INTRODUCTION OF A NEW SINTER-HARDENING PM STEEL

advertisement

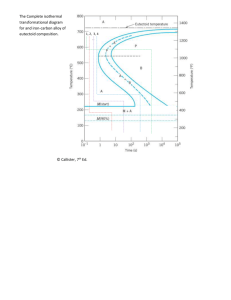

INTRODUCTION OF A NEW SINTER-HARDENING PM STEEL Peter Sokolowski, Bruce Lindsley and Francis Hanejko Hoeganaes Corporation Cinnaminson, NJ 08077, USA ABSTRACT The initial sinter-hardenable alloys introduced into the marketplace relied on high concentrations of alloying elements in the steel. As sinter hardening has become more commonplace, sinter furnace producers have improved the cooling zones in the furnace. The increase in obtainable cooling rates allows lower alloyed steels to be used to obtain sinter-hardened parts. This is especially pertinent to small parts, where higher cooling rates can be achieved. Therefore, the need exists for an alloy with a composition that optimizes the amount of price sensitive elements while maintaining the ability to sinter harden in current belt furnaces. A new sinter-hardenable alloy is introduced and the physical properties and hardenability of the alloy are discussed. INTRODUCTION Traditional sinter-hardening PM steel compositions utilize high levels of Mo, Ni and Cu along with high carbon contents to achieve martensitic microstructures in the as-sintered condition. Historically, high cooling rates could not be achieved in the sintering furnace, leading to only the most highly alloyed materials being used for sinter hardening. With the advent of accelerated cooling zones and the adoption of these technologies, lower alloy contents can be used. When alloy prices are low, it is easier to use heavily alloyed materials, to ensure a martensitic microstructure forms regardless of section size and cooling rate in the part. As price pressures force a re-assessment of alloy selection, it may be more cost effective to invest in additional processing to reduce the content of high priced alloying elements. The added processing may include longer sintering times to fully utilize admixed ingredients, accelerated cooling, and an analysis of the actual cooling rate in each part to determine the lowest alloy content necessary for sinter hardening. There are several approaches that can be taken to address the raw material costs. The first is to introduce lower cost alloying elements, such as Cr and/or Mn. These oxygen sensitive elements provide excellent hardenability, but may lead to higher processing costs associated with powder production and sintering. One benefit of these more effective alloying elements is that lower carbon levels can be used while maintaining a martensitic microstructure. These lower carbon martensitic alloys provide lower dimensional variation and enhanced mechanical properties [1]. The Cr-containing Ancorsteel® 4300 and Ancorsteel 4300L (0.3% Mo) are examples of such alloys, where as-sintered martensitic microstructures are common with sintered carbon contents less than or equal to 0.6 % (wt%) [2]. Another approach to lower cost sinter hardening is the development of alloys that have intermediate levels of alloying elements. Earlier alloys used high levels of Mo and Ni as powder costs were relatively low compared with secondary heat-treating steps. Ancorsteel 737 SH (MPIF FL-4800 [3]) has the combination of good compressibility and excellent hardenability, but at current price levels, the 1.25% Mo and 1.4% Ni prealloyed in the powder make it somewhat less attractive. Nevertheless, when processing larger parts or where accelerated cooling is not an option, slow cooling rates within the part require these high levels of alloying for sinter hardening. The diffusion alloyed materials containing 4% Ni and either 0.5% or 1.5% Mo also have relatively high cost, and given that the Ni is not prealloyed, do not take full advantage of the alloying elements present. Those parts producers that have