MECHANICAL CONTRIBUTIONS TO THE PLANE-STRAIN ... PRACHEESHWAR SWAROOP MATHUR AND

advertisement

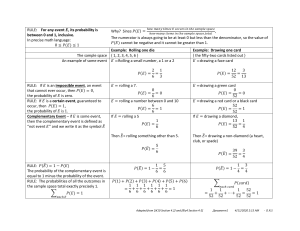

MECHANICAL CONTRIBUTIONS TO THE PLANE-STRAIN DEFORMATION

AND RECRYSTALLIZATION TEXTURES OF AL-KILLED STEEL

by

PRACHEESHWAR SWAROOP MATHUR

B. Tech., Indian Institute of Technology, Kanpur

(1967)

S. M., Massachusetts Institute of Technology

(1968)

Submitted in Partial Fulfillment of the Requirements

for the Degree of

DOCTOR OF SCIENCE

at the

Massachusetts Institute of Technology

June 1972

D

Signature of Author

Department of Metallurgy and Materials Science

May 5, 1972

Certified by

Thesis Supervisor

Zoo

A~

.11

Accepted by

Chairman, Departmental Committee on Graduate Students

Archives

JUL 5 1972

LIBRARIES

ii

MECHANICAL CONTRIBUTIONS TO THE PLANE-STRAIN DEFORMATION

AND RECRYSTALLIZATION TEXTURES OF AL-KILLED STEEL

by

PRACHEESHWAR S. MATHUR

Submitted to the Department of Metallurgy and Materials Science on

May 5, 1972 in partial fulfillment of the requirements of the

degree of Doctor of Science

ABSTRACT

This work is concerned with the texture changes which underlie

the reduction dependence of the plastic anisotropy of cold rolled

and recrystallized killed-steel strip. The earlier observations of

Whiteley and Wisel on the maxima in the intensity of rolling plane

{lll and in the anisotropy parameter, Rf, were repeated and extended

by introducing into the cold-reduction step the variable of deformation-zone geometry (i.e. A, the ratio of the mean height of the zone

to its length). A range of A < 1 to A = 4 was covered by cold rolling (< 1) and strip drawing (from 1 to 4). Pole figures after rolling reductions of about 98% are changed abruptly as if by a 550 rotation of part of the stable texture around the transverse direction.

It is suggested that the mechanism is localized flow in macroscopic

bands along maximum shear planes as strain hardening capacity is

exhausted. There is both mechanical and metallographic evidence of

such bands. Assigning a shear texture to them modifies the parent

texture in a way which is consistent with the pole figures. As A

becomes > 1, strain and texture gradients appear and the texture

inversion occurs in the more strained regions at smaller total reductions -- after as little as 40% for surface layers with A = 4.

The mechanism appears not to be changed,however, only accelerated

in terms of the imposed reduction. Implications for practical

texture control are discussed.

Thesis Supervisor:

Title:

Walter A. Backofen

Professor of Metallurgy and Materials Science

TABLE OF CONTENTS

Page

ABSTRACT ----------------------------------------------------------

1i

LIST OF FIGURES ---------------------------------------------------

v

LIST OF TABLES ----------------------------------------------------

viii

ACKNOWLEDGEMENTS --------------------------------------------------

ix

INTRODUCTION ------------------------------------------------------

1

EXPERIMENTAL PROCEDURES -------------------------------------------

3

Choice of Process --------------------------------------------

3

Design of Experiments ----------------------------------------

6

Material and Specimen Preparation ----------------------------

8

Texture Measurements -----------------------------------------

10

Microscopy ---------------------------------------------------

11

RESULTS -----------------------------------------------------------

11

The Homogeneous Deformation Texture --------------------------

11

Inhomogeneous Deformation and Texture Gradients --------------

20

IMPLICATIONS FOR TEXTURE CONTROL ----------------------------------

33

SUMMARY AND CONCLUSIONS -------------------------------------------

36

REFERENCES --------------------------------------------------------

37

APPENDIX I -

Procedural Details ---------------------------------

40

APPENDIX II -

The Uniformity of Rolling Texture ------------------

48

iv

-

Stereographic Rotation of Ideal Rolling

Textures in {100} and {110} Projections ----------

51

Stereographic Rotation of the Ideal Shear

Textures of Iron in {lOO1} and {110}

Projections --------------------------------------

54

Gradients in {lOO} Reflection Intensity for A > 1

56

SUGGESTIONS FOR FUTURE RESEARCH -----------------------------------

58

BIOGRAPHICAL NOTE -------------------------------------------------

60

APPENDIX III

APPENDIX IV

APPENDIX V

-

-

v

LIST OF FIGURES

Pagj

Figure

1

Deformation zone geometry for strip drawing (a) and

rolling (b). -------------------------------------------

4

2

Cold rolling pole figures: {100}, {llO}, and {111}.

Cumulative reductions noted on each. Ideal fiber

textures identified by A, B, and C. Fiber axis is

<110> along the R.D. for A, <110> 600 from the R.D.

toward the sheet normal for B, and <111> along the

sheet normal for C.------------------------------------

12

Strain and reduction dependence of rolling-plane reflection intensities. The insert shows the more usual

method of plotting directly against cumulative reduction. --------------------------------------------------

14

Ideal fiber textures from Fig. 2 in a {1lll} projection

in (a) and after a + 550 rotation around the T.D. in

(b). --------------------------------------------------

15

Ideal shear (or torsion) textures for iron in a {1lll}

projection in (a) and after a + 350 rotation around the

T.D. in (b). The 350 rotation in (b) leads to pole

reinforcement at 55' from the sheet normal. ------------

17

6

Shear bands after 99% cold rolling reduction.-----------

19

7

Strain and reduction dependence of {111} reflection

intensities from the drawing plane of strip reduced

with different A. The various a-r combinations for

any A are noted in each case. Curve u is for the

homogeneously cold rolled strip of Fig. 3. Curve s

(filled symbols) represents near-surface reflections;

curve c (open symbols) is from the center.--------------

21

8

The {l00} companion to Fig. 7.

--------------------------

22

9

The variation with depth, At, below the surface

(where At/to = 0) of {111} reflection intensities

in strip reduced different amounts with several A. -----

23

3

4

5

vi

Fiqure

Pagi

The A dependence of the imposed (or apparent) strain, Ei,

for the {111} inversion in Fig. 7 and for the appearance

of edge cracking, Rolling A is known only to be < 1. --

25

The effect of friction on surface-reflection intensities

from strip drawn with constant A = 1.5 and a = 6 .------

26

Strain and reduction dependence of {111} reflection intensities from the drawing plane of strip reduced with

different A and then recrystallized. The various a-r

combinations for any A are noted in each case. All

measurements are from the surface. Curve u is

"recrystallized" from Fig. 3.

---------------------------

27

13

The {100} companion to Fig. 12.-------------------------

28

14

Pole figures from different locations in strip cold drawn

a total of 80% with A = 2 and a = 120. Location is defined by At/to: 0.05 is just below the surface, at a

depth of 5% of the drawn thickness; 0.44 is near the

center; 0.20 is about midway between surface and center.

Ideal textures from Figs. 2 and 4a are included. -------

30

Scanning-electron micrographs of edge cracking in the

99% cold rolled strip of Fig. 6 and in the 80% colddrawn strip from which the pole figures in Fig. 14

were taken. Cracks penetrate only about 20% of the

thickness in the drawn strip.---------------------------

32

Variation of rolling-plane {100} and {111} intensity

through the thickness of strips cold rolled to various

cumulative reduction. ----------------------------------

49

11-2

{111} pole figures of 80% and 92% cold-rolled strips. --

50

III-1

Ideal fiber textures A, B and C in {100} and {110} pole

figures (a); and rotated + 550 around T.D. (b). A and

B are two partial fiber textures with fiber axis <110>

parallel to R.D. (A), and at 600 to R.D. toward N.D.

