Ancorsteel 2000

advertisement

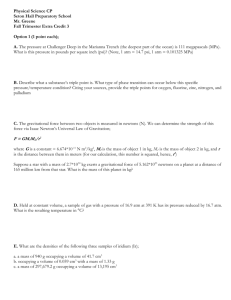

0715-AS2000-D-2 Pg 1 of 5 Ancorsteel 2000 ® Ancorsteel 2000 is a water atomized low-alloy steel powder containing nickel, molybdenum, and manganese which satisfies Metal Powder Industries Federation (MPIF) material specification FL-4200. Ancorsteel 2000 is particularly useful for conventional P/M parts requiring greater hardenability than is possible when using admixed or diffusion alloyed powders. It has good compressibility and green strength, enabling parts to be made easily to densities above 6.7 g/cm3. The use of nickel and molybdenum as the principal alloying elements permits Ancorsteel 2000 to be processed using conventional P/M sintering temperatures and atmospheres. Ancorsteel 2000, because of its high degree of cleanliness and uniform chemistry, is ideally suited for powder forging (P/F) applications that require the hardenability and mechanical properties associated with cast and wrought steels. Part densities of 7.60 to 7.86 g/cm3 can be obtained using hot forming pressures of 415–1100 MPa (30–80 tsi). Typical Analysis and Properties Composition (weight %) (w/o) C Mo Ni Mn <0.01 0.61 0.46 0.25 O 0.13 Apparent Density Flow Rate 2.98 g /cm3 25 s/ 50 g Sieve Distribution (w/o) Micrometers +250 -250 /+150 -150 /+45 -45 U.S. Standard Mesh +60 -60 /+100 -100 /+325 -325 Trace 10 65 25 The Effect of Compaction Pressure on Green Properties Compaction Pressure (tsi) 30 40 Compaction Pressure (tsi) 50 14 Green Strength (MPa) Green Density (g/cm3) 30 40 50 60 2.0 12 7.0 6.6 6.2 1 w/o Zinc Stearate Added 5.8 5.4 5.0 200 20 1.5 10 8 1.0 6 1 w/o Zinc Stearate Added 4 0.5 Green Strength (103 psi) 7.4 20 2 300 400 500 600 700 800 Compaction Pressure (MPa) NORTH AMERICA Cinnaminson, NJ: +1-856-829-2220, tim.hale@hoeganaes.com EUROPE Meerbusch, Germany: +49-2132-6598-20, klaus.vossen@hoeganaes.com 0 200 300 400 500 600 700 0.0 800 Compaction Pressure (MPa) ASIA Seoul, Korea: +82-2-3486-4471, jongsik.na@hoeganaes.com Pudong Shanghai, China: +86-21-2037-3950, oliver.he@hoeganaes.com 0715-AS2000-D-2 Data Sheet Pg 2 of 5 Ancorsteel 2000 ® The Effect of the Combined Carbon on Sintered Properties 1000 Sintered 30 min. at 1120ºC (2050ºF) in a dissociated ammonia atmosphere 7.0 g/cm3 120 750 6.6 g/cm3 90 500 60 6.0 g/cm3 250 0 0.25 0.50 0.75 Combined Carbon (w/o) 30 1.00 Dimensional Change (% From Die Size) Dimensional Change 150 Transverse Rupture Strength (103 psi) Transverse Rupture Strength (MPa) Transverse Rupture Strength +0.4 Sintered 30 min. at 1120ºC (2050ºF) in a dissociated ammonia atmosphere +0.3 7.0 g/cm3 +0.2 6.6 g/cm3 6.0 g/cm3 +0.1 0.0 -0.1 0 0.25 0.50 0.75 Combined Carbon (w/o) 1.00 Apparent Hardness Apparent Hardness (HRB) 100 Sintered 30 min. at 1120ºC (2050ºF) in a dissociated ammonia atmosphere 7.0 g/cm3 80 6.6 g/cm3 60 6.0 g/cm3 40 20 0 0 0.25 0.50 0.75 Combined Carbon (w/o) 1.00 The Effect of the Sintering Temperature and Time on Properties 0.8 w/o graphite added 6.8 g/cm3 1138˚C (2080˚F) 1000 1110˚C (2030˚F) 900 150 140 130 120 800 100 700 0 30 60 90 120 Sintering Time At Temperature (mins.) Dimensional Change (% From Die Size) 1100 Dimensional Change Transverse Rupture Strength (103 psi) Transverse Rupture