the ability to cool components at higher rates than conventional cooling need not pay for extra alloying when a leaner alloy would suffice. With that in mind, a new alloy, Ancorsteel 721 SH, has been developed for lower cost sinter hardening. This paper discusses the mechanical properties and hardenability of this new alloy. EXPERIMENTAL PROCEDURE The nominal compositions of Ancorsteel 721 SH and Ancorsteel 737 SH (FL-4800) are given in Table I. The new alloy, Ancorsteel 721 SH, contains the same prealloyed constituents as FL-4800, however with 0.3% less Mo and 0.9% less Ni. All mixes for this study were prepared with 0.75% EBS wax (Acrawax® C) as the lubricant and varying amounts of Asbury type 3203H graphite. Admixed copper was used to produce alloys with 1% and 2% Cu. Transverse rupture strength, dogbone tensile, and impact bars were pressed at 415 MPa (30 tsi), 550 MPa (40 tsi) and 690 MPa (50 tsi) and sintered in 90% N2- 10% H2 (vol%) atmosphere at 1120 °C (2050 °F) for 15 minutes in an Abbott continuous-belt furnace with an accelerated cooling system. Three average cooling rates were chosen for study: 0.7 °C/s (1.3 °F/s), 1.6 °C/s (2.8 °F/s) and 2.2 °C/s (4.0 °F/s). The cooling rate was measured in the sample between 650 °C (1200 °F) and 315 °C (600 °F). All samples were tempered at 205 °C (400 °F) for 1 hour in a N2 atmosphere prior to testing. Measurements were performed in accordance with the relative MPIF standards [4]. Table I. Nominal composition (in wt%) of the base alloys studied. Alloy Fe Mo Ni Mn Ancorsteel 721 SH Bal. 0.9 0.5 0.4 Ancorsteel 737 SH (FL-4800) Bal. 1.2 1.4 0.4 Hardenability of the new alloy was evaluated using the Jominy end-quench method. Cylindrical test specimens were machined to a length of 100 mm (4 in.) and 25 mm (1 in.) diameter from blocks compacted to a green density of approximately 7.0 g/cm3. All bars were initially sintered in 90% N2 - 10% H2 (vol%) atmosphere at 1120 °C (2050 °F) for 15 minutes in a continuous-belt furnace. These samples were austenitized at 900 °C (1650 °F) for 30 minutes in 90% N2 - 10% H2 (vol%) atmosphere prior to end-quenching. The Jominy end-quench test method and hardness measurements were carried out according to ASTM standard A 255 [5] and MPIF standard 65 [4]. RESULTS Figure 1 demonstrates the compressibility of Ancorsteel 721 SH in comparison to the more heavily alloyed version, FL-4800. It is apparent that the new alloy has an improved compressibility with the capability of achieving a green density of 7.1 g/cm3 or better at a compaction pressure of 690 MPa. The increase in density at similar compaction pressures, in part, plays a significant role in the new alloy’s capacity to achieve and even surpass the mechanical properties of FL-4800. As will be presented herein, processing considerations (i.e. accelerated cooling zones) strongly dictate the effectiveness of the new alloy in providing the necessary mechanical properties attributed to a viable sinter-hardening alloy. Figure 1: Compressibility of Ancorsteel 721 SH and FL-4800. Mechanical Properties Mixes of Ancorsteel 721 SH and FL-4800 were prepared with additions of 1% Cu with 0.7% graphite (Table II) and 2% Cu with 0.9% graphite (Table III). Compaction pressures of 550 MPa and 690 MPa are presented which allow for an easy comparison of mechanical properties as a function of sintered density. The hardness and tensile data are arranged according to conventional (0.7 °C/s) and accelerated cooling (1.6-2.2 °C/s) conditions within a continuous-belt furnace. FL-4800 clearly displays superior mechanical properties over Ancorsteel 721 SH at conventional cooling rates when only 1% Cu and 0.7% graphite is added. This demonstrates the capability for a fully hardening FL-4800 under even the most difficult processing