Effect of Antioxidant Application Methods of Irradiated Ground Beef

advertisement

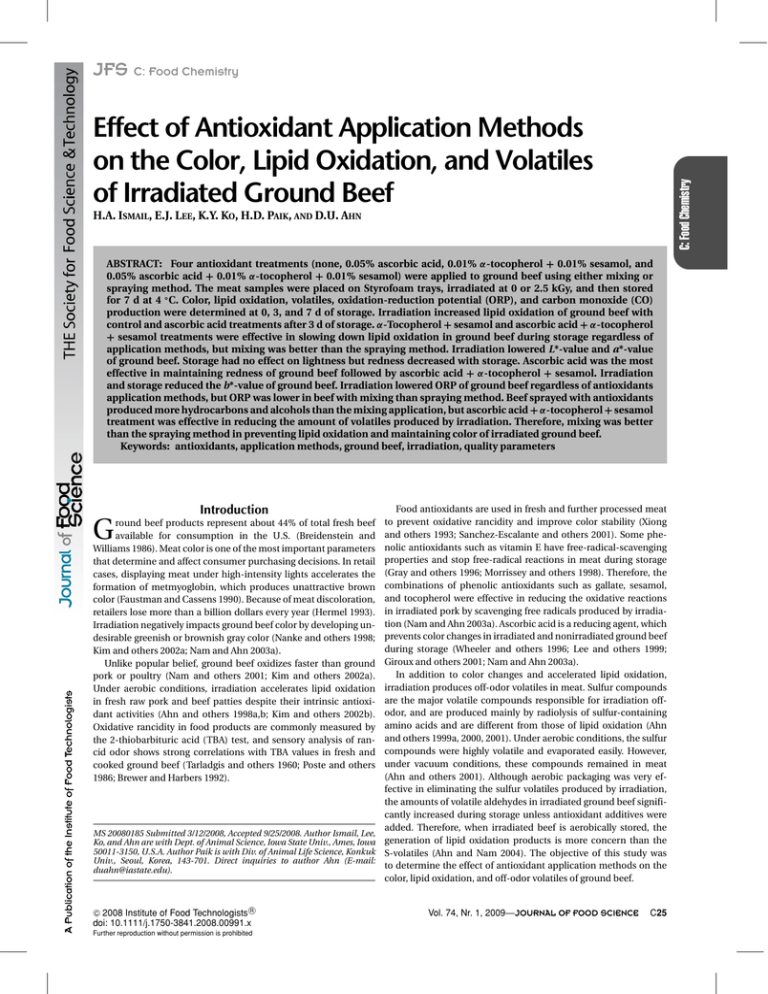

JFS C: Food Chemistry C: Food Chemistry Effect of Antioxidant Application Methods on the Color, Lipid Oxidation, and Volatiles of Irradiated Ground Beef H.A. ISMAIL, E.J. LEE, K.Y. KO, H.D. PAIK, AND D.U. AHN ABSTRACT: Four antioxidant treatments (none, 0.05% ascorbic acid, 0.01% α-tocopherol + 0.01% sesamol, and 0.05% ascorbic acid + 0.01% α-tocopherol + 0.01% sesamol) were applied to ground beef using either mixing or spraying method. The meat samples were placed on Styrofoam trays, irradiated at 0 or 2.5 kGy, and then stored for 7 d at 4 ◦ C. Color, lipid oxidation, volatiles, oxidation-reduction potential (ORP), and carbon monoxide (CO) production were determined at 0, 3, and 7 d of storage. Irradiation increased lipid oxidation of ground beef with control and ascorbic acid treatments after 3 d of storage. α-Tocopherol + sesamol and ascorbic acid + α-tocopherol + sesamol treatments were effective in slowing down lipid oxidation in ground beef during storage regardless of application methods, but mixing was better than the spraying method. Irradiation lowered L*-value and a*-value of ground beef. Storage had no effect on lightness but redness decreased with storage. Ascorbic acid was the most effective in maintaining redness of ground beef followed by ascorbic acid + α-tocopherol + sesamol. Irradiation and storage reduced the b*-value of ground beef. Irradiation lowered ORP of ground beef regardless of antioxidants application methods, but ORP was lower in beef with mixing than spraying method. Beef sprayed with antioxidants produced more hydrocarbons and alcohols than the mixing application, but ascorbic acid + α-tocopherol + sesamol treatment was effective in reducing the amount of volatiles produced by irradiation. Therefore, mixing was better than the spraying method in preventing lipid oxidation and maintaining color of irradiated ground beef. Keywords: antioxidants, application methods, ground beef, irradiation, quality parameters Introduction G round beef products represent about 44% of total fresh beef available for consumption in the U.S. (Breidenstein and Williams 1986). Meat color is one of the most important parameters that determine and affect consumer purchasing decisions. In retail cases, displaying meat under high-intensity lights accelerates the formation of metmyoglobin, which produces unattractive brown color (Faustman and Cassens 1990). Because of meat discoloration, retailers lose more than a billion dollars every year (Hermel 1993). Irradiation negatively impacts ground beef color by developing undesirable greenish or brownish gray color (Nanke and others 1998; Kim and others 2002a; Nam and Ahn 2003a). Unlike popular belief, ground beef oxidizes faster than ground pork or poultry (Nam and others 2001; Kim and others 2002a). Under aerobic conditions, irradiation accelerates lipid oxidation in fresh raw pork and beef patties despite their intrinsic antioxidant activities (Ahn and others 1998a,b; Kim and others 2002b). Oxidative rancidity in food products are commonly measured by the 2-thiobarbituric acid (TBA) test, and sensory analysis of rancid odor shows strong correlations with TBA values in fresh and cooked ground beef (Tarladgis and others 1960; Poste and others 1986; Brewer and Harbers 1992). MS 20080185 Submitted 3/12/2008, Accepted 9/25/2008. Author Ismail, Lee, Ko, and Ahn are with Dept. of Animal Science, Iowa State Univ., Ames, Iowa 50011-3150, U.S.A. Author Paik is with Div. of Animal Life Science, Konkuk Univ., Seoul, Korea, 143-701. Direct inquiries to author Ahn (E-mail: duahn@iastate.edu). R Institute of Food Technologists doi: 10.1111/j.1750-3841.2008.00991.x C 2008 Further reproduction without permission is prohibited Food antioxidants are used in fresh and further processed meat to prevent oxidative rancidity and improve color stability (Xiong and others 1993; Sanchez-Escalante and others 2001). Some phenolic antioxidants such as vitamin E have free-radical-scavenging properties and stop free-radical reactions in meat during storage (Gray and others 1996; Morrissey and others 1998). Therefore, the combinations of phenolic antioxidants such as gallate, sesamol, and tocopherol were effective in reducing the oxidative reactions in irradiated pork by scavenging free radicals produced by irradiation (Nam and Ahn 2003a). Ascorbic acid is a reducing agent, which prevents color changes in irradiated and nonirradiated ground beef during storage (Wheeler and others 1996; Lee and others 1999; Giroux and others 2001; Nam and Ahn 2003a). In addition to color changes and accelerated lipid oxidation, irradiation produces off-odor volatiles in meat. Sulfur compounds are the major volatile compounds responsible for irradiation offodor, and are produced mainly by radiolysis of sulfur-containing amino acids and are different from those of lipid oxidation (Ahn and others 1999a, 2000, 2001). Under aerobic conditions, the sulfur compounds were highly volatile and evaporated easily. However, under vacuum conditions, these compounds remained in meat (Ahn and others 2001). Although aerobic packaging was very effective in eliminating the sulfur volatiles produced by irradiation, the amounts of volatile aldehydes in irradiated ground beef significantly increased during storage unless antioxidant additives were added. Therefore, when irradiated beef is aerobically stored, the generation of lipid oxidation products is more concern than the S-volatiles (Ahn and Nam 2004). The objective of this study was to determine the effect of antioxidant application methods on the color, lipid oxidation, and off-odor volatiles of ground beef. Vol. 74, Nr. 1, 2009—JOURNAL OF FOOD SCIENCE C25 Antioxidant application methods on irradiated beef quality . . . Materials and Methods sis, ORP, and CO production were determined at 0, 3, and 7 d of