Assessment of Ocean Thermal Energy Conversion

By

ARCHIVES

Shylesh Muralidharan

B. Tech. Mechanical Engineering, Pondicherry University, 1998

Master of Management Studies, University of Mumbai, 2001

,SACHiUSFTTS INSTITUTE

Submitted to the System Design and Management Program

in Partial Fulfillment of the Requirements for the Degree of

Master of Science in Engineering and Management

at the

Massachusetts Institute of Technology

February 2012

@ 2012 Massachusetts Institute of Technology. All Rights Reserved

Signature of Author

u

Shylesh Muralidharan, January 30, 2012

System Design and Management Program

Certified by

_

or,

E. Eric Adams, Senior Lecturer, Senior Research Engineer,

Dept. of Civil & Environmental Engineering

Thesis Supervisor

Certified by

Jessia E. Trancik, Assistant Professor,

Engineering Systems Division

Thesis Supervisor

Certified by

Ricardo Valerdi, Research Affiliate,

Center for Technology, Policy & Industrial Development

f Arizona

strial Engineering, Universi

Associate Professor of Systems & I

pervisor

S

Thes

Accepted by

Hale, Director,

System Design and Management Program

PA R IES

This page is left intentionallyblank

2

Assessment of Ocean Thermal Energy Conversion

By

Shylesh Muralidharan

Submitted to the System Design and Management Program on January 31, 2012 in Partial

Fulfillment of the Requirements for the Degree of Master of Science in Engineering and

Management

Abstract

Ocean thermal energy conversion (OTEC) is a promising renewable energy technology to

generate electricity and has other applications such as production of freshwater, seawater airconditioning, marine culture and chilled-soil agriculture. Previous studies on the technology have

focused on promoting it to generate electricity and produce energy-intensive products such as

ammonia and hydrogen. Though the technology has been understood in the past couple of

decades through academic studies and limited demonstration projects, the uncertainty around the

financial viability of a large-scale plant and the lack of an operational demonstration project have

delayed large investments in the technology.

This study brings together a broad overview of the technology, market locations, technical and

economic assessment of the technology, environmental impact of the technology and a

comparison of the levelized costs of energy of this technology with competing ones. It also

provides an analysis and discussion on application of this technology in water scarce regions of

the world, emphasized with a case study of the economic feasibility of this technology for the

Bahamas.

It was found that current technology exists to build OTEC plants except for some components

such as the cold water pipe which presents an engineering challenge when scaled for large-scale

power output. The technology is capital intensive and unviable at small scale of power output but

can become viable when approached as a sustainable integrated solution to co-generate

electricity and freshwater, especially for island nations in the OTEC resource zones with supply

constraints on both these commodities.

To succeed, this technology requires the support of appropriate government regulation and

innovative financing models to mitigate risks associated with the huge upfront investment costs.

If the viability of this technology can be improved by integrating the production of by-products,

OTEC can be an important means of producing more electricity, freshwater and food for the

planet's increasing population.

Thesis Supervisor: E. Eric Adams

Title: Senior Lecturer, Dept. of Civil & Environmental Engineering

Thesis Supervisor: Jessika E. Trancik

Title: Assistant Professor, Engineering Systems Division

Thesis Supervisor: Ricardo Valerdi

Title: Research Affiliate, Center for Technology, Policy & Industrial Development

3

Acknowledgements

I would like to thank a number of people who have contributed, both directly and indirectly, to

my work at MIT and to the writing of this thesis. This thesis is possible because of the guidance,

feedback and insights contributed by those around me.

I am sincerely grateful to Eric Adams, Jessika Trancik and Ricardo Valerdi who have provided

support and guidance throughout this thesis and over the course of my education in MIT. They

contributed with their professional knowledge, personal experiences and friendship. All their

insights and suggestions added to my learning and vastly enriched my academic experience. I

would also like to thank Lockheed Martin Corporation for providing me with the opportunity to

work on this topic and the support throughout the duration of the project.

I am forever thankful to my wonderful colleagues in the SDM course who have patiently listened

to all my ideas and provided valuable feedback. SDM is host to several great minds and my

interaction with each one of them has been invaluable, helping me grow as a professional and a

better individual. I would like to specially thank Pat Hale and the staff in SDM without whom

many of things I accomplished in the past year would have been impossible.

On a personal note, I am grateful to my wife, Reshma, who was patient with me as I toiled away

and provided encouragement when needed. And of course, last but not the least, I would like to

thank my parents who are an eternal source of inspiration as they continue to provide strength

and support through all my adventures.

4

TABLE OF CONTENTS

1. INTRO D UCTIO N...............................................................................................................................

9

10

Objective, Scope and M ethodology.........................................................................................................

M ethodology..............................................................................................................----..............-....11

12

Thesis organization .................................................................................................................................

1.1.

1.2.

1.3.

OCEA N TH ERM A L EN ERGY CONVERSIO N ............................................................................

2.

14

.... 14

OTEC as an renewable energy technology ....................................................................

2.1.

.....--....... .--- 14

W ater-energy nexus .....................................................................................................2.2.

15

-.

-------...................

History of OTEC .................................................................................................2.3.

17

. ---.. -----........

The thermodynam ics.....................................................................................................--.

2.4.

17

. ----------------..................

Closed-cycle ..........................................................................................-----.....2.4.1.

19

.. ------------...................

......

Open-cycle .........................................................................................-2.4.2.

21

Hy b rid Cy cle ..........................................................................................-------.....---------.---------..................

2 .4.3 .

-.... 22

.....................

M arket locations for OTEC ......................................................................................

2.5.

25

Siting characteristics for OTEC plants ................................................

2.6.

26

. --------.........

Shore-based ..............................................................................................................---.....2.6.1.

26

..................................................................................................................

Plantships

M oored/Floating

2.6.2.

.... 27

OTEC Demonstration Case Studies ................................................................................................

2.7.

-......... -----............... 27

...........

Haw aii.....................................................................................................

2 .7 .1 .

2.7 .2 .

Nau ru .....................................................................................................................

............................

27

2.7.3.

East coast of India ...................................................................................................

...........................

27

TECHNICAL ASSESSMENT OF OTEC COMPONENTS..........................................................

29

Review of historical OTEC configurations ...............................................................................................

3.1.

Technical readiness of OTEC com ponents .....................................................................................

3.2.

- ... ----------..... -------..................

Platfo rm s.............................................................................................3 .2 .1.

Platform mooring systems .....................................................................................................................

3.2.2.

29

. 36

37

3.

38

..39

3.2.5.

Platform-pipe interface ...................................................................................................----....---...

-------.......... 39

Heat exchangers .......................................................................................................--....

40

-------...........

..

Cold water pipe......................................................................................................--..

3.2.6.

Pumps and turbines .............................................................................................------...

3.2.3.

3.2.4.

3.2.7.

3.3.

41

. --------............

--------------............ 42

Power cables ...........................................................................................................-...

Overall state-of-art of OTEC technology ..............................................................................................

42

ECO NOM ICA SSESSM ENT OF OTEC ........................................................................................

44

---------................

M ethodology.................................................................................................----.........-..

