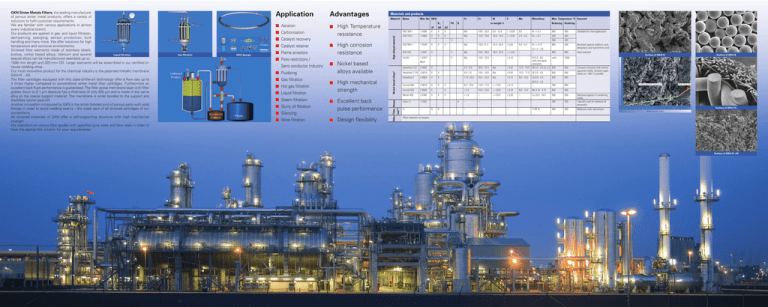

Advantages Application GKN Sinter Metals Filters, of porous sinter metal products, offers a variety of

advertisement

Catalystrecovery Catalystretainer Gas filtration Flamearrestors SIKA-Sparger Flowrestrictors/ SemiconductorIndustry Fluidizing Gasfiltration Hotgasfiltration Liquidfiltration Steamfiltration Slurryoilfiltration Silencing Winefiltration HighTemperature resistance Highcorrosion resistance Nickelbased alloysavailable Highmechanical strength Excellentback pulseperformance Designflexibility Material Name Mat.-No. SIKA- Fe R... High alloyed material Carbonisation Materials and products FIL Cr B Ni C Mo Miscellany in weight-% Max. Temperature °C Keyword Reducing Oxidizing AISI 304 L 1.4306 IS X AX X AS X Bal. 18.0 - 20.0 8.0 - 12.0 < = 0.03 0.5 N < = 0.1 600 500 AISI 316 L 1.4404 X X X Bal. 16.0 - 18.0 10.0 - 14.0 < = 0.03 2.0 - 3.0 N < = 0.1 540 400 380 320 AISI 904 L 1.4539 X X X Bal. 19.0 -21.0 24.0 - 26.0 < 0,02 4.0 - 5.0 N < = 0.15 600 500 Cu 1.2 - 2.0 – Resistant against sulphuric acid, phosphoric and hydrochloric acid 800 600 Heat resistant X AISI 310 1.4841 FeCrAl 1.4767 X X Bal. 24.0 - 26.0 19.0 - 22.0 < = 0.25 – X Bal. 19.0 - 22.0 – < 0.10 – 2.4602 X 2.0 - 6.0 20.0 - 22.5 Bal. < 0.02 12.0 - 14.5 Al 5.0 - 6.5 unfit with rare earth elememts W 2.0 - 3.5 Co 2.5 650 Hastelloy C 276 2.4819 X X 4.0 -7.0 14.0 - 16.0 Bal. < 0.02 15.0 - 17.0 W 3.0 - 4.5 650 650 Hastelloy X X X 17.0 -20.0 20.5 - 23.0 Bal. < 0.15 8.0 - 10.0 Co 0.5 - 2.5 930 800 Mod. Hastelloy C 22 Nickel based alloys* Aeration Advantages ium** Application Other Titan- Bronze GKN Sinter Metals Filters, theleadingmanufacturer of porous sinter metal products, offers a variety of solutionstofulfilcustomerrequirements. We are familiar with various applications in almost everyindustrialbranch. Ourproductsareappliedingas-andliquidfiltration, dampening, sparging, sensor protection, bulk handlingandmanymore.Weoffersolutionsforhigh temperatureandcorrosiveenvironments. Sintered filter elements made of stainless steels, bronze, nickel based alloys, titanium and several Liquid filtration specialalloyscanbemanufacturedseamlessupto 1500mmlengthand320mmOD.Largerelementswillbeassembledinourcertifiedinhouseweldingshop. Ourmostinnovativeproductforthechemicalindustry isthepatentedmetallicmembrane SIKA-R…AS. Thefiltercartridgesequippedwiththisstate-of-the-arttechnologyofferaflowrateupto 4 times higher compared to conventional sinter metal filter cartridges. Furthermore an excellentbackflushperformanceisguaranteed.Thefilteractivemembranelayerwithfilter gradesdownto0.1µmabsolutehasathicknessofonly200µmandismadeofthesame alloyasthecoarsesupportmaterial.Themembraneissinterbondedtothesupportand thereforecannotpeeloff. AnotherinnovationintroducedbyGKNisthesinterbondedjointofporouspartswithsolid fittingsinordertoavoidweldingseams–theweakspotofallsinteredcartridgesofour competitors. All sintered materials of GKN offer a self-supporting structure with high mechanical strength. Wemanufacturevariousfiltergradeswithspecifiedporesizesandflowratesinorderto havetheappropriatesolutionforyourrequirements. 