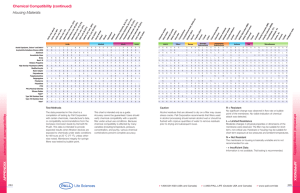

Chemical Compatibility (continued) Centrifugal and TFF Devices c h

advertisement

Chemical Compatibility (continued) Acids Alcohols Bases Esters Glycols HH* Ac eto ne (10 Ac %) eto ne (20 Me % thy ) l et hyl Ph k eno eto l (0 ne .5% (M Ac EK ) eto ) (1 nit 0% rile ) Alc (20 ono % ) x◆ (1% Am ) mo niu m Am c hlo mo rid niu e( m Ca 1% sul lciu ) f a m te c hlo Dim r i d eth e( yl f 5% orm ) Dim am eth ide yl f (DM orm Dim am F) eth (< ide yl f 5% (20 orm Dim ) % am eth ) ide yl s (10 ulf Dim oxi 0% eth de ) yl s (DM ulf Dim SO oxi eth ) (< de yl s (20 5% ulf Dis %) ) oxi odi de um (10 sal For 0% to ma ) fE lde DT hyd A( For 10% e( ma 1% lde ) ) hyd Glu e( tal 5% deh ) yde Gly (0. cer 5% ine ) (50 Gu %) ani din eH Hyd CI rog (6M en ) per Ph osp oxi de hat (10 eb Sod %) uff ium er azi Sod de (1% ium ) chl Sod ori d ium e( 5% deo , 50 Sod xyc C) ium hol ate dod Sod (5% ecy ium ) l su hyp lfa te Sod och ( 0.0 ium lor 1M ite hyp ) (0. Sod och 0 5% ium lor ) ite nit (0. rat Ter 1% e g-a ) -zy m Tri ◆ e sb ( 1 uff %) er Ult (1M ras ) il 1 1( Ure 2% a( ) 6M ) Ac etic aci d( Cit 10% ric aci ) d For (1% mic ) aci d( Hyd 1N roc ) hlo ric Lac aci tic d( aci 1N d( Nit ) (0 5% ric .1N ) aci , 50 d Ox ( ºC) 1 % alic ) aci d( Ph 1% osp ) hor ic a Su cid lfu ric (1N aci ) (0 Bu d( .1N tan 1N , 25 ol ( ) 70% ºC) Bu tyl ) cel los Eth olv ano e( 10% l (7 0% ) Iso ) pr o pan ol ( Me 25% rca pto ) e tha Me tha nol nol (10 %) (70 Pro %) pan ( 25% ol ( 70% Am ) mo ) niu m Sod hyd ium rox ide hyd Iso rox (1 pr o N) i d e( pyl 1N ace Eth ) t yl a ate cet (1% ate Eth ) (10 yl a % cet ) ate Gly (10 cer 0% ol ) Pol yet hyl ene Ch gly lor ofo col r (0. m Ch 1% (0. lor 8 ) %) ofo rm (10 0% ) Centrifugal and TFF Devices Miscellaneous Ketones Centrifugal Devices Nanosep® Device Microsep™ Advance Device Macrosep® Advance Device Jumbosep™ Device R R R R - R R R R R R R R - - - R R R R R R R R R R R R R R R R R R R R - - R R R R R R R R R R R R R R R R - N N N N N N R R R R R R R R R R R R N - R R R R R R R R - R R R R - - R R R R - - R R R R N N - R R R R N N - - R R R R - - R R R R R R R R R R R R - - - R R R R R R R R N R R R - R R R R R - R - R - R R R R R R R R - R - R R R R R R R - R N - R R R R N R R - R R - R R R - R - R R - R - R N R - R N R - R - R R - R - R R R R R R R - R - R - R R R R - R - R - - - R - - - R - - - - N - - - - - - - - - - - - - R - - - - - - - - - - R - - R R - - - - - R - R R R R R R R - - - R R - - - - R R - - - - R - R - - R R R R - R R - - R - - R R - R R R - - R R R R - R R R R R R R R R R R R R R R R N R - R R R R R R R R R - - R - - - R - R R R - - TFF Devices Minimate™ Device Ultrasette™ Device T-Series TFF Cassettes *HH = Halogenated Hydrocarbons Cassettes Centramate™ Cassettes *AH = Aromatic Hydrocarbons **HH = Halogenated Hydrocarbons R R R R R R R Alcohols R R R N R R R R Bases R R N N R R Ethers Esters R R R N R R R N R AH* R HH** N R Ketones R R N R Miscellaneous R R R specific filter under actual use conditions. Because chemical compatibility is affected by many variables (including temperature, pressure, concentration, and purity), various chemical combinations prevent complete accuracy. N N R R R R R R R R R R R N R R R R R R R R R R Compatibility with Omega™ membrane cassettes should be used only as a guide. Cassettes should be tested in the appropriate solvent and product under actual operating conditions and for an appropriate time to determine compatibility for the specific application. No significant change was observed in flow rate or bubble point of the membrane. No visible indication of chemical attack was detected. L = Limited Resistance Moderate changes in physical properties or dimensions of the membrane were observed. The filter may be suitable for short term, non-critical use. Hardware or housing may be suitable for short-term exposure at low pressures and ambient temperatures. N = Not Resistant APPENDIX Our ultrafiltration membranes have been evaluated for compatibility with many common laboratory buffers and solvents over a wide pH range. R R = Resistant Alcohol residues that are allowed to dry on a filter may cause stress cracks. Pall Corporation recommends that filters used in alcohol processing should remain alcohol wet, or should be flushed with copious quantities of water to remove residuals prior to drying and subsequent reuse. This chart is intended only as a guide. Accuracy cannot be guaranteed. Users should verify chemical compatibility with a 296 R Caution Test Methods This data is a compilation of testing by Pall Corporation with the listed chemicals. Chemical compatibility was determined with discs. Flux rates and solute retention was determined before and after a two-hour exposure to the indicated chemical. If membrane integrity was unchanged, the chemical was deemed compatible. Membrane integrity for syringe filters was tested by bubble point. APPENDIX R Eth ers Tet rah ydr Tol uen ofura n( 5% Aro e (1% ) ) ma tic Ch &c lor hlo of rin Me orm ate (0. thy dh 8% len ydr ) Ac ec oca eto hlo r bo ne rid ns (< e( Ket ME 30% one K) ) (1% Me ) thy l et Ph eno hyl k eto l (0 ne Ac (1% eto .5%) nit ) r ile Am (< mo 40% niu Alc m chl ) ono ori x◆ de Ca ( lciu 1%) (1% m ) chl Dim o rid eth e( Dim yl ac 5