4.1.

Cost Analysis ................................................................................................................---..--------.---......

4.2.

OTEC Plants 1 - 10 MW ................................................................................................-----....-----......4.2.1.

OTEC plans 11 - 100 MW .......................................................................................................................

4.2.2.

44

45

47

4.

47

OTEC plants >100 MW (up to 500 MW ).................................................................................................48

48

OTEC Plant scale and costs ....................................................................................................................

4.2.4.

49

Cost drivers for various OTEC com ponents..........................................................................................

4.3.

Uncertainty in cost components...........................................................................................................53

4.3.1.

Com parison of OTEC with other energy technologies........................................................................... 54

4.4.

--... ---------................... 54

Levelized cost of energy......................................................................-......---.....

4.4.1.

4.2.3.

4.4.2.

5.

5.1.

5.2.

5.3.

Comparison of capital cost and O&M costs.........................................................................55

OTEC A ND W A TER SCA RCITY ..........................

............................

........................................

65

........ 65

.

Introduction to seawater desalination .............................................................................

67

. . ---------..............................

..

------OTEC and Desalination ....................................................-..

---......................... 68

A study of water scarcity metrics .........................................................................

5

5.3.2.

5.3.3.

69

W ater Stress Indicator (W SI) .................................................................................................................

Physical and economic water scarcity ................................................................................................

5.3.1.

70

W ater Poverty Index.............................................................................................................................71

73

W ater foot printing ................................................................................................................................

74

................................................................................................--..........................

OTEC

Freshw ater from

76

OTEC Case Study: BAHAM AS ......................................................................................--..........................

5.3.4.

5.4.

5.5.

5.5.1.

Climate and Geology..............................................................................................-------------..........--------77

78

5.5.2.

W ater Supply ..........................................................................................................................--.......

5.5.3.

5.5.4.

79

Regulation.............................................................................................................----...-..-------...........

-----.............. 79

W ater Tariffs ...................................................................................................-.....---.....

5.5.5.

Access to water ...........................................................................................-....--....

5.5.6.

80

..................................

Electricity in the Bahamas..............................................................................81

.....

..................................................................................

OTEC Potential in the Bahamas

5.5.7.

OT H ER BY -PRODUCTS OF OT EC...........................

6.

79

----------................

- -................. ......................................

87

...........

.....

....

Sea W ater Air Conditioning (SW AC) .........................................................................

6.1.

....- ..------.. ...........

Chilled-soil agriculture .......................................................................................-6.2.

-----------....................

M arine culture ......................................................................................-.....---....

6.3.

.---OTEC as an energy carrier........................................................................................................--...6.4.

------------..................

Hydrogen ...............................................................................................-----......---...

6.4.1.

----.... ----------.................

M ethaolnol .....................................................................................................

6.4.2.

6.4.3.

6.4.4.

Am m onia................................................................................................................-.

. ---------.......

Jet Fuel..............................................................................................

87

87

88

88

89

89

89

-...... . ----.............

--------....................

90

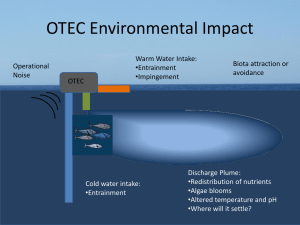

EN V IRONM EN TA L IM PA CT OF OTEC.....................................................................................91

7.

.............. 91

Entrainm ent and im pingem ent of organism s ........................................................................

7.1.

92

Upwelling of nutrient-rich deep ocean water ......................................................................................

7.2.

.----------..... 92

Lowering surface tem perature .....................................................................................--...7.3.

93

Other im pacts ....................................................................................................---------.......-----.----..........

7.4.

93

--------......................

.

.

............................................................................................-Structure

7.4.1.

93

Construction and deployment noise and vibration ............................................................................

7.4.2.

93

....---------......

.......................................................................................................

Seabed disturbance

7.4.3.

7.4.4.

7.4.5.

7.4.6.

7.4.7.

7.5.

8.

8.1.

8.2.

8.3.

8.4.

8.5.

8.6.

8.7.

9.

.--.------....... 94

W ater circulation changes ..........................................................................................94

.......-------.----...................

.............................................................................--Electrom agnetic field

-.............. -------................. 94

Light disturbances....................................................................................-...............95

Chem ical releases ..........................................................................................----..........

Ecological Risk Assessment - Comparison of OTEC with other ocean energy technologies...................95

CO NCLU SIO N .................................................................................................................................

97

98

Attractiveness as a base load generator ...............................................................................................

98

Im portan ce of scale .............................................................................................................----..............

98

Key to the energy-water nexus................................................................................................................

99

Current Challenges..............................................................................................................----.....----..

... ----....... 100

Recom m endation........................................................................................................---...101

Discussion .......................................................................................................................-------------.......

102

Future work .........................................................................................................--------------------.............

SO URCES ......................................................................................

...........................

A PPEN D IX ............................................................................................................................................

-------...... -. 103

110

6

LIST OF TABLES

Table 1: Developing countries with OTEC favorable temperature difference and depth ......................

Table 2: Risks associated with the three different types of platform configurations .............................

Table 3: Estimated capital cost /kW from previous OTEC literature ..........................................................

Table 4: Range of costs in OTEC plants ($/kW installed) ............................................................................

24

Table 5: Levelized cost calculations of various sizes of OTEC plants .....................................................

Table 6: Capacity Factor and levelized costs of various technologies ...................................................

Table 7: Levelized capital costs and O&M costs of various plant types .................................................

57

38

45

52

59

61

64

Table 8: Range of LCOE for various energy technologies .......................................................................

66

Table 9: Average Capacities and costs for seawater desalination technologies ...................................

Table 10: The Bahamas: population and water demand statistics........................................................82

83

Table 11: Capacities and costs of purchasing freshwater in The Bahamas ............................................

84

Table 12: Table to calculate the average price of water........................................................................

111

Table 13: Break-up of cost from previous OTEC cost evaluations studies ...............................................

Table 14: Comparison of risk ranking scores for three different ocean energy technologies..................113

7

LIST OF FIGURES

Figure 1: Schem atic of closed-cycle OTEC...............................................................................................

Figure 2: Schem atic of open-cycle OTEC.................................................................................................

18

20

Figure 3: Schem atic of hybrid cycle OTEC...............................................................................................

Figure 4: Global ocean map showing OTEC resource zones with surface temp. color scale in C ......

Figure 5: Lockheed design of moored OTEC plant (1978) .....................................................................

21

Figure 6: GE tow er design for OTEC offshore plant .................................................................................

Figure 7: PREPA OTEC power plant layout (Proposed)..........................................................................

Figure 8: Design of SOLARAMCO Ammonia plantship (proposed) ........................................................

31

Figure 9: Flow chart for VIW APA OTEC pilot plant ...................................................................................

Figure 10: Schem atic of a 5 M W OTEC pre-com mercial plant....................................................................

Figure 11: Design of an OTEC plant with sub-sea condenser .................................................................

Figure 12: Trend line of capital costs of OTEC plant for increasing plant sizes ......................................

