by MAR 0 8

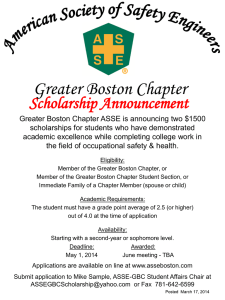

advertisement