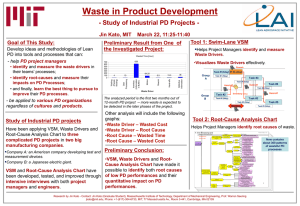

Recent LAI PD VSM Research Presented By Eric Rebentisch MIT/LAI

advertisement

Recent LAI PD VSM Research Presented By Eric Rebentisch MIT/LAI April 18, 2006 http://lean.mit.edu © 2006 Massachusetts Institute of Technology 18 April - 1 Overview • LAI PDVSM 1.0 released • Predecessors in widespread (?) distribution and use (??) in the LAI consortium • • • Several recent research projects completed using value stream mapping in PD • Kato—Waste in PD • Whitaker—VSM and EVMS • MacKenzie—VSM in USAF SPOs Evidence of significant PDVSM activities among LAI consortium members Where do we stand as a learning community? • What are the next steps? http://lean.mit.edu © 2006 Massachusetts Institute of Technology April 18 - 2 Product Development Value Stream Mapping (PDVSM) Tactical guide to applying value stream mapping techniques to PD, engineering, and other “off-the floor” processes http://lean.mit.edu © 2006 Massachusetts Institute of Technology April 18 - 3 Embedded Software Development VSM Inventory without Hand-off (over 3days) Hand-off with Inventory (over 3days) Hand-off without Inventory Jan‘ 02 1/9 Hand-off,31-33, 31-35, 31-36, 31-37, w-31 Transaction waste 1/27 Risk: tentative information 2/6 1/30 Negotiation. 1/23 1/16 RISK of “defective information” 28 Investigation Summarize Scope/Product Definition (1day) 11 Features Soft. Req. Analysis (1day) 11 (1day) Hand-off 1-14, 1-15, 1-16, 1-17, 1-18, 1-20, 1-21, 1-22, 1-23, 1-25, 1-26, w-26 1-25, 1-26 (11days), w-07 1/27 17-27 (5 days), w-44 2/28 72(1day) (Defective info. – under processing) 31 Architecture Software Architecture Document (4day) 31 Architecture Software Architecture Document (1day) 40 1/24 1/20 21 Investigation 8-XXXXXXX (3day) 31 (5day) 31 31 31 (0.25day) (0.25day) (0.25day) 31Ex Architecture Software Architecture Document (1day) 31 31 Weekly (0.25day) 8 Meeting w-21 Defective Information, Under Processing, Over Utilization, Expedited task, Schedule Enforcement, Premature input from others, based on tentative infromation. Wasteful discussion XX (Bug Fix of Other Product) 1/25 14 Investigation 1-XXXXXX (1day) 2/1 14-1 25 Investigation 12Elimination Of Performance Issue (1day) 23-27 (7 days), w-03 Weekly Meeting w-21 2/8 8 8 23 (5day) 1/11 Hand-off 22-27, w-28 25-Re CIC Filter 1/18 2/4 NVA (Documenting): XX. Required by RUP w-14 16 Investigation XXXXX Restriction (1day) 1/20 22-3day Member C 1/24 1/21 40 Weekly Meeting (.5h) w-34 Defective Information, Under Processing, Over Utilization, Expedited task, Schedule Enforcement 59-1 Low priority 1/12 18 Investigation 5-XXXXXXX Enhancements (0.5day) 1/11 1/15 18 Investigation 5-XXXXXXXX Enhancements (0.5day) Other Tasks Other Tasks 1/17 18 (5day) 1/7 1/7 1/18 82-1 2/2 Weekly Meeting (.5h) w-35 73(2day) 3/8 74(1day) Weekly Meeting Story board only 2/24 45 Specifications Formal Review Functional Spec XXX Review 1 (1day) Indecisive discussions because of so many stakeholders (not XXXXXX only) 40 -5day 2/15 2/4 8 3/2 71(1day) XXXXXX Workshop 1/25 Rework Estimate XXX Xput-1h 3/9 3/8 64 (1day) 3/4? 