Properties of High Density Sinter-Hardening P/M Steels

advertisement

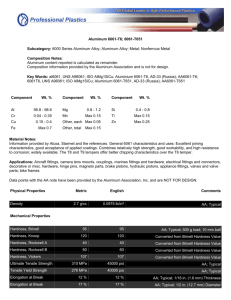

Properties of High Density Sinter-Hardening P/M Steels Processed Using an Advanced Binder System Michael L. Marucci, Michael C. Baran, and K.S. Narasimhan Hoeganaes Corporation Cinnaminson, NJ 08077 Presented at PM2TEC2002 World Congress on Powder Metallurgy & Particulate Materials June 16-21, 2002, Orlando, Florida ABSTRACT Sinter-hardening P/M alloys offer an excellent opportunity for a part manufacturer to produce hardened components in an economical fashion by eliminating secondary heat-treatments. Unfortunately, sinter-hardening P/M base iron grades are prealloyed with substantial levels of Ni, Mn, and Mo which increase hardenability but reduce compressibility. Furthermore, Cu and graphite are added to further increase strength and hardness. These alloying additions all reduce compressibility limiting the maximum attainable green and sintered densities. This paper explores how processing sinter-hardening alloys with a new proprietary binder system can improve compressibility and lead to higher densities and mechanical properties. The data show green density increases of 0.05-0.15 g/cm3 and be achieved and can result in tensile strength and hardness improvements. BACKGROUND Increasingly, powder metallurgy parts producers have improved the performance of their products by using sinter-hardening steel alloys. The ability to harden a part directly from sintering temperature without the use of a secondary heat-treatment is very attractive as it reduces cost. Unfortunately, most sinter-hardening alloys are prealloyed with nickel, a ferrite hardener, that can reduce compressibility resulting in a compact with a reduced density. In addition, these prealloys are often admixed with copper to further increase hardenability. When sintered at conventional temperatures [1120 °C (2050 °F)] copper often causes growth resulting in a sintered density which is lower than the green density. There are several approaches to increase the final sintered density including double pressdouble sinter, high temperature sintering, and/or the use of lubricant/binder systems. The use of specialized lubricant/binder systems is especially attractive because it does not involve the use of additional process steps and, depending on the alloy system, can be sintered at conventional temperatures. This paper presents the mechanical properties of sinter-hardening alloys that have been processed using ANCORMAX DTM, a recently developed proprietary lubricant/binder system. This process is an improvement over previous systems because it provides a significant increase in green density without requiring powder heating. However, to realize the full green density increase, the die temperature must be in the range of 60 to 70 °C (140 to 160 °F). INTRODUCTION Density It is widely accepted that increasing the density improves the mechanical properties of a sintered part. In a sinter-hardening material the sintered microstructure consist of more than 90% martensite. This very hard structure improves the ultimate strength and apparent hardness, however, as the hardness increase the material becomes more notch sensitive. Therefore, higher densities are necessary to further increase the strength of the steel because the reduced number/size of pores lowers the maximum defect size in the material. When attempting to attain high densities the concept of pore free density must be considered. Pore free density is the density