23

30

32

33

34

35

36

48

51

Figure 13: Proportion of costs in historical OTEC designs (n=20)..........................................................

Figure 14: Range of costs of OTEC components (includes estimated from various plant sizes)............52

Figure 15: Levelized capital costs vs. capacity factor for various energy technologies..........................60

62

Figure 16: Comparison of levelized capital costs and O&M costs of energy technologies ....................

Figure 17: Average LCOE for energy technologies within a range of max. and min. values .................. 64

69

Figure 18: Global m ap of W SI taking into account EW R ........................................................................

Figure 19: Global map of physical and economic water scarcity...........................................................70

71

Figure 20: Global m ap of w ater poverty index .......................................................................................

73

Figure 21: Global m ap of w ater stress index .........................................................................................

Figure 22: M ap of the Baham as..................................................................................................................76

96

Figure 23: Comparison of risk ranking scores of ocean renewable energy technologies ......................

0

Figure 24: Ocean map of OTEC resource zones around Americas with surface temp. color scale in C.. 110

110

Figure 25: Equation to calculate LCO E ...................................................................................................

8

1. INTRODUCTION

Energy from the oceans represents one of the largest renewable resources on the planet [1]. Of

the several options to harness energy from the ocean - tidal energy, wave energy, osmotic energy

and ocean thermal energy - ocean thermal energy has the most abundant of resources to the

extent of at least 10,000 TWh/year [1]. This potential, in the context of world electricity

consumption of 16,000 TWh/year, can satisfy most of the global demand for electricity. When

coupled with its by-products such as freshwater and production of fuels, the technology may

offer an attractive option for sustainable energy conversion.

Though the thermodynamics of the ocean thermal energy conversion (OTEC) process are

inefficient and the economics of the technology does not match that of popular renewables such

as wind or solar, availability of abundant and free ocean water makes this an attractive

technology to study. In this study, we aim to understand whether it might be effectively designed

to become cost-competitive with conventional energy technologies or at least with competing

renewable energy technologies.

The open-cycle configuration of this technology uses water as a working fluid and produces

desalinated water as a by-product. This makes it an attractive option for islands and other coastal

locations which have challenges with the supply of both electricity and freshwater. The plantship

configuration has the potential to be a mobile energy carrier, providing energy security for

ocean-based defense applications. There are also applications such as seawater air-conditioning,

marine aquaculturel, chilled-soil 2 agriculture, for huge amounts of cold water that is pumped up

to the surface from the deep ocean. These by-products and applications have the potential to

balance some of the unfavorable economics of the technology and make this a viable solution for

communities worldwide.

The technology attracted scientists and economists alike in the 1970s as the "next big thing" in

renewable energy, due to the spike in oil prices, but fell out of favor a couple of decades later

due to oil's resurgence as the predominant fuel of the world. In the recent years, the renewed

Aquaculture, also known as aqua farming, is the farming of aquatic organisms such as fish, crustaceans, molluscs

and aquatic plants

2 Chilled-soil agriculture is a method of growing produce that circulates cold water through the soil by a method of

condensation, which creates a temperature differential between roots and leaves, simulating the seasons

9

push to adopt the technology is more a sustainable one. Currently there are several attempts

across the world to reinvigorate this technology, which are at different stages of fruition. This

report is a meta-analysis to look at ocean thermal technology with a systems perspective and

offer directions to those who are looking at investing in this technology. It might require several

continued and in-depth studies subsequent to this one, before this technology can be considered

as a preferred source of base load in geographically favorable locations.

1.1.Objective, Scope and Methodology

OTEC's technical and economic viability as a reliable base load electricity supply has been

validated by several engineering evaluations in the past including the experimental work

performed at different government laboratories. Some of the initial apprehensions were around

low cycle efficiency, disproportionate cost estimates compared to value derived from the

technology, lack of potential as a comprehensive solution to national energy problems and of

course the most significant factor of them all, capital-intensiveness. Recent studies and

demonstrations by industry, government and academia have attempted to put things in

perspective but the technology has always been affected by commercialization issues.

The lack of an operational prototype of the technology for most part of the last two decades has

been due to the lack of commitment on the part of government or the private sector to invest and

build a demonstration plant, except for some recent news on the industry taking concrete steps

ahead 3 such as the Lockheed Martin-Makai Ocean Engineering 10MW pilot plant in Hawaii and

the recent Memorandum of Understanding between Ocean Thermal Energy Corporation and the

Bahamian government to build commercial plants4 . There have been projects in the past which

have addressed specific challenges with OTEC implementation but there is yet no single project

that comprehensively addresses the full range of issues for large-scale deployment of this

technology.

The objective of this study was to perform a meta-analysis of existing literature in order to

understand the state-of-art and alternative designs for OTEC technology. The project focused on

assessing the technical readiness of all OTEC components and the economic feasibility of the

http://www.economist.com/node/21542381 accessed 1st Feb 2012

http://www.theonproiect.org/2011/the-bahamas-sign-memorandum-of-understanding-to-build-two-otec-plants/

accessed on 1st Feb 2012

3

4

10

current OTEC technology, especially in comparison to other renewable technologies. The

objective was also to study some of the bi-products of OTEC with a focus on one of them,

freshwater, to study the market and economic feasibility of co-locating its production with

electricity generation. There is also an assessment of environmental impact of building OTEC

plants and its influence on the large-scale commercialization of the technology.

1.2.Methodology

Previous designs and assessment of the technology were reviewed to determine the state-of-art

designs of OTEC and technical readiness of OTEC. The views of several OTEC experts, which

were captured at the National Oceanic and Atmospheric Administration (NOAA) workshop of

November 2009[2], were distilled to identify the critical parameters for major OTEC

components. This was followed by an economic assessment of the technology through

systematic review of cost valuations of twenty-four previous OTEC designs. The cost drivers for

the major components were studied for patterns with respect to scaling the output of an OTEC

plant.

The initial capital cost, the levelized capital costs, the levelized operation and maintenance costs,

and the overall levelized cost of energy for different scales of OTEC plants were compared with

other energy technologies to understand financial viability.

To study OTEC in the context of global energy demand and water scarcity, a systematic review

of water scarcity indices was conducted. These were compared to the OTEC resource assessment

maps to arrive at worldwide regions with high potential for co-locating electricity and freshwater

production through open-cycle OTEC plants. This was further reinforced with the case study of

the Bahamas - a group of islands which are both energy and water-constrained - as a potential

market for co-locating generation of both products.

The final part of the research includes a study of other by-products of this technology followed

by an assessment of the environmental impact of this technology on the marine and shore

ecosystem and how its impact compares with those of other marine renewable energy

technologies.

11

1.3.Thesis organization

The second chapter introduces the concept of ocean thermal energy conversion (OTEC),

discusses the evolution of the technology through history, followed by thermodynamics of the

technology and the various options of the Rankine cycle that are possible for OTEC plant

configurations. There is also a discussion on the favorable worldwide markets for this technology

and previously deployed demonstration plants.