58-2 Prototype w/ Clone Coding & Unit Test Clone XXX (3day) Weekly Meeting w-42 About XXX 4 24(1day) 62 (2day) 75 (1day) 4 3/2 1/24 24 Investigation XXXXXXX Communication (0.5day) 3/8 3/3 Rework w-17 XX (Bug Fix of Other Product) NVA (Documenting): Change Req. Required by RUP w-15 Customizable Configuration 3/4 XXXXX Inventory (0.5day) Weekly Review (.5h) w-39 XXX, XXXX (Not dedicated) 19-5day 69 (3day) 3/2 Weekly Meeting 36(1day) 19 Investigation 6-XXXXXXXXx Enhancements (0.5day) 3/7 Trip to Other Country 25-Re CIC Filter (0.25day) Meeting, about 2h Meeting, about 2h 2/10 46 Specifications Formal Review Functional Spec XXXX Modification (2day) 46 Specifications Formal Review Functional Spec XXXX Modification (2day) (1day) 36-Re Change Request XXXX -XXX (0.5day) 70(2day) 3/4 44 Specifications Formal Review Functional Spec XXX Workshop (2day) 2/8 42 (5day) 49 (3day) 8 34-1 42 Ex Defective Info., Under Processing, Incomplete 8 Info. w-16 3/3 2/25 49 Specifications Non-Functional Spec XXXXXXX (3day) Story board only 24 Weekly Meeting w-41 Inventory,2/10 w-22 3/7 3/3 2/7 2/1 36 Change Request XXXX -XXX (1day) 1/20 Other Tasks 1/18 Low priority 4 Other Tasks 19 Investigation 6XXXXX Enhancements (0.5day) Member D Hand-off,14-27, 1527, 16-27, 24-27, 2527, 26-27, w-29 12 Email XXXXXX Defective Information, Under Processing, Over Utilization, Expedited task, Schedule Enforcement (0.5day) 2/5 XX (Bug Fix of Other Product) 35 Re ChangeWaste: Over Processing, Task not clear, Introduction of new Requestprocess, engineer’s desire for perfection w-33 XXXX 2/14 8 XXXX 2/9 41-3day (1day) Weekly Meeting (.5h) w-38 NVA (Documenting): Change Req. Required by RUP 34-1 Rework w-01 29 Investigation Agree Final Feature List With Stakeholders (1day) 41 Specifications Compatibility Definition (2day) Inventory 41-41 w-23 2/15 41Ex 2/14 2/10 42 Specifications Functional Spec. XXXXXXXXXXXX (5day) About XX 26-2day Other Tasks 2/1 35 Change Request XXXX XXXX (1day) 35 (1day) 16(1day) 26 Investigation 13-XXXXXXX (2day) 2/4 41 Specifications Compatibility Definition (1day) 32 15(1day) 22 Investigation 9-XXXXX for RUP Support (0.5day) XXX 1/25 15 Investigation 2-XXXXXX Compatibility (1day) 1/17 40 Specifications Functional Spec. XXXXXXXX (?day) 25-Re XXX XXX (0.25day) XXXXX Workshop Hand-off, 33-41, w-32 33-1 25 (1day) 23 Investigation 10-Improved Application XX Management (5day) 47 Specifications Formal Review Functional Spec XXXXXx (0.5day) ? 31Re Architecture Software Architecture Document (1day) 2/8 33 Change Request XXXX XXXX 1. Weekly Meeting (.5h) w-11 Lowerd quality because of so many stop-and-go tasks 2/15 40 (5day) ? Motion (Documenting): Change Req. Required by RUP w-13 Weekly Meeting (.5h) w-20 67 Control Design Control XXX Review Workshop (0.25h) (0.25day) Requested by H/W team (1h) 2/7 31 (5day) 2/2 31 (0.25day) 1/26 1/24 21 (5day) 1/18 Member B 67 Control Design Control XXX Review Workshop (0.25h) 2/25 1/28 17 (2day) 1/17 17 (5day) 72 Control Design H/W Control Details XXXX Enhancement Spec. (1day) (2day) 27 (1day) 17 Investigation 4-Dynamic Setup (5day) 1/11 Jun ‘03 3/13 42 Ex 79-1 w-47 (1day*7) Rework (.5h) Correcting incomplete