of a green compact where all porosity between particles has been eliminated. This value can be calculated by taking the weighted average of the specific density of each addition in the premix. Therefore, light additions such as graphite or lubricant will reduce the pore free density of a iron/graphite compact. In uniaxial compaction, there is a practical upper limit of pore free density that can be attained due to material plasticity limitations. This limit falls around 98.5%1. If a material is compacted beyond 98.5% of its pore free density, it tends to develop cracks or laminations and its mechanical performance is reduced. The newly developed lubricant/binder system enables the compaction of sinter-hardening P/M steels to densities in the range of 95-97% of pore free density. The intrinsically less compressible sinter-hardening base iron alloys reduce the chance of exceeding 98.5% of pore free density. However, this concept is important when compacting any alloy because the experimenter should know the maximum attainable green density. Lubricant/Binder System The use of advanced lubricant/binder systems yields many advantages over more traditional admixed lubricant additions2. Advantages include reduced alloy segregation, reduced dusting, and better alloy homogeneity. Bonding also produces better flow and die fill that results in improved weight control and dimensional tolerance. In addition, advancements in the bonding technology has resulted in improved compressibility and reduced ejection forces. Established technologies such as ANCORDENSE processing require that the die and powder be heated to 120-150 °C (250-300 °F) in order to attain improvements in density. The heating is necessitated by the thermal properties of the organic binder. Continued research efforts have yielded improvements in binder technology that will, for certain part geometries, increase the green density by 0.05-0.15 g/cm3. The resulting system has been designed so that only the die need to be heated in the range of 60-70 °C (140-160 °F). The powder can be left at ambient temperature until it flows into the die. The advantages of this system include the aforementioned density gain of 0.05-0.15 g/cm3, less compulsory equipment such as powder heaters, and less powder waste. Some limitations include a maximum part height of 19-25.4 mm (0.75-1.00 in.) due to limited heat transfer in the die and the continued need for a heated die. Alloy Composition The alloying additions, both prealloyed and admixed, affect the final properties of the sintered part. The hardenability of the alloy plays a large part in determining the final mechanical properties of a given alloy. In general, more hardenable materials (steels that form martensite at lower cooling rates) have higher strength, hardness, and impact properties. Unfortunately, alloy additions alone are not the only determiner of final properties. The cooling rate from sintering temperature has a large effect on the properties of any sinter-hardening P/M steel. The alloy must be tailored for the intended cooling rate to ensure the desired final microstructure contains beneficial constituents such as martensite, bainite, or fine pearlite that aid properties. Highly hardenable steels which contain high levels of Cu, Mn, Mo, and Ni in combination with a carbon level >0.75 w/o C tend to form retained austenite at moderate cooling rates (convection cooling like rates)3. In addition, it has been shown that sinter-hardening steels containing 2.0 w/o Cu and greater than 