(B); C is a complete fiber texture with fiber axis

<111> parallel to N.D. ---------------------------------

53

10

11

12

15

II-1

vii

Page

Figure

IV-1

V-1

Ideal orientations of the shear texture in iron in {lOO1}

and {110} projections and rotated + 350 around T.D. ----

55

Variation of rolling-plane {00} reflection intensity as

a multiple of random through the thickness of strips

drawn to various cumulative reductions with constant A

and a. -------------------------------------------------

57

viii

LIST OF TABLES

Table

1

Strip Drawing Conditions -----------------------------------

7

2

Composition ------------------------------------------------

9

3

Some Mechanical Properties ---------------------------------

9

I-1

Conditions for Pole Figure Determination -------------------

44

1-2

Conditions of Diffractometry -----------------------------

45

ix

ACKNOWLEDGEMENTS

The author is grateful to Professor W.A. Backofen for his help,

guidance and encouragement throughout the course of this work.

He also wishes to thank Mr. R.L. Whiteley of Bethlehem Steel

Corporation for providing the sheet steel used in the research.

Discussions with members of the Metals Processing Laboratory are

gratefully acknowledged.

Special thanks are due Miss Jean L.

DiMauro for typing the manuscript.

The research program was generously supported by the American

Iron and Steel Institute.

1

MECHANICAL CONTRIBUTIONS TO THE PLANE-STRAIN DEFORMATION

AND RECRYSTALLIZATION TEXTURES OF AL-KILLED STEEL

INTRODUCTION

The crystallographic textures of wrought metals are commonly classed

according to the processes by which they are produced, e.g. rolling, wire

drawing, deep drawing.2,3

This implies that the strain state is defined

by the shape change imposed in processing, or that straining is homogeneous.

In many practical operations the implication is a reasonable one.

It can happen, however, that the strain state is not fully known from just

the external shape-change; local variations are possible depending upon

the geometry of the deformation zone in the processing system.

A useful

index of that geometry is the ratio of the mean zone thickness, II,to the

zone contact-length, L, or A = I/L (Fig. 1).

Many effects of processing

respond to changes in A. One of interest here is the amount of redundant

strain in a given reduction; there are good theoretical grounds4 for expecting it to increase with A, and experiment has shown it to be an approximately single-valued and linear function of A irrespective of the

particular reduction and zone contour, e.g. die angle.5-7

Strain dis-

tribution, also, has been found to be strongly dependent on A.7 ,8

It seemed reasonable therefore, as a starting point in the present

work, to suppose that texture would be sensitive to A level and even

2

subject to some control through control of A. Ferritic low-carbon steel

strip was the material choice because it can be given a texture by planestrain reduction and annealing which causes large amounts of useful

plastic anisotropy.l*

The texture of cold-rolled ferrite is known from earlier pole figure

studies, and there is no serious argument about how it ought to be de2 3 9 14

cribed. 9 ~14 The recrystallization texture is also well known. , , '

A number of mechanical studies after recrystallization have emphasized

14 15

i values and the intensity of rolling-plane X-ray reflections.1, ,

In cold rolled and recrystallized killed-steel there is a maximum in '

after about 80% reduction and, somewhat later, at , 98%, a maximum in

the intensity of rolling-plane {lll}.

Texture gradients have been studied as well, although there is

still some controversy over their origin.

Roll-gap friction can con-

tribute to the gradients but from weighing all of the evidence friction

appears not to influence cold rolling texture to a depth greater than

*

The usual index of plastic anisotropy is the width-to-thickness

strain ratio in the uniaxial tension test; this is designated

as R (which often represents roll radius as well) or r (which

might now be confused with strip reduction). The average, R',

from measurements at 00, 450, and 90* to the rolling direction

is commonly reported. Drawability usually impoves with

increasing R.1

3

16 -20

about 5% of the strip thickness even when there is no lubricant.

There is other evidence that large A, i.e. > 1, or what has been called

"high-body rolling", also contributes, even more importantly, to texture

gradients. 20

Background in this area, however, is extremely limited,

and adding to it was another goal of the present work.

EXPERIMENTAL PROCEDURES

Choice of Process:

The A for each of two plane-strain reductions

is defined in Fig. 1. The process in Fig. la is strip drawing through

a die of semi-angle a; mean thickness, F, is taken to be the circular

arc midway through the deformation zone, drawn normal to both die

faces, and L is the interface length.

A

In these terms,

~

L r (2 - r)

where a is in radians and r = 1

-

(1)

(h1 /h0 ) is the reduction in the pass.

For strip rolling (Fig. lb),

Az ~

h0

R (2 - r)

where R is roll radius, h0 is entering thickness, and r is again the

fractional reduction in the pass; the usual approximation is made of

L ~ Aii~.

0

Thus the equivalent die angle in a rolling reduction is

(2)

4

L

a

r

2-r)

(b)

-4Rr ( 2 -r )=

CI

(2-r

Figure 1. Deformation zone geometry for strip drawing (a)

and rolling (b).

5

rh '

In cold strip rolling A tends to lie near 1 because a horizontally

directed friction force large enough for the rolls to "bite" and deliver

well-lubricated strip cannot usually be developed with A much larger than

that.

To fix A at any level, however, is nearly tantamount to making roll

size, R, a variable, for only then could a sequence of constant-reduction

passes be made on any given lot of material.

To achieve constant A in a

given mill r could be lowered in succeeding passes, but then r would no

longer be an independent variable and would eventually become extremely

small and difficult to control.

To avoid such complications, the process choice for much of this work

was plane-strain strip drawing.

As Eq. 1 shows, A can be held constant

now for given r by fixing the die angle, a; and as Eq. 3 shows, this is

equivalent to reducing R along with strip thickness in rolling to produce

the same effect.

drawing.

There are, however, two related disadvantages to strip

One is that the final cumulative reduction (Er) will not be as

large as in rolling because the applied tension encourages drawing failure as the material's strain hardening capacity is exhausted.

Its effect

in these experiments was to limit the total strip-drawing reduction to

Er ~ 90%.

The other disadvantage for present purposes is that the low

rolling-A magnifies frictional stresses.

In low-A drawing, the effect

again contributes to a total allowable reduction less than that in rolling.

Accordingly, the highest cumulative reductions in the work about

6

to be described (Er ~ 99%) were still reached by rolling under conditions

which could be controlled only to the extent that A was always kept < 1

(in a range of about 0.3 to 0.5).

in strip drawing.

The range of A > 1 is easy to explore

Although the high end of that range, e.g. A > 2, is

not usually entered in practical rolling it was important to do so here,

to establish the trends which carry down to lower A.

There is good reason to expect that textures will be essentially

the same in strip which has been rolled and drawn the same amount in

plane strain under identical conditions of deformation-zone geometry

and friction.

The displacement boundary conditions, i.e. the shape

changes, which determine the kind of texture that develops in a given

material are the same.

The processes differ only in the hydrostatic

part of their stress systems.

This expectation is borne out by the

findings.

Design of Experiments:

Experimental conditions for strip drawing

are summarized in Table I. Each A was produced by different combinations

of a and r to see if texture did depend on the variables which fix A, at

least within the range of values in Table I.

The drawing apparatus was almost a copy of that used by Rogers and

Coffin 2 1 in their study of plane-strain strip drawing, although without

the provision for measuring die load.

A different pair of tungsten-

carbide inserts was used for each die angle.

A constant r was maintained

7

TABLE I

STRIP DRAWING CONDITIONS

(Terms are defined in Eq.

r, %

A

1

1.5

2

1 and Fig. 1)

30

10.0

60

20.0

120

40.0

30

6.7

60

13.5

120

27.0

30

5.0

60

10.0

120

20.0

60

4

120

120

5.0

10.0

10.0

8

by changing the die-face separation after each pass by inserting pieces of

hardened-steel shim stock between the backs of the inserts and the outside

casing in which they were mounted.

machine at 1.0 in/min.

Drawing was done in an Instron testing

Other procedural details are given in Appendix I.

A Teflon coating was the usual lubricant.*

by Alexander's

22

method, was about 0.08.

The friction coefficient,

Friction effects were studied

for A = 1.5 with a = 60 and r = 0.135 by lubricating some strips with an

ordinary washing soap and water solution.