storage. Sample preparation C: Food Chemistry Four blocks of beef chuck from 4 different animals were purchased from different grocery stores. Each meat block was trimmed off any visible fat, ground separately through a 6-mm plate and a 3-mm plate, and used as a replication. Eight batches of 4 antioxidant treatments were prepared. Four batches of them were used for mixing and the other 4 batches for spraying method. The antioxidant treatments were: (1) control, (2) 0.05% L-ascorbic acid (Fisher Scientific, Fair Lawn, N.J., U.S.A.), (3) 0.01% dl-αtocopherol (Aldrich Chemical Co., Milwaukee, Wis., U.S.A.) + 0.01% sesamol (3,4-methylenedioxyphenol, final conc.; Sigma, St. Louis, Mo., U.S.A.), (4) 0.05% L-ascorbic acid + 0.01% dl-α-tocopherol + 0.01% sesamol. All the antioxidant treatments were on w/w basis and final concentrations. For the mixing application, each additive was added to the ground meat and then mixed for 2 min in a bowl mixer (Model KSM 90; Kitchen Aid Inc., St. Joseph, Mich., U.S.A.). Ground beef patties (approximately 50 g) were prepared by hand, placed individually on Styrofoam trays, and wrapped with clear stretch, oxygen-permeable meat film RMF-61 Hy (Borden Div., Borden Packaging and Industrial Products Inc., North Andover, Mass., U.S.A.), using a single-roll overwrapper (Model 600A, Heat Sealing Equipment Manufacturing Co., Cleveland, Ohio, U.S.A.). A dlα-tocopherol was dissolve in corn oil first, and then oil emulsion (water-in-oil) was prepared using water or the aqueous solutions of ascorbate and/or sesamol before use. For spraying method, ground beef patties were placed on large metal trays, and sprayed with antioxidant treatments on both sides using an electrostatic spraying device (Electrostatic Spraying System, Inc., Watkinsville, Ga., U.S.A.). After spraying, beef patties were placed individually on Styrofoam trays and wrapped as in mixing application. Prepared patties were stored overnight at 4 ◦ C, and irradiated the next day morning. The additive treatments were applied as solution form: ascorbic acid and sesamol were dissolved in distilled water, while tocopherol was dissolved first in corn oil, and then oil emulsion was prepared using the aqueous solutions of ascorbic acid and/or sesamol. The same amounts of water and corn oil were added to all other treatments. For both application methods, 3 sets of samples were prepared and each set was used for color and chemical analyses at each storage time. For both mixing and spray applications, half of the patties from each antioxidant treatment was used for nonirradiated and the other half was used for irradiated meat. Ionizing radiation For irradiation treatment, ground beef patties from each antioxidant application was irradiated at 2.5 kGy using a linear accelerator facility (Circe IIIR; Thomson CSF Linac, St. Aubin, France) with 10 MeV of energy and 5.6 KW of power level. The average dose rate was 68.7 kGy/min. Alanine dosimeter were placed on the top and bottom surfaces of a sample and were read using a 104 Electron Paramagnetic Resonance Instrument (Bruker Instruments Inc., Billerica, Mass., U.S.A.) to check the absorbed dose. The dose range absorbed by meat samples was 2.45 to 2.95 kGy (max/min ratio was 1.20). The nonirradiated control samples were exposed to ambient temperature of linear acceleration facility while other samples were being irradiated. After irradiation, the irradiated and nonirradiated meat samples were immediately returned to a 4 ◦ C cold room where they were displayed in a single layer on illuminated racks under standard fluorescent light (1000 lux, Philips, fluorescent light 40 W Cool White) for 7 d. Incident light reaching the sample surface had an intensity of 2018 lux. Color, lipid oxidation, volatile analyC26 JOURNAL OF FOOD SCIENCE—Vol. 74, Nr. 1, 2009 Thiobarbituric acid-reactive substances (TBARS) measurement Lipid oxidation was determined using a TBARS method (Ahn and others 1999a). Five grams of ground beef were weighed into a 50-mL test tube and homogenized with 50 μL butylated hydroxytoluene (7.2% in ethanol) and 15 mL deionized distilled water (DDW) using a Polytron homogenizer (Type PT 10/35, Brinkman Instruments Inc., Westbury N.Y., U.S.A.) for 15 s at high speed. One milliliter of the meat homogenate was transferred to a disposable test tube (13 × 100 mm) and thiobarbituric acid/trichloroacetic acid (15 mM TBA/15% TCA, 2 mL) was added. The mixture was vortex mixed and incubated in a boiling water bath for 15 min to develop color. Then samples were cooled in ice-water for 10 min, mixed again, and centrifuged for 15 min at 2500 × g at 4 ◦ C. The absorbance of the resulting supernatant solution was determined at 531 nm against a blank containing 1 mL DDW and 2 mL TBA/TCA solution. The amounts of TBARS were expressed as milligrams of malonaldehyde (MDA) per kilogram of meat. Table 1 --- TBARS values of beef mixed or sprayed with different additives during storage at 4 ◦ C. Mixing Non-IR Spraying IR SEM Non-IR IR SEM (mg MDA/kg meat) Day 0 Control A E+S A+E+S SEM Day 3 Control A E+S A+E+S SEM Day 7 Control A E+S A+E+S SEM 0.87 0.33y 0.29 0.30 0.14 0.91a 0.50bx 0.34b 0.35b 0.12 0.26 0.03 0.03 0.03 0.97a 0.53by 0.42b 0.47b 0.12 0.75a 0.83ax 0.47b 0.55b 0.05 0.16 0.06 0.05 0.04 1.27a 0.45by 0.26b 0.31b 0.20 2.00a 1.06bx 0.30c 0.33c 0.20 0.38 0.11 0.03 0.03 0.89ay 0.76aby 0.37b 0.37b 0.11 1.94ax 2.29ax 0.45b 0.46b 0.19 0.25 0.17 0.04 0.03 1.55 0.51y 0.31 0.30z 0.30 3.06a 1.68bx 0.36b 0.36b 0.37 0.66 0.15 0.03 0.03 1.06ay 0.85aby 0.42b 0.46b 0.14 3.01ax 3.85ax 0.45b 0.51b 0.35 0.31 0.43 0.05 0.04 Application (A) Irradiation (IR) Additives (AD) Storage (S) A × IR A × AD A×S IR × AD IR × S AD × S A × IR × AD A × IR × S A × AD × S IR × AD × S A × IR × AD × S DF F -value 1 1 3 2 1 3 2 3 2 6 3 2 6 6 6 11.88 71.35 85.12 33.26 5.58 10.19 0.71 19.94 18.31 11.32 3.37 1.92 1.70 6.28 0.94 P 0.0007 0.0001 0.0001 0.0001 0.0195 0.0001 0.4948 0.0001 0.0001 0.0001 0.0203 