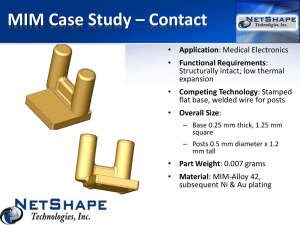

MIM Technology

advertisement

MIM Technology

MIM – Let Your Ideas

Innovative components meeting technical challenges often require a complex design and

superior material properties; high manufacturing costs often prevent them from being realised. The freedom of shape offered by MIM (metal injection molding) technology provides a

universal platform for design engineers and product designers to develop creative solutions

and at the same time observe tight target costs. Applications that used to be manufactured

by more costly conventional processes can now take advantage of the cost savings of MIM

technology.

2

Come True

MIM components combine the outstanding material properties of metal and the complex design options of plastic technology. Shaping by the injection molding of metal powders

(MIM) offers maximum freedom with respect to part geometry

and material options far exceeding the design possibilities of

machining and casting technologies.

Undercuts, bores and blind holes can be formed in any direction. Wall thickness of 1 mm or less as well as bore diameters

of just a few tenths of a millimetre can be realised.

Relief-like structures and engravings such as company logos

or identification marks can be produced in detail. Even the

use of expensive high strength alloys, corrosion resistant and

other premium steels is possible as no additional machining

costs are incurred.

MIM components achieve an excellent surface finish (usually

surface roughness values Ra < 1 µm) without any subsequent

operations. The microstructure of the sintered components

allows electroplating and electro-polishing without any pretreatment.

The depth of penetration after case hardening is comparable

to the values of forged steels. MIM materials are usually weldable too.

3

MIM – Enjoy the Benefits

The benefits of MIM processing can best be exploited if MIM design concepts are employed in the

development phase. Entirely new possibilities for

dimensional and shape design are opened to the

design engineer.

High volume production of highly complex components

is economical due to fully automatic MIM processing and

yields process reliabilities conforming even to the strict requirements of the automotive industry

The flexible geometric design can even be applied to high

strength metals and premium steels

Applications of plastics, aluminium, or zinc die castings

whose loading conditions are at the limit can be replaced by

high strength MIM parts

Costly joining or assembling techniques can be avoided by

designing complex MIM components that can replace two

or even more assembled parts

Threads can be produced in the primary shaping process

(ie injection molding)

Material and costs can be saved by optimising the part volume. Weight reduction leads to further savings for dynamically loaded components in the form of a reduced moment

of inertia

The most intricate geometries are exactly reproduced in detail

Even innovative alloy materials according to specific customer requirements can be economically processed

4

Metal injection molding technology offers virtually

unlimited design freedom to the design engineer –

these are just a few examples of the possible variety

of shapes.

MIM – Its Strengths in

Summary

3 dimensional

dimens

sional complexity:

The forming process of MIM technology is closely related to

traditional plastic injection molding and thus allows the same

level of complexity in a regard to the design geometries.

Parts with bore holes, blind holes, slots, notches, inner and

outer threads, recesses, undercuts, structured surfaces, and

cavities are made by MIM without problems. Similarly sophisticated design elements are not feasible with alternative chipless shaping processes.

Weight reduction:

Optimum part design allows for weight reduction without losing functionality. Weight reduction has a positive effect on

the cost of the finished product.

High productivity:

When large numbers of identical parts are required, the cost

advantage of MIM technology is particularly evident. Depending on the application, even highly complex components can

be made without costly finishing operations. This is why this

technology is particularly suitable for high volume production.

5

MIM – A Highly Technical Manufacturing Process

1.) Feedstock preparation

For the preparation of the feedstock, metal powders are first

blended according to the desired alloy composition. Then

thermoplastic polymers and additives are kneaded with the

powder mix and heated to obtain a viscous mass. The mass is

then cooled down and processed into granular pellets (feedstock).

The metal powder alloy determines the mechanical and chemical properties achieved by the finished product. GKN engineers have excellent know-how for powder development as

well as for controlling the feedstock properties achieved.

2.) Injection molding

Thermoplastics injection molding machines with special modifications are used in MIM technology, similar process as applied in conventional plastics injection molding.

After being dosed and fed into the injection unit the input material (feedstock) is molten and densified in front of the screwconveyor. By a forward movement of the screw the plasticized

mass is injected with high pressure through a sprue and runner system into the individual cavities of the mold.