The third chapter discusses the state-of-art for the major components of an OTEC system. It

begins with the evolution of OTEC plant designs by looking at some of the popular

configurations. It talks about the latest technical thinking on seven major cost components platforms, platform mooring systems, platform-pipe interface, heat exchangers, cold water pipe,

pumps and turbines, and power cables, and provides the cost drivers of the components based on

the technical assessment and the scaling impact for each of the components.

The fourth chapter identifies the cost drivers for OTEC systems and analyzes the evolution of

OTEC costs from previous OTEC literature. The main cost components of an OTEC system are

then distilled and their impact on the overall cost of the system is studied. The uncertainties

associated with each of the cost components are also discussed. There is also a comparison of the

capital costs and the levelized costs of electricity for OTEC with other electricity generation

technologies.

The fifth chapter discusses the relevance of OTEC in the context of water scarcity. It explores

some models of water scarcity to identify the areas of water scarcity that overlap that with the

OTEC-friendly locations worldwide. This is followed by a case study of the Bahamas (which is

electricity and water-constrained) where OTEC is evaluated as a favorable technology to cogenerate electricity and freshwater, making a case for a sustainable technology for island nations

in the future.

The sixth chapter discusses some of the other by-products of OTEC such as sea water airconditioning (SWAC), chilled-soil agriculture, marine aquaculture, mineral extraction and OTEC

as an energy carrier, used in the production of hydrogen, methanol, ammonia and jet fuel.

12

The seventh chapter focuses on the environmental impact of OTEC followed by a discussion of a

framework for assessment of the risks posed by this technology compared to other marine energy

technologies.

Finally, in the eighth chapter we conclude and validate the hypothesis about the viability of

OTEC, current challenges with commercialization, recommendations and conclusions of this

study. It is followed by the key topics of future research and development that can be pursued to

get a better understanding of this technology.

13

2. OCEAN THERMAL ENERGY CONVERSION

2.1. OTEC as an renewable energy technology

OTEC is a renewable solar source of energy as the ocean is a massive natural receptacle for solar

energy. Annually the ocean absorbs energy from the sun, an amount equivalent to several

thousand times the primary energy demand of the planet [3]. This energy is stored as heat in the

upper surface layers of the oceans (35-100 meters) and redistributed between the ocean and

atmosphere causing winds, waves, clouds, rain and warming up of the polar regions. At these

depths, the temperature and salinity is uniform in the ocean. In most tropical coastal regions of

the earth, the average temperature of these surface layers is between 27 and 29 'C. Beneath these

shallow layers, the water temperature drops to about 4 - 5 'C as the depth increases to about

1000 m. Beyond this depth, the temperature drops only a few additional degrees even at an

average ocean depth of 3650 meters [4]. The cold water that is below 1000 m is melted from the

polar regions and stays in the ocean depths due to its higher density and mixes minimally with

the warmer water layers above it. This creates a dual oceanic structure of warm water at the

surface and cold water at depths beyond 1000 m, where possible. OTEC uses this temperature

difference between surface ocean water and deep ocean water to operate a heat engine and

produce electricity. To bring the cold water to the surface, OTEC plants require a large diameter

intake pipe called the cold water pipe, which is submerged more than 1000 meters to access the

cold water.

OTEC works best when the temperature difference between the surface of the ocean and the

deep ocean water is at least 20 'C. The surface layers of the ocean act as a natural energy storage

body permitting the OTEC plant to operate 24 hours per day. For continuous operation, it is

important that this temperature difference is consistent and available throughout the year.

2.2. Water-energy nexus

As per a UNICEF report [5], one of mankind's most serious challenges in the

2 1st

century will

be a lack of adequate fresh water supply. Population growth, climate change and water

pollution can lead to a drastic decline in the water supply worldwide. In 2010, about 80% of

the world's population lived in areas with an impending threat to water supply [6]. Water

14

scarcity may become a main driver of OTEC plant adoption in several geographies of the

world. The oceans cover 70% of the Earth's surface, making them the largest repository of

unconverted energy and potential desalinated water[4]. OTEC plants can generate clean,

renewable consistent electricity, desalinate water and also support a marine aquaculture

economy which can power some of the island nations in the OTEC-friendly belt5 . Though the

initial costs to install these plants are significant, governments are evaluating support to these

types of projects to infuse the grid with alternative and sustainable sources of power, solve

freshwater and food issues and create additional jobs.

2.3. History of OTEC

The concept of OTEC originated in 1881 by D'Arsonval who proposed the initial concept based

on the thermodynamic Rankine cycle using the closed-cycle concept with ammonia as the

working fluid[7]. Georges Claude, a French engineer and former student of D'Arsonval,

demonstrated the feasibility of this concept in 1928 in Ougree-Marhaye in Belgium using warm

water at 30 0C from a steel plant for the evaporator and cold water at 10 0C from the Meuse River

as the condensing fluid[8]. This test achieved turbine speeds of 5000 rpm and a power output of

50 kW. The success of this test helped Claude get financial support in 1930 for an OTEC

demonstration project 1600m off the shore of Mantazas bay in Cuba. This 50 kW project was

operational for 11 days before the cold water pipe was destroyed in a storm [3]. In 1933, Claude

installed an open-cycle plant off the coat of Brazil, for ice production on a 10,000-ton barge

Tunisie. Designed with a turbine shaft power of 2000 kW of which 1200 kW were to be used for

producing ice, the project was abandoned during deployment due to an unsuccessful attempt to

attach the cold water pipe suspended from a semi-submersible float [9]. Despite these financial

losses, Claude proposed a 40MW plant at Abidjan, Ivory Coast, in 1940 to the French

government but the project proceeded slowly until 1948 when the government set up the

company "Energie de Mer" with objectives to develop the concept. However this project too was

abandoned in favor of a large hydro-electric plant in Abidjan. This was the end of active French

interest in the technology [10].

s OTEC-friendly belt is defined are the regions of the water with favorable temperature difference between surface

and deep ocean water, elaborated further in this report.

15

Subsequently there was no commercial activity in OTEC until the late 1970s when Lockheed

Corporation, the Dillingham Corporation and Hawaii State government completed an at-sea test

of the OTEC system christened "Mini-OTEC" in August 1978 which successfully produced a net

of 18 kW for 3 months before its planned shutdown [9].

The next major advancement came in 1980 - 1981 with the experimental OTEC-l project at

Kalua-Kona, Hawaii, by the US Department of Energy program aboard a modified T-2 tanker,

Chepachetwhich served as a floating platform. This facility did not have a turbine-generator as it

was not designed to generate electricity; rather, it was designed as a platform to test various

OTEC-related technologies such as the platform, cold water pipe, the mooring systems, energy

transfer systems and heat exchangers. Though it was terminated in May 1981 due to funding

restrictions, OTEC-1 reached several milestones: successful deployment of a 670 meter long

cold water pipe, mooring in 1,370 m of water, successful operation of the cold water pipe during

wind, wave and current changes, operation of a shell-and-tube heat exchanger in a closed

ammonia cycle at 38MW heat duty and demonstration of biofouling control with low-level

chlorine injection.