information from upstream task w-04 1/19 1/11 May ‘03 Mar ‘03 3/4 3/1 3/3 Inventory, Stop-andGo Tasks, Expedited Tasks, Over Utilization(140%),+low availability of H/W system Motion (Meetings): Agreement w-12 27 Investigation Select the Project Scope (1day) Hand-off 17-27, 23-27, w-27 3/6 2/24 71 Control Design H/W Control Details XXXX XXXX (1day) 79 Planning Plan for Construction Phase 20 28 (1day) 1-21, 1-22 (5 days), w-08 2/27 2/23 1/31 1-14, 1-15, 1-16 (10days), w-06 1/7 Feb ‘03 2/20 Inventory, Expedited Work, Stop-and-go, Over Utilization (XX, Bug Fix of Other Product), w-05 1/28 Under-Processing, Information not complete, w-24 Member A 1/7 Apr ‘03 2/13 Hand-off,27-31, w-30 77 Planning Release Mgt. Plan (1day) 12 1/24 1/11 1/12 Hand-off, w25 20 Investigation 7-Customizable Configuration and XXX Agreement (2day) 2/1 53 Prototype w/ XXX XXXX 32 Weekly Meeting (1day) 20-37 (13days, until the end), w-02 Weekly Review (.5h) w-40 37 Change Request XXXXX (1day) 1/28 (.5h) w-36 Waiting(4h)wait ing for Bench w-10 53-1 20-2day 1/25 Weekly Meeting w-43 55 Prototype w/ Clone Coding & Unit Test XXXXX (6day) 16, 16 55(10day) 2/2 Workshop 61 (0.5day) Prototype w/ Clone Integration Test Defective Information, Under Processing Creating Test Loopback (1day) Testing System is Busy for Releasing Other Products 16 ? 3/8 61 (3day) 3/10 3/11 3/8 63 (3day) 3/15 Over Processing (2-hour loss) w-19 1/11 Creating unnecessary information. Proceeding without proper knowledge of the current model’s S/W structure. 2/7 83-1 Low priority XXXXX 57 (2day) 2/15 58-1 Prototype w/ Clone XXXXXX Clone XXXX (2day) 2/9 55(10day) Risk of “Defective Information” Proceeding with tentative information 20,24 8 2/14 2/25 57 Prototype w/ Clone Coding & Unit Test XXXXXX (2day) Weekly Meeting XX (Bug Fix of Other Product) NVA (Documenting): Change Req. Required by RUP w-18 37-1 55 Prototype w/ Clone Coding & Unit Test XXXXXXXXXXXX (4day) Member E 2/24 56-1 Prototype w/ Clone Coding & Unit Test XXXXXX (6day) Motion(4h) Info. hunting w-09 29-1 2/10 3/4 57 (2day) 3/7 3/2 2/24 2/15 56 (3day) 56-2 Prototype w/ Clone Coding & Unit Test Clone Diag (6day) 2/7 XXXX Study Licensing Agreement 2/15 56-2 Ex Prototype w/ Clone Coding & Unit Test XXXXXX (6day) 2/21 2/15 58 (3day) 58 (3day) 2/25 2/25 (4h) XXXX Lecture Weekly Review (.5h) w-45 XXXX Lecture XXXX Lecture 44-2day 2/22 2/21 45-1 3/1 67 Control Design Control XXX Review Workshop (2day) 40 2/28 46 Weekly Meeting Specifications Formal Review Functional Spec XXXXXXXXXX (2day) Weekly Review (.5h) w-46 Member F XXX Lecture XXX Lecture XXX Lecture (1h) (1h) (1h) 32 Motion - Information hunting, not knowing the existence of the search engine for source code, poor communication, OJT, training (1h) 47 Specifications Formal Review Functional Spec XXXXXXXXXX (1day) 32 Inqury Inqury Inqury Inqury Inqury Information Pulling 2/4 Inqury Other country XXXX External XXX (Closer to Customers) Other segments of R&D dept. H/W Team (Closer to Other Customers) segments of XXX dept. H/W Team H/W Team Information not documented H/W Team Interface design, optimization in terms of performance Project