Drawing forces now were about

twice as large as those with Teflon, which meant that the friction coefficient (from an analysis by Wistreich 23 ) was raised to about 0.20.

Material and Specimen Preparation:

The test material was an an-

nealed and temper-rolled aluminum-killed steel of ASTM grain Size No. 7

processed to yield a nearly random orientation.

Its composition and

some mechanical properties are given in Tables II and III.

Drawing specimens were 1-in wide, 12-in long (along the rolling

direction) and surface ground to a uniform thickness which varied from

batch to batch but was about 0.2 in. They were "pointed" by rolling

half their length so as to pass through the drawing die and then

cleaned and lubricated.

Periodically during the reduction sequence

pieces about 4-in long were cut off for the texture studies.

*

Emeralon 323 from the Acheson Colloid Co.

9

TABLE II

COMPOSITION

Mn

C

Al

Si

Ni

Cr

S

Cu

P

Mo

Sn

0.33

0.052

0.05

0.01

0.01

0.01

0.004

0.004

0.002

0.002

0.002

TABLE III

SOME MECHANICAL PROPERTIES

Test Direction

I

_________

*

+

Tensile

Strength (psi)

R

00 (R.D.)

0.93

450

1.0

900 (T.D.)

0.97

________

___

0.98

= (R0 + 2R4 5 + R90

n is the slope of a log a - log s plot

0.25

45,000

0.26

44,500

0.24

45,500

10

The recrystallization treatment after cold working involved heating

in vacuum to 1300*F over a six-hour period, soaking for 28 hours at 1300*F,

and finally furnace cooling.

Texture Measurements:

These were made at different locations in a

reduced strip, from the surface to center.

Each location was exposed by

etching at room temperature in a 50:50 hydrogen peroxide and phosphoric

acid bath.

The surface location was also reached by etching away material,

usually from 1 to 3% of the sample thickness; this proved to be enough to

avoid frictional complications with the Teflon lubricant used here.

There were two kinds of measurements:

parallel to the exposed surface (I

figures. 24

line intensities from planes

and I{100}) and Schulz-type pole

The latter were constructed using a Siemen's texture goniom-

eter and are plotted with intensity contours based on unit intensity

from a random iron-powder sample.

Line intensities are integrated in-

tensities and are plotted after normalizing with respect to the same

line from a random sample, i.e. Io, using Harris' method for doing

this.25

All line-intensity data are given with their 90% confidence

limits; at the surface these are based on measurements at three or

four different areas from each side of the strip, while six different

areas were usually scanned for any one interior location.

detail is found in Appendix I.

Further

11

Microscopy:

The as-drawn and rolled edges were sometimes examined,

after degreasing only, in the scanning electron microscope.

Strips were

also nickel-plated and sectioned for more conventional metallographic

work (Appendix I).

RESULTS

The Homogeneous Deformation Texture:

This is the base for evaluating

A effects and was produced here by cold rolling with A < 1. The result

was a texture uniform through the thickness and, over a large reductionrange, no different from what has already been reported. 9-1

details are given in Appendix II.).

(Supporting

The two <110> fiber textures normally

assigned to cold-rolled steel have been overlaid on the pole figures in

Fig. 2,although a slight improvement in the description could be made with

the recent suggestion, from work on cold-rolled niobium, to substitute

<320> for the fiber axis.26

A <111> fiber texture around the normal to

the rolling plane is also called for by the intense central region in

the {111} pole figures, especially that for 98% reduction.

The new observation appears in the last reduction step, 98% to 99%

(an increase in the logarithmic thickness-strain, c = kn [1/(1-Er)],

of 3.9 to 4.6).

It is most clear in the {111} pole figures where the

central intensity-peak is nearly halved while that at 550 toward the

rolling direction is raised almost 40%.

4.

Companion changes in the other

12

R. D.

R.D.

{Il0}

80%

I

\r

\B

T. D.

R. D.

-

--

T.D.

R. D.

R.D.

92%

1.5

4

3

1.5

T. D.

R.D.

D.

i18

4

T. D.

2

R D.

R.D.

{100}

98%

98%

0.5

-

432

1-

1.5

2

0.5

R 5

T. D.

T. D.

8

R.D.

6

3

T.D.

R.D.

T. D.

Figure 2.

Cold rolling pole figures: {100}, {110}, and {111},

Cumulative reductions noted on each. Ideal fiber

textures identified by A, B, and C. Fiber axis is

<110> along the R.D. for A, <110> 60' from the R.D.

toward the sheet normal for B, and <111> along the

sheet normal for C.

T. D.

13

pole figures are a 30% drop in the {110} peak and a 50% gain in the interior {100} peak, near the intersection of the <110> fiber textures.

A high-reduction texture change has also been found in cold-rolled niobium, in {100} and {111} pole figures; in {100} the interior peak was

doubled while in {111} the central peak was hardly changed as the 550

peak became about three times as strong as that at the center. 26

Reflection intensities from rolling-plane {111} and {100},

i.e. Ill}/I

and I{100} /,

are related to the cumulative reduction

in Fig. 3. Measurements for each reduction were made at 4-5 locations

between the strip surface and center and were sufficiently alike to be

combined.

The trends for cold-rolled material parallel those in Fig. 2,

with a {111} peak somewhat better defined now at Er ~ 98%.

One way of producing the major textural change in Fig. 2 (from

Er = 98%

+

99%) is simply to rotate the ideal orientations of some

fraction of the sample by 55* around the transverse direction.

That

has been done in Fig. 4 with a {111} projection which shows that all

components now reinforce at 550 from the rolling-plane normal while

the central region is spread out.

The same rotation for {110} and

{100} projections also shows that changes in high-intensity regions

follow those in Fig. 2 (See Appendix III).

The mechanism for producing such a rotation might be found in

an area of overlap between continuum mechanics and crystal plasticity.

14

%r,%

40

60

99

98

95

90

80

7-

6

Recrystallized

4-

Cold Rol led

10

3--

2-2

3

2

90

92

94

96

98

0I

IXroo

Cold Rolled

(100)

Recrystallized

00

0

3

2

4

6

Figure 3. Strain and reduction dependence of rolling-plane

reflection intensities. The insert shows the more

usual method of plotting directly against cumulative reduction.

15

R.D.

(a)

A ---

..

-

....

----------

..---

T.D.

L--------

.D

-A

R.D.