0.75 w/o C form retained austenite at particle boundaries where admixed Cu has diffused, when an accelerated cooling profile is used4. These materials should be used with a slower conventional cooling rate, which is slow enough to allow retained austenite to form intermediate phases such as ferrite and carbide. Accelerated sintering furnace cooling should be used in conjunction with moderately alloyed steels containing less carbon and Cu. The fast cooling rate will allow for the formation of martensite and be less likely to form retained austenite. EXPERIMENTAL PROCEDURE Alloys The compositions tested in this study are listed in Table I. All materials were prepared using the proprietary ANCORMAX D system (Except Material #3 which is a premix containing 0.75 w/o Lonza Acrawax C as a reference.). 225 kg (500 lb.) mixes were prepared for each alloy. The elemental copper used was ACuPowder 8081, the elemental nickel used was INCO Type 123, and the graphite used was Asbury 3203. Table I: Sinter-Hardening Alloy Matrix Prealloyed Material Base Iron 1 2 3 (Ref.) 4 Ancorsteel 737SH Ancorsteel 737SH Ancorsteel 737SH Ancorsteel 4600V Mo ( w/o ) 1.25 1.25 1.25 0.56 Admixed Ni ( w/o ) Mn ( w/o ) Cu ( w/o ) Gr ( w/o ) Organic ( w/o ) 1.40 1.40 1.40 1.83 0.42 0.42 0.42 0.15 2.0 1.0 2.0 2.0 0.9 0.7 0.9 0.9 0.55 0.55 0.75 (Acrawax C) 0.55 Compaction The mechanical test samples were uniaxially compacted in a rigid die at 550, 690, and 830 MPa (40, 50, and 60 tsi). All samples were compacted with a die preheated to 63 °C (145 °F). Sintering All test pieces were sintered in a continuous Abbott furnace equipped with a high temperature ceramic belt and a convection cooling section. Several sintering conditions were used to mimic different production sintering cycles and are outlined in Table II. All samples were at sintering temperature for 30 minutes. The standard and accelerated cooling rates are 16 °C/min (30 °F/min) and 47 °C/min (85 °F/min), respectively, from 700 °C (1300 °F) to 150° C (300 °F). Table II: Sintering Conditions for Sinter-Hardening Alloys Material 1 2 3 (Ref.) 4 Sintering Temperatures °C (°F) 1120 (2050) 1120 (2050) 1120 (2050) 1120 (2050) Sintering Atmospheres (v/o) 90N2/10H2 & 25N2/75H2 90N2/10H2 & 25N2/75H2 90N2/10H2 & 25N2/75H2 90N2/10H2 & 25N2/75H2 Cooling Standard & Accelerated Standard & Accelerated Standard & Accelerated Standard & Accelerated Mechanical Testing Tensile tests were performed using dog-bone samples tested according to ASTM Standard E85 and MPIF Standard 106, transverse rupture (TRS) tests were performed using MPIF Standard 41, unnotched Charpy impact tests were conducted according to MPIF Standard 40, and rotating bending fatigue (RBF) testing was done according to MPIF Standard 56. Five specimens were made and tested for each condition. The properties obtained from the mechanical test samples include: green and sintered density, dimensional change, transverse rupture, yield strength, tensile strength, elongation, impact energy and apparent hardness. RESULTS AND DISCUSSION The mechanical property data for the sinter-hardening alloys is shown in Appendix A. The data show some interesting trends which will be discussed in the proceeding paragraphs. Density The green density attained by using the advanced lubricant/binder system on these alloys was an improvement over conventional lubricant additions. This system produced a green density increase of 0.10 g/cm3. This density gained is especially beneficial to sinter-hardening alloy system because the base iron powders