condition. However, if the cooling rate can be increased beyond 0.7 °C/s during processing, Ancorsteel 721 SH is capable of exhibiting comparable values to FL-4800 at a lower alloy cost. Though not presented in this study, the new alloy even offers a sufficient hardenability with no admixed copper, similar to that of FL-4800, given an increased cooling rate [6]. Section size and belt speed are increasingly more important factors when considering the usefulness of accelerated cooling with a lean sinter-hardening alloy. Therefore, careful consideration as to the amount of admixed constituents should be explored to fully utilize the alloy. With the addition of 2% copper and 0.9% graphite to Ancorsteel 721 SH, the mechanical properties appear to be less sensitive to cooling rate, although reduced levels are still apparent at conventional cooling rates when compared with FL-4800. Beyond conventional cooling, Ancorsteel 721 SH with 2% Cu notably achieves the same, if not greater properties over FL-4800. Table II: Comparison of the new alloy Ancorsteel 721 SH and FL-4800 at cooling rates of 0.7-2.2 °C/s with 1 wt% Copper and 0.9 % Graphite. Base Alloy Copper (wt%) Graphite Cooling Compaction Density (wt%) Rate (°C/s) (MPa) (g/cm³) DC (%) Hardness YS UTS Elong. (HRA) (MPa) (MPa) (%) 721 SH 1 0.7 0.7 550 6.96 0.21 52 449 559 1.2 721 SH 1 0.7 0.7 690 7.11 0.23 54 540 644 1.3 FL-4800 1 0.7 0.7 550 6.83 0.31 65 726 783 1.0 FL-4800 1 0.7 0.7 690 6.98 0.33 67 777 875 1.0 721 SH 1 0.7 1.6 550 6.94 0.29 66 770 884 1.1 721 SH 1 0.7 1.6 690 7.10 0.31 68 858 955 1.1 FL-4800 1 0.7 1.6 550 6.83 0.33 67 767 785 0.8 FL-4800 1 0.7 1.6 690 6.99 0.35 69 849 906 0.9 721 SH 1 0.7 2.2 550 6.87 0.30 71 804 903 1.0 721 SH 1 0.7 2.2 690 7.03 0.33 71 873 963 0.9 FL-4800 1 0.7 2.2 550 6.83 0.34 67 732 823 0.8 FL-4800 1 0.7 2.2 690 6.99 0.37 69 891 945 0.8 Table III: Comparison of the new alloy Ancorsteel 721 SH and FL-4800 at cooling rates of 0.7-2.2 °C/s with 2 wt% Copper and 0.9 wt% Graphite. Base Alloy Copper (wt%) Graphite Cooling Compaction Density (wt%) Rate (°C/s) (MPa) (g/cm³) DC (%) Hardness YS UTS Elong. (HRA) (MPa) (MPa) (%) 721 SH 2 0.9 0.7 550 6.95 0.23 63 679 840 1.2 721 SH 2 0.9 0.7 690 7.09 0.27 66 733 912 1.2 FL-4800 2 0.9 0.7 550 6.85 0.15 68 654 818 1.2 FL-4800 2 0.9 0.7 690 7.00 0.22 69 693 996 1.4 721 SH 2 0.9 1.6 550 6.93 0.27 68 637 849 1.1 721 SH 2 0.9 1.6 690 7.08 0.31 71 701 954 1.2 FL-4800 2 0.9 1.6 550 6.85 0.16 69 634 829 1.2 FL-4800 2 0.9 1.6 690 7.00 0.22 70 685 983 1.4 721 SH 2 0.9 2.2 550 6.87 0.29 73 706 902 1.1 721 SH 2 0.9 2.2 690 7.00 0.32 74 759 919 1.0 FL-4800 2 0.9 2.2 550 6.85 0.18 69 618 944 1.3 FL-4800 2 0.9 2.2 690 6.99 0.23 70 649 914 1.1 Figures 2-6 highlight the mechanical properties of the alloys studied at a compaction pressure of 690 MPa over the range of cooling rates tested. With the addition of 2% Cu and 0.9% graphite, the two alloys perform similarly. Both alloys have sufficient hardenability, over the three cooling rates, to achieve 30 HRC and above, as shown in Figure 2. A major difference between Ancorsteel 721 SH and FL-4800 is the dimensional change after sintering. Current die dimensions would require modification to account for the increase in part expansion beyond that which is currently seen with FL-4800. However, one benefit of the lower alloy content (especially Ni) in Ancorsteel 721 SH is less retained austenite in the as-sintered microstructure. The lower retained austenite content will lead to better dimensional consistency in parts. Additionally, elongation, ultimate tensile strength, and yield strength are comparable in level and observed trend for parts admixed with 2% Cu and 0.9% graphite for both alloys. These results suggest that Ancorsteel 721 SH is a feasible sinter-hardening alternative to