B

C

rotated 550

~~~

(b)

550

.----

-

T. D.

Figure 4. Ideal fiber textures from Fig. 2 in a {111}

projection in (a) and after a + 550 rotation

around the T.D. in (b).

16

The inversion in the upward trend in {111} comes after large reductions

when the strain hardening rate (which has not yet been measured in plane

strain at such large strains) is probably low and perhaps even vanishing.

Were all strain hardening to disappear flow could be expected on the

macroscopic maximum-shear surfaces, or along the continuum slip lines

at 450 to a frictionless interface.

Shear strain in stably flowing

volumes around these surfaces in a non hardening solid would be of the

order of 1*; without strain hardening and, if the zone is sufficiently

thick, with any adiabatic heating the flow could become unstable and

still larger localized shear develop, even to the point of fracture.

There would be no need to change crystallographic deformation mechanisms.

The effect on rolling texture would enter from the shear

texture in the locally flowing zones.

This texture is known for

iron, 27 and its ideal orientations are given with reference to the

shear plane in a {111} projection in Fig. 5a.

To fit the argument

being developed, Fig. 5a ought to be rotated 450 around its transverse direction and then compared with the rolling pole-figures.

The comparison is a more useful one, however, if the rotation is

350 instead, as in Fig. 5b.

*

Now two ideal orientations reinforce

With two orthogonal zonesthe shear displacement in one is the

amount by which the other thickens. In each zone, therefore,

shear displacement and thickness are roughly the same so that

the shear strain is n 1.

17

shear

direction

shear

plane

(a)

0

V

0

-7

R.D.

rotated 350

7

0

o

(10)

< 12>

1~

112}

< Il>

(110{

{110)

< I Il>

<001>

v

0

V

o0

550

(b)

0

0

I

Figure 5.

V T.D.

Ideal shear (or torsion) textures for iron in a {1l1}

projection in (a) and after a + 350 rotation around

the T.D. in (b). The 35* rotation in (b) leads to

pole reinforcement at 550 from the sheet normal.

18

(three poles overlap) at the 55* peak in the {lll} pole figures in Fig. 2.

The same exercise for {110} and {100} projections (Appendix IV) also produces a pole redistribution consistent with that in the 98

-+

99% reduction-

step in Fig. 2. The implication, of course, is that the shear planes are

inclined at 350 to the rolling plane, not 450, as they could be owing to

some friction and other uncertainties in the slip-line field in an actual

rolling reduction.

Although the argument is somewhat speculative there is nothing speculative about the shear zones or bands that it calls for.

There is ex-

cellent metallographic evidence for them, beginning with Adcock 28 in

1922.

They appear after heavy cold-rolling reduction and almost always

at an angle of 30-40* to the rolling plane.

All reported observations

seem to be for flat rolled non-ferrous materials,29-33 although some

excellent pictures from what may be a more nearly axisymmetric reduction on a low-carbon steel have been published by Cockcroft.34

An

example from the 99% reduced strip of the present work is given in

Fig. 6. Metallographic contrast is poor in Fig. 6 but sheared zones

are visible.

From many such observations on this material the volume

fraction of its bands was estimated to be not less than about 15%.

That amount may be quite enough for noticeably transferring <111>

poles from the normal toward the rolling direction, as in Fig. 2.

Just the presence of such bands is good support for the premise

that the hardening rate does decay in plane strain.

19

Figure 6. Shear bands after 99% cold rolling reduction.

20

The distinction between shear bands and shear cracks must be subtle.

At the edge of a strip, where the hydrostatic part of the roll-gap stress

system is substantially reduced and even tension may develop, the band

will first become a crack.

That was the observation here at Er > 98%,

shear cracks at the edge becoming shear bands inward from the edge.

Therefore shear cracks are also a symptom of this localized flow which,

it is being argued, may act to modify a previously stabilized texture.

Inhomogeneous Deformation and Texture Gradients:

The effect of

A > 1 on deformation-texture development is largely summarized in

Figs. 7 and 8 with the strip drawing reduction dependence

of I{lll/I

and I{1o}/I o for the different A. The curves marked u are from Fig. 3

for the cold rolled and uniformly textured strips.

The other trend

lines and data represent the center, c and surface, s. The c and s

curves are plotted with data gathered in making gradient determinations

of the kind found in Fig. 9; more gradient data are given in Appendix V.

It seems clear from Figs. 7 and 8 that curve c is about the same as

u, as it ought to be since it represents a principal plane.

For A = 1

there is not yet any texture gradient, and c and s are indistinguishable.

For A > 1 there are differences, and for A = 1.5 and 2 in Fig. 7 there

is also indication of some a-effect on the reduction dependence; with

a

30, Il l}/I

seems to be raised a small amount. The broad,

dotted bands are drawn to accommodate any a effect and the scatter in

the data (which tends to characterize such measurements).

21

Ir, %

Er,%

20

40

60

70

80

20

90

85

60

40

70

9C

85

80

2

a* r%

.30

A

620

a r%

.

12 40

.

A

3 6.7

612.5

1 1227

0

A=2

0(11

C

- 3

_

-.

____c--

a' r%C

1

2-

0

A

6 10

m

12206

r%

3-a,

5

U12

10

TO

6

EA

0

2

0

2

Figure 7. Strain and reduction dependence of {111} reflection

intensities from the drawing plane of strip reduced

with different A. The various a,-r combinations for

any A are noted in each case. Curve u is for the

homogeneously cold rolled strip of Fig. 3. Curve s

(filled symbols) represents near-surface reflections;

curve c (open symbols) is from the center.

1(100)

10

1(100)

I0

OL

0

2

2

0

Figure 8. The {100} companion to Fig. 7.

E

N)~

rNa

23

A=1.5,I

j{

6*

Ir=80%

62%

3

Io

5O/%

29%

0

2

3

o

~~aIo

E r=60%-

3

10

r=83%0/

240%

26%1%

(

sufae)(srfce(ener

10

0igue9

(Surface)

Figure 9.

h

20

arainwt

40

30

At

to(Surface)

depth,

0

10

30

20

40

1t9eowtesufc

50

At

(oCenter)

The variation with depth, At, below the surface

= 0) of {111} reflection intensities

(where t/t

in strip resuced different amounts with several A.

24

The I f

/I

in Fig. 7 is strongly dependent on Er and A, This

particular intensity has a peak value at the surface after an imposed

strain, e

(or reduction, Zri), for all but A = 1 when

than the total reduction limit.

Ei

was larger

The pattern is an extension of the

rolling results (Fig. 3).

There is some uncertainty in picking Ei

from Fig. 7 and what has been done is to let it be defined by the

maximum in the upper side of the dotted band.

The A-dependence in

Fig. 10 is too strong, however, to be seriously affected by that

uncertainty:

the strain for inversion falls with increasing A from

its highest level in rolling when A is < 1. The peak I{ll /I falls

also, although not so regularly.

Held

18

has suggested that the cumulative reduction for the re-

lated peak in the anisotropy parameter, If, of recrystallized material

is sensitive to friction.

The possibility was tested here at the

surface for A = 1.5 with the results in Fig. 11.

Intensity levels

are changed, but Ei is not.

Measurements on cold drawn and recrystallized strips are summarized in Figs. 12 and 13.

alent.

Rolling and A = 1 are again nearly equiv-

The I{lll}/Io pattern is not basically changed, although

intensity levels are raised as others have shown them to be in

rolled strip (cf. Figs. 7 and 12).14,35

The I{100}/o pattern is

changed by recrystallization and resembles that previously observed

25

99

4

-]98

95

3 -

C

90

cracking

21--

IF-

85

80

1111

70

inversion

(E)

-160

40

20

OL

I

I

I

I

0

1

2

3

4

Figure 10.

The A dependence of the imposed (or apparent) strain,

