Volatiles Production and Lipid Oxidation in Packaging and Storage

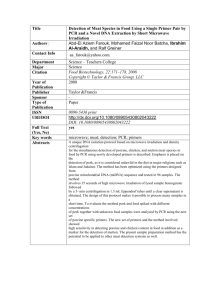

advertisement

JOURNAL OF FOOD SCIENCE CHEMISTRY/BIOCHEMISTRY Volatiles Production and Lipid Oxidation in Irradiated Cooked Sausage as Related to Packaging and Storage D. U. Ahn, D. G. Olson, C. Jo, J. Love, and S. K. Jin ABSTRACT Irradiation dose affected production of volatiles in vacuumand aerobic-packaged cooked pork sausage, but its effect on TBARS was minor. Storage increased production of volatiles and changed their composition only in aerobic-packaged sausage. Among volatile components, 1-heptene and 1-nonene were influenced most by irradiation dose, and aldehydes by packaging type. TBARS and volatiles of vacuumpackaged irradiated cooked sausage did not correlate well. However, TBARS had very high correlation with amount of aldehydes, total volatiles, ketones and alcohols with long retention times in aerobic-packaged pork sausage. Heptene and 1-nonene could be indicators for irradiation; and propanal, pentanal, and hexanal for oxygen-dependent changes of cooked meat. Key Words: irradiation, TBARS, volatiles, packaging, pork sausage INTRODUCTION IRRADIATION IS AN EFFECTIVE METHOD FOR MICROORGANISM CONtrol in raw meat and is permitted for use in both poultry and red meat. A major concerns, however, is its effect on meat quality. Irradiationinduced oxidative chemical changes are dose-dependent, and the presence of oxygen affects the rate of oxidation (Katusin-Razem et al., 1992). Lee et al. (1996) reported that pre-rigor beef irradiated with an absorbed dose of 2.0 kGy and stored at 2⬚C in modified atmosphere packaging (25% CO2 and 75% N2), did not show increased lipid oxidation. Al-Kahtani et al. (1996) and Hampson et al. (1996), however, have shown that irradiation at 1.5- to 10-kGy dosages increased thiobarbituric acid (TBARS) values and decreased thiamin and tocopherol levels in turkey breast and fish muscles. Results have indicated that irradiation accelerated lipid oxidation of raw and cooked meat only when they were stored in oxygen-permeable bags after irradiation (Ahn et al., 1997, 1998b). Hashim et al. (1995) showed that irradiating uncooked chicken breast and thigh produced a characteristic bloody and sweet aroma that remained after the thighs were cooked but was not detectable after the breasts were cooked. It was long been known that the precursors of undesirable odor compounds in irradiated meat were water soluble and contained nitrogen and/or sulfur. Methyl mercaptan and sulfur dioxide formed from sulfur (S)-containing compounds (e.g., glutathione) also contributed to irradiation odor. Patterson and Stevenson (1995) reported that dimethyltrisulfide is the most potent off-odor compound, and dietary tocopherol and ascorbic acid reduced the development of off-odor in irradiated raw chicken meat. However, others reported that irradiation had no detrimental effect on flavor of vacuum-packaged raw and cured meat, and electron beam treatment The authors are affiliated with the Dept. of Animal Science, Iowa State Univ., Ames, IA 50011-3150. Direct inquiries to Dr. D. U. Ahn. 226 JOURNAL OF FOOD SCIENCE—Volume 64, No. 2, 1999 had little effect on odor and flavor of reheated meat with sous-vide treatment (Shamsuzzaman et al., 1992). Irradiated raw pork, regardless of packaging, produced more