Subsequently the mass is 'frozen' inside the mold cavities

with their geometric design ('green compact'). After cooling

down to the ejection temperature the mold is opened along

the parting plane. The solidified parts, ie the green compacts,

are ejected from their cavities by means of ejection pins and

can then be removed by suitable handling systems.

6

MIM – Metal Injection Molding

Green compacts are characterised by:

portions of approximately 10% binder and 90% metal powder

strength similar to thermoplastic polymer parts

homogeneous powder distribution without particle alignment

3.) Debinding and sintering

Subsequent debinding serves to remove the polymer binder

from the green compacts. At GKN Sinter Metals this first step

is carried out in continuous sintering equipment.

A catalyst is fed into the debinding muffle which is evaporated at temperature, thereby forming a reactive atmosphere

by which the polymer is completely de-polymerised. The binder is continuously degraded during the reaction and escapes

in a gaseous form from the compact. The resulting structure

has an open porosity. This porous structure is known as the

'brown part'.

The brown parts are directly transferred into the sintering

muffle. Here the temperatures are increased almost to the

melting point in a well-controlled process until the metal particles sinter. The furnace atmospheres applied may be inert

or reducing.

Processing conditions in the computer controlled equipment

are precisely monitored. Only due to this effort is it possible

to keep the 16 to 18 percent shrinkage of the parts under control in order to attain the final dimensions as specified by the

customer.

7

MIM – Secondary Processing

MIM components can be further processed and enhanced in many ways. Among others, the following

processes may be applied:

8

Heat treatment

Hardening, tempering, quenching

and tempering, surface hardening, case hardening

Physicochemical surface

treatment

Nitriding, carbonitriding, nitrocarburizing, boriding, siliciding

Chemical surface treatment

Pickling, chemical deburring,

burnishing, etching

Mechanical surface treatment

Engraving, barrel finishing, grinding, polishing, deburring, shot

peening

Applying nonmetallic anorganic coatings

Chromatising, phosphating,

anodizing, enamelling

Applying metallic coatings

Electroplating, chemical metal

coating, melt dip coating, metal

spraying, chromizing

Applying organic coatings

Printing, adhesive bonding,

varnishing

Applying wear resistant

coatings

CVD coating, PVD coating

MIM - Dimensional

Tolerances

MIM dimensional tolerances*

[mm]

Nominal dimension X

[mm]

Standard tolerance

[mm]

Up to 3

+/- 0,05

3 <x> 6

+/- 0,06

6 <x> 15

+/- 0,075

15 <x> 30

+/- 0,15

30 <x> 60

+/- 0,25

(* Given tolerances serve as guidelines)

Parts / Year

die casting

low

investment

casting

average

Part Complexity

The standard dimensional tolerances given in the adjoining

table are generally achieved after sintering with consideration of the 16 to 18 percent shrinkage.

These standard values are just guidelines since the real dimensional tolerances depend on the geometry and material

composition and therefore can easily vary.

If even closer dimensional tolerances are required, these

can sometimes be achieved by re-designing the MIM component.

In addition to that, GKN offers a variety of chipless and chipping finishing operations in order to conform to the highest

requirements.

MIM – compared to competing technologies

If the strengths and benefits of MIM technology are employed

at the design stage, substantial advantages can be achieved

over almost all conventional technologies. These are usually

reflected as improved function and enormous cost savings.

MIM paves the way to simplify entire component assemblies

by reducing the number of individual parts. This helps to reduce the sources of error in the manufacturing process, enhance process reliability and thus guarantee higher quality.

presssinter

machining

Typical tolerances of sintered MIM components

high

Résumé: MIM technology proves economical where complex

shaped components with close dimensional tolerances, demanding mechanical properties and excellent surface finish

are required.

9

MIM - Guidelines for Part

Design

In order to fully exploit the inherent potential of

MIM technology, these guidelines for part design

should be observed at the earliest possible design

stage.

We have compiled the most important design principles in the following graphics – for optimum MIM

design from the beginning!

Example: fixture

Flat bottom face

MIM components exhibit about 16 to 18 percent shrinkage during the debinding and sintering process and therefore require a sliding bottom surface.

Ideally a flat bottom face should be designed for sufficient

part stablility. This can help to avoid distortion and resulting

subsequent leveling costs.

Threads

Inner threads that are planned in the design stage can be

shaped by MIM in the primary shaping process, provided they

are designed adequately and can be realised by so-called

„spinning cores“.