e.-,for the {111} inversion in Fig. 7 and for the

appearance of edge cracking. Rolling A is known only

to be < 1.

26

Er,/

20

l

3KF

40

I

60

70

80

|

85

90

|

|____

soa p

1(100)

10

2H

Teflon

0

21-

Teflon

1(Il1 )

I0

I -

0

0

2

6

Figure 11.

The effect of friction on surface-reflection intensities

from strip drawn with constant A = 1.5 and a = 60.

27

r,%

70

80

85

90

5

4

3

0(II

2

0

4

3

Jo

2

OL

0

Figure 12.

2

0

2

Strain and reduction dependence of {111} reflection

intensities from the drawing plane of strip reduced

with different A and then recrystallized. The

various a-r combinations for any A are noted in each

case. All measurements are from the surface. Curve

u is "recrystallized" from Fig. 3.

2

I(1oo)

I0

0

2

'(100)

I0

OL

0

2

0

8

Figure 13.

2

8

The {100} companion to Fig. 12.

r%)

CO

29

for rolling, '51

in

1

except that as A is increased above 1 the upward trend

00/}1 0 begins at smaller reductions.

At this point pole figures were invoked to find reasons for such

behavior, especially that to be seen in Fig. 7. Material reduced 80%

at A = 2 (when Er. ~ 65%) was chosen for the study.

The {100}, {110},

and {111} pole figures at c and s locations and at an intermediate one

as well

are given in Fig. 14.

At the center they compare well with

those for 80% rolling reduction in Fig. 2. Moving from center to

surface, there are changes in Fig. 14 which resemble those produced

by the last reduction-step in Fig. 2, from 98 to 99%, which brought

in Fig. 14 the central intensity-

on the rolling-texture inversion:

peak of the {111} is nearly halved while that 550 away is now doubled;

the {110} peak is lowered by about 40%; and there is some gain, perhaps

50%, in the interior {100} peak.

Figure 9 indicates a similar change

for the {111} peak around the normal direction.

are lower in Fig. 14 than in the 98

Measured intensities

99% step in Fig. 2, but so is

-+

the overall reduction.

Because trends are alike ---

through the thickness in an in-

homogeneously strained material in Fig. 14 and with reduction in one

homogeneously strained in Fig. 2 ---

it

that their explanations might be, too.

seemed reasonable now to think

On that basis, the texture

gradient must derive from a gradient of the same macroscopic shear

which produced the uniformly distributed inversion in Fig. 2.

There

30

R.D.

R.D.

R.D.

{Ioo} {1001~

~

{uo}

10

N

{IuI}

B

\Bj

A0.5

.-.BC

2 1.5N

\B

c

0.5

I

5

0.\

)\\Bo

c.5\

T.

1

AC

15/' A~

1

\B

/

j

A

B

1'

CB1

At0.44 (center)

R.D.

R.D.

R.D.

{I00}

{nIo}

T.D.

0.5-

{III}

[------.2

,-

2.5

=

Figur

P

.

2

(su5

fen

TD

14.

00.5

IT..T

4T.D.

"t

to

R.D.

0.2

R.D.

R.D.

{I10}

J1001

{II

0.5

0515j

5

3

21.

1.51.

5

35 2

2

1.51.

3.5-

rm

2re1.5cluded

ig02.5d4

2.5

TD.

1

05

T. .

2.5

2

T.

4

t 0.5(surface)

Figure 14.

Pole figures from different locations in strip cold drawn

a total of 80% with A = 2 and a~ = 120. Location is defined

by At/t :0.05 is just below the surface, at a depth of 5%

of the Krawn thickness; 0.44 is near the center; 0.20 is

about midway between surface and center. Ideal textures

from Figs. 2 and 4a are included.

31

is good evidence of such a gradient in the shear cracks at the edges of

strips after drawing beyond Ei.

An example from the material of Fig. 14

is given in Fig. 15 along with one from the cold-rolled strip shown

earlier in Fig. 6. The rolled strip is cracked through the thickness,

while for A = 2 the cracks penetrate only about 20% of the thickness or

to about the depth in Fig. 9 at which I{lll1/Io begins climbing.

The

implication in this is that the {111} inversion begins where strainhardening rate first drops down to some more or less critical upper

limit for shear flow.

Texture inversion is therefore initiated at the

surface because strain gradients rise with A7,8 and strain hardening

rate is tied fairly directly to the effective or equivalent strain

(with an inverse relationship).

The imposed e. for inversion must

therefore fall as A rises, as it is shown to in Fig. 10.

Also

plotted in Fig. 10 are the imposed strains at which edge cracks

were first clearly seen.

Their A-dependence closely parallels that

of e . These strains are larger, presumably because the shear bandto-crack conversion requires more strain, but their closeness is

evidence that e. is determined by localized shear flow.

The shear

cracks after 80% reduction at A = 2 (Fig. 15) were followed inward

from the edge and observed to turn into shear-bands.

The problem with Fig. 10 is that it

requires very large strain

gradients for which there is little independent experimental support.

If the strain for inversion in rolling at

£

~ 4 is the critical level

32

Figure 15.

Scanning-electron micrographs of edge cracking in the

99% cold rolled strip of Fig. 6 and in the 80% colddrawn strip from which the pole figures in Fig. 14

were taken. Cracks penetrate only about 20% of the

thickness in the drawn strip.

33

which must be reached for all A, the surface-to-center strain ratio must

then be close to 8 at A = 4, nearer 5 at A = 2, and about 2 at A = 1.5.

Related work on hardness (and strain) gradients in initially annealed

copper suggests a maximum ratio of 4, or perhaps somewhat more, for

A ~ 4 and no more than about 2 for A ~ 2.7

The roughly factor of 2

difference between that work and this may reflect different strain

hardening characteristics and different measurement techniques, or

it may mean that a critical-strain inversion criterion is too simple.

The lower I 11/I

at E: as A is raised is perhaps to be explained

as a result of the redundant character of the straining in which two

principal axes are rotated away from those of the strip, i.e. the

pulling and thickness directions.

IMPLICATIONS FOR TEXTURE CONTROL

The findings show that there is a mechanical basis for close and

perhaps even useful control of texture.

Although real textures are

complex, their ideal components are about all that can be accommodated

in analysis of texture-controlled behavior.

In the past, however, this

has not been a serious limitation to such analysis, and that is why

only two components known to be important in Al-killed steel strip are

singled out for comment here:

{111} and {100} in the rolling plane.

34

{111}:

Control of {111} is very much an exercise in control of the

inversion, or of Er

(or Eg)

in Figs. 7 and 12.

Suppressing the in-

version must allow Ifill/10 to continue rising; hastening it cuts off

that trend.

Therefore to intensify {111}, macroscopic shearing ought

to be avoided in reductions with A < 1. Restoring enough strain hardening capacity to disperse localized flow should have that effect.

What seems called for is repeated low-A reduction, to below Er , and

annealing.

This general approach has been tried for maximizing if,

but without conclusive results. 36

It might work better if practiced

on killed-steel strip with stricter regard for maximizing the cold

reduction but stopping short of an upper limit, which is at the i

peak (below Er.) if that is the emphasis.

Should interest focus

more on elastic constants, e.g. as in maximizing Young's modulus,

then Er

is a more logical upper limit.

To promote lower Il

/I,

macroshearing can be induced at smaller imposed reductions by raising

A; gradients are unavoidable now with surface layers being the first

to undergo the inversion (Figs. 7 and 9).

{100}:

The reduction dependence of {100} in either cold worked

or recrystallized material seems unrelated to the macroshearing.

strip rolling the characteristic upward turn in I{100}o1/

In

after re-

crystallization starts before the {111} inversion at Er , which was

first pointed out by Whiteley and Wise.1

With increased A both re-

ductions are lowered (cf. Figs. 12 and 13) and eventually come

35

together at around Er = 50% when A = 2. There is little basis in these

data for anticipating how {100} will be affected by repeated reduction