FL-4800. At 1% Cu and 0.7% graphite, the new alloy exhibits a reduced level of hardness than that of FL-4800 at the lower cooling rates as a result of diminished hardenability. Nevertheless, Ancorsteel 721 SH is capable of demonstrating an improved hardness at the highest cooling rate, 41 HRC, exceeding FL-4800. Under conventional cooling rates, Ancorsteel 721 SH is clearly inferior to FL-4800 in hardenability and therefore mechanical properties. Accelerated cooling in conjunction with enhanced compressibility of the alloy does however, provide the capability to greatly enhance these properties to comparable values. Figure 2: Apparent hardness of Ancorsteel 721 SH and FL-4800. Figure 3: Dimensional change of Ancorsteel 721 SH and FL-4800. Figure 4: Elongation of Ancorsteel 721 SH and FL-4800. Figure 5: Ultimate Tensile Strength of Ancorsteel 721 SH and FL-4800. Figure 6: Yield Strength of Ancorsteel 721 SH and FL-4800. Microstructure The microstructure of Ancorsteel 721 SH admixed with 1% Cu and 0.7% graphite is increasingly martensitic when processed at higher cooling rates, Figure 7. When slow cooled at 0.7 °C/s, this new alloy largely transforms into a pearlitic (with some bainite) microstructure, which agrees well with the lower mechanical properties already presented. At increased cooling rates however, the microstructure almost fully transforms into martensite; increasing from approximately (a) 15% martensite, 85% bainite/pearlite, to (b) 72% martensite, 28% bainite/pearlite, and (c) 87%martensite, 13%bainite/pearlite at the highest cooling rate; based on a point-count method [7]. This clearly displays the significance and necessity of using accelerated cooling rates in order to take full advantage of this lean sinter-hardening alloy. When admixed with 2% Cu and 0.9% graphite, the microstructural development of Ancorsteel 721 SH follows a similar trend when processed with increasing cooling rates, Figure 8. With the increased amount of admixed constituents, the slow cooled microstructure transforms to a greater fraction of martensite compared with the 1% Cu version; starting at approximately (a) 45% martensite, 55% bainite/pearlite for a cooling rate of 0.7 °C/s, to (b) and (c) 97% martensite, 3% bainite/pearlite for cooling rates of 1.6 to 2.2 °C/s, respectively. A small amount of retained austenite was observed in the martensitic microstructure. As mentioned previously, the increase in copper and graphite content generally leads to the formation of retained austenite, typically around the prior particle boundaries [7], potentially generating a negative impact on properties. The amount of retained austenite appeared to be lower in the Ancorsteel 721 SH alloy compared with FL-4800. This alloy is most effective when sintering furnaces are equipped with accelerated cooling zones. (a) 0.7 °C/s (b) 1.6 °C/s (c) 2.2 °C/s Figure 7: Microstructures of Ancorsteel 721 SH with 1% Cu and 0.7% graphite compacted at 690 MPa, sintered at 1120 °C for 15 minutes, and cooled at (a) 0.7 °C/s (b) 1.6 °C/s and (c) 2.2 °C/s. (a) 0.7 °C/s (b) 1.6 °C/s (c) 2.2 °C/s Figure 8: Microstructures of Ancorsteel 721 SH with 2% Cu and 0.9% graphite compacted at 690 MPa, sintered at 1120 °C for 15 minutes, and cooled at (a) 0.7 °C/s (b) 1.6 °C/s and (c) 2.2 °C/s. Jominy End-Quench Hardenability The hardenability of ferrous alloys has been well documented using the Jominy end-quench test. This method is used as an indicator of the depth, or thickness to which an alloy is capable of being transformed to martensite. Figure 9 compares the hardness profiles along the length of water end-quenched bars of Ancorsteel 721 SH to another commonly used sinter-hardenable alloy, Ancorsteel 4600V (MPIF FL-4600 [3]), which has 0.5% Mo, 1.8% Ni, and 0.2% Mn. Notably, Ancorsteel 721 SH