10

Example: shaft guide

Radii

The use of radii on edges, for example, has several positive

effects on the overall picture of the MIM component. Not only

are handling and aesthetic appearance of the finished parts

improved, but also the material costs can be reduced. Rounded edges improve the strength, too, as the load is better distributed.

Weight reduction

Weight reduction can best be realised by creating free space

in the MIM component. Besides reducing the weight of the

component, the reduction of material cost also leads to a lower

sales price of the part.

Further the dynamic properties of the component can also be

improved.

Example: linking block

Constant wall thickness

If possible, the wall thickness should be constant all over the

part and abrupt wall changes should be avoided. This guarantees a uniform mold fill during injection molding.

Ribs and links

Ribs and links serve to stiffen the part and mainly improve the

strength of the MIM component. These design elements can

also be used to improve the dimensional accuracy.

11

About GKN Sinter Metals

Production Plants

Argentina

GKN Sinter Metals – a wholly owned

subsidiary of U.K.-based GKN plc,

a global industrial company – is the

world’s largest producer of precision

powder metal products. With a focus

on superior delivery, quality and total

solutions, the company offers

extensive technical expertise in

design, testing and various process

technologies. GKN Sinter Metals

offers a full range of more than

10,000 complex shape, highstrength

products for the automotive,

commercial vehicle, home

appliance, lawn and garden, office

equipment, power tool, recreational

vehicle and process industry markets.

The company’s global footprint

spans more than 13 countries

across five continents. GKN Sinter

Metals is in close proximity to its

customers with more than 30 global

locations and a workforce of

approximately 5,500 employees.

For more information about GKN’s

world of solutions visit

www.gknsintermetals.com

India

GKN Sinter Metals de Argentina S.A.

Ruta Nac. 5 Km. 159,5

(B6622GKA) Chivilcoy – Bs. As.

Argentina

GKN Sinter Metals Ltd.

146, Mumbai Pune Road

Pimpri, Pune 411 018

Maharashtra, India

Phone:

E-mail:

Phone:

E-mail:

*54-11-5368-3700

infoargentina@gknsintermetals.com

*91-20-2742-6261, 6262, 6263

infoindia@gknsintermetals.com

Italy

Brazil

GKN Sinter Metals Ltda.

Av. Emancipacão, 4.500 - Santa Esmeralada

CEP 13186-542

Hortolandia – SP – Brazil

GKN Sinter Metals SpA

Fabrikstraße 5

39 031 Bruneck (BZ)

Italy

Phone:

E-Mail:

Phone.

E-mail:

*55-19-2118-9400

infobrazil@gknsintermetals.com

*39-0474-570211

infoitaly@gknsintermetals.com

North America

Canada

GKN Sinter Metals – St. Thomas Ltd.

7 Michigan Boulevard

St. Thomas, Ontario

Canada N5P 1H1

GKN Sinter Metals

3300 University Drive

Auburn Hills, Michigan 48326-2362

USA

Phone:

E-mail:

Phone:

E-mail:

*1-519-631-4880

infona@gknsintermetals.com

*1-248-371-0800

infona@gknsintermetals.com

South Africa

China

GKN Sinter Metals – Danyang

Number 7 Mechanical Industry Park

Danyang Development Zone

Danyang,

China

GKN Sinter Metals – Cape Town

P.O.Box 156

Sacks Circle

Bellville, 7530

South Africa

Phone:

E-mail:

Phone:

E-mail:

*86-511-86-885-556

infochina@gknsintermetals.com

*27-21-950-6200

infoafrica@gknsintermetals.com

Germany

GKN Sinter Metals Engineering GmbH

Krebsöge 10

42 477 Radevormwald

Germany

Phone :

E-mail :

*49 2191-693-0

infogermany@gknsintermetals.com

GKN Sinter Metals Sales Offices Worldwide

China

E-mail:

France

E-mail:

GKN Sinter Metals Filters GmbH

Dahlienstraße 43

P.O.Box 1520

42 477 Radevormwald

Germany

Phone:

E-Mail:

*49 2195-609-27

feedback@gkn-filters.com

infochina@gknsintermetals.com

infofrance@gknsintermetals.com

Japan

E-mail:

infojapan@gknsintermetals.com

Korea

E-mail:

infokorea@gknsintermetals.com

Spain

E-mail:

infospain@gknsintermetals.com

Sweden

E-mail:

infosweden@gknsintermetals.com

United Kingdom

E-mail:

© Copyright by GKN Sinter Metals - Rev. 1.0

infouk@gknsintermetals.com