2.4665 Inconel 600 2.4816 X Inconel 625 2.4856 X Monel 400 2.4360 X CuSn 11 2.1052 Ti – X X X 650 X 6.0 - 10.0 14.0 - 17.0 > = 72.0 < 0.15 – W 0.2 - 1.0 – 700 600 X < 5.0 20.0 - 23.0 > = 58.0 < 0.10 8.0 - 10.0 Nb 3.15 - 4.15 650 650 X < 2.0 – > = 63.0 < 0.30 – Cu 28.0 - 34.0 500 500 – – – – – 300 250 – – – – – 500 500 X X 1000 Ti 99 % Standard for food application Surface of SIKA-R Surface of SIKA-B Corrosion resistant with various agressive media. Duration application at > 400 °C possible Resistant against Cl-containing media Typically used for hydraulic & pneumatic Medicine, acid, electrolysis Surface of SIKA-FIL Other materials on request. Surface of SIKA-R..AS GKN-Filters around the world Dimension a 1463 (57.598“) 1200 (47.244“) 1083 (42.638“) 1000 (39.37“) 953 (3752“) 903 (35.551“) 874,5 (34.429“) 807 (31.772“) 800 (31.496“) 693 (27.284“) 600 (23.622“) 563 (22.1654“) 360 (14.173“) Questionnaire Liquid Filtration POROUS Metal Products Fibre felt Standard Dimensions Outer Diameter Length (mm) (mm) Powdered Metal Standard Dimensions Outer Diameter Length (mm) (mm) 50 90 150 60 Customer Address Address Dept. Phone Fax 1. Liquid Chem. Composition of Liquid Operating Temperature Operating Pressure Flow Rate Liquid density (actual) Liquid viscosity (actual) 2. Solids in the fluid Chemical composition Particle concentration Particle size distribution Solids Density 3. Operating Parameter Mode of operation Solids recovery Cleaning procedure Max. allowed Pressure Drop Particle size to be removed Cycle of back washing Back washing media Back washing Pressure 4. Filter Unit Material of Construction Connecting pipes 5. Activities E-mail min °C max °C bar (abs.) m3/h kg/m³ Pa s min °F max °F psi CFH g/m³N µm g/cm³ lb/ft³ continous yes automatic mbar µm discontinous no manual psi bar (abs.) psi O O O O O O O O New Equipment Increase Capacity Resell Offer 500, 1000, 1200 Questionnaire Gas Filtration Customer Contact person 500, 1000, 1500, 2000 500, 1000, 1500, 2000 500, 1000, 1500, 2000 lb/ft³ Spare part Pre/After filter own requirements Visit GKN Sinter Metals Filters GmbH Dahlienstraße43·D-42477Radevormwald P.O.Box1520·D-42464Radevormwald Phone: +49(0)21 95-609-0 Fax: +49(0)21 95-609-48 E-Mail: info@gkn-filters.com www.gkn-filters.com Contact person Dept. Phone Fax 1. Gas (Chem. Composition) Operating Temperature Dew point Operating Pressure Gas Volumetric Flow Rate (nominal) Gas Volumetric Flow Rate (actual) Gas density Gas viscosity 2. Solids in Gas Chemical composition Dust concentration Particle size distribution Solids Density 3. Operating Parameter Mode of operation Solids recovery Cleaning procedure Max. allowed Pressure Drop Max. permissible contents of dust Type of back pulse gas Back Pulse gas Temperature Back Pulse gas Pressure 4. Filter Unit Material of Construction Connecting pipes 5. Activities E-mail min °C max °C °C bar (abs.) mN3/h mA3/h kg/m³ Pa s min °F °F psi CFH CFH g/m³N µm g/cm³ lb/ft³ continous yes automatic mbar g/mA³ discontinous no manual psi lb/ft³ °C bar (abs.) °F psi O O O O O O O O New Equipment Increase Capacity Resell Offer max °F lb/ft³ Spare part Pre/After filter own requirements Visit