and annealing; perhaps some enhancement will be found with reductions

greater than that for the up-turn in I{100} /o'

An unfortunate practical complication is that I is driven down

more rapidly by increasing {100} than it is raised by increasing {111}.

As Whiteley and Wise 1 have shown, the peak in if vs. Er is determined

more by the up-turn in {100} than the inversion in {111}.

With low A,

therefore, raising i would have to be concerned more with suppressing

{100} than with the comparatively easier task of increasing {111}.

What this appears to mean is that the proposed macroshearing development has little influence on the Rf peak.

Perhaps the most obvious

merit of increased {100} would be in magnetic-material processing

when it should make some improvement in permeability. 37

The greatest practical problem is to use these findings in strip

rolling, a basically low-A operation.

From Eq. 2, A > 1 requires

R/h0 < 10 (where R is now the roll radius) when the reduction per

pass is r ~ 10%; with larger r, the R/h0 falls, e.g. when r ~ 25%,

R/he

3 for A > 1. These are low values of R/h0 , more common to

heavy-section hot rolling and cluster-mill cold rolling; they must

also reflect roll flattening so that the apparent R/h0 (based on

measured roll radius) may have to be smaller still for A > 1. But

this is hardly a serious disadvantage in strip rolling, for the

36

inhomogeneous deformation under A > 1 is only occasionally useful.

What

has been given here are some guide lines for the control of that kind of

deformation.

SUMMARY AND CONCLUSIONS

The mechanical factors of total reduction and deformation-zone

geometry can have strong effects on both the deformation and recrystallization textures of killed-steel strip.

When the height of

the zone is less than its length, or the ratio A is < 1, texture is

uniform through the thickness but undergoes an inversion, largely

in the intensity of {111} in the rolling plane, after a reduction

of about 98%.

Inversion has been associated with the formation of

shear bands as an outgrowth of diminished strain hardening capacity

and the development of shear texture in the bands which changes the

previously stable rolling texture.

As A becomes > 1, texture gradi-

ents appear and the inversion occurs at smaller total reduction,

beginning at the surface where straining is most advanced.

The

implications for control of the plastic-anisotropy parameter are

discussed.

37

REFERENCES

1.

R. L. Whiteley and D. E. Wise: "Relationship among Texture, Hot

Mill Practice and the Deep Drawability of Sheet Steel", Flat

Rolled Products-III, p. 47, Interscience Publisher, Chicago, 1962.

2.

C. S. Barrett and T. B. Massalski:

McGraw-Hill, New York, 1966.

3.

I. L. Dillamore and W. T. Roberts: "Preferred Orientation in

Wrought and Annealed Metals", in Met. Rev. 1965, Vol. 10, p. 271.

4.

A. P. Green: "Plane Strain Theories of Drawing", Proc. Instn.

Mech. Engrs., 1960, Vol. 174, No. 31, p. 847.

5.

R. M. Caddell and A. G. Atkins: "The Influence of Redundant Work

When Drawing Through Conical Dies", Journal of Enqineering for

Industry, Trans. ASME, Series B, 1967, Vol. 89, p. 1.

6.

R. W. Johnson and G. W. Rowe, "Redundant Work in Drawing Cylindrical

Stock", J. Inst. Metals, 1968, Vol. 96, p. 97.

7.

J. J. Burke, Sc. D. Thesis, Department of Metallurgy and Materials

Science, M.I.T., Cambridge, Mass., 1968.

8.

B. B. Hundy and A. R. E. Singer, "Inhomogeneous Deformation in

Rolling and Wire Drawing", J. Inst. Metals, Vol. 83, 1955, p. 401.

9.

F. Haessner and H. Weik: "Untersuchungen der Walz-und

Rekristallisationstexturen von Karbonyleisen", Arch. Eisenhuettenw.9

1956, Vol. 27, p. 153.

10.

M. Moller and H. Stablein: "Walztexturen von Transformatorenstahl",

Arch. Eisenhuettenw., 1958, Vol. 29, p. 377.

11.

J. Bennewitz: "Untersuchungen uber die Walztextur von Eisen und

Kubisch-raumzentrierten Eisenlegierungen", Arch. Eisenhuettenw.,

1962, Vol. 33, p. 393.

12.

H. Takechi, H. Kato, and S. Nagashima: "Rolling and Annealing

Textures of Low Carbon Steel Sheets", Trans. TMS-AIME, 1968,

Vol. 242, p. 56.

in Structure of Metals, p. 541,

38

13.

P. N. Richards and M. K. Ormay: "Preferred Orientations in

Commercial Cold-Reduced Low Carbon Steels", Trans. TMS-AIME,

1969, Vol. 245, p. 715.

14.

R. H. Goodenow and J. F. Held: "Recrystallization of Low Carbon

Titanium Stabilized Steel", Met. Trans., 1970, Vol. 1, p. 2507

15.

M. Fukuda: "Mathematical Analysis on the Relation between

Crystallographic Texture and Lankford r Value in Steel Sheets",

Trans. ISIJ, 1968, Vol. 8, p. 68.

16.

I. L. Dillamore and W. T. Roberts: "Crystallographic Texture

Variations through Rolled Aluminum and Copper Sheet", J. Inst.

Metals, (1963-64), Vol. 92, p. 193.

17.

C. S. Stickels: "Surface Texture in Iron and Steel", Trans.

TMS-AIME, 1967, Vol. 239, p. 1857.

18.

J. F. Held: "The Effect of Inhomogeneous Textures on Mechanical

Properties of Low Carbon Steel Sheets", Trans. TMS-AIME, 1967,

Vol. 239, p. 573.

19.

F. Haessner and D. Mayer-Rosa: "Uber den Aufbau der Walztextur

kubisch raumzentrierter Metalle und Legierungen", Z. Metallk.,

1967, Vol. 58, p. 12.

20.

R. A. Vandermeer and J. C. Ogle: "Texture Inhomogeneities in

Cold-Rolled Niobium", Trans. TMS-AIME, 1969, Vol. 245, p. 1511.

21.

H. C. Rogers, Jr. and L. F. Coffin: "Influence of Pressure on

the Structural Damage in Metal Forming Processes", Trans. ASM,

1967, Vol. 60, p. 672.

22.

J. M. Alexander: "The Effect of Coloumb Friction in the Plane

Strain Compression of a Plastic Rigid Material", J. Mech. and

Phys. Solids, 1955, Vol. 3, p. 233.

23.

J. W. Wistreich: "Investigation of the Mechanics of Wire

Drawing", Proc. Instn. Mech. Engrs., 1968, Vol. 174, p. 847.

24.

L. G. Schulz: "A Direct Method of Determining Preferred

Orientation of a Flat Reflection Sample Using Geiger Counter

X-Ray Spectrometer", J. Appl. Phys., 1948, Vol. 20, p. 1030.

25.

G. B. Harris: "Ouantitative Measurement of Preferred

Orientation in Rolled Uranium Bars", Phil. Mag., 1952,

Vol. 43, p. 113.

39

26.

R. A. Vandermeer and J. C. Ogle: "The Development of Preferred

Orientations in Cold Rolled Niobium", Trans. TMS-AIME, 1968,

Vol. 242, p. 1317.

27.

W. A. Backofen and B. B. Hundy: "Torsion Texture of 70:30 Brass

and Armco Iron", Trans. AIME, 195 3, Vol. 197, p. 61.

28.

F. Adcock: "The Internal Mechanism of Cold Work and Recrystallization in Cupro Nickel", J. Inst. Metals, 1922, Vol. 27, p. 73.

29.

J. D. Grogan: in Communication on Adcock's paper, J. Inst. Metals,

1922, Vol. 27, p. 103.

30.

M. Cook and T. L. Richards: "The Structural Changes in Copper

Effected by Cold Rolling and Annealing", J. Inst. Metals, 1940,

Vol. 66, p. 1.

31.

M. Cook and T. Ll. Richards: "The Structural Changes Effected in

70:30 Brass Strip by Cold Rolling and Annealing", J. Inst. Metals,

1943, Vol. 69 p. 351.

32.

W. T. Roberts: in "Discussion on Preferred Orientation", J. Inst.

Metals, 1954, Vol. 82, p. 654.

33.

S. L. Couling, J. F. Pashak, and L. Sturkey: "Unique Deformation

and Aging Characteristics of Certain Magnesium-Base Alloys",

Trans. ASM, 1959, Vol. 51, p. 94.

34.

M. G. Cockraft: "Ductile Fracture in Cold Working Operations",

in Ductility, p. 199, ASM Metals Park, Ohio, 1968.

35.

J. T. Michalak and R. D. Schoone: "Recrystallization and Texture

Development in a Low-Carbon, Aluminum-Killed Steel", Trans. TMSAIME, 1968, Vol. 242, p. 1149.

36.

K. Matsudo, T. Shimomura and Y. Hashimoto, "Effect of Two-Stage

Cold Rolling-Annealing Process on Deep Drawability of Low Carbon

Rimmed Steel Sheet", Report of Tech. Res. Inst., Nippon Kokan Ltd.,

1966.

37.

S. Chikazumi: "Magnetic Anisotropy", in Physics of Magnetism,

p. 128, John Wiley and Sons, Inc., London, 1964.

40

APPENDIX I

PROCEDURAL DETAILS

Strip Drawing:

The drawing apparatus was almost a copy of that used

by Rogers and CoffinI in their study of plane-strain strip drawing, although without the provision for measuring the drawing load.

A wedge-

shaped orifice for two dimensional strip drawing was provided with a pair

