.958 23.79 21.41 60G7x72r6x63 54.836 28.97 26.07 70G7x82r6x63 63.144 39.24 75G7x90r6x63 85.681 40.04 1-50 51-200 201-500 501-999 Bearings Flange bearings (bronze) 51-200 201-500 501-999 6G7x10r6/14x6/2 0.312 0.72 0.60 0.52 0.45 6G7x10r6/14x10/2 0.451 0.74 0.62 0.54 0.47 8G7x12r6/16x8/2 0.468 0.76 0.63 0.55 0.48 8G7x12r6/16x12/2 0.641 0.85 0.72 0.63 0.56 10G7x16r6/20x10/3 1.079 1.40 0.95 0.83 0.73 10G7x16r6/22x10/3 1.215 1.42 1.07 0.93 0.80 10G7x16r6/22x20/3 2.060 1.70 1.25 1.09 0.95 12G7x18r6/22x12/4 1.517 1.35 1.00 0.85 0.72 12G7x18r6/24x12/3 1.579 1.36 1.14 0.99 0.86 14G7x20r6/25x14/4 2.034 1.64 1.38 1.07 0.93 14G7x20r6/26x20/3 2.658 1.74 1.41 1.09 0.95 15G7x21r6/26x16/5 2.508 1.82 1.51 1.26 1.09 16G7x22r6/28x16/5 2.788 1.98 1.65 1.38 1.20 16G7x22r6/28x16/3 2.463 1.88 1.57 1.31 1.14 16G7x22r6/28x25/3 3.575 2.32 1.82 1.35 1.17 18G7x24r6/30x18/5 3.334 2.30 1.80 1.28 1.11 20G7x26r6/32x20/5 3.932 2.18 1.88 1.47 1.28 20G7x26r6/32x20/3 3.555 2.16 1.86 1.44 1.25 22G7x28r6/34x22/5 4.582 2.84 2.42 1.86 1.52 25G7x32r6/39x20/3,5 5.265 2.90 2.48 1.92 1.58 25G7x32r6/38x25/6 6.768 3.35 2.68 2.27 1.93 25G7x32r6/39x25/3,5 6.345 3.25 2.58 2.17 1.83 25G7x32r6/39x30/3,5 7.426 3.90 3.12 2.65 2.25 28G7x36r6/42x28/6 9.286 5.42 4.51 3.76 3.27 30G7x38r6/46x30/4 10.296 5.41 4.42 3.94 3.73 30G7x38r6/44x32/6 11.028 5.43 4.44 3.96 3.75 32G7x40r6/48x30/4 10.885 5.42 4.41 3.95 3.74 32G7x40r6/46x32/6 11.661 5.57 4.56 4.10 3.90 35G7x44r6/50x36/6 15.697 7.50 6.54 6.00 5.34 35G7x45r6/55x40/5 20.041 7.90 6.94 6.40 5.74 40G7x50r6/58x40/6 22.307 11.10 9.99 40G7x50r6/60x50/5 27.353 12.40 11.16 45G7x55r6/63x45/7 27.953 12.82 11.54 50G7x60r6/68x50/7 33.673 13.14 11.83 70G7x82r6/95x63/8 72.213 36.55 80G7x95r6/110x63/8 102.900 51.83 dE1 A A F 1-50 C Weight kg/100 pieces Larger quantities on request Dimensions Piece price in € R dB2 IT8 A Tolerances d1 = G7 ( after fitting H7) d2 = r6 11 Bearings Sintered plugs (bronze), all-over unmachined, oil-soaked Piece price in € d Dimensions b Weight kg/100 pieces up to 10 up to 20 up to 30 10 x 30 1.6 18.00 15.00 12.00 15 x 50 6.1 20.00 16.00 13.00 20 x 90 19.5 22.00 17.00 14.00 25 x 70 23.7 23.00 19.00 16.00 31 x 80 46.9 24.00 20.00 17.00 41 x 90 82.0 40.00 28.00 23.00 50 x 80 108.3 44.00 31.00 26.00 Larger quantities on request Price List 2010 Changes of the available dimensions and falsities excepted Requests: If you have requests please give us following information if possible: · · · · · · sliding speed or rotations/min bearing load motion sequence and action time environmental effects and temperatures case of application assembling tolerances The more exactly your specifications, the easier we can offer you the right material. Delivery time: in general: from stock. Prior sale excepted. Delivery: ex works, packaging excluded Prices: EURO per piece, plus material supplementary charge for bronze, which is continuously presented by the Del-notation. All prices excl. VAT. On delivery from stock up to a net order value of Euro 100.00 plus Euro 25.00 order basic costs. All order are obliged to our general terms of sale. 12 Bearings Further brochures available: 13 Bearings Additional Applications of GKN Filters… Catalyst recovery Refinery Water treatment 14 Bearings Pneumatic valves Ex-protection Food shaping 15 GKN Sinter Metals Filters GmbH Dahlienstraße 43 D-42477 Radevormwald P.O. Box 1520 D-42464 Radevormwald Phone: +49 (0) 2195-609-0 Fax: +49 (0) 2195-609-348 Email: info@gkn-filters.com www.gkn.com/filters © Copyright by GKN Sinter Metals Filters GmbH Radevormwald - Rev. 1.2