were prealloyed with Ni, Mo, and Mn, all alloys that reduced compressibility. Figure 1 shows the compressibility curve for these sinter-hardening alloys. The chart shows that density continues to increase beyond 690 MPa (50 tsi) up to 830 MPa (60 tsi). For Material 1, the green density had reached 7.27 g/cm3, which is 97% of the alloy's pore free density. In addition, Material 2 displayed a slightly higher compressibility throughout the range tested. The density of these alloys sintered at 1120°C (2050°F) is shown in Figure 2. The copper caused a net volume gain in the sample upon sintering, reducing the density. However, the higher green density of the ANCORMAX D processed alloys carried over through sintering resulting in a finished part density that was greater than a part produced using a traditional system. 7.40 7.30 GD (g/cm3) 7.20 7.10 7.00 Material 1 Material 2 6.90 Material 3 (Ref.) Material 4 6.80 35 (480) 40 (550) 45 (620) 50 (690) 55 (760) 60 (830) 65 (900) Compaction Pressure, tsi (MPa) Figure 1: Compressibility Curve for Sinter-Hardening Alloys 7.40 7.30 SD (g/cm3) 7.20 7.10 7.00 Material 1 Material 2 6.90 Material 3 (Ref.) Material 4 6.80 35 (480) 40 (550) 45 (620) 50 (690) 55 (760) 60 (830) 65 (900) Compaction Pressure, tsi (MPa) Figure 2: Sintered Density of Sinter-Hardening Alloys (Sintered at 1120 °C (2050 °F) in 90 v/o N2/10 v/o H2, Tempered at 200 °C (400 °F) for 1 h) Strength The strength advantage due to the density gain was apparent when comparing the tensile strengths of the different alloys. Comparing the tensile data for Material 1 with the data for Material 3 (Figure 3) revealed that the tensile strength increased by 10% throughout the entire range using the standard cooling profile. Accelerated cooling showed similar results at the higher compaction pressure but less of a change at 550 MPa (40 tsi). Another advantage of the density gain was seen by comparing the tensile data for the Material 2 with the Material 3 data in Figure 5. The density increase has improved the strength of the leaner alloy to the same level as the more highly alloyed mix. This observation was notable because with the higher density a leaner alloy addition may be substituted, leading to a more economical premix. (1100) 160 TS, 103 psi (MPa) (1035) 150 (965) 140 (900) 130 (830) 120 Material 1 Material 2 (760) 110 Material 3 (Ref.) Material 4 (690) 100 35 (480) 40 (550) 45 (620) 50 (690) 55 (760) 60 (830) 65 (900) Compaction Pressure, tsi (MPa) Figure 3: Tensile Strength of Sinter-Hardening Alloys (Sintered at 1120 °C (2050 °F) in 90 v/o N2/10 v/o H2, Standard Cooling, Tempered at 200 °C (400 °F) for 1 h) (1100)160 TS, 103 psi (MPa) (1035)150 (965) 140 (900) 130 (830) 120 Material 1 Material 2 (760) 110 Material 3 (Ref.) Material 4 (690) 100 35 (480) 40 (550) 45 (620) 50 (690) 55 (760) 60 (830) 65 (900) Compaction Pressure, tsi (MPa) Figure 4: Tensile Strength of Sinter-Hardening Alloys (Sintered at 1120 °C (2050 °F) in 90 v/o N2/10 v/o H2, Accelerated Cooling, Tempered at 200 °C (400 °F) for 1 h) (1100) 160 (965) 140 (900) 130 3 TS, 10 psi (MPa) (1035) 150 (830) 120 Material 1 (760) 110 Material 2 Material 3 (Ref.) (690) 100 6.90 6.95 7.00 7.05 7.10 7.15 7.20 7.25 7.30 Sintered Density, g/cm3 Figure 5: Tensile Strength of Sinter-Hardening Alloys (Sintered at 1120 °C (2050 °F) in 90 v/o N2/10 v/o H2, Standard Cooling, Tempered at 200 °C (400 °F) for 1 h) Hardness The hardness data for these alloys is shown in Figures 6 and 7. The hardness scaled with density. Again an increase in apparent hardness in higher density materials was observed compared with the standard premix. This increase was valuable as it can enhance wear resistance. 