volatiles than nonirradiated patties and developed a characteristic aroma shortly after irradiation (Ahn et al., 1998a). The gas chromatography (GC) profiles of irradiated raw meat showed that irradiation produced many unidentified volatiles that were not major peaks of lipid oxidation. The chromatograms of raw irradiated meat suggested that substances that imparted the characteristic irradiation aroma had low molecular weights, and were highly volatile and difficult to separate (Ahn et al., 1997, 1998a). Although lipid oxidation still may be responsible for part of the characteristic aroma in irradiated meat, other mechanisms, such as radiolysis of proteins, could be important in its production. The effects of irradiation on lipid oxidation in cooked meat would be quite different from those in raw meat. Cooked meat is highly susceptible to lipid oxidation because the cooking process denatures antioxidant components, damages cell structure, and exposes membrane lipids to the environment. Raw meat has very strong antioxidant effects unless it is heated, denatured, or contains added prooxidants. Cooked meat, however, is highly susceptible to lipid oxidation (Ahn et al., 1993). Irradiation studies have been mainly focused on the antimicrobial and certain quality aspects of raw meat and little information on lipid oxidation of irradiated cooked or further processed meat products has been reported. The objective of this research was to determine the effects of irradiation dose on lipid oxidation and volatiles production in cooked sausages as related to packaging and storage time. MATERIALS & METHODS Sample preparation Fresh lean pork (95%) was purchased from a local meat packing plant and ground twice through a 9-mm plate. Sausage was prepared from lean ground pork, backfat (10% of lean meat), salt (2%), ice (7.5%), and 1% soy protein concentrate (90% protein). No spices were added to aviod any potential antioxidant effects or complication of volatile profiles. The sausage was cooked in a smokehouse with steam to an internal temperature of 75°C and chilled in ice water. Half of the cooked sausages were vacuum-packaged (-1.0 bar) using a Multi Vac vacuum packager (AG-800, Wolfertschwenden/Allgau, Germany) in impermeable nylon/polyethylene bags (O2 permeability, 9.3 mL O2/m2/24h at 0⬚C; Koch, Kansas City, MO), and the other half in oxygen-permeable bags. After packaging, they were electron irradiated from a Linear Accelerator (Circe IIIR, Thomson CSF Linac, Saint-Aubin, France) to an absorbed dose of 0, 2.5, or 4.5 kGy (dose rate was 107 kGy/min). The sausages were at 4⬚C during irradiation and stored for up to 8 days at 4⬚C. The degree of lipid oxidation and volatiles in cooked sausages was determined after 0, 4, and 8 days storage. Lipid oxidation was determined by the thiobarbituric acid reactive substances (TBARS) method as previously described (Ahn et al., 1998b). A purge-and-trap apparatus connected to a GC was used to trap and quantify the volatile compounds produced in cooked pork sausage during irradiation and storage. Volatiles analysis Precept II and Purge-and-Trap Concentrator 3000 (Tekmar-Dohrmann, Cincinnati, OH) were used to purge and trap the volatiles potentially responsible for off-odor in irradiated cooked pork sausage. A GC (Model 6890, Hewlett Packard Co., Wilmington, DE) equipped with a flame