with 2% Cu and 0.9% graphite through-hardens in excess of 75 mm (3 in.), maintaining a hardness above 45 HRC throughout the majority of the bar length. The higher content of carbon in solution is generally a significant contributing factor in maximum attainable hardenability [8]. Nevertheless, the difference between the two alloys is clearly a result of other alloy additions and their relative alloying behavior [2]. It is well known that the hardenability factors for Mn and Mo are greater than that of Ni, and as Ancorsteel 721 SH contains more Mn and Mo than FL-4600, the Jominy results represent the expected performance of the alloy constituents. This material feature, in connection with accelerated cooling, should allow for parts with thick cross-sections to be constructed from this new alloy. Even with a reduced level of admixed copper and graphite, the alloy retains an appreciable level of hardenability, not dropping below the J Depth (65 HRA) until approximately 57 mm (36/16 in.). In comparison with FL4600, Ancorsteel 721 SH is a superior sinter-hardening grade at similar levels of admixed copper and graphite. The amount of admixing can be tailored to meet customer specific requirements based on part dimension, sinter furnace design, and required mechanical constraints. Figure 9: Jominy end-quench hardenability of Ancorsteel 721 SH and Ancorsteel 4600V. CONCLUSIONS A new sinter-hardening alloy, Ancorsteel 721 SH, has been developed as a viable alternative to address the continuing trend in metal price volatility. The reduced level of alloying, in comparison with its predecessor Ancorsteel 737 SH (FL-4800), can lead to insufficient hardening under conventional cooling parameters (~ 0.7 ºC/s). Nonetheless, with the incorporation of advanced cooling systems in modern sintering furnaces, accelerated cooling rates of 1.6 to 2.2 °C/sec are capable of yielding almost fully martensitic microstructures within the new alloy. The relative amount of martensitic transformation under accelerated cooling, of Ancorsteel 721 SH, provides suitable mechanical properties rivaling those of FL-4800 at a reduced cost. In the event part manufacturers are willing to utilize elevated cooling systems along with judicious tailoring of the premix, Ancorsteel 721 SH provides the appropriate level of strength and mechanical response required for selective components. ACKNOWLEDGEMENTS The authors would like to thank Gerard Golin for his assistance in providing the microstructures and analysis thereof as well as Andrew Chan and Paul Fallis in collecting the data found within this paper. REFERENCES 1. B. Lindsley and T. F. Murphy, “Effect of post sintering thermal treatments on dimensional precision and mechanical properties in sinter-hardening PM steels”, Advances in Powder Metallurgy & Particulate Materials, MPIF, Princeton, NJ, 2007. 2. P. King and B. Lindsley, “Performance Capabilities Of High Strength Powder Metallurgy Chromium Steels With Two Different Molybdenum Contents” Advances in Powder Metallurgy & Particulate Materials, MPIF, Princeton, NJ, 2006. 3. MPIF Standard 35, Materials Standards for PM Structural Parts, 2007 Edition. 4. MPIF Standard Test Methods for Metal Powders and Powder Metallurgy Products, 2007 Edition. 5. ASTM A 255, Standard Method of End-quench test for Hardenability of Steel. 6. B. Lindsley, “Alloy Development of Sinter-Hardenable Compositions”, EuroPM Proceedings, 2007. 7. T.F. Murphy, M. Baran, “An Investigation Into the Effect of Copper and Graphite Additions to Sinter Hardening Steels”, Advances in Powder Metallurgy & Particulate Materials – 2004, compiled by W.B. James and R.A. Chernenkoff, Metal Powder Industries Federation, Princeton, NJ, Part 10, pp. 266-274. 8. W.B. James, “What is Sinter-Hardening?” Presented at PM2TEC 1998.