50 Hardness, HRC 45 40 35 Material 1 30 Material 2 Material 3 (Ref.) 25 Material 4 20 35 (480) 40 (550) 45 (620) 50 (690) 55 (760) 60 (830) 65 (900) Compaction Pressure, tsi (MPa) Figure 6: Apparent Hardness of Sinter-Hardening Alloys (Sintered at 1120 °C (2050 °F) in 90 v/o N2/10 v/o H2, Standard Cooling, Tempered at 200 °C (400 °F) for 1 h) The apparent hardness of materials containing 2.0 w/o Cu and 0.9 w/o Gr was not substantially changed by the accelerated cooling rate. However, the 1.0 w/o Cu + 0.7 w/o Gr samples displayed a substantial increase in hardness when the accelerated cooling rate was used. This was a clear example of how an accelerated cooling rate can be used in conjunction with high densities to improve mechanical properties without increasing alloy content. 50 45 Hardness, HRC 40 35 30 Material 1 Material 2 Material 3 (Ref.) 25 Material 4 20 35 (480) 40 (550) 45 (620) 50 (690) 55 (760) 60 (830) 65 (900) Compaction Pressure, tsi (MPa) Figure 7: Apparent Hardness of Sinter-Hardening Alloys (Sintered at 1120 °C (2050 °F) in 90 v/o N2/10 v/o H2, Accelerated Cooling, Tempered at 200 °C (400 °F) for 1 h) The higher density materials resulted in only a modest increases in elongation and impact energy. The toughness of the material stayed relatively constant across the density range and was unaffected by what system was used. Also, there was no appreciable difference between tensile strength and yield strength. All of these properties are related to the highly martensitic microstructure, and it has been shown that the elongation, impact energy plateau at graphite levels above 0.7 w/o and Cu levels above 1.0 w/o in Ancorsteel 737SH7. Fatigue Rotating bending fatigue (RBF) tests show that the survival limit increases when the sintered density is increased by 0.10 g/cm3 for materials mixed with 0.9 w/o Graphite and 2.0 w/o Cu. Table III shows the RBF results for Materials 1 and 3. A 14% increase in the 50 and 90% survival limits was observed for Material 1, which has a higher density. Table III: RBF Data for Sinter-Hardening Alloys Material 1 3 (Ref.) Pressure Pressure (tsi) (MPa) 50 50 690 690 Sintered D ensity (g/cm 3) 7.14 7.05 90% Survival 90% Survival 50% Survival 50% Survival Limit Limit Limit Limit (tsi) (MPa) (tsi) (MPa) 44.4 38.3 306 264 45.8 39.4 316 272 TS TS (tsi) 143 130 (MPa) 986 894 Microstructure Examination of Figure 8 shows that the sample that underwent standard cooling consists of coarse lath martensite and areas of bainite the accelerated cooling sample has finer martensite and fine areas of retained austenite. The presence of bainite in the standard cooled sample toughens the steel producing better properties than the accelerated cooling sample with the retained austenite. Reducing the admixed copper will produce the desirable fine martensitic structure with reduced quantities of retained austenite. Figure 9 shows this clearly. The standard cooling sample consist of coarse lath martensite, divorced pearlite, and bainite. The accelerated cooling sample consists of fine martensite with a trace amount of bainite. In this instance the retained austenite is not present in the final microstructure leading to a steel with excellent properties. a. b. 40 µm 40 µm Figure 8: Microstructure of Material 1 sintered at 1120 °C (2050 °F) in 90 v/o N2/10 v/o H2, a.) standard cooling, b.) accelerated cooling, optical