of tungsten carbide dies inserted in die holders which were made of low

carbon steel heat treated to a hardness of Rc 45.

Three pairs of dies

with flat surfaces and semi die angles of 30, 6* and 120 were used.

The die holders were supported by the walls of a rectangular hole

(2.2 in. x 2.1 in.) in a thick steel cylinder of 5-in. diameter.

This

cylinder, of 2-in. height, was resting on a 6-in. diameter and 1.25 in.thick steel base-plate having a 2.5-in. diameter hole.

Everything was

then bolted through a 0.5-in. thick aluminum "washer" to the top of the

Instron Machine (in the cavity provided for the load cell.)

The gap

between the dies could be adjusted by inserting pieces of hardened

steel shimstock of various thicknesses between the die holders and the

sides of the rectangular hole.

Strips used were about 12-in. long.

They were surface ground to

uniform thickness and width which varied from batch to batch but were

about 0.2-in. and 1-in., respectively.

Strips were "pointed" by rolling

half their length so as to pass through the drawing die.

After cleaning

41

with acetone, Teflon was sprayed on the thicker part of the strip and

allowed to dry.

The dies were cleaned with acetone and the rolled

portion of the strip inserted into the gap which had been set for the

desired reduction of the undeformed and Teflon-coated portion.

The

rolled portion of the strip was tightly gripped in wedge-type jaws

mounted on the moving crosshead of the Instron machine and pulled

at a constant speed of 1-in/minute.

All strips were drawn at constant A by keeping r constant during

repeated drawing through the same pair of dies.

A constant r was

maintained by changing the die-face separation after each pass.

The coefficient of friction for Teflon coated strip was determined by Alexander's 2 method which involves plane-strain compression

of lubricated strip.

lubrication.

It was a reasonable choice for dry, solid-film

With liquid lubrication, however, a veritcally aligned

drawing operation provides a better and more nearly uniform supply

of the lubricant than plane-strain compression; liquid is much more

easily displaced from the latter.

Therefore the friction coefficient

with the soap and water solution was evaluated in drawing.

This was

done according to an analysis by Wistreich3 and involved the comparison of drawing forces for Teflon-lubricated and liquid-lubricated

strips of the same thickness reduced the same amount in dies of the

same design.

It is assumed in doing this that the value for Teflon,

42

derived from compression, applies in drawing as well.

Reduction

details were A = 1.5 from a = 6* and r = 0.135.

Drawing loads were measured for this purpose by attaching a load

cell to the moving crosshead of the Instron machine.

The inverted

load cell was bolted on top of an adapter-cylinder of 1-in. wall

thickness and 3-in. height with its base plate bolted to the moving

cross head of the Instron machine.

screwed into the load cell.

The wedge-type jaws were now

Drawing loads for six successive passes

with r = 0.135 and cumulative reductions up to 70% were measured for

both kinds of strips.

In each pass the drawing loads were always

uniform and showed a variation of no more than + 5%.

The ratio of

drawing loads for two strips, in identical passes, was always

2.1 + 0.07.

Using the coefficient of friction for Teflon coated

strip (0.08) as the base, that for soap and water lubrication was

calculated to be 0.2.

Rolling:

A quantity of strip was cold rolled to 99% reduc-

tion in thickness.

Cumulative reduction up to 80% was carried

out on a two-high laboratory mill with unlubricated 5-in.

diameter rolls.

For further reduction, up to 99%, a four-high

mill with 1-5/8-in. diameter work rolls was used, with lubrication only in the last step of the reduction.

43

Texture Measurement:

Experimental conditions for pole figure

determination are given in Table I-1.

made with a GE X-RD5 diffractometer.

given in Table 1-2.

Line-intensity measurements were

Conditions of diffractometry are

The intensities are always represented as a mul-

tiple of the intensities from a random sample.

As reported by Takechi,

Kato, and Nagashima, 4 random samples were prepared by spraying -325

mesh electrolytic-iron powder on a glass microscope slide with a fine

coating of silicone grease to act as binder.

For line intensity measurements, integrated intensity, i.e. the

area under a peak, was used as a measure of line intensity.

area was measured graphically.)

(The

The intensity ratios (with respect

to the same lines in a random sample) were normalized to avoid any

effect of surface preparation, sample thickness, and instrumental

errors.

It was done as proposed by Harris

5

who has shown that the

measured ratio of intensity, I{hkZ}, from textured material to that

from a random sample, Io, is related to the actual ratio as

I[{hkU

1

k

I hkj(

measured

where k depends on variables noted above.

from the X-ray source is constant,

1

_

real

As the power emanating

44

TABLE I-1

CONDITIONS FOR POLE FIGURE DETERMINATION

Radiation . . . . . . .

Filter

Slits

.

.

.

.

.

* Mo K

* Zr

* Diverging:

2 x 1 cm

Receiving:

4 x 1 cm

Rotation of specimen in its own plane . . . . 36*/minute

Rotation of specimen in a plane

perpendicular to its own . . . . . . . . . .

0.5*/minute

45

TABLE 1-2

CONDITIONS OF DIFFRACTOMETRY

Radiation

Mo K

. . .

Filter

Slits

. . .

Zr, 0.002-in thick

Diverging,

.

30

Receiving, 0.20

Scanning speed

. . . . . . 2-in/minute

46

{hkk}

1o

=

n

(2)

real

provided summation is done over a large number of peaks.

Summing

both sides of Eq. 1 and using Eq. 2

f{hk}]

o

k.n

measured

or

k =1

hkt}

n0

measured

or

I{hk}

o

{hkk}

j

real

L

measured

1

{hk}

n

Io

measured

This is the ratio plotted in all the reflection intensity measurements.

Summation was done over the first thirteen lines (n = 13).

Microscopy:

examination.

Strips were nickel-plated before metallographic

Mounted in bakelite, samples were mechanically polished

and etched with 1%Nital solution for observation under the optical

47

microscope.

Specimens whose edges were examined by scanning electron

microscopy to observe edge cracking were only cleaned with acetone.

For grain-size measurement, a piece of undeformed strip was mounted

in bakelite so as to have the rolling plane as the plane of polish.

After adequate mechanical polishing and etching with 1% Nital solution

four micrographs were taken.

as proposed by Hilliard.6

A.S.T.M. grain size No. was determined

Mean linear intercept measurements were

made with the Hilliard circle, with at least four arbitrary, non

overlapping circle placements on each photograph to insure accuracy.

APPENDIX I -

REFERENCES

1.

H. C. Rogers, Jr. and L. F. Coffin: "Influence of Pressure on

the Structural Damage in Metal Forming Processes", Trans. ASM,

1967, Vol. 60, p. 672.

2.

J. M. Alexander: "The Effect of Coloumb Friction in the Plane

Strain Compression of a Plastic Rigid Material", J. Mech. and

Phys. Solids, 1955, Vol. 3, p. 233.

3.

J. W. Wistreich: "investigation of the Mechanics of Wire

Drawing", Proc. Instn. Mech. Engrs., 1968, Vol. 174, p. 867.

4.

H. Takechi, H. Kato, and S. Nagashima: "Rolling and Annealing

Textures of Low Carbon Steel Sheets", Trans. TMS-AIME, 1968

Vol. 242, p. 56.

5.

G. B. Harris: "Ouantitative Measurement of Preferred

Orientation in Rolled Uranium Bars", Phil. Mag., 1952,

Vol. 43, p. 113.

6.

J. E. Hilliard: "Estimating Grain Size by the Intercept

Method", Metal Progress, 1964, Vol. 85, No. 5, p. 99.

48

APPENDIX II

THE UNIFORMITY OF ROLLING TEXTURE

The {100} and {111} reflection intensities from the rolling-plane

of strips cold rolled to various cumulative reductions showed no variation with position in the strip (Fig. II-1).

Also, the'{lll} pole

figures from positions near the center of the strips cold rolled to

80% and 92% reduction (Fig. 11-2) are similar to those from positions

near the surface of the same strips (Fig. 2).

