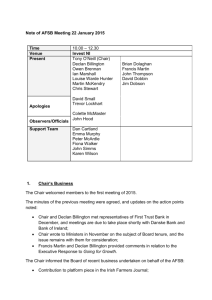

Document 10712656

advertisement