micrograph (2% Nital/4% Picral Etch) b. a. 40 µm 40 µm Figure 9: Microstructure of Material 2 sintered at 1120 °C (2050 °F) in 90 v/o N2/10 v/o H2, a.) standard cooling, b.) accelerated cooling, optical micrograph (2% Nital/4% Picral Etch) CONCLUSIONS • • • • ANCORMAX D processing can increase the green and sintered density of common sinterhardening alloys by 0.05-0.15 g/cm3. A 10% increase in tensile strength was observed when the density was increased by about 0.10 g/cm3. Apparent hardness increased as the density increased in sinter-hardening alloys. A 14% increase in RBF survival limits was observed when the sintered density was increased by 0.10 g/cm3. FUTURE WORK The next step in this work would be to combine the ANCORMAX D system with different Cu and graphite additions to identify the best composition. This work will be done in conjunction with a specific cooling rate to attain greater impact energies and more ductility in a sinter-hardening material. ACKNOWLEGEMENTS The authors would like to extend their appreciation to George Fillari and Dave Southwick for their significant work on mechanical testing for this work. In addition, Gerry Golin and Steve Kolwicz have to be recognized for their work on preparing the microstructures reproduced above. REFERENCES 1 Hanejko, F.G., "Warm Compaction", ASM Handbook, Vol. 7, pp. 327-328, ASM International, Materials Park, OH, 1998. 2 Semel, F.J. and McDermott, M.J., "Recent Applications of Binder Treatment Technology", Advances in Powder Metallurgy & Particulate Materials, Vol. 1, pp. 2-23 - 2-49, Metal Powder Industries Federation, Princeton, NJ, 1997. 3 Roberts, G.A. and Cary, R.A., Tool Steels, 4th Ed. American Society for Materials, Metals Park, OH, 1980, pp. 213-217. 4 Baran, M.C., and Murphy, T.F., "Metallographic Testing to Determine the Influence of Carbon and Copper on the Retained Austenite Content in a Sinter-Hardening Material", P/M Science & Technology Briefs, Vol. 1, No. 3, 1999 pp. 22-26. 5 ASTM Standard E8, "Standard Test Methods for Tension Testing of Metallic Materials", Annual Book of ASTM Standards, Vol. 3.01, pp. 57-72, American Society for Testing and Materials, West Conshohocken, PA, 2000. 6 Standard Test Methods for Metal Powders and Powder Metallurgy Products, Metal Powder Industries Federation, Princeton, NJ, 2002. Appendix A: Mechanical Properties of Sinter-Hardening Alloys Green Properties Sintered Properties of Sinter-Hardening Alloys, Standard Cooling Sintered at 1120 °C (2050 °F) in 90 v/o N2/10 v/o H2, Tempered at 200 °C (400 °F) for 1 h Pressure Pressure (tsi) (MPa) Sintered Density (g/cm³) Dimensional Hardness Change (%) (HRC) ANCORMAX D 737SH + 2.0 w/o Cu + 0.9 w/o Gr 40 550 6.97 0.27 50 690 7.14 0.32 60 830 7.24 0.36 ANCORMAX D 737SH + 1.0 w/o Cu + 0.7 w/o Gr 40 550 7.01 0.23 50 690 7.11 0.27 60 830 7.25 0.32 TRS YS YS TS TS Elong. (10 psi) TRS (MPa) (10 psi) (MPa) (10 psi) (MPa) (%) (ft.lbf) (J) 36 40 42 230 266 278 1586 1834 1917 126 137 143 871 946 986 130 143 151 894 986 1044 0.9 0.9 0.9 11 12 15 17 28 27 36 217 242 274 1497 1669 1890 111 127 134 764 879 923 117 130 135 804 896 929 0.7 0.8 0.8 10 10 13 14 35 37 39 238 266 271 1641 1834 1869 109 121 128 749 838 883 117 130 135 808 894 931 0.9 0.9 0.9 13 12 18 17 32 36 39 220 247 271 1517 1703 1869 NY NY NY NY NY NY 111 128 128 769 883 886 0.7 0.8 0.8 11 13 14 18 3 3 3 Impact Impact Ancorsteel 737SH + 2.0 w/o Cu + 0.9 w/o Gr + 0.75 w/o Acrawax C 40 550 6.92 0.14 50 690 7.05 0.17 60 830 7.12 0.22 ANCORMAX D 4600V + 2.0 w/o Cu + 0.9 w/o Gr 40 550 6.93 