Strength (MPa) Transverse Rupture Strength +0.40 0.8 w/o graphite added 6.8 g/cm3 +0.20 1110˚C (2030˚F) 0 1138˚C (2080˚F) -0.20 0 30 60 90 Sintering Time At Temperature (mins.) 120 Test specimens were sintered in an endothermic gas atmosphere. NORTH AMERICA Cinnaminson, NJ: +1-856-829-2220, tim.hale@hoeganaes.com EUROPE Meerbusch, Germany: +49-2132-6598-20, klaus.vossen@hoeganaes.com ASIA Seoul, Korea: +82-2-3486-4471, jongsik.na@hoeganaes.com Pudong Shanghai, China: +86-21-2037-3950, oliver.he@hoeganaes.com 0715-AS2000-D-2 Data Sheet Pg 3 of 5 Ancorsteel 2000 ® Comparison of the Hardenability of Premixed and Prealloyed Powders with Equivalent Compositions Distance From Quenched End, in 1/16˝ Apparent Hardness (HRC) 60 0 2 4 6 8 10 0.40 w/o Carbon Jominy Hardenability 40 Ancorsteel 2000 20 Ancorsteel 1000 plus 0.50 w/o Ni, 0.65 w/o Mo 0 3 6 9 12 15 Distance from Quenched End (millimeters) The Effect of Heat Treatment Transverse Rupture Strength, MPa (103 psi) Apparent Hardness (HRA) Tempering Temperature (˚F) Combined Carbon (w/o) 0.80 400 600 800 Tempering Temperature (˚F) 200 1000 1400 (200) 0.60 1200 (175) 1400 (200) 1200 (175) 0.40 1050 (150) 0.20 100 400 600 800 1000 0.80 1050 (150) 200 300 400 Tempering Temperature (˚C) 500 Combined Carbon (w/o) 200 75 70 65 0.60 0.40 60 0.20 100 200 300 400 500 Tempering Temperature (˚C) Test specimens were at a density of 7.0 g/cm3. The specimens were austenitized in an endothermic atmosphere at 790˚C to 870˚C (1450˚F to 1600˚F), oil quenched and tempered. NORTH AMERICA Cinnaminson, NJ: +1-856-829-2220, tim.hale@hoeganaes.com EUROPE Meerbusch, Germany: +49-2132-6598-20, klaus.vossen@hoeganaes.com ASIA Seoul, Korea: +82-2-3486-4471, jongsik.na@hoeganaes.com Pudong Shanghai, China: +86-21-2037-3950, oliver.he@hoeganaes.com 0715-AS2000-D-2 Data Sheet Pg 4 of 5 Ancorsteel 2000 ® The Effect of Sintering Temperature and Sintered Carbon on the Tensile Properties of Ancorsteel 2000 Compacted to 6.8 g/cm3 Sintering Temperature ˚C ˚F 1120 1260 1120 1260 1120 1260 2050 2300 2050 2300 2050 2300 Sintered Carbon w/o 0.4 0.4 0.6 0.6 0.8 0.8 Yield Strength 2% Offset MPa psi Ultimate Tensile Strength MPa psi 250 285 295 330 360 410 290 365 345 420 385 510 36,500 41,500 42,500 48,000 52,000 59,000 Elongation % in 25.4 mm (1 inch) 42,000 53,000 50,000 61,000 56,000 74,000 <1.0 1.9 <1.0 1.5 <1.0 1.2 The Effect of Sintering Temperature and Sintered Carbon on the Tensile Properties of Heat Treated Ancorsteel 2000 Compacted to 6.8 g/cm3 Sintering Temperature ˚C ˚F 1120 1260 1120 1260 1120 1260 2050 2300 2050 2300 2050 2300 Sintered Carbon w/o 0.4 0.4 0.6 0.6 0.8 0.8 Ultimate Tensile Strength MPa psi 620 815 495 705 430 620 Yield Strength 0.2% Offset 90,000 118,000 72,000 102,000 62,000 90,000 Elongation There was no yielding or elongation in the heat treated bars. Apparent Hardness HRC 28 28 36 36 42 42 The test bars were austenitized at 845˚C (1550˚F) and 815˚C (1500˚F) for the 0.4 w/o and 0.6 w/o sintered carbon respectively. All bars were quenched in a fast cooling oil and stress relieved at 175˚C (350˚F). Sinter-Hardening Characteristics of Ancorsteel 2000 Premixed With 2 w/o Copper Graphite Compaction Pressure Additions* for 6.8 g/cm3 w/o MPa psi 0 0.3 0.6 0.6 1.0 1.0 