A-1 Project Manager, Mr. XXXXX 7 H/W Block Diagram Available 2/28 8 H/W ControlXXX Low availability, need to set up a scheduled meeting Investigation Phase (around 100 tasks) Construction Phase 350 tasks) Source: Jin Kato, Development of a Process for Continuous Creation of Lean Value in Product Development (around http://lean.mit.edu Organizations, MIT Master’s Thesis, May 2005 © 2006 Massachusetts Institute of Technology April 18 - 4 Hardware/Software Development Program VSM (Part of Major System) http://lean.mit.edu Source: Ryan Whitaker, Using PDVSM to Better Characterize Waste and © 2006 Massachusetts Institute of Technology Value in Product Development, MIT Master’s Thesis, August 2005 April 18 - 5 Small USAF Acquisition Program VSM Congressional add DCAA 33 DCMA 34 64 10 Engineering 71 72 15 67 Contracting 1 3 64 16 64 17 71 72 69 67 71 72 24 40 25 30 41 46 26 30 42 46 27 30 43 46 28 44 69 18 Logistics 39 69 67 Finance 23 72 Program Management 2 5 7 9 32 3511 63 64 71 14 19 66 67 68 69 29 38 30 45 54 55 48 51 46 57 56 52 58 62 59 60 61 53 47 46 57 56 52 58 62 59 60 61 53 72 64 65 Wing Senior Leadership 22 67 69 70 72 63 6 PACAF/DOY 66 4 8 LM 31 3612 64 13 68 20 69 72 21 37 30 54 55 84th RADES 46th TS 54 55 56 49 52 50 52 53 57 58 Nugget 59 60 61 Senator Stevens 11th AF Elmendorf OG/ALC-LHH Alaskan DNR Civil Eng Shop Eilsen 353rd CSS Sep 04 http://lean.mit.edu Jan 05 May 05 Sep 05 Jan 06 May 06 Sep 06 Source: Scott MacKenzie, Utilizing Value Stream Mapping © 2006 Massachusetts Institute of Technology In Air Force Acquisition Program Offices, MIT Master’s Thesis, January 2006 April 18 - 6 Value Measurement • • Earned Value Management System (EVMS) commonly used to measure and manage PD, but can suffer from lack of tight linkages to actual value-creating activities in PD Initial research shows compatibility between value stream thinking in PD and EVMS, but little current convergence http://lean.mit.edu Source: Ryan Whitaker, Using PDVSM to Better Characterize Waste and Value in Product Development, MIT Master’s Thesis, August 2005 © 2006 Massachusetts Institute of Technology April 18 - 7 Observations About the Current State of the Research • We are pushing the limits of traditional VSM tools to represent complex projects • • • Working premise is that uncertainty reduction activities are a surrogate for value creation progress in PD • • • Forced by limitations of existing methods to create VSMs at the level of local activities VSMs of more complex activities resemble Gantt charts— inexact measures of value creation processes and the state of the processes that are producing the product Existing measures (EVMS) used for PD management can distract from true levels of uncertainty in development effort Mismatch between level of measurement (EVMS elements) and work processes suggest limited potential impact of measurement system on actual behavior Existing management tools at program level could be improved to provide additional insight into state of the process, and flow of value through the system http://lean.mit.edu © 2006 Massachusetts Institute of Technology April 18 - 8