UW-Stout Biological Safety Program Policy Manual

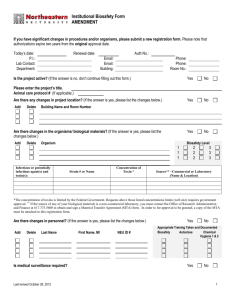

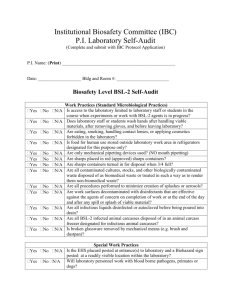

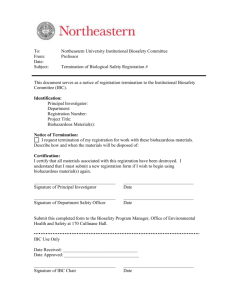

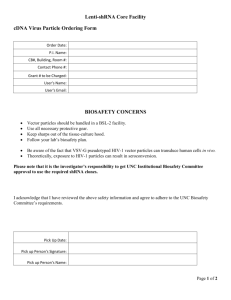

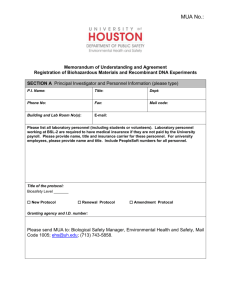

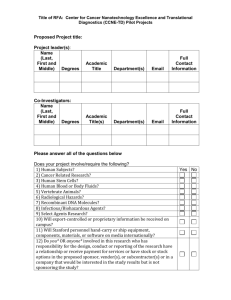

advertisement