1.0 1.0 490 490 495 495 510 510 510 510 71,200 71,200 72,000 72,000 73,600 73,600 73,600 73,600 Temper 60 min. Dimensional Change % Apparent Hardness HRB — — — 260˚C (500˚F) — 150˚C (300˚F) 200˚C (400˚F) 260˚C (500˚F) +0.44 +0.46 +0.33 +0.33 +0.05 +0.03 +0.03 +0.03 31 66 72 73 89 89 89 89 Transverse Rupture Strength Martensite MPa psi % 480 790 885 890 945 1040 1065 1010 71,400 114,200 128,000 128,700 136,700 150,900 154,500 146,700 0 0 0 0 30 30 30 30 *All mixes include 0.75 w/o zinc stearate and were sintered at 1120˚C (2050˚F) for 30 minutes in a dissociated ammonia atmosphere. NORTH AMERICA Cinnaminson, NJ: +1-856-829-2220, tim.hale@hoeganaes.com EUROPE Meerbusch, Germany: +49-2132-6598-20, klaus.vossen@hoeganaes.com ASIA Seoul, Korea: +82-2-3486-4471, jongsik.na@hoeganaes.com Pudong Shanghai, China: +86-21-2037-3950, oliver.he@hoeganaes.com 0715-AS2000-D-2 Data Sheet Pg 5 of 5 Ancorsteel 2000 ® Powder Forging Power forging (P/F) is a natural extension of the conventional press and sinter (P/M) process, which has long been recognized as an effective technology for producing a great variety of parts to net or near-net shape. In essence, a porous preform is densified by means of hot forming in a single operation. Forging is carried out in heated, totally enclosed dies, and virtually no flash is generated. Powder forging, therefore, is a deformation processing technology aimed at increasing the density of P/M parts and thus their performance characteristics. The Effect of P/F Carbon Content on Hardenability 70 0.20–0.25 w/o C 20–25 HRC 60 80 50 60 40 40 0 0.04 0.08 Oxygen (w/o) 30 0.16 0.12 85 Apparent Hardness (HRA) 100 Charpy V-Notch Impact Strength (ft. lbf) Charpy V-Notch Impact Energy (Joules) The Effect of Oxygen Content on the Impact Energy of the Finished P/F Part 0 Distance From Quenched End (inches) 0.2 0.4 0.6 0.8 80 1.0 0.52 w/o C 75 70 0.28 w/o C 65 60 0.22 w/o C 55 50 45 0 5 10 15 20 Distance From Quenched End (mm) 25 Tensile and Impact Properties for Heat Treated Ancorsteel 2000 with Various Forged Carbon Levels Forged Carbon w/o Tempering Temp Yield Strength Ultimate Tensile 0.2% Offset Strength Tensile Elongation Reduction R.T. Charpy V-Notch of Area Impact Energy Core Hardness ˚C ˚F MPa psi MPa psi % in 25.4 mm (1 in) % Joules ft. lbf HRA 0.28 0.37 0.56 0.70 0.86 175 315 315 345 425 350 600 600 650 800 900 1385 1560 1560 1310 130,000 200,700 226,100 226,500 189,800 1050 1450 1685 1805 1430 152,700 210,300 244,400 261,900 207,400 11 10 10 5 10 43 33 29 12 30 22 10 10 7 7 16 7 7 5 5 67 73 73 76 73 0.26 0.38 0.55 0.73 0.87 620 650 660 675 675 1150 1200 1225 1250 1250 700 785 840 860 850 101,800 113,800 119,100 124,400 122,800 830 860 920 970 995 120,700 124,700 133,100 140,400 144,200 23 21 18 15 16 58 57 50 43 34 34 54 42 20 12 25 40 31 15 9 63 64 66 66 66 IMPORTANT NOTICE: The data shown are based on laboratory processing standard test specimens. Results may vary from those obtained in production processing. NORTH AMERICA Cinnaminson, NJ: +1-856-829-2220, tim.hale@hoeganaes.com EUROPE Meerbusch, Germany: +49-2132-6598-20, klaus.vossen@hoeganaes.com ASIA Seoul, Korea: +82-2-3486-4471, jongsik.na@hoeganaes.com Pudong Shanghai, China: +86-21-2037-3950, oliver.he@hoeganaes.com