0.1510 0.1242 0.0001 0.4698 a –c Values with different letters within a column of each storage period are significantly different (P < 0.05). x –y Values with different letters within a row of each application are significantly different (P < 0.05). Non-IR = nonirradiated samples (0 kGy); IR = irradiated samples (2.5 kGy); Cont. = control; A = ascorbic acid; E = vitamin E; S = sesamol; and SEM = standard error of the means (n = 4). Antioxidant application methods on irradiated beef quality . . . A purge-and-trap apparatus (Solatek 72 and Concentrator 3100; Tekmar-Dohrmann, Cincinnati, Ohio, U.S.A.) connected to a gas chromatograph/mass spectrometer (HP 6890/HP 5973; HewlettPackard Co., Wilmington, Del., U.S.A.) was used to analyze volatiles produced. The ground beef sample (3 g) was placed in a 40-mL sample vial, and the vial was flushed with helium gas (40 psi) for 5 s. The maximum waiting time of a sample in a refrigerated (4 ◦ C) holding tray was less than 4 h to minimize oxidative changes before analysis (Ahn and others 2001). The meat sample was purged with helium gas (40 mL/min) for 14 min at 40 ◦ C. Volatiles were trapped using a Tenax-charcoal-silica column (Tekmar-Dohrmann) and desorbed for 2 min at 225 ◦ C, focused in a cryofocusing module (−80 ◦ C), and then thermally desorbed into a capillary column for 60 s at 225 ◦ C. An HP-624 column (8.5 m × 0.25 mm i.d., 1.4 μm nominal), an HP-1 column (60 m × 0.25 mm i.d., 0.25 μm nominal; HewlettPackard Co.), and an HP-Wax column (6.5 m × 0.25 mm i.d., 0.25 μm nominal) were connected using zero dead-volume column connectors (J &W Scientific, Folsom, Calif., U.S.A.). Ramped oven temperature was used to improve volatile separation. The initial oven temperature of 30 ◦ C was held for 6 min. After that, the oven temperature was increased to 60 ◦ C at 5 ◦ C/min, increased to 180 ◦ C at 20 ◦ C/min, increased to 210 ◦ C at 15 ◦ C/min, and then was held for 5 min at the temperature. Constant column pressure at 22.5 psi was maintained. The ionization potential of the mass selective detector (Model 5973; Hewlett-Packard Co.) was 70 eV, and the scan range was 19.1 to 400 m/z. Identification of volatiles was achieved by comparing mass spectral data of samples with those of the Wiley Library (Hewlett-Packard Co.). Standards were used to confirm the identification by the mass-selective detector. The area of each peak was integrated using the ChemStation (Hewlett-Packard Co.), and the total peak area (pA∗ seconds × 104) was reported as an indicator of volatiles generated from the sample. Color measurement The color of meat was measured on the upper and the bottom surfaces of meat samples using a Labscan spectrophotometer (Hunter Assoc. Labs Inc., Reston, Va., U.S.A.) that had been calibrated against white and black reference tiles covered with the same film as those used for meat samples. CIE L∗ - (lightness), a∗ - (redness), and b∗ - (yellowness) values were obtained (AMSA 1991) using an illuminant A (light source). Area view and port size were 0.64 and 1.02 cm, respectively. An average value from 2 random locations on each side, upper and lower, of sample surface was used for statistical analysis. Oxidation-reduction potential (ORP) The method of Moiseeve and Cornforth (1999) was used in determining the change of ORP in meat. A pH/ion meter (Accumet 25, Fisher Scientific) connected to a platinum electrode filled with a 4 M-KCl solution saturated with AgCl was tightly inserted in the center of meat sample. To minimize the effect of air, the smallest possible pore was made before inserting the electrode and recording the ORP readings (microvolts). Carbon monoxide To measure carbon monoxide (CO) produced by irradiation, CO gas was purchased from Aldrich (Milwaukee, Wis., U.S.A.). The standard gas was analyzed using a gas chromatograph (GC, Table 2 --- CIE color L∗ -values of beef mixed or sprayed with different additives during storage at 4 ◦ C. Mixing Spraying Non-IR Day 0 Cont. A E+S A+E+S SEM Day 3 Cont. A E+S A+E+S SEM Day 7 Cont. A E+S A+E+S SEM Application (A) Irradiation (IR) Additives (AD) Storage (S) A × IR A × AD A×S IR × AD IR Non-IR IR Upper Lower Upper Lower SEM Upper Lower Upper Lower 46.00w 45.87w 44.81w 45.3w 0.47 44.93abw 45.75aw 43.5bx 44.64abw 0.42 42.67x 41.87x 40.95y 42.09x 0.49 41.02y 41.05x 40.82y 41.28x 0.56 0.45 0.51 0.43 0.55 45.25w 45.59w 45.35w 45.79w 0.38 44.62w 44.61w 44.62w 44.81w 0.52 41.90x 40.48x 40.35x 40.60x 0.45 38.86y 40.26x 39.66x 41.67x 0.76 0.41 0.57 0.54 0.64 45.49bc 47.46aw 44.48c 46.31abw 0.49 44.63 46.34w 44.60 44.75w 0.68 45.23 45.35wx 43.56 44.91w 0.60 43.85 43.84x 43.09 43.21x 0.52 0.51 0.62 0.70 0.47 43.33b 45.9aw 43.34b 44.71abw 0.46 42.84 44.8w 43.01 44.16wx 0.58 42.09 43.44x 42.56 43.00wx 0.50 42.00 41.23y 41.83 42.47x 0.55 0.56 0.45 0.55 0.53 46.07cwx 45.80a 44.71c 44.11b 0.66 45.47abwx 45.97a 44.08b 43.89b 0.47 46.95aw 46.15a 43.93b 43.40b 0.56 44.66x 45.32 43.61 43.01 0.61 0.58 0.63 0.53 0.57 43.80wx 43.14 41.56 41.81 0.64 42.92abx 44.37a 41.94b 42.86ab 0.51 44.29w 43.48 42.36 42.47 0.55 42.56x 43.57 42.33 42.95 0.48 0.39 0.60 0.55 0.75 DF F -value P 1 1 3 2 1 3 2 3 109.83 159.53 5.56 26.64 2.76 1.23 12.62 4.02 0.0001 0.0001 0.0010 0.0001 0.0974 0.2988 0.0001 0.0078 IR × S AD × S A × IR × AD A × IR × S A × AD × S IR × AD × S A × IR × AD × S DF F -value 2 6 3 2 6 6 6 66.66 7.38 0.15 1.08 0.81 0.48 0.40 SEM P 0.0001 0.0001 0.9321 0.3400 0.5623 0.8251 0.8779 a–c Values w–y with different letters within a column of each storage period are significantly different (P < 0.05). Values with different letters within a row of each application are significantly different (P < 0.05). Non-IR = nonirradiated samples (0 kGy); IR = irradiated samples (2.5 kGy); Cont = control; A = ascorbic acid; E = vitamin E; S = sesamol; and SEM = standard error of the means (n = 4). Vol. 74, Nr. 1, 2009—JOURNAL OF FOOD SCIENCE C27 C: Food Chemistry Volatile compounds Antioxidant application methods