In 1980, Saga University conducted OTEC experiments off the coast of Shimane and in 1981-82,

a 100 kW gross power land-based plant was set up in the republic of Nauru[ 11]. Most of these

were experimental programs initiated to support the OTEC design with data on advanced

materials, design methods and processes. In 1986, following a drop in oil prices, there was a cut

back in the funding of OTEC projects but small-scale studies and experiments have continued in

various parts of the world until a land-based OTEC facility on the island of Hawaii successfully

operated from 1993 to 1998, and produced a net 103 kW, still the world record for OTEC

output[ 12].

The results from all these design studies, tests and pilot projects indicate that there is enough data

available for commercially scaling up OTEC systems. Most tests have focused on ammonia as a

working fluid in a closed Rankine cycle (except for Nauru, 1981 where Freon was used) due to

its superior thermodynamic and thermal characteristics. Also, there is significant operational

experience with commercial and industrial ammonia refrigeration, which is essentially an OTEC

closed-cycle system in reverse operation.

16

Recent spatial studies [13][14] estimate maximum steady-state OTEC resources in the range of

3-5 TW which is more than the annual electricity demand of the planet. Hence OTEC still has a

favorable case for feeding into the base-load demand in locations where the technology can make

economic sense.

In recent developments, the US Department of Energy (DOE) awarded a $ 1.2 million contract to

demonstrate how the special cold water pipe can be designed and fabricated to carry large

volumes of seawater for commercial-sized OTEC plants. This was followed by a two grants

worth $ 1 million awarded to Lockheed Martin in 2009. The first one was to develop a

Geographic Information System (GIS)-based tool to estimate the energy that can be extracted

from OTEC and identify sites favorable for OTEC and seawater air-conditioning. The second

grant was to study life-cycle costs to demonstrate economic feasibility of utility-scale OTEC

systems. Seawater air-conditioning has been successfully demonstrated in recent district cooling

projects at Hawaii, Canada, Netherlands and Sweden by Honolulu Seawater Air Conditioning,

LLC6 .

2.4. The thermodynamics

2.4.1. Closed-cycle

There are two principal configurations usually proposed for OTEC. One is the closed-cycle as

shown in [Figure 1]. In the closed-cycle configuration, there is a working fluid, usually ammonia,

which is in a closed flow path. The working fluid is boiled using the heat from the warm ocean

water using the hot water pipe in a heat exchanger called the evaporator. The working fluid

vaporizes, passes through the turbine, turns a generator and produces electricity.

Then the

working fluid is condensed using a cold water pipe seawater system in another heat exchanger

called the condenser. For the closed-cycle configuration, the working fluid should have specific

thermodynamic properties so that maximum energy may be extracted per cycle over the

temperature limits difference of around 20 0C. Usually a temperature difference of 20 0 C or

greater is required for a net positive generation of energy. Compared to a conventional power

plant where the temperature difference is in the order of hundreds of degrees Celsius, this

temperature difference is minimal and might even be considered infeasible in the conventional

6

http://honoluluswac.com/casestudies.html accessed on Feb 4, 2012

17

plants. This lower temperature difference leads to a lower Carnot efficiency 7 . Hence, if the

OTEC power plant is supposed to produce useful amounts of power, it will require large amounts

of both the heat source and the sink with large surface areas for both heat exchangers - the

evaporator and the condenser.

woring

LP

Turbine

synchronous

generator

AC

system

fluid ,

automatic

volt11age

regulator

system

condenser heat

exchanger

Source: [15]

Figure 1: Schematic of closed-cycle OTEC

The evaporator is one of the key elements in the design of the OTEC system since the loss of

efficiency is determined mainly by this component. Several designs of evaporators with

reasonable coupling of warm water and working fluid have been tried in the past. Deposition of

living organisms on the inflow pipes and the degradation of surfaces by biological entities, called

biofouling, which plagued some of the earlier designs, have also been addressed in the recent

designs. Another solution to the problem of bio-fouling has been by using the hot water pipe

intake at some point well below the actual sea surface: usually about 30 m but increasing the

Carnot cycle efficiency is the efficiency of an ideal reversible engine cycle called the Carnot cycle, a theoretical

thermodynamic cycle proposed by Nicolas Leonard Sadi Carnot

18

depth of intake lowers the temperature at the warm water intake thus reducing the efficiency of

the process and power output [15].

The condenser heat exchanger is another important component of the OTEC plant design as

optimum condensation of the working fluid requires a specified volumetric flow rate of cold

water. The auxiliary power required to pump the cold water has a direct impact and reduces the

net electrical power output. Other significant auxiliary power consumption areas are warm water

pumping, working fluid pumping, excitation system requirements and control system

requirements [15].

Though several studies on OTEC have suggested different working fluids, ammonia was the

original fluid proposed by D'Arsonval and was the fluid used in the "mini-OTEC" plant which

operated successfully off the coast of Hawaii [16]. Subsequent studies have indicated that

ammonia is the best theoretical fluid because of favorable thermodynamics.

2.4.2. Open-cycle

In the open-cycle OTEC as shown in [Figure 2], the working fluid is the warm seawater from the

surface of the ocean. Warm seawater is brought to a low-pressure chamber to boil and the

corresponding steam expansion drives a very low-pressure turbine. The condensation of the

steam is accomplished using the cold seawater brought up by the cold water pipe from the deep

ocean.

19

AC

system

generator

.

cold water

AVRI

voltage

regulator

i

pump

condenser

precooler

exhaust

intake

Source: [15]

Figure 2: Schematic of open-cycle OTEC

The low-pressure environment is attained in a specially designed vacuum vessel that is integrated

with the low-pressure steam turbine. The steam exiting the vacuum vessel is salt free, and when

condensed, the discharge is a desalinated one. The open-cycle process has an advantage over the

closed-cycle process because it eliminates one of the heat-exchangers in the process and also has

a by-product of economic value, fresh water. The challenge in this configuration is the platform

size which is almost twice the size as that of the closed-cycle architecture for the same power

output.

20

2.4.3.

Hybrid Cycle

Source: [17]

Figure 3: Schematic of hybrid cycle OTEC

There is also a proposed third-concept of OTEC which is a hybrid of the open-cycle and closedcycle design [17]. The main advantage of the hybrid cycle is that it can produce power in the

closed-cycle and fresh water in the open-cycle. In this design both seawater and the closed-cycle

working fluid are used in combination. The same vacuum vessel is used for flashing seawater

into steam to produce desalinated water as well as the evaporation of the second working fluid

through heat exchanged with the warm seawater. The second fluid is physically mixed with the

warm seawater in an effervescent two-phase, two-substance mixture. The evaporated second

working fluid is separated from the steam/water, and re-condensed as in the closed-cycle design.

The phase change of the sea water/second working fluid combination results in useful work to

drive a low-pressure turbine.

Other advantages of the hybrid-cycle over the pure open-cycle is that a commercially available

ammonia turbine can be used to produce power compared to a large-diameter low-pressure

21

turbine and condensation can take place at a higher temperature increasing the fraction of

recoverable thermal energy as well as reducing auxiliary power requirements to remove noncondensable gases.