ionization detector was used to analyze volatiles after thermally desorbing the trapped volatiles. In preparation for volatiles analysis, sausage (2g) was weighed into a sample vial (40 mL), an oxygen absorber (Ageless type ZPT-50, Mitsubishi Gas Chemical America, Inc., New York) was added, and the vial was capped tightly with a Teflon-lined open-mouth cap and was placed in a refrigerated (3⬚C) sample tray. The sample was purged by using an auto sampling unit (Precept II) equipped with a robotic arm. The sample was heated to 32⬚C and then purged with helium gas (40 mL/min) for 11 min. Volatiles were trapped by using a Tenax/silica gel/charcoal column (Tekmar-Dohrmann, Cincinnati, OH) and desorbed for 1 min at 220⬚C. All transfer lines connecting Precept II, the Concentrator 3000 and the GC inlet, were maintained at 135⬚C. A split inlet (split ratio, 49:1) was used to inject volatiles into a DB-Wax capillary GC column (0.25 mm i.d. ⫻ 60 m, and 0.25 m film thickness, Hewlett Packard), and ramped oven temperature conditions (32⬚C for 2 min, increased to 40⬚C at 2⬚C/min, increased to 50⬚C at 5⬚C/min, increased to 70⬚C at 10⬚C/min, increased to 140⬚C at 20⬚C/min, increased to 200⬚C at 30⬚C/min, and held for 4.5 min) were used. Inlet temperature was 180⬚C, and detector temperature was 280⬚C. Helium was the carrier gas with a constant column flow of 1.2 mL/min. Detector air, H2, and make-up gas (He) flow rates were 300 mL/min, 30 mL/min, and 28 mL/min, respectively. Individual peaks were tentatively identified by retention times of volatile standards. Standard kits (aldehydes, ketones, alcohols, hydrocarbons, and alkenes C6-C10) were purchased from Chromatography Research Supplies (Addison, IL), and 49 standards (9 aldehydes, 11 alcohols, 13 ketones, and 16 hydrocarbones) were used to identify peaks in meat volatiles. A few peaks that could not be identified with the standards were identified using a Mass Selective (MS) detector (Model 5973, Hewlett Packard Co., Wilmington, DE). GCMS was performed with column and other purge-and-trap/GC conditions as described. The ionization potential of MS was 70 eV, and the scan range was 50 to 550 m/z. The identification of volatiles was achieved by comparing mass spectral data with those of the Wiley library (Hewlett Packard Co., Wilmington, DE). The area of each peak was integrated by using ChemStation software (Hewlett Packard Co., Wilmington, DE), and the total peak area (pA*sec) was reported as an indicator of generated volatiles. Statistical analysis Analysis of variance (ANOVA) was used to determine the effects of irradiation dose and storage time on volatiles and lipid oxidation of irradiated cooked pork sausage with different packaging conditions. The volatiles data of samples from different packaging types were analyzed independently by SAS software (SAS Institute, Inc., 1989). Correlation coefficients between volatile components and TBARS were calculated. The Student-Newman-Keuls multiple range test was used to compare differences among means. Mean values and standard errors of the mean (SEM) were reported. Significance of differences was defined at P⬍0.05. RESULTS & DISCUSSION Volatiles production In vacuum-packaged cooked sausage, irradiation dose affected (P ⬍ 0.05) the production of volatiles but the effects of storage time were not significant (Table 1). At Day 