on irradiated beef quality . . . C: Food Chemistry Model 6890; Hewlett Packard Co., Wilmington, Del., U.S.A.) with a flame ionization detector (FID). Meat sample (10 g) was placed in a 24-mL glass vial, and the vials were flushed with helium gas (40 psi) for 5 s to minimize experimental errors due to air incorporation, then samples were microwaved for 10 s at full power. Ten minutes after microwave heating, the headspace gas of each sample (200 μL) was withdrawn using an airtight syringe and injected into a splitless inlet of a GC (Model 6890; Hewlett Packard Co.). A Carboxen-1006 Plot column (30 m × 0.32 mm id; Supelco, Bellefonte, Pa., U.S.A.) was used. Helium was used as a carrier gas at a constant flow of 1.8 mL/min and oven conditions were set at 120 ◦ C. A FID equipped with a nickel catalyst (Hewlett Packard Co.) was used for the methanization of CO, and the temperatures of inlet, detector, and nickel catalyst were 250, 280, and 375 ◦ C, respectively. Detector (FID) air, H2, and make-up gas (He) flows were 350, 35, and 40 mL/min, respectively. The identification of CO was achieved using standard gas, and the area of each peak was integrated by using the Chemstation software (Hewlett Packard Co.). To quantify the amount of gas released, peak areas (pA × seconds) were converted to the concentration (parts per million) of gas in the sample headspace (14 mL) using CO 2 concentration (330 ppm) in air. Statistical analysis The experiment was an incomplete randomized design with 4 replications. Data were analyzed by the procedures of generalized linear model of SAS (SAS Inst. 1995). Student–Newman–Keuls’ multiple-range test was used to compare the mean values of the treatments. Mean values and standard error of the means (SEM) were reported. Significance was defined at P < 0.05. Analysis of variance (ANOVA) was used to determine the effects of application methods, irradiation, additives and storage period on lipid oxidation, color, CO production, and oxidation-reduction potential of ground beef. Results and Discussion Lipid oxidation Application method, irradiation, additives, and storage influenced the TBARS values of ground beef (Table 1). In control samples, irradiation had no effect on lipid oxidation of ground beef at 0 d regardless of application method. In ascorbate-added samples, however, irradiation accelerated lipid oxidation during storage. Ascorbate was effective antioxidant only in nonirradiated ground beef, and addition of ascorbate by mixing was better than spraying method. Spraying of ascorbate was effective only in nonirradiated ground beef. The effectiveness of ascorbic acid in lowering TBARS values decreased as storage period increased. Antioxidant combinations (α-tocopherol + sesamol and ascorbic acid + α-tocopherol + sesamol) were effective in preventing oxidative changes in irradiated and nonirradiated ground beef during storage regardless of application methods. Nam and Ahn (2003b) reported that sesamol + α-tocopherol and gallate + α-tocopherol were effective in preventing lipid oxidation in turkey breast meat during storage. The addition of ascorbic acid to ground meat in combination with such antioxidants as rosemary or α-tocopherol exerted a synergistic effect (Mitsumoto and others 1991; Sanchez-Escalante and others 2001). Liu and others (1994) found that the antioxidant effect of α-tocopherol in cooked Table 3 --- CIE color a∗ -values of beef mixed or sprayed with different additives during storage at 4 ◦ C. Mixing Spraying Non-IR Day 0 Cont. A E+S A+E+S SEM Day 3 Cont. A E+S A+E+S SEM Day 7 Cont. A E+S A+E+S SEM Non-IR IR Upper Lower Upper Lower SEM Upper Lower Upper Lower 27.23cw 30.43aw 26.90cw 28.57bw 0.45 26.49cw 29.3ax 26.08cw 28.02bw 0.39 15.87cx 17.23by 16.95bx 18.90ax 0.26 16.97bx 16.70by 17.12bx 18.61ax 0.37 0.53 0.22 0.32 0.35 30.58aw 30.27aw 28.55bw 28.96bw 0.33 30.18abw 30.79aw 29.02bcw 28.75cw 0.41 15.72cy 16.91bx 16.91bx 18.26ax 0.31 16.95x 16.3x 17.14x 17.57x 0.41 0.33 0.49 0.36 0.24 21.66cw 30.55aw 19.60dw 25.32bw 0.41 20.51cw 29.53aw 18.86dx 25.16bw 0.52 16.05cx 22.94ax 16.37cy 21.24bx 0.31 16.06cx 22.36ax 16.29cy 21.12bx 0.43 0.59 0.45 0.22 0.33 24.73cw 30.24aw 22.60dw 26.76bw 0.41 25.27cw 30.61aw 23.35dw 27.16bw 0.51 17.00bx 21.77ax 17.37bx 21.32ax 0.27 16.80bx 21.77ax 17.19bx 20.91ax 0.37 0.32 0.46 0.40 0.40 13.71c 21.76a 13.01cx 17.03bx 0.73 13.59b 19.87a 14.41bwx 17.75awx 1.00 14.39b 22.89a 13.85cx 19.53bw 0.57 15.83c 22.99a 15.55cw 19.80bw 0.39 0.75 0.97 0.43 0.59 16.21cwx 22.92aw 13.51dy 18.15bx 0.59 16.93cw 22.64aw 15.04cx 19.25buwx 0.74 13.85bx 16.60ay 16.19awx 17.16ax 0.67 15.58cwx 19.50ax 17.12bw 20.36aw 0.50 0.68 0.73 0.50 0.61 DF Application (A) Irradiation (IR) Additives (AD) Storage (S) A × IR A × AD A×S IR × AD IR 1 1 3 2 1 3 2 3 F -value 9.22 1582.86 118.26 389.31 78.81 5.18 4.28 9.04 P 0.0026 0.0001 0.0001 0.0001 0.0001 0.0016 0.0146 0.0001 a –c Values w –y DF IR × S AD × S A × IR × AD A × IR × S A × AD × S IR × AD × S A × IR × AD × S 2 6 3 2 6 6 6 F -value 426.54 114.66 2.11 14.11 7.43 8.27 1.89 SEM P 0.0001 0.0001 0.0987 0.0001 0.0001 0.0001 0.0823 with different letters within a column of each storage period are significantly different (P < 0.05). Values with different letters within a row of each application are significantly different (P < 0.05). Non-IR = nonirradiated samples (0 kGy); IR = irradiated samples (2.5 kGy); Cont = control; A = ascorbic acid; E = vitamin E; S = sesamol; and SEM = standard error of the means (n = 4). C28 JOURNAL OF FOOD SCIENCE—Vol. 74, Nr. 1, 2009 meat was lower than that in raw meat. Pearson and others (1977) explained that the difference in α-tocopherol effect between raw and cooked meat could be due to protein denaturation, release of heme and noneheme iron, which resulted in the catalysis of lipid oxidation during and after cooking. Overall, adding antioxidants to ground beef by mixing was better than that by spraying method in preventing oxidative changes during