2.5.Market locations for OTEC

Sixty percent of all seawater originates from the Polar Regions. The Atlantic and North Pacific

oceans are fed by Arctic seas and all other major oceans are fed by Antarctic seas. Therefore,

temperature of cold water at a given depth, approximately below 500 m, does not vary much

throughout all OTEC regions. It is also a weak function of depth, with a typical gradient of 1 C

per 150 m between 500 m and 1000 m and this gradient dropping even further, below the 1000 m

depth. Previous studies have shown that if the appropriate sites are chosen with the natural

resources and the socio-economic conditions favoring a market for OTEC by-products [3][18],

the technology can be viable.

A US DOE study in 1981 identified ninety-eight nations and territories with access to the OTEC

thermal resource (20 'C temperature difference between surface water and deep ocean water)

within their 200 nautical miles EEZ . For countries in the Caribbean and the Pacific, the thermal

resource is available throughout the year round and OTEC-friendly 9 deep ocean water is

relatively close to the shore. These conditions make these the most attractive sites for costeffective commercial OTEC plants. These sites can support land-based, shelf-mounted or

moored platform designs.

Favorable OTEC thermal resource regions across the world are:

"

Equatorial waters between 10'N and 10'S are the first choice but there are concerns raised

for the west coast of South America due to temperature inconsistencies through the year,

especially impacting the surface temperature during the winter months [19].

*

Equatorial tropical waters stretching to 20'N and 20'S, again with exceptions of West Coasts

of South America, Southern Africa, West Coast of Northern Africa, Horn of Africa and off

the Arabian Peninsula due to similar weather temperature inconsistencies.

8

9

Exclusive Economic Zone

Depth of 1000 meters

22

*

Countries along the east coast of Africa, Central and Latin American Islands and Islands in

the Pacific Ocean.

BON-

60N

40N

20N

EQ

20S

40S

60S

BOS

20E

46E

66E

-1.5

BE

0

120E

1&0E

2

4

6

140E

160E

8

10

180

12

160W

14

16

140W

18

120W

20

100W

22

BoW

24

66W

26

28

46W

30

20W

0

20E

32

Source: http://polar.ncep.noaa.gov/sst/oper/global sst oper0.png accessed Feb 2, 2012

Figure 4: Global ocean map showing OTEC resource zones with surface temp. color scale in0C

Some of the specific regions within the above OTEC resource zones, extracted from the hightemperature difference zones in Figure 4 are:

*

Gulf of Mexico region covering the coastal regions of southeast Florida and the east coast of

Mexico

" The coastal regions of the Caribbean Sea including the countries of Guatemala, Honduras,

Nicaragua, Costa Rica, Panama, Cuba, Dominican Republic, Puerto Rico, Colombia and

Venezuela

*

In the North Atlantic Ocean, Guyana, Surinam, French Guiana and a small part of the

Northern coast of Brazil

"

North Western African countries of Guinea, Sierra Leone and Liberia

23

*

In the Indian Ocean, the southern coastal regions along the Arabian Sea and the Bay of

Bengal in India, Sri Lanka, Burma, Thailand, Malaysia, Singapore, east coast of Africa along

the states of Somalia, Tanzania, Mozambique and the island of Madagascar.

* Northern coast of Western Australia, Northern Territory and some parts of Queensland and

Papua New Guinea

" Several islands in regions of the South China Sea including Cambodia, Vietnam, Philippines

and Indonesia

Some of the countries in this list are developing islands nations. These regions with the requisite

OTEC temperature differential and the ocean shelf depth gradient for a near-shore OTEC plant

are attractive markets for this sustainable energy source.

Table 1: Developing countries with OTEC favorable temperature difference and depth

Country/Area

Temp. Diff (*C) between

Distance from

2010

0 and 1000 m

Shore (km)

Population (million)

Africa

Benin

22-24

25

8.8

Gabon

20-22

15

1.5

Ghana

22-24

25

24.4

Kenya

20-21

25

40.5

Mozambique

18-21

25

23.4

22

1-10

0.2

Somalia

18-20

25

9.3

Tanzania

20-22

25

44.8

S5o Tom6 and

Principe

Latin America and Caribbean

Bahamas, The

20-22

15

0.3

Barbados

22

1-10

0.3

Cuba

22-24

1

11.3

Dominica

22

1-10

0.1

Dominican Republic

21-24

1

9.9

24

Grenada

27

1-10

0.1

Haiti

21-24

1

10.0

Jamaica

22

1-10

2.7

Saint Lucia

22

1-10

0.2

22

1-10

0.1

Trinidad and Tobago

22-24

10

1.3

U.S. Virgin Islands

21-24

1

0.1

Saint Vincent and the

Grenadines

Indian and Pacific Ocean

Comoros

20-25

1-10

0.7

Cook Islands

21-22

1-10

0.0

Fiji

22-23

1-10

0.9

Guam

24

1

0.2

Kiribati

23-24

1-10

0.1

Maldives

22

1-10

0.3

Mauritius

20-21

1-10

1.3

New Caledonia

20-21

1-10

0.3

Philippines

22-24

1

93.3

Samoa

22-23

1-10

0.2

Seychelles

21-22

1

0.1

Solomon Islands

23-24

1-10

0.5

Vanuatu

22-23

1-10

0.2

Source: http://www.nrel.gov/otec/design location.html

2.6.Siting characteristics for OTEC plants

To site shore-based plants or moored/floating plantships, there are specific characteristics for a

location to qualify as a potential OTEC site:

25

2.6.1.

e

Shore-based

Consistent source of warm surface seawater close to the shore, relatively clean of pollutants this is to avoid additional effort required to clean the warm water taken in by the OTEC

system

" Typical tropical weather with a mean annual surface water temperature of at least 25'C

*

Steep offshore slope quickly reaching depth of 1000 meters within a few kilometers of the

coast. Since water temperatures at these depths are the same worldwide (about 5'C), the

temperature difference will be about 20'C, the minimum considered necessary for OTEC

" A shore site suitable for construction activities including excavation.

" Elevation of an OTEC plant as close to sea level as possible to minimize pumping-power

requirements.

" Offshore topography that is suitable for deploying the cold-water pipe. The topography

should be conducive to the pipe design, which has evolved from corrugated-steel pipe

sections, flanged and bolted together (as used by Claude in his early design) to a Fiberreinforced-plastic design anchored to the bottom by weights.

2.6.2.

Moored/Floating Plantships

Similarly, there is set of suitable siting characteristics for locating OTEC plantshipsl" which may

be moored or floating in a specified geographical area [20]:

e

Water temperature differences between surface and the deep ocean water exceeding 20'C

" Surface temperature of 25'C or greater

*

Surface currents less than 1 kph"

" Deep currents less than 0.4 kph

" Winds of 13-30 kph

" Wave height < 4 meters

10 Vessels designed to use temperature differences in ocean water while floating unmoored or moving through

such water, to produce electricity or another form of energy capable of being used directly to perform work, and

includes any equipment installed on such vessel to use such electricity or other form of energy

1 Kilometers per hour

26

2.7.OTEC Demonstration Case Studies

There have been several demonstrations of OTEC in the past several decades. All these studies

have helped further the cause of the technology by helping scientists and engineers understand

some part of the OTEC system better. A few of the most popular demonstrations studies are:

2.7.1. Hawaii

One of the first-ever OTEC plant was commissioned in 1979 in Hawaii. It was an offshore

demonstration 50 kW closed-cycle plant which used up 40 kW in running the plant and produced

10 kW as the net output. The platform was moored by using a 30,000 lb weight. Cold water at a

temperature of 4.4'C was drawn from a depth of 670 m. Ammonia was used as the working fluid

and the cold water pipe was made out of Polyethylene to reduce bio-fouling which was one of

the biggest concerns for the cold water pipe then. The heat exchangers were made out of

Titanium. At 120 hours, it was one of longest continuous running time of an OTEC plant [3].