0, amounts of 1-heptene, 2propanone, and 1-nonene increased as irradiation dose increased. The production of hexanal, 1-pentanol, and 1-heptanol decreased (P ⬍ 0.05) with increased irradiation dose. Except for 1-pentene⫹hexane and nonanal, changes in the amount and profile of volatiles in the sausages were not significant. The changes in 1-pentene⫹hexane and nonanal during storage were not consistent with storage time. Amounts of propanal and pentanal were influenced by irradiation at Day 8 but changes were not consistent with irradiation dose (Table 1). Irradiated sausages (2.5 or 4.5 kGy) produced more total volatiles than nonirradiated except for those irradiated at 4.5 kGy and stored 8 days. Amounts of total volatiles during storage were mainly influenced by 1-pentene⫹hexane, 2-methylpentanal, and trimethylhexane but changes were not consistent with storage time. Ahn et al. (1997, 1998b) reported that the amount of total volatiles was not consistently influenced by storage time but was increased (P⬍0.05) by irradiation. In aerobic-packaged irradiated cooked pork sausage, irradiation dose and storage time affected (P⬍0.05) the production and composition of volatiles (Table 2). The amounts of 1-heptene and 1-nonene increased (P⬍0.05) as irradiation dose increased as in vacuum-packaged sausages. Cooked pork sausage irradiated at 2.5 kGy produced higher amounts of 1-pentanol and 1-heptanol than those at 0 and 4.5 kGy at Day 0 but the amount of 1-pentanol, 1-hexanol, and 1-heptanol decreased as irradiation dose increased at Day 4 and Day 8. In Day 0 samples, irradiation greatly increased (P⬍0.05) the production of 1pentene⫹hexane but had no effect on Day 4 and Day 8 samples. Amounts of propanal, pentanal, 2-methyl pentanal, and hexanal were not influenced by irradiation dose but increased (P⬍0.05) during storage. After 4 days storage in aerobic-packaging these aldehydes became the major volatile compounds of irradiated cooked pork sausage. Amounts were two- to four-fold higher than that of the Day 0 samples. Other volatiles such as 1-pentene⫹hexane, 1-pentanol, 1hexanol, and 1-heptanol also increased (P⬍0.05) during storage in aerobic packaging (Table 2). Among the volatile components, the amounts of 1-heptene and 1nonene were the only compounds influenced (P⬍0.001) by irradiation dose. Therefore, they could be indicators for irradiation treatment in cooked pork sausage. The production of 2-methylpentanal and trimethylhexane was influenced (P⬍0.001) by storage (Table 3) but changes were not consistent with storage time (Tables 1-2). The production of 1-pentene+hexane, aldehydes (propanal, pentanal, hexanal, and nonanal), ketones, alcohols, and total volatiles were influenced (P⬍0.05) by both storage time and packaging (Table 3). More than 1,000 compounds have been identified as flavor/aroma components in cooked meat. They are produced by thermal degradation of sugars, amino acids, and nucleotides as well as the Maillard reaction and lipid oxidation (Shahidi et al., 1986; Specht and Baltes, 1994). Many researchers (Chang and Peterson, 1977; Min et al., 1979; Wasserman, 1979; Ruther and Baltes, 1994) have reported that lactones, aromatic and nonaromatic heterocyclic compounds, sulfurcontaining compounds, and furan compounds are important contributors to meaty aroma notes of cooked meat. The volatile compounds responsible for off-odors in irradiated meat have long been hypothesized to be produced by changes in the protein and lipid molecules and different from those of lipid oxidation. The major volatile components found in irradiated cooked pork sausage analyzed by the purge-andtrap/GC method we used were lipid oxidation-related compounds, most of which were aldehydes, alcohols, ketones, and alkenes with low carbon numbers. The major reason our samples had relatively simple volatile compounds was probably because of the low temperature purge (40⬚C) we used. Exhaustive distillation of meat at high temperature would not produce the kind of volatile compounds found in cooked sausages that affect sensory quality. Little if any sulfur-containing compounds, pyrazines, or furans were detected in the irradiated cooked pork sausage when purged at 40⬚C. Although the flavor dilution factors of sulfur-containing compounds, pyrazines, and furans were very high (Specht and Baltes, 1994; Patterson and Stevenson, 1995), their contributions to flavor of cooked sausages at 40°C should be negligible. As shown by Ramarathnam et al. (1993), hexanal was the major lipid oxidation-related volatile in cooked meat. However, the Volume 64, No. 2, 1999—JOURNAL OF FOOD SCIENCE 227 Volatiles of Cooked Irradiated Sausages . . . Table 1—Relative production of volatiles in vacuum-packaged cooked irradiated pork sausages as affected by irradiation dose and storage time (4°C)d Day 0 Volatile compound 1-Pentene, hexane 1-Heptene Propanal 2-Propanone 1-Nonene Pentanal 2-Methylpentanal 2-Pentanone Trimethylhexane Hexanal 3-Heptanone 1-Pentanol Nonanal 1-Heptanol Total volatiles 0 kGy 84.78 6.35c 2.26 18.93c 12.93c 20.75 104.80 12.85 70.70 57.43a 2.30 13.35a 2.80 3.55a 420.55b 2.5 kGy 99.33 38.03b 3.19 22.80b 30.43b 26.13 133.15 16.95 90.90 48.65ab 1.95 11.40b 2.70 2.98ab 534.60a 4.5 kGy 93.88 73.38a 2.65 25.60a 44.38a 25.45 134.23 19.05 92.75 37.30b 1.90 9.23c 2.65 2.35b 571.33a Day 4 SEM 6.02 4.27 0.24 0.66 0.61 3.35 23.76 2.45 16.49 5.00 0.13 0.56 0.08 0.21 20.79 0 kGy 2.5 kGy 4.5 kGy 45.28c 8.25c 3.81 20.55c 11.55c 21.53 99.00 13.10 62.15 66.83a 2.23 14.35a 2.35b 3.55a 381.35b Peak area (pA*sec) 67.35b 89.20a 36.50b 73.05a 3.18 3.80 24.28b 28.75a b 28.78 41.88a 24.23 21.15 115.53 98.00 12.30 10.63 71.55 59.83 ab 55.25 47.58b 2.30 1.90 11.23b 10.40b ab 2.65 2.93a 2.88b 2.60b 465.03a 499.23a Day 8 SEM 0 kGy 2.5 kGy 4.5 kGy SEM 4.93 5.92 0.33 0.65 0.66 1.62 11.73 1.30 8.75 4.62 0.15 0.50 0.12 0.20 25.07 118.13 10.90c 8.58b 19.45c 11.75c 26.15ab 155.20 20.10 97.63 48.80a 2.20 12.33a tr 3.48a 540.38b 132.63 40.80b 9.55a 22.78b 30.05b 28.58a 163.70 20.00 103.40 48.58a 2.03 13.55a tr 3.20a 624.98a 120.73 8.73 60.73a 1.47 b 8.75 0.19 26.35a 0.42 a 41.33 0.47 24.38b 0.95 143.85 5.52 20.13 0.80 90.65 4.02 b 34.75 3.54 2.00 0.08 8.83b 0.83 tr — 2.18b 0.19 ab 590.33 16.34 a-cDifferent letters within a row of the same storage time are different (P < 0.05). dSamples (2g) were purged at 32°C. n = 4. SEM = standard error of mean. Table 2—Relative production of volatiles in aerobic-packaged cooked irradiated pork sausages as affected by irradiation dose and storage time (4°C)d Day 0 Volatile compound 1-Pentene,hexane 1-Heptene Propanal 2-Propanone 1-Nonene Pentanal 2-Methylpentanal 2-Pentanone Trimethyl hexane Hexanal 3-Heptanone 1-Pentanol Cyclohexanone 1-Hexanol Nonanal 1-Heptanol Total volatiles 0 kGy 41.63b 7.35c 3.10 21.73c 12.90c 15.13 57.13 8.15 44.80 44.18 2.15ab 11.78b tr tr 2.68 2.93b 281.90b 2.5 kGy 91.10a 48.13b 4.60 27.98b 30.78b 14.65 43.40 5.83 34.54 68.20 2.38a 16.08a tr tr 2.35 4.08a 397.86a 4.5 kGy 94.40a 86.18a 5.03 31.60a 40.40a 14.28 42.65 7.10 33.48 56.48 1.90b 12.13b tr tr 3.08 3.03b 435.50a Day 4 SEM 4.20 5.35 0.41 0.68 0.82 1.72 7.65 1.63 5.72 6.11 0.08 0.78 — — 0.25 0.20 19.34 0 kGy 2.5 kGy 4.5 kGy 131.28 16.18c 20.03 80.55a 15.30c 37.43 182.98 20.85 122.03 287.68 4.13 37.28a 3.68 2.80 4.43 10.00 981.50 Peak area (pA*sec) 137.78 154.05 48.03b 89.58a 23.25 23.52 61.40b 32.15c 30.28b 40.38a 40.53 42.40 168.58 166.98 19.03 21.75 112.05 110.78 283.18 270.90 4.00 3.70 a 34.18 30.08b 3.33 3.10 2.80 2.60 4.60 4.53 9.28 8.48 988.08 1010.53 Day 8 SEM 0 kGy 2.5 kGy 4.5 kGy SEM 9.29 6.11 2.25 8.24 1.15 2.29 16.76 2.33 11.60 19.16 0.21 1.26 0.40 0.09 0.17 0.45 32.53 182.48 21.50a 24.92 55.20 14.85c 36.60 110.28 11.35 70.18 333.70 5.08 44.33a 3.85 3.43a 3.95 10.93a 941.03 183.18 64.10b 27.25 30.45 31.83b 38.80 114.30 11.50 73.45 338.30 4.63 38.25b 3.65 3.13a 4.33 10.18a 986.71 185.00 14.40 88.50c 3.34 24.25 1.80 33.78 9.82 a 40.60 1.30 37.43 1.50 115.58 8.25 11.58 1.09 74.35 6.26 291.25 16.84 3.83 0.15 31.70b 1.21 3.30 0.25 2.63b 0.11 4.30 0.15 b 8.05 0.44 964.23 32.67 a-cDifferent letters within a row of the same storage time are different (P < 0.05). dSamples (2g) were purged at 32°C. SEM=standard error of mean. contribution of other aldehydes such as heptanal, octanal, and nonanal to off-flavor of cooked meat would probably be considerably as evidenced by their high flavor dilution factors (Specht and Baltes, 1994). Table 3—Statistical significance of effects of irradiation dose, storage time, and packaging on volatiles production from cooked pork sausagesa Volatile compound d.f. Irradiation effect 2 TBARS The changes of TBARS in irradiated cooked pork sausage with different packaging conditions and storage time indicated that storage time had no effect in vacuum-packaged sausage but had effects (P⬍0.05) in aerobic-packaged sausage (Table 4). TBARS of sausage in aerobic packaging increased two- to four-fold from Day 0 values. Irradiating cooked pork sausage had some effect on TBARS of vacuum-packaged sausages at Day 0 and values of aerobic-packaged sausages at Day 0 and Day 4. Compared with storage time in aerobic packaging, however, irradiation effects on the TBARS of cooked meat were minor (Table 4). Ahn et al. (1998a,b) had reported that preventing oxygen exposure after cooking had more important effects on TBARS than antioxidant, irradiation, or storage conditions of raw meat. 228 JOURNAL OF FOOD SCIENCE—Volume 64, No. 2, 1999 1-Pentene, hexane 1-Heptene Propanal 2-Propanone 1-Nonene Pentanal 2-Methylpentanal 2-Pentanone Trimethylhexane Hexanal 3-Heptanone 1-Pentanol Nonanal 1-Heptanol Total volatiles 0.19 0.0001 0.95 0.48 0.0001 0.66 0.89 0.89 0.89 0.86 0.30 0.30 0.75 0.34 0.45 Storage effect 2 Packaging effect 1 Probabilities 0.0001 0.88 0.0001 0.007 0.98 0.0001 0.0001 0.01 0.002 0.0001 0.0001 0.0002 0.007 0.0003 0.0001 an = 24 for irradiation effect and storage effect; n = 36 for packaging effect. 0.0001 0.06 0.0001 0.0001 0.88 0.004 0.115 0.03 0.33 0.0001 0.0001 0.0001 0.0001 0.0001 0.0001 Table 4—Changes of TBARS in cooked irradiated pork sausages as related to packaging and storage conditions Vacuum packaging Storage (day)) 0 4 8 SEM 0 kGy 2.5 kGy 4.5 kGy 0.71by 0.89a 0.83a 0.03 1.08x 0.92 0.85 0.08 Aerobic packaging SEM 0 kGy 2.5 kGy 4.5 kGy SEM TBARS values (mg MDA/kg meat) 0.91xy 0.08 1.23cy 1.33cy 0.87 0.03 4.57bxy 3.97by 0.77 0.05 6.91a 5.94a 0.05 0.27 0.36 1.95bx 0.10 5.16ax 0.24 5.41a 0.44 0.25 x-zDifferent letters within a row of the same packaging are different (P<0.05). n=4. a-cValues with different superscript letters within a column of the same irradiation dose are different (P<0.05). SEM=standard error of mean. Table 5—Correlation coefficients between specific volatile compounds and TBARS Volatile compound 1-Pentene, hexane 1-Heptene Propanal 2-Propanone 1-Nonene Pentanal 2-Methylpentanal 2-Pentanone Trimethylhexane Hexanal 3-Heptanone 1-Pentanol Cyclohexanone 1-Hexanol Nonanal 1-Heptanol Total volatiles Vacuum packaginga 0.02 0.02 0.04 0.04 0.03 0.19* 0.05 0.09 0.01 0.01 0.00 0.00 0.00 0.00 0.00 0.02 0.06 Aerobic packaging Vacuum+aerobic packaging 0.77** 0.02 0.81** 0.11 0.00 0.65** 0.30* 0.16 0.23* 0.86** 0.83** 0.83** 0.69** 0.82** 0.60* 0.80** 0.75** 0.61** 0.06 0.84** 0.31** 0.00 0.54** 0.03 0.00 0.03 0.93** 0.88** 0.90** 0.79** 0.89** 0.74** 0.89** 0.74** an=36 for vacuum-packaged and aerobic-packaged; n=72 for vacuum+aerobic packaged. *P<0.01; **P<0.0001. Relationships of volatile compounds with TBARS There was little relationship between TBARS and volatiles produced in irradiated cooked pork sausage with vacuum packaging (Table 5). However, with aerobic packaging, TBARS of irradiated cooked pork sausage highly correlated (P⬍0.0001) with production of 1pentene+hexane, propanal, pentanal, hexanal, 3-heptanone, 1-pentanol, cyclohexanone, 1-hexanol, 1-heptanol, and total volatiles. Relationships were also found between TBARS and amounts of 2-methylpentanal, trimethylhexane, and nonanal (P⬍0.05). The production of pentanal was the only volatile compound correlated (P⬍0.01) with TBARS in both vacuum and aerobic packaged cooked sausages. The production of 1-pentene⫹hexane, propanal, pentanal, hexanal, 3-heptanone, 1-pentanol, cyclohexanone, 1-hexanol, nonanal, 1-heptanol, and total volatiles had a very high correlation (P⬍0.0001) with TBARS of irradiated cooked pork sausage when vacuum- and aerobic-packaged sausages were combined. 2-Propanone correlated (P⬍0.0001) with TBARS when both aerobic and vacuum packaging were combined but not when packaging type was analyzed separately. This indicated that the amount of aldehydes, total volatiles, and ketones and alcohols with longer retention times could be good indicators of oxidative changes in cooked irradiated meat. CONCLUSIONS IRRADIATION AFFECTED LIPID OXIDATION OF COOKED PORK SAUsages, especially with aerobic packaging, but oxygen availability (packaging) to meat during storage had much stronger effects. The production of 1-heptene and 1-nonene in cooked sausages increased proportionally with the increase of irradiation dose but was not affected by packaging or storage time. The low correlations of irradiation-dependent volatiles (e.g., 1-heptene and 1-nonene) with TBARS values regardless of packaging and storage conditions indicated that volatile compounds responsible for irradiation odor were different from those of lipid oxidation odor in cooked pork sausages. REFERENCES Ahn, D.U., Ajuyah, A., Wolfe, F.H., and Sim, J.S. 1993. Oxygen availability effects in prooxidant-catalyzed lipid oxidation of cooked turkey patties. J. Food Sci. 58: 278282. Ahn, D.U., Olson, D.G., Jo, C., Chen, X., Wu, C., and Lee, J.I. 1998a. Effect of muscle type, packaging, and irradiation on lipid oxidation, volatile production and color in raw pork patties. Meat Sci. 49: 27-39. Ahn, D.U., Olson, D.G., Lee, J.I., Jo, C., Chen, X., and Wu, C. 1998b. Packaging and irradiation effects on lipid oxidation and volatiles in pork patties. J. Food Sci. 63: 15-19. Ahn, D.U., Sell, J.L., Jeffery, M., Jo, C., Chen, X., Wu, C., and Lee, J.I. 1997. Dietary vitamin E affects lipid oxidation and total volatiles of irradiated raw turkey meat. J. Food Sci. 62: 954-959. Al-Kahtani, H.A., Abu-Tarboush, H.M., Bajaber, A.S., Atia, H., Abou-Arab, A.A., and ElMojaddidi, M.A. 1996. Chemical changes after irradiation and post-irradiation storage in tilapia and Spanish mackerel. J. Food Sci. 61: 729-733. Chang, S.S. and Peterson, R.J. 1977. Symposium: The basis of quality in muscle foods. Recent developments in the flavor of meat. J. Food Sci. 42: 298-305. Hampson, J.W., Fox, J.B. Jr., Lakritz, L., and Thayer, D.W. 1996. Effect of low-dose gamma radiation on lipids in five different meats. Meat Sci. 42: 271-276. Hashim, I.B., Resurreccion, A.V.A., and MacWatters, K.H. 1995. Disruptive sensory analysis of irradiated frozen or refrigerated chicken. J. Food Sci. 60: 664-666. Katusin-Razem, B., Mihaljevic, K.W., and Razem, D. 1992. Time-dependent post irradiation oxidative chemical changes in dehydrated egg products. J. Agric. Food Chem. 40: 1948-1952. Lee, M., Sebranek, J., and Parrish, F.C. Jr. 1996. Accelerated postmortem aging of beef utilizing electron-beam irradiation and modified atmosphere packaging. J. Food Sci. 61: 133-136. Min, D.B., Ina, K., Peterson, R.J., and Chang, S.S. 1979. Preliminary identification of volatile flavor compounds in the neutral fraction of roasted beef. J. Food Sci. 44: 639-642. Patterson, R.L.S. and Stevenson, M.H.1995. Irradiation-induced off-odor in chicken and its possible control. Br. Poult. Sci. 36: 425-441. Ramarathnam, N., Rubin, L.J., and Diosady, L.L. 1993. Studies on meat flavor. 4. Fractionation, characterization, and quantitation of volatiles from uncured and cured beef and chicken. J. Agric. Food Chem. 41: 939-945. Ruther, J. and Baltes, W. 1994. Sulfur-containing furans in commercial meat flavorings. J. Agric. Food Chem. 42: 2254-2259. SAS Institute, Inc. 1989. SAS User’s Guide. SAS Institute Inc., Cary, NC. Shahidi, F., Rubin, L.J., and D’Souza, L.A. 1986. Meat flavor volatiles: A review of the composition, techniques of analysis, and sensory evaluation. CRC Crit. Rev. Food Sci. Nutr. 24: 141-243. Shamsuzzaman, K., Chuaqui-Offermann, N., Lucht, L., McDougall, T., and Borsa, J. 1992. Microbial and other characteristics of chicken breast meat following electron-beam and sous-vide treatments. J. Food Protect. 55: 528-533. Specht, K. and Baltes, W. 1994. Identification of volatile flavor compounds with high aroma values from shallow-fried beef. J. Agric. Food Chem. 42: 2246-2253. Wasserman, A.E. 1979. Symposium in meat flavor. Chemical basis of meat flavor: A review. J. Food Sci. 44: 6-11. Ms received 5/19/98; revised 9/12/98; accepted 10/3/98. Volume 64, No. 2, 1999—JOURNAL OF FOOD SCIENCE 229