storage. Color values Irradiation decreased the lightness (L∗ -value) of ground beef regardless of antioxidant application methods (Table 2). Similar results were reported by Zhu and others (2003) who found significant decrease in lightness values in irradiated turkey ham. Application methods influenced the lightness of beef at 0 d, but the differences were small. There were no differences in the L∗ -values between the upper and lower surfaces of beef patties and none of the antioxidant treatments affected the L∗ -value of ground beef. However, storage increased the L∗ -values of irradiated ground beef. Changes in L∗ -value itself may not have that much impact on beef color, but are important for light meat color. Especially, high L∗ -values in combination with increased a∗ -value intensify the redness of meat. Houser and others (2003) found that storage had no significant effects on the L∗ -value for irradiated cured ham. Also, Nam and Ahn (2002a) reported that packaging, irradiation and storage had no effect on the L∗ -value of precooked turkey breast. Irradiation, antioxidant treatments, and storage influenced the redness (a∗ -value) of ground beef (Table 3). Irradiated ground beef had significantly lower redness values than nonirradiated ones. Adding antioxidants by spraying maintained higher a∗ -values than those by mixing method in nonirradiated meat for 3 d, but the difference was not consistent after 7 d. Antioxidant application methods had no effects on the a∗ -values of irradiated meat. No consistent difference in a∗ -value was observed between the upper and lower surfaces of ground beef. Among the antioxidant treatments, ascorbic acid was the most effective in maintaining red color in both irradiated and nonirradiated ground beef. Addition of tocopherol + sesamol had negative effect on the a∗ -value of ground beef. Nam and Ahn (2003b) showed that addition of sesamol significantly reduced the redness of turkey breast meat after storage. In all antioxidant treatments, a∗ -values started to decrease with storage time regardless of application method. At 3 d, only ascorbic acid maintained the same level of redness values as 0 d. At day 7, the redness of ground beef was not acceptable regardless of antioxidant treatments and application methods. Luchsinger and others (1997) reported that beef patties irradiated at 2.0 kGy were less red than nonirradiated controls. The yellowness (b∗ -values) of beef was dramatically decreased by irradiation in both application methods at day 0 (Table 4). While the b∗ -values of nonirradiated beef decreased over the storage time, those of the irradiated ones increased after 3 d of storage. Nanke and others (1999) reported that the yellowness values decreased in beef and pork because of irradiation. Ascorbic acid increased the yellowness of nonirradiated meat, but as storage period increased, the yellowness decreased. Overall, spraying of antioxidants was better than mixing in maintaining the color of ground beef for short term (<3 d). Significant increases in yellowness (b∗ -value) are frequently seen in irradiated meat, but its impact to overall color of meat because a∗ -value mainly determines the color of meat color. Table 4 --- CIE color b∗ -values of beef mixed or sprayed with different additives during storage at 4 ◦ C. Mixing Non-IR Day 0 Cont. A E+S A+E+S SEM Day 3 Cont. A E+S A+E+S SEM Day 7 Cont. A E+S A+E+S SEM Application (A) Irradiation (IR) Additives (AD) Storage (S) A × IR A × AD A×S IR × AD Spraying IR Non-IR IR Upper Lower Upper Lower SEM Upper Lower Upper Lower 23.70bw 26.20aw 24.08bw 24.96bw 0.38 23.70bw 25.30ax 23.99bw 25.10aw 0.32 15.36cy 17.30by 17.65abx 18.60ax 0.35 17.34x 17.38y 18.30x 18.75x 0.42 0.50 0.28 0.32 0.36 25.44w 25.19w 24.55w 25.04w 0.36 26.35aw 26.44aw 24.96bw 24.94bw 0.35 15.46cy 16.99bx 17.88abx 18.33ax 0.35 17.83x 17.51x 18.65x 17.67x 0.45 0.36 0.44 0.40 0.31 21.07cw 26.25aw 20.00c 23.13bw 0.43 21.42cw 25.13aw 19.90d 22.93bw 0.45 17.71cx 20.81ax 19.00b 20.15ax 0.33 18.34bx 20.42ax 18.90a 20.23ax 0.44 0.37 0.48 0.40 0.40 22.27bx 25.21aw 20.74cx 23.38bw 0.41 23.73bw 26.29aw 22.56bw 24.33bw 0.58 18.34by 20.53ax 19.28aby 20.04ax 0.39 19.15by 20.72ax 19.16by 19.85abx 0.38 0.35 0.55 0.43 0.41 17.20b 19.72a 18.26abwx 18.56ab 0.57 18.52 20.23 19.15w 19.95 0.56 17.43b 20.84a 17.63bx 19.53a 0.47 18.39c 20.81a 18.82bcwx 19.65b 0.33 0.43 0.65 0.34 0.48 18.22bwx 20.29aw 17.26by 18.44bx 0.37 19.58w 21.04w 19.54w 20.38w 0.43 17.13x 17.50x 18.23x 17.41x 0.35 18.68w 20.00w 19.08wx 19.70w 0.46 0.42 0.45 0.33 0.42 DF F -value P 1 1 3 2 1 3 2 3 0.47 994.56 70.29 118.71 11.29 3.31 0.53 12.99 0.4920 0.0001 0.0001 0.0001 0.0009 0.0204 0.5865 0.0001 DF IR × S AD × S A × IR × AD A × IR × S A × AD × S IR × AD × S A × IR × AD × S 2 6 3 2 6 6 6 F -value 298.57 20.60 2.47 5.12 3.25 5.99 1.04 SEM P 0.0001 0.0001 0.0615 0.0064 0.0040 0.0001 0.3978 a–c Values w–y with different letters within a column of each storage period are significantly different (P < 0.05). Values with different letters within a row of each application are significantly different (P < 0.05). Non-IR = nonirradiated samples (0 kGy); IR = irradiated samples (2.5 kGy); Cont = control; A = ascorbic acid; E = vitamin E; S = sesamol; and SEM = standard error of the means (n = 4). Vol. 74, Nr. 1, 2009—JOURNAL OF FOOD SCIENCE C29 C: Food Chemistry Antioxidant application methods on irradiated beef quality . . . Antioxidant application methods on irradiated beef quality . . . Oxidation-reduction potential C: Food Chemistry For both mixing and spraying applications of antioxidants, the ORP values of ground beef decreased after irradiation at 0 d (Table 5). The decrease of ORP by irradiation in ground beef was greater (lower ORP values) with mixing than spraying method. Lowered ORP in irradiated meat rapidly increased during storage under aerobic conditions as previously reported (Hannah and Simic 1985; Nam and Ahn 2002b). Addition of ascorbic acid lowered