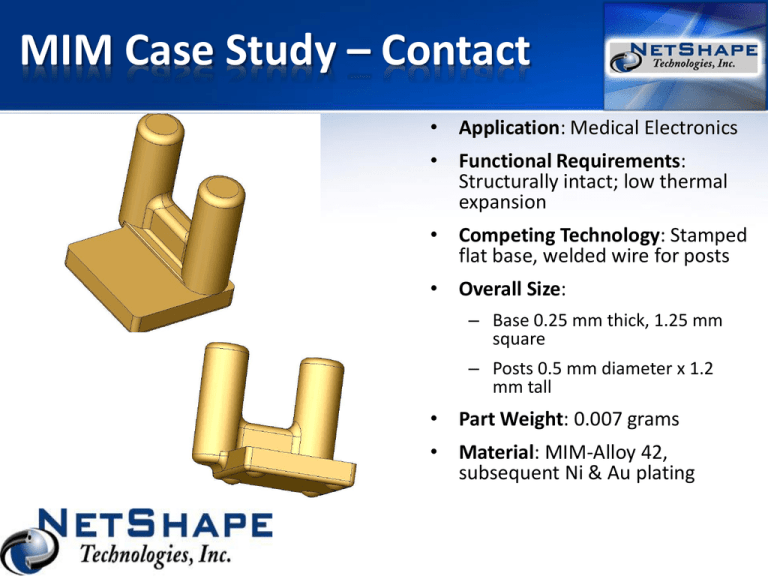

MIM Case Study - Key - Net Shape Technologies

advertisement

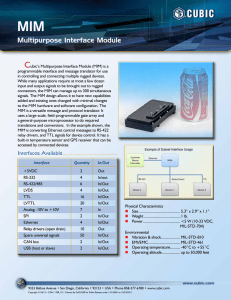

MIM Case Study – Contact • Application: Medical Electronics • Functional Requirements: Structurally intact; low thermal expansion • Competing Technology: Stamped flat base, welded wire for posts • Overall Size: – Base 0.25 mm thick, 1.25 mm square – Posts 0.5 mm diameter x 1.2 mm tall • Part Weight: 0.007 grams • Material: MIM-Alloy 42, subsequent Ni & Au plating MIM Case Study – Contact - Small Part! MIM to replace existing process: - Base stamped out of goldplated sheet - Posts made from wire form welded to base • - MIM seen as a cost savings with better consistency Key Characteristics- Contact One of two posts intact No cracks Minimal flash Posts strong enough to not deflect when wire is welded to posts; center support section added Parts needs to be solderable to the circuit board; bumps molded in to allow flow of solder under part MIM Case Study – Contact • Why MIM? – More consistent position of posts – Connection of the posts to the base is more reliable in a onepiece MIM part than the welded wire to the stamped base. – MIM Alloy 42 consistent with expected material properties – Economics of MIM regarding CAPEX, part price significantly better than stamp & weld – MIM a more repeatable for high-volume technology for this application MIM Case Study – Contact

![Anti-Cytokeratin antibody [AE1AE3] ab174707 Product datasheet 1 Image Overview](http://s2.studylib.net/store/data/012747555_1-02dfbd38a388870acc4075884fa092c1-300x300.png)