Document 10670402

advertisement

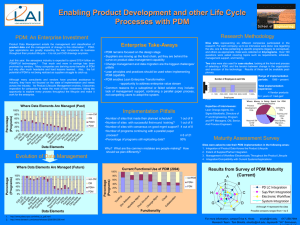

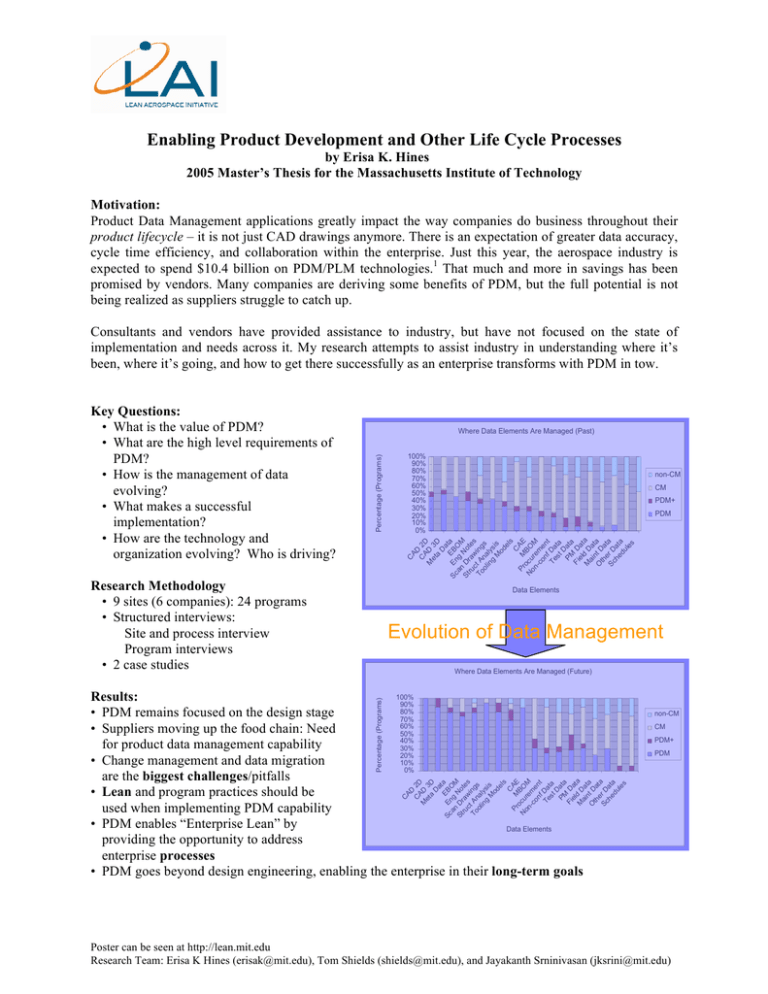

Enabling Product Development and Other Life Cycle Processes by Erisa K. Hines 2005 Master’s Thesis for the Massachusetts Institute of Technology Motivation: Product Data Management applications greatly impact the way companies do business throughout their product lifecycle – it is not just CAD drawings anymore. There is an expectation of greater data accuracy, cycle time efficiency, and collaboration within the enterprise. Just this year, the aerospace industry is expected to spend $10.4 billion on PDM/PLM technologies.1 That much and more in savings has been promised by vendors. Many companies are deriving some benefits of PDM, but the full potential is not being realized as suppliers struggle to catch up. Consultants and vendors have provided assistance to industry, but have not focused on the state of implementation and needs across it. My research attempts to assist industry in understanding where it’s been, where it’s going, and how to get there successfully as an enterprise transforms with PDM in tow. Where Data Elements Are Managed (Past) 100% 90% 80% 70% 60% 50% 40% 30% 20% 10% 0% non-CM CM PDM+ PDM CA D CA 2D M D et 3D a Da t Sc En EB a an g OM St D No ru raw tes c To t A ing ol na s in ly g si M s od el s C Pr M AE o B No cu O n- rem M co e nf n Te Da t st ta D PM ata Fi D el at M dD a ai a t O nt D a th a e t Sc r D a he at du a le s Percentage (Programs) Key Questions: • What is the value of PDM? • What are the high level requirements of PDM? • How is the management of data evolving? • What makes a successful implementation? • How are the technology and organization evolving? Who is driving? Research Methodology • 9 sites (6 companies): 24 programs • Structured interviews: Site and process interview Program interviews • 2 case studies Data Elements Evolution of Data Management Where Data Elements Are Managed (Future) non-CM CM PDM+ PDM CA D C 2D M AD et 3D a Da ta Sc E EB n an g OM St Dr No ru aw te s c To t A ing ol nal s in ys g M is od el s C Pr M AE oc B No u O n- rem M co e nf nt Te Da st ta D PM ata Fi D el a M d D ta ai a n t O tD a th a e t Sc r D a he ata du le s Percentage (Programs) 100% Results: 90% 80% • PDM remains focused on the design stage 70% 60% • Suppliers moving up the food chain: Need 50% 40% for product data management capability 30% 20% • Change management and data migration 10% 0% are the biggest challenges/pitfalls • Lean and program practices should be used when implementing PDM capability • PDM enables “Enterprise Lean” by Data Elements providing the opportunity to address enterprise processes • PDM goes beyond design engineering, enabling the enterprise in their long-term goals Poster can be seen at http://lean.mit.edu Research Team: Erisa K Hines (erisak@mit.edu), Tom Shields (shields@mit.edu), and Jayakanth Srninivasan (jksrini@mit.edu)