ORP values in both irradiated and nonirradiated beef regardless of application methods, but the decrease was greater by mixing than spraying. The other 2 antioxidant treatments (E + S, A + E + S) had a higher ORP values than ascorbic acid alone in both application methods, but mixing method was better than spraying in maintaining reducing conditions (low ORP) for short-term storage (3 d). After 3 d storage, the ORP values of all ground beef increased significantly. sistent. CO was produced by radiolysis of meat components in meat by irradiation (Lee and Ahn 2004). E + S treatment produced smaller amounts of CO in irradiated ground beef after 3 and 7 d of storage, but other treatments had no effect. As storage period increased, the amount of CO in ground beef decreased regardless of application methods or antioxidant treatments. Volatiles production Irradiation, antioxidants, and storage time influenced volatile production in both application methods (Table 7 and 8). Irradiation increased the production of total volatiles from beef at days 0 and 3. However, the amounts of total volatiles in nonirradiated ground beef were higher than those of irradiated ones regardless of antioxidant treatments or application methods due to great increase in alcohol content at day 7. Ethanol was the major alcohol and the content increased greatly in nonirradiated ground beef after 7 d of storage probably due to microbial growth. However, total CO production plate count of microorganisms in the samples was not conducted. Irradiation increased CO production from ground beef (Table 6). There was no clear trend in the production of all volatiles between The amount of CO produced in irradiated ground beef was higher mixing and spraying method. with mixing than spraying application in general, but was not conTable 6 --- Carbon monoxide (CO) gas formation from beef Table 5 --- ORP values of beef mixed or sprayed with dif- mixed or sprayed with different additives during storage ferent additives during storage at 4 ◦ C. at 4 ◦ C. Mixing Non-IR Spraying IR SEM Non-IR Mixing IR SEM Spraying Non-IR IR (Unit: mVolt) Day 0 Cont. A E+S A+E+S SEM Day 3 Cont. A E+S A+E+S SEM Day 7 Cont. A E+S A+E+S SEM cy 30.13 −87.75 −6.13b −17.38b 46.19a 22.20a 8.53a 7.58b 5.62 7.86 7.01 6.11 9.12 4.12 69.58a 95.05a 42.78b 27.70b 80.15ay 102.23ax 37.53by 55.38bx 8.13 5.95 9.66 7.00 6.10 4.83 44.38a 92.33 −6.95by 88.10x 72.23ay 132.50x 55.03ay 90.75x 15.71 10.74 16.14 15.12 11.35 10.30 ax Application (A) Irradiation (IR) Additives (AD) Storage (S) A × IR A × AD A×S IR × AD IR × S AD × S A × IR × AD A × IR × S A × AD × S IR × AD × S A × IR × AD × S Non-IR IR SEM (Unit: mVolt) ax cy 2.85 35.83b 73.63ax 14.83c 6.41 8.02 3.06 4.70 4.96 113.58a 116.90a 72.93b 74.93b 117.55ay 120.88ax 74.95b 84.45b 3.25 5.23 5.43 4.97 0.83 4.58 56.75 30.50b 49.73ay 12.80c 4.36 68.38 38.13y 46.23y 38.35y DF F -value 1 1 3 2 1 3 2 3 2 6 3 2 6 6 6 94.20 42.43 52.52 256.99 0.81 9.78 14.93 11.24 86.85 9.17 1.15 8.38 2.76 8.35 1.75 113.33 15.80 98.55x 9.57 111.65x 7.74 93.15x 8.16 10.21 11.39 JOURNAL OF FOOD SCIENCE—Vol. 74, Nr. 1, 2009 Day 0 Cont. A E+S A+E+S SEM Day 3 Cont. A E+S A+E+S SEM Day 7 Cont. A E+S A+E+S SEM 38.86 18.34y 22.43y 18.50y 13.83 135.72 85.65x 91.70x 87.33x 27.23 29.51ay 22.09ay 5.50by 30.03ay 4.20 100.56ax 15.18 87.67abx 7.91 47.85bx 5.01 69.23abx 5.00 12.40 0.00y 0.00y 0.00y 0.00y 0.00 P 0.0001 0.0001 0.0001 0.0001 0.3685 0.0001 0.0001 0.0001 0.0001 0.0001 0.3309 0.0004 0.0143 0.0001 0.1135 a –c Values with different letters within a column of each storage period are significantly different (P < 0.05). x –y Values with different letters within a row of each application are significantly different (P < 0.05). Non-IR = non-irradiated samples (0 kGy); IR = irradiated samples (2.5 kGy); Cont = control; A = ascorbic acid; E = vitamin E; S = sesamol; and SEM = standard error of the means (n = 4). C30 SEM Application (A) Irradiation (IR) Additives (AD) Storage (S) A × IR A × AD A×S IR × AD IR × S AD × S A × IR × AD A × IR × S A × AD × S IR × AD × S A × IR × AD × S 85.09x 61.19ax 27.26bx 61.04ax 7.65 35.65 16.18 14.18 11.48 7.14 7.61 2.31 1.71 18.11y 11.50y 10.00y 10.84y 6.05 83.49x 8.53 91.68x 8.99 82.01x 8.93 97.23x 12.87 12.77 23.97y 16.01aby 5.76by 28.10ay 4.52 74.27x 82.90ax 49.68bx 57.06abx 7.64 4.33 7.62 7.13 5.47 0.00y 3.60y 0.00y 0.00y 1.80 49.94x 64.77ax 30.65bx 47.88abx 5.36 4.01 3.87 1.89 5.42 DF F -value 1 1 3 2 1 3 2 3 2 6 3 2 6 6 6 6.53 356.14 8.97 27.94 0.64 2.56 0.60 2.29 6.82 0.88 1.64 0.43 0.54 0.97 0.15 P 0.0117 0.0001 0.0001 0.0001 0.4255 0.0571 0.5517 0.0804 0.0015 0.5105 0.1833 0.6511 0.7745 0.4461 0.9891 a –c Values with different letters within a column of each storage period are significantly different (P < 0.05). x –y Values with different letters within a row of each application are significantly different (P < 0.05). Non-IR = nonirradiated samples (0 kGy); IR = irradiated samples (2.5 kGy); Cont = control; A = ascorbic acid; E = vitamin E; S = sesamol; and SEM = standard error of the means. n = 4. Antioxidant application methods on irradiated beef quality . . . increased the most after 3 and 7 d of storage, especially in irradiated meat with control and ascorbic acid treatments. Addition of α-tocopherol + sesamol or ascorbic acid + α-tocopherol + sesamol was more effective than ascorbic acid in lowering the amounts of aldehydes in irradiated beef. Aromatic compounds, mainly tolune, were produced only in irradiated ground beef. Similar trends were detected in meat with spraying application (Table 8). Nam and Table 7 --- Volatile compounds of beef mixed with different additives during storage at 4 ◦ C. Cont Compound Non-IR E+S A IR Non-IR IR A+E+S Non-IR IR Non-IR IR SEM (Total ion counts × 10 ) 4 Day 0 Hydrocarbons Ketones Alcohols Aldehydes Aromatics Total volatiles Day 3 Hydrocarbons Ketones Alcohols Aldehydes Aromatics Total volatiles Day 7 Hydrocarbons Ketones Alcohols Aldehydes Aromatics Total