2.7.2. Nauru

The Hawaii demonstration plant was followed by a 100 kW land-based plant in the Republic of

Nauru in October 1981 built by Japan. The system operated with a temperature difference of

about 20'C between the surface water and the cold ocean water at a depth of 500-700 m. A

depth of 580 m was covered by pipeline length of 945 m. The heat exchanger tubes were surfacetreated with titanium to improve performance. Freon-22 was used as the working fluid. Freon-22

was considered less harmful to the environment compared to ammonia. Again the material used

for the cold water pipe was polyethylene. This project tested the load response characteristics,

turbine, and heat exchanger performance tests. The results were fairly satisfactory with the

efficiency of the turbine recorded at over 80%. The plant achieved a continuous power

generation of 31.5 kW and an operational record of 10 days.

2.7.3. East coast of India

National Institute of Ocean Technology (NIOT), India, built a 1 MW floating plant off the coast

of Tamil Nadu close to Tuticorin in the South east coast of India. The plant was integrated on a

floating barge and had a gross power generation capacity of 1 MW and net power of 500 kW.

The plant was supposed to have ammonia as a working fluid with evaporators coated with

27

special steel on the ammonia side to enhance nucleate boiling. Power was generated through a

four-stage turbine. The floating barge was to be moored on a single point mooring at a depth of

1200 meters by using a one-meter-diameter high-density cold water pipe made of polyethylene.

The project was abandoned because of problems that crept in while deploying the pipe to the

platform. Following this incident, the project shifted focus to desalination using the OTEC cold

water pipe.

28

3. TECHNICAL ASSESSMENT OF OTEC COMPONENTS

3.1.Review of historical OTEC configurations

One of the earliest configurations for an OTEC project was the design of an OTEC plantship to

produce ammonia via hydrogen[20]. A baseline 100 MW OTEC plantship design was developed

with an output of 313 tons of ammonia per day. This design was then extrapolated to a 500 MW

ammonia and liquid hydrogen plantship which could produce ammonia at very competitive costs

compared to the then prevailing market prices of ammonia by the sixth subsequent ship that

could have been built for this purpose. The major cost drivers of this design were the platform,

heat exchangers and the ammonia plant which would use the electricity produced on-board to

convert electrolytic hydrogen into ammonia.

This was followed by a pure electricity-production design [21] based on a 240 MW spar-type

configuration which was designed specifically for survivability and station-keeping as the

initially proposed locations for OTEC plants were along the Gulf of Mexico and off the Florida

coast, which were hurricane belts. In this configuration, most of the structure was under the

surface of water, shielded from hurricane winds and waves. The configuration consisted of four

major systems; the platform, the cold water pipe, the mooring, the anchor and the power modules

[Figure 5]. The power module consisted of the two large heat exchangers, turbo-generators,

pumps and the power conditioning equipment with the entire module detachable for periodic

maintenance. Of the two types of heat exchangers that were proposed for this configuration,

costs of the aluminum-tube heat exchangers were cheaper than the titanium-based one by $ 100

million.

29

POWER

MODULE

,-SWIVEL-TRAPEZE

MOORING SYSTEM

PREVENTS PIPE

FROM ECOMING

ENTANGLED AS THE

POWER PLANT ADJUSTS

TO CHANGING

COLD

CURRENTS

WATER

PtPE

POWER CABLE

TRANSMITS

ELECTRICITY

TO SHORE

ANCHOR

Source: [21]

Figure 5: Lockheed design of moored OTEC plant (1978)

Some of the other conceptual designs proposed historically include two tower-mounted designs One design was the General Electric (GE) tower-mounted OTEC facility [Figure 6] which was

planned to be at Kahe Point, Oahu, Hawaii with a cold water pipe made of steel along the sloping

sea bottom with modular components for power production, pumps, and heat exchangers with a

plan for convenient transfer of components to and from their mounting positions on the tower via

elevators, semi-automated subsea transfer equipment and derricks. The second was a similar 40

30

MW tower-mounted plant [Figure 7] sited close to the shore on the continental shelf off Punta

Tuna, Puerto Rico proposed by Puerto Rico Electric Power Authority (PREPA).

Source: [3]

Figure 6: GE tower design for OTEC offshore plant

31

2

E

Legerid

Water intake

Waterdscharge

working fluid

Source: [3]

Figure 7: PREPA OTEC power plant layout (Proposed)

Other designs such as the 40MW OTEC grazing plantship was proposed by the solar Ammonia

Company (SOLARAMCO) to be situated south of Hawaii for ammonia production. This design

used a concrete-based barge-type hull with rotatable thrusters provided below the hull for seakeeping and grazing [Figure 8].

32

Helo pad

Pincipal dimensions

Length

180rn

NH3

process

plant

~Beam

Depth

.

..

8

Draft..-------..

.... 20m

Displacement FL -110

000t

360 deg.

CWP (7m x 1000m FRP)

steerabile

thrusters (4)

Source: [3]

Figure 8: Design of SOLARAMCO Ammonia plantship (proposed)

One of the earliest designs of a combined electricity and water production OTEC design was

proposed by Virgin Islands Water Power Authority (VIWAPA) as a 12.5 MW shelf-mounted

tower delivering 10MW of electricity and 190,000 m 3 of fresh water with a portion of the

discharged cold water used for marine culture experiments [Figure 9].

33

Retum to sea 230 to 26"C

Source: [3]

Figure 9: Flowchart for VIWAPA OTEC pilot plant

There have also been detailed evaluation of economic feasibility and financial viability of OTEC

by Vega [12], [19], [22] that showed that in Hawaii, plants would have to be floating platforms

sized at about 50-100 MW and any size smaller than that might not be cost-effective. The plant

design was based on a closed-cycle for electricity production and on a second stage, using the

effluent water streams from the power cycle, for desalinated water production. This facility

included ammonia as the working fluid. The design of a pre-commercial floating hybrid OTEC

plant [Figure 10] had an open-cycle process housed in a barge or ship with the electricity

transmitted to shore via a submarine power cable and the desalinated water via a small hose pipe

34

000

wowee

WOe

ploacubo*i

wat

Pr~?

f

),I'

W

Water

c.~irae~

L1s*AE

Pamp

wow

Cv.rg'o

WIIrh;

Wwe

Infl I

QNC damoaus

(2) Condener

(2) EvIraw

175m (L) x n em

1S (4 x Ime

(2) TuAnsU4n,: 14.4m1 (LI x 3m0 e

(1) WP St Eva: ISm (H)X9.m e

(W VIBM (L) X1A (H)