These provide suf-

ficient basis to conclude that the deformation texture developed in

cold rolled strip is uniform through the thickness of the strip.

Xr=

980/

Ir=

990/

91%/

(100)

60%

40%

-

-

10

o~

-:

2I

I

I

I

10

20

30

40

(Gee

I

I

0

10

(Surface)

20

30

At

40

50

0

(Ce nter)

(Surface)

At

50

(Cen ter)

S0

5

4

I0

10

2 -

2O

(Surface)

Figure II-l.

At

to

(Center)

I

3

10

0

(Surface)

-

I

I

30

20

At

to

40

50

(Center)

Variation of rolling plane {100} and {111} intensity through the

thickness of strips cold rolled to various cumulative reduction.

11

5 4

Figure 11-2.

7

{111} pole figures of 80% and 92% cold-rolled strips.

Cn

C0

51

APPENDIX III

STEREOGRAPHIC ROTATION OF IDEAL ROLLING TEXTURES

IN {100} AND {110} PROJECTIONS

The ideal rolling textures, A, B, and C, are shown in Fig. III-la

for {100} and {110} projections.

A and B are similar to that reported

by Bennewitz. 1 A has <110> as fiber axis parallel to N.D. (the sheet

normal) and is limited to a + 550 rotation of {001} <110> around it.

In B, the <110> fiber axis lies at 600 from R.D. towards N.D. with a

+ 350 rotation of {554} <225> around it. In C, the fiber axis is

<111> parallel to N.D. and the rotation is a full 3600 around it.

The new positions of these fiber textures after a + 550 rotation

around T.D. are shown in Fig. III-lb.

The rotated {lOO} projection shows a concentration of ideal

textures near the "interior" high intensity region to be seen in

the {100} pole figures of Fig. 2. This would explain the increase

in intensity of this region in Fig. 2 (98%

different trend in {110}.

-* 99%).

There is a

Before rotation there is a marked

intersection of ideal textures at o 300 from the center towards

N.D. (Fig. III-la).

With rotation, however, this spreads out

over a 20-350 range which is held responsible for the drop in

the high-intensity region of the {110} pole figures of Fig. 2

(98%

+

99%).

52

APPENDIX III

1.

-

REFERENCES

J. Bennewitz: "Untersuchungen uber die Walztextur von Eisen und

Kubisch-raumzentrierten Eisenlegierungen", Arch. Eisenhuettenw.,

1962, Vol. 33, p. 393.

53

R.D.

R.D.

{oo}

* N

(n o}

N

-~.

(a)

-N.

ISN

L... . .

..

. .. .

>IT.D.

T. D.

A

B

C

R. D.

--

R.D

(100){

110

rotated 55*

rotated 550

(b)

T D.

Figure III-1.

-

Ideal textures A, B and C in {l00} and {110} pole

figures (a); and rotated + 550 around T.D. (b).

A and B are two partial fiber textures with fiber

axis <110> parallel to R.D. (A), and at 60* to

R.D. toward N.D. (B); C is a complete fiber

texture with fiber axis <111> parallel to N.D.

D

54

APPENDIX IV

STEREOGRAPHIC ROTATION OF THE IDEAL SHEAR TEXTURES

OF IRON IN {100} AND {110} PROJECTIONS

The ideal orientations in the shear texture of iron are shown in

f100} and {110} projections in Fig. IV-la.

To fit the argument being

developed in Fig. 5, a rotation of these ideal orientations by + 350

around T.D. (Fig. IV-lb) is imposed to simulate the new rolling-plane

texture.

A cluster of ideal orientations in the rotated {100} pro-

jection near the position of the "interior" high-intensity region of

the {100} pole figure of Fig. 2 shown by dotted region is thus

offered as the explanation of the rise in the intensity in this

region in Fig. 2 (98%

-.-

99%).

55

(100)

(110)

shear

direction

shear

direction

O1

I7

00

she ar

Pla ne

0

(a)

0

COC

V

{1 10)

< 112>

0

(112)

<I ll>

< I II>

(11 0)

R.D.

-~-P,

0

35

rotated 35*

El

S7

V

C

0

T. D.

Figure IV-1.

Ideal orientations of the shear texture in iron in

{100} and {110} projections and rotated + 350 around

T.D.

(b)

56

APPENDIX V

GRADIENTS IN {100} REFLECTION INTENSITY FOR A > 1

The variation with depth, At, below the surface (where At/t 0 = 0)

of {100} reflection intensities from strips reduced different amounts

with several A is shown in Fig. V-1.

The data from positions near the

center (At/t 0 = 0.50) were used to plot curve c in Fig. 8. Extrapolated

values of I{100}1 o were used in the absence of measurements at the

center.

57

I

1.5, a= 6*

2

1(100)

I0

0

62%

i!N2 ,a=6*

2

1(100)

29

3

=2

A2

2

(100)

--

10

..---

48%

0

2

(100)

I0

I

0

0

(Surface)

Figure V-1.

10

30

20

t

to

40

50

(Center)

Variation of rolling-plane {lOO} reflection intensity as a

multiple of random through the thickness of strips drawn to

various cumulative reductions with constant A and a.

58

SUGGESTIONS FOR FUTURE RESEARCH

There are three areas for further investigation, briefly outlined

below.

1.

Texture Sharpening:

Increasing Illl}/Io without raising I{100}/o

is essentially what is implied here. The reason for such interest

is the correlation between large R (Plastic Anisotropy Ratio) and

large I{ll}/I{100}.

drawability.

The large R in turn contributes to greater

The proposed experiments would involve controlled-A

reductions to levels just below those that will be known to bring

an increase in I{100}

o after recrystallization.

would be recrystallization.

The next step

Repeating the sequence may lead to

both interesting and useful results.

The variables would be A

(in a range of direct interest in rolling, e.g. 0.5 - 1.5),

cumulative reduction, and the recrystallization practice.

2.

Mechanical Control of Texture in Non Ferrous Metals:

There is

reason to believe that macroshear and texture inversion are not

at all unique to low carbon steel sheet and strip.2,3

A

parallel study of the mechanical contributions to the planestrain deformation and recrystallization textures of non ferrous

materials would test the hypotheses of macroshear and shear

texture development in shear bands, suggested in this study.

59

It may also provide some information about R and/or AR control in

such materials.

3.

Plane Strain vs, Axisymmetric Strain Hardening:

Strain hardening

in iron to large strain has been studied in detail in recent years.

The medium for much of this work has been axisymmetric reductions

by wire drawing.4

When straining is axisymmetric, however, macro-

shear is prevented because of the difficulty of accumulating

shear on unchanging macroscopic shear surfaces in axisymmetric

reduction.

Therefore the strain hardening behavior, especially

as the strain hardening rate falls, may be markedly different in

the two cases.

Considering the practical importance of plane-

strain reduction in sheet processing, this deformation mode is

an appropriate area for similar study.

REFERENCES

1.

M. Fukuda: "Mathematical Analysis on the Relation between

Crystallographic Texture and Lankford r Value in Steel Sheets",

Trans. ISIJ, 1968, Vol. 8, p. 68.

2.

M. Cook and T. Ll. Richards: "Fundamental Aspects of the Cold

Working of Metals", J. Inst. Metals, 1950-51, Vol. 78, p. 463.

3.

R. F. Braybrook and E. A. Calnan: "Some Observations on the

Development of Face-Centered Cubic Rolling Textures",

J. Inst. Metals, 1956-57, Vol. 85, p. 11.

4.

G. Langford and M. Cohen: "Strain Hardening of Iron by Severe

Plastic Deformation", Trans. ASM, 1969, Vol. 62, p. 623.

60

BIOGRAPHICAL NOTE

The author is the eldest son of Mr. Parmeshwar Sarup Mathur and

Mrs. Gopal Rani Mathur of Moradabad, U.P. India.

Born on December 19,

1945, he graduated with a Bachelor of Science degree from Agra

University in 1962.

He received the degree of Bachelor of Technology

in Metallurgical Engineering from Indian Institute of Technology,

Kanpur, India in 1967 and was judged to be the best graduating student

in Metallurgical Engineering.

thesis award the same year.

He also received the best Bachelor's

He then entered Massachusetts Institute

of Technology and received the degree of Master of Science from the

Department of Metallurgy and Materials Science in 1968.

After work-

ing with the Division of Sponsored Research at Massachusetts Institute

of Technology for a brief period he started on his doctoral program

in 1969.

The author is a member of Sigma Xi, American Society for Metals,

and the American Institute of Mining, Metallurgical and Petroleum

Engineers.