volatiles 9847bc 9027 6589 2092a 0c 27556c 13059b 12870 8601 2480a 383b 37392ab 1047d 10199 5859 706b 0c 17811d 8661c 14712 7852 1246b 666a 33136c 24038a 10102 4990 952b 0c 40082ab 25045a 11558 7283 1118b 608a 45612a 4642cd 9380 4969 969b 0c 19960d 9592bc 14137 8352 1044b 626a 33750bc 1681 1597 1010 206 23 2485 6615cd 5359b 7601abc 3325ab 0c 22900bc 13914b 7407ab 8965a 4646a 508b 35440a 1823d 6384ab 5289abc 653b 0c 14149c 10441bc 8807ab 8123ab 1360b 586a 29316ab 20160a 9342a 4037bc 537b 0c 34076a 19542a 9603a 6578abc 746b 501b 36970a 4415d 6965ab 3752c 579b 0c 15710c 7213cd 8490ab 5381abc 599b 477b 22161bc 1435 835 941 668 20 2763 7736cd 18085 40494a 3420b 0c 69735a 17160b 12378 10511b 9138a 553a 49740ab 3717d 13056 52917a 3156b 0c 72846a 10430c 11727 7536b 1970b 506a 32169b 20390b 13262 12671b 1301b 146b 47770ab 27688a 12769 4434b 833b 564a 46288ab 8318cd 12634 17452b 1632b 189b 40225ab 8922c 11763 3706b 559b 488a 25439b 1329 1878 6854 1240 21 8582 a–c Values with different superscripts within a row are significantly different (P < 0.05). n = 4. Non-IR = non-irradiated (0 kGy); IR = irradiated (2.5 kGy); A = ascorbic acid; E = vitamin E; S = sesamol; and SEM = standard error of the means. Hydrocarbons: 2-Methyl butane, propane, 1-pentene, pentane, 1-hexene, hexane, 1-heptene, heptane, octane, nonane; Ketones: 2-Propanone, 2,3-butanedione, 2-butanone, 2-pentanone, 2-heptanone; Alcohols: Ethanol, 1-propanol, 2-butanol, 1-pentanol, 2-methyl-1-propanol, 3-methyl-1-butanol, hexanol; Aldehydes: Acetaldehyde, propanal, 3-methyl butanal, hexanal, heptanal; Aromatics: Toluene. Table 8 --- Volatile compounds of irradiated and nonirradiated ground beef with antioxidants added by spraying during storage at 4 ◦ C. Cont Compound Non-IR E+S A IR Non-IR IR Non-IR A+E+S IR Non-IR IR SEM (Total ion counts × 10 ) 4 Day 0 Hydrocarbons Ketones Alcohols Aldehydes Aromatics Total volatiles Day 3 Hydrocarbons Ketones Alcohols Aldehydes Aromatics Total volatiles Day 7 Hydrocarbons Ketones Alcohols Aldehydes Aromatics Total volatiles 12499bc 10603 12843ab 1474ab 0c 37419abc 17180a 11553 13912a 1927a 594ab 45166a 3617e 9389 11521ab 705c 0c 25231d 8066de 13762 14107a 1454ab 591ab 37980abc 7248de 10518 10919ab 1257abc 0c 29942cd 14884ab 11681 11703ab 1822ab 715a 40805ab 6416de 10044 9572b 1108bc 0c 27140cd 8933cd 12564 10740ab 1688ab 553b 34479bcd 1235 1737 815 172 38 2398 7721b 5218 10123bc 1645b 0b 24707bc 14966a 7080 13135ab 5575a 500a 40256a 3544b 5517 10263bc 1311b 0b 20634c 9315ab 8057 14101a 4824a 495a 35802a 6139b 5340 8252c 553b 0b 20284c 15827a 6393 10264bc 1483b 445a 33523ab 3372b 5312 7064c 407b 0b 16156c 7211b 7235 9803bc 1493b 502a 25240bc 1921 773 829 621 27 2615 10212ab 13542a 30612a 2409b 0c 56776a 16112a 11063abc 11136b 7085a 512ab 45909ab 5046c 10193bc 23866ab 1396b 0c 40501abc 13245a 9800bc 9858b 9343a 558a 42804abc 11310a 12689ab 30657a 2231b 0c 56887a 9537bc 9073c 7179b 896b 479b 27163c 3790c 11973abc 29487a 1558b 0c 46809ab 7311c 9643bc 6172b 640b 472b 24238c 1461 710 4357 945 17 4981 a–d Values with different superscripts within a row are significantly different (P < 0.05). n = 4. Non-IR = nonirradiated (0 kGy); IR = irradiated (2.5 kGy); A = ascorbic acid; E = vitamin E; S = sesamol; SEM = standard error of the means. Hydrocarbons: 2-Methyl butane, 1-pentene, pentane, 1-hexene, hexane, 1-heptene, heptane, octane, nonane; Ketones: 2-Propanone, 2,3-butanedione, 2-butanone, 2-pentanone, 3-hexanone, 2-heptanone; Alcohols: Ethanol, 1-propanol, 1-butanol, 2-butanol, 1-pentanol, 1-hexanol, 2-methyl-1-propanol, 3-methyl-1-butanol; Aldehydes: Acetaldehyde, propanal, 3-methyl butanal, hexanal, heptanal; Aromatics: Toluene. Vol. 74, Nr. 1, 2009—JOURNAL OF FOOD SCIENCE C31 C: Food Chemistry With mixing method (Table 7), the amounts of hydrocarbons were the highest in irradiated meat with E + S treatment and the lowest in nonirradiated meat with ascorbic acid treatment. Aldehydes were produced the most in control beef regardless of irradiation treatment and increased as storage time increased. Acetaldehyde, propanal, 3-methyl-butanal, hexanal, and heptanal were the aldehydes detected in ground beef, but the amount of hexanal Antioxidant application methods on irradiated beef quality . . . C: Food Chemistry others (2006) reported that the combination of rosemarytocopherol reduced the amount of hexanal in irradiated pork loin by 30%. Hexanal is a common indicator of lipid oxidation in meat (Ahn and others 1999b). Sulfur compounds were detected only in irradiated meat but the amounts were very small. The reason for the low sulfur volatiles in irradiated ground beef, especially at day 0, in this study is not clear, but could be related to the somewhat lengthy exposure of samples to aerobic conditions before analysis at day 0. A Conclusions ntioxidant combinations E + S and A + E + S were highly effective in preventing oxidative changes in irradiated and nonirradiated ground beef. However, ascorbate alone was effective only in nonirradiated ground beef. Adding antioxidants in beef patties by spraying produced more volatiles, hydrocarbons, and alcohols, and had higher ORP values than those with mixing. This indicated that patties with tested antioxidants applied on the surfaces would be more susceptible to oxidative changes than those spread antioxidants throughout by mixing. Therefore, mixing method is recommended for applying ascorbic acid and antioxidants to avoid any quality changes in irradiated ground beef. References Ahn DU, Nam KC. 2004. Effects of ascorbic acid and antioxidants on color, lipid oxidation and volatiles of irradiated ground beef. Rad Phys Chem 71(1/2):151– 6. Ahn DU, Olson DG, Lee JI, Jo C, Chen X, Wu C. 1998a. Packaging and irradiation effects on lipid oxidation and volatiles in pork patties. J Food Sci 63:15–9. Ahn DU, Olson DG, Jo C, Chen X, Wu C, Lee JI. 1998b. Effect of muscle type, packaging, and irradiation on lipid oxidation, volatile production and color in raw pork patties. Meat Sci 49:27–39. Ahn DU, Jo C, Olson DG. 1999a. Headspace oxygen in sample vials affects volatiles production of meat during the automated purge-and-trap/GC analysis. J Agric Food Chem 47(7):2776–81. Ahn DU, Olson DG, Jo C, Love J, Jin SK. 1999b. Volatiles production and lipid oxidation of irradiated cooked sausage with different packaging during storage. J Food Sci 64:226–9. Ahn DU, Jo C, Du M, Olson DG, Nam KC. 2000. Quality characteristics of pork patties irradiated and stored in different packaging and storage conditions. Meat Sci 56:203–9. Ahn DU, Nam KC, Du M, Jo C. 2001. Volatile production in irradiated normal, pale soft exudative (PSE) and dark firm dry (DFD) pork under different packaging and storage conditions. Meat Sci 57(4):419–26. [AMSA] American Meat Science Association. 