(1) WP 8 Cond i

(1) W&M Wa rk e in x Ne

x 1000n (4 m

(1) Cll Was Pp; &Sa

(1) Mood W&y Dcttwg Pot 5.11 * x M0T(L)

Platifort

LanO - itEm

areamt - 30M

splacemens -2C000

MT

Source: [12]

Figure 10: Schematic of a 5 MW OTEC pre-commercial plant

Recently, there has been new architecture explored [23] in the form of a 100 MW floating vessel

OTEC plant designed with the purpose of reducing capital costs. The main difference in this

technology was the shifting of the condenser from near the surface to the deep ocean, alleviating

OTEC's main challenge of pumping cold ocean water to the floating vessels through cold water

pipes. This architecture was proposed to reduce the costs and technical problems related to large

OTEC systems. When the condenser is placed in a colder environment, the efficiency of the

condenser is improved too. And the coldwater pipe is now not directly exposed to the harsh

ocean environment. However, the supporting vessel for the condenser has to be specially

designed for this application. There are several cost-saving elements associated with this new

configuration to the extent of upto 45% compared to conventional OTEC capital costs in the

form of reduced platform costs, evaporator costs and installation costs.

35

Warm Water - o

A40'4m

~~~~~ 3010 feet below Sea Level

Cold Water -i]

Source: [24]

Figure 11: Design of an OTEC plant with sub-sea condenser

3.2. Technical readiness of OTEC components

NOAA's Office of Ocean and Coastal Resource Management (OCRM), in cooperation with the

Coastal Response Research Center (CRRC) collaborated on a workshop in November 2009 to

compile qualitative information[2] utilizing the knowledge of several experts in the field to focus

on the state-of art of OTEC components and technical readiness of the technology to be scaled to

a size greater than 100 MW. This effort identified seven critical components of any OTEC

system as the limiting ones for advancement of this technology. They are:

1) Platform

2) Platform Mooring Systems

3) Platform/pipe Interface

36

4) Heat Exchangers (HX)

5) Power Cable

6) Pumps and turbines

7) Cold water pipe

3.2.1.

Platforms

Since the 1980's, developments in meteorological and oceanographic data gathering methods,

primarily driven by the petroleum industry, has led to more reliable and weather-resistant

platform designs. Three platform designs have been identified as being most feasible for OTEC

projects: semi-submersible, spar, and (mono-hull) plant ship. All these three designs have been

tested and operational in other industries such as offshore oil, wind farms, etc. There are no

significant challenges for their use in an OTEC application.

The life cycle of a platform in an OTEC facility has well-established procedures. Monohull

manufacturing uses a Floating, Production, Storage, and Off-loading Unit (FPSO) for

construction while semi-submersible platforms have standard offshore rig fabrication procedures.

Spar platforms present the most difficulties for installation and operation because they require

deepwater work, which increases the risk and complexity of the project. However, the spar

configuration is most favorable for the cold water pipe attachment because there is less variable

motion at the joint [25]. Also, the platform should be either built on-site or transported from an

offsite location, depending on the OTEC system requirements. Operation and maintenance

procedures for these platforms are well-established and include maintenance of machinery and

removal of biological growth on the submerged sections. Decommissioning of platforms is

regularly performed in other industries and should not cause significant challenges for OTEC

facilities. Though OTEC can heavily borrow platform technology from other mature industries,

there should be unique standards for all the OTEC equipment/technology. The standards can lay

the ground for interoperability for various components and support innovation specific to this

industry.

37

Table 2: Risks associated with the three different types of platform configurations

Platform Type

Arrangement

difficulty

Cost

Technical

Readiness

Small

Medium

Medium

High

Small

Medium

High

Low

Medium-High

Low

Medium

High

Motion/

survivability

risk

Semisubmersible

Spar

Ship

shape/monohull

Source: [2]

3.2.2.

Platform mooring systems

This technical readiness of this component also been influenced by advancements of similar

components in other industries. Deep water platform mooring technologies have made the most

advancement in the past three decades increasing the depth limit from a few hundred meters in

1980s to several thousand meters in the past decade [26]. Mooring platforms can also borrow

technology from the offshore oil industry which uses similar platforms in a more demanding

environment. Technologies such as GPS and high-resolution Sound Navigation and Ranging

(SONAR) along with software which aid precision-modeling of platform moorings have enabled

enhanced mooring systems.

Design, fabrication, and construction of the platform mooring components are established as

standardized procedures with customization procedures varying with increasing platform size,

weight, bottom slope and exotic seafloor characteristics.

Mobilization, deployment and

decommissioning of platform mooring, though labor-intensive and expensive, have also been

identified as processes that can be borrowed from the offshore oil industry with minimum

customization. Installation, operation and maintenance of the platform mooring components are

relatively simple and reliable with existing technology. Maintenance focuses on periodic

replacement/repair of integrity monitoring instrumentation and mitigating the impact of marine

fouling on equipment. Bio-fouling is seen as a major risk and deviation for deep-sea OTEC

projects compared to near-shore oil platforms [17]. Bio-fouling will have a major impact on the

lifespan of the equipment, the load carrying capacity of the equipment and resulting maintenance

schedules. For initial prototype plants, the current mooring technologies are adequate in terms of

38

materials, design and fabrication but challenges can be anticipated as the plant's output goes

beyond 100 MW.

3.2.3.

Platform-pipe interface

Since the 1980s, significant advances in material science along with sensor and modeling

technology have helped the OTEC industry to design lighter, stronger and durable platform-pipe

interfaces. The experience of the industry until now has been with pipes -1 m diameter and this

can challenge the feasibility of 10 meter diameter pipes for 100 MW. The offshore oil industry's

expertise in multiple risers up to 1 meter diameter can be scaled for large OTEC applications.

The currently accepted platform pipe interface designs are:

*

Flex pipe attached to a surface buoy,

" Fixed interface

" Interface with a gimbal

Fixed and gimbal interfaces are considered simpler to design and manufacture compared to flex

interfaces. The fixed interface has a simpler maintenance process and can be scaled easily to

larger facilities, compared to flex and gimbal interfaces. The flex and gimbal interfaces are prone

to frequent maintenance and cleaning due to additional fatigue points and connections.

Horizontal interfaces are difficult to deploy compared to vertical interfaces and the ability to

detach the cold water pipe also adds complexity and costs to the interface. There is still no clear

technical anticipation of the special requirements of custom platform-pipe interfaces for large

OTEC facilities. In the past, the platform-pipe interface has been a vulnerable component for

failure, either due to loss of the cold water pipe or leakage issues at the interface. Local climate,

currents and wave patterns, the ability to couple/decouple the cold water pipe will impact the

overall complexity of design of the system.

3.2.4.

Heat exchangers

Advances in heat exchangers since the 1980s have been primarily driven by industries such as

aerospace, power plant, petroleum, cryogenic, Liquefied Natural Gas (LNG), geothermal, etc.

Today heat exchangers have improved heat transfer co-efficient due to the use of new materials

such as cost-effective titanium, aluminum alloys and plastics. Fabrication processes and surface

39