0.42 50 690 7.11 0.47 60 830 7.20 0.51 Sintered Properties of Sinter-Hardening Alloys, Accelerated Cooling Sintered at 1120 °C (2050 °F) in 90 v/o N2/10 v/o H2, Tempered at 200 °C (400 °F) for 1 h Pressure Pressure (tsi) (MPa) Sintered Density (g/cm³) Dimensional Hardness Change (%) (HRC) ANCORMAX D 737SH + 2.0 w/o Cu + 0.9 w/o Gr 40 550 6.95 0.27 50 690 7.14 0.30 60 830 7.23 0.35 ANCORMAX D 737SH + 1.0 w/o Cu + 0.7 w/o Gr 40 550 6.98 0.24 50 690 7.15 0.30 60 830 7.25 0.36 TRS YS YS TS TS Elong. (10 psi) TRS (MPa) (10 psi) (MPa) (10 psi) (MPa) (%) (ft.lbf) (J) 37 42 43 234 261 282 1614 1800 1945 NY NY NY NY NY NY 122 140 145 842 965 1002 0.8 0.8 0.8 11 13 14 17 34 38 42 243 269 276 1676 1855 1903 NY 108 NY NY 747 NY 114 128 132 789 880 909 0.7 0.7 0.6 9 10 12 14 35 39 42 232 260 278 1600 1793 1917 NY NY 129 NY NY 890 120 127 133 828 876 916 0.8 0.8 0.8 11 12 15 17 36 40 43 204 229 255 1407 1579 1759 NY NY NY NY NY NY 113 123 130 776 848 893 0.7 0.7 0.7 10 11 13 15 3 3 3 Impact Impact Ancorsteel 737SH + 2.0 w/o Cu + 0.9 w/o Gr + 0.75 w/o Acrawax C 40 550 6.90 0.13 50 690 7.05 0.17 60 830 7.13 0.19 ANCORMAX D 4600V + 2.0 w/o Cu + 0.9 w/o Gr 40 550 6.93 0.41 50 690 7.11 0.46 60 830 7.22 0.50 Sintered Properties of Sinter-Hardening Alloys, Standard Cooling Sintered at 1120 °C (2050 °F) in 75 v/o H2/25 v/o N2, Tempered at 200 °C (400 °F) for 1 h Pressure Pressure (tsi) (MPa) Sintered Density (g/cm³) Dimensional Hardness Change (%) (HRC) ANCORMAX D 737SH + 2.0 w/o Cu + 0.9 w/o Gr 40 550 6.98 0.23 50 690 7.14 0.27 60 830 7.23 0.34 ANCORMAX D 737SH + 1.0 w/o Cu + 0.7 w/o Gr 40 550 6.96 0.26 50 690 7.15 0.28 60 830 7.24 0.32 TRS YS YS TS TS Elong. (10 psi) TRS (MPa) (10 psi) (MPa) (10 psi) (MPa) (%) (ft.lbf) (J) 36 42 44 219 248 253 1510 1710 1745 NY NY NY NY NY NY 121 129 137 837 891 945 0.7 0.7 0.7 11 12 15 16 28 35 36 256 286 298 1766 1972 2055 NY 147 NY NY 1016 NY 120 152 160 830 1046 1104 0.6 0.8 0.9 12 0 84 35 38 41 220 220 241 1517 1517 1662 NY 125 132 NY 863 908 119 136 138 822 935 948 0.7 0.9 0.9 13 12 18 17 34 40 41 207 212 229 1428 1462 1579 NY NY 141 NY NY 974 122 133 144 843 918 994 0.8 0.7 0.8 13 15 17 20 3 3 3 Impact Impact Ancorsteel 737SH + 2.0 w/o Cu + 0.9 w/o Gr + 0.75 w/o Acrawax C 40 550 6.90 0.14 50 690 7.04 0.19 60 830 7.11 0.24 ANCORMAX D 4600V + 2.0 w/o Cu + 0.9 w/o Gr 40 550 6.93 0.34 50 690 7.10 0.47 60 830 7.19 0.52 Sintered Properties of Sinter-Hardening Alloys, Accelerated Cooling Sintered at 1120 °C (2050 °F) in 75 v/o H2/25 v/o N2, Tempered at 200 °C (400 °F) for 1 h Pressure Pressure (tsi) (MPa) Sintered Density (g/cm³) Dimensional Hardness Change (%) (HRC) ANCORMAX D 737SH + 2.0 w/o Cu + 0.9 w/o Gr 40 550 6.98 0.23 50 690 7.15 0.29 60 830 7.23 0.37 ANCORMAX D 737SH + 1.0 w/o Cu + 0.7 w/o Gr 40 550 6.96 0.25 50 690 7.15 0.30 60 830 7.25 0.35 TRS YS YS TS TS Elong. (10 psi) TRS (MPa) (10 psi) (MPa) (10 psi) (MPa) (%) (ft.lbf) (J) 37 42 44 227 239 254 1566 1648 1752 NY NY NY NY NY NY 118 124 129 814 855 889 0.7 0.6 0.6 11 12 15 17 32 39 41 228 265 281 1572 1828 1938 NY NY NY NY NY NY 122 159 157 840 1094 1084 0.7 0.8 0.8 10 11 14 15 36 39 41 214 243 239 1476 1676 1648 121 NY NY 834 NY NY 127 130 139 876 896 958 0.9 0.8 0.8 11 12 15 17 35 41 42 215 217 230 1483 1497 1586 NY NY NY NY NY NY 117 141 137 810 974 948 0.7 0.8 0.8 11 13 15 18 3 3 3 Impact Impact Ancorsteel 737SH + 2.0 w/o Cu + 0.9 w/o Gr + 0.75 w/o Acrawax C 40 550 6.89 0.16 50 690 7.04 0.22 60 830 7.11 0.25 ANCORMAX D 4600V + 2.0 w/o Cu + 0.9 w/o Gr 40 550 6.92 0.40 50 690 7.10 0.46 60 830 7.18 0.50