1991. Guidelines for meat color evaluation. In: Proceedings of the 4th reciprocal meat conference. Chicago, Ill.: Natl. Live Stock and Meat Board 1–17. Breidenstein BC, Williams JC. 1986. The consumer climate for red meat. Special Issue. Washington, D.C.: American Meat Inst. Chicago, Ill.: Natl. Livestock and Meat Board. Brewer MS, Harbers CAZ. 1992. Effect of packaging on physical and sensory characteristics of ground pork in long-term frozen storage. J Food Sci 56:627–31. Faustman C, Cassens RG. 1990. The biochemical basis for discoloration in fresh meat: a review. J Muscle Foods 1:217–43. Giroux M, Ouattara B, Yefsah R, Smoragiewicz W, Saucier L, Lacroix M. 2001. Combined effect of ascorbic acid and gamma irradiation on microbial and senso- C32 JOURNAL OF FOOD SCIENCE—Vol. 74, Nr. 1, 2009 rial characteristics of beef patties during refrigerated storage. J Agric Food Chem 49(2):919–25. Gray JI, Gomaa EA, Buckley DJ. 1996. Oxidative quality and shelf life of meats. Meat Sci 43(Suppl):111–23. Hannah KW, Simic MG. 1985. Long-term preservation of bacon by high energy electrons. Rad Phys Chem 25:167–71. Hermel SR. 1993. Extending the bloom. Beef (May):8–12. Houser TA, Sebranek JG, Lonergan SM. 2003. Effects of irradiation on properties of cured ham. J Food Sci 68(7):2362–5. Kim YH, Nam KC, Ahn DU. 2002a. Color, oxidation-reduction potential, and gas production of irradiated meats from different animal species. J Food Sci 67(5):1692–5. Kim YH, Nam KC, Ahn DU. 2002b. Volatile profiles, lipid oxidation and sensory characteristics of irradiated meat from different animal species. Meat Sci 61(3):257–65. Lee EJ, Ahn DU. 2004. Sources and mechanisms of carbon monoxide production by irradiation. J Food Sci 69(6):C485–90. Lee BJ, Hendricks DG, Cornforth DP. 1999. A comparison of carnosine and ascorbic acid on color and lipid stability in a ground beef patties model system. Meat Sci 51(3):245–53. Liu Q, Scheller KK, Schaefer DM, Arp SC, Williams SN. 1994. Dietary α-tocopheryl acetate contributes to lipid stability in cooked beef. J Food Sci 59(2):288–90. Luchsinger SE, Kropf DH, Garcia-Zepeda CM, Hunt MC, Stroda SL, Marsden JL, Kastne CL. 1997. Color and oxidative properties of irradiated ground beef patties. J Muscle Foods 8:445–64. Mitsumoto M, Faustman C, Cassens G, Arnold DM, Schaefer DM, Scheller KK. 1991. Vitamins E and C improve pigment and lipid stability in ground beef. J Food Sci 56(1):194–7. Moiseeve IV, Cornforth DP. 1999. Treatments for prevention of persistent pinking in dark-cutting beef patties. J Food Sci 64:738–43. Morrissey PA, Sheehy PJA, Galvin K, Kerry JP, Buckley DJ. 1998. Lipid stability in meat and meat products. Meat Sci 49(S):73–86. Nam KC, Ahn DU. 2002a. Mechanism of pink color formation in irradiated precooked turkey breast meat. J Food Sci 67(2):600–7. Nam KC, Ahn DU. 2002b. Carbon monoxide-heme pigment is responsible for the pink color in irradiated raw turkey breast meat. Meat Sci 60:25–33. Nam KC, Ahn DU. 2003a. Effects of ascorbic acid and antioxidants on the color of irradiated ground beef. J Food Sci 68(5):1686–90. Nam KC, Ahn DU. 2003b. Use of double packaging and antioxidant combinations to improve color, lipid oxidation, and volatiles of irradiated raw and cooked turkey breast patties. Poultry Sci 82:850–7. Nam KC, Ahn DU, Du M, Jo C. 2001. Cholesterol oxides in irradiated raw meat with different packaging and storage time. Meat Sci 58(4):431–5. Nam KC, Ko KY, Min BR, Ismail H, Lee EJ, Cordary J, Ahn DU. 2006. Influence of rosemary-tochopherol/packaging combination on meat quality and the survival of pathogens in restructured irradiated pork loins. Meat Sci 74:380–7. Nanke KE, Sebranek JG, Olson DG. 1998. Color characteristics of irradiated vacuumpackaged pork, beef, and turkey. J Food Sci 63(6):1001–6. Nanke KE, Sebranek JG, Olson DG. 1999. Color characteristics of irradiated aerobically packaged pork, beef, and turkey. J Food Sci 64(2):272–8. Pearson AM, Love LD, Shorland FB. 1977. Warmed-over flavor in meat, poultry and fish. Adv Food Res 23:1–74. Poste LM, Willment G, Butler G, Patterson C. 1986. Sensory aroma scores and TBA values as indices of warmed-over flavor in pork. J Food Sci 51:886–8. Sanchez-Escalante A, Djenane D, Torrescano G, Beltran JA, Roncales P. 2001. The effects of ascorbic acid, taurine, carnosine and rosemary powder on colour and lipid stability of beef patties packaged in modified atmosphere. Meat Sci 58(4):421–9. SAS Inst. 1995. SAS/STAT user’s guide. Cary, N.C.: SAS Inst. Inc. Tarladgis BG, Watts BM, Younathan MT, Dugan L. 1960. A distillation method for the quantitative determination of malonaldehyde in rancid foods. J Am Oil Chem Soc 37:44–8. Wheeler TL, Koohmaraie M, Shackelford SD. 1996. Effect of vitamin C concentration and co-injection with calcium chloride on beef retail display color. J Anim Sci 74(8):1846–53. Xiong YL, Decker EA, Robe GH, Moody WG. 1993. Gelation of crude myofibrillar protein isolated from beef heart under antioxidant conditions. J Food Sci 58(6):1241–4. Zhu MJ, Lee EJ, Mendonca A, Ahn DU. 2003. Effect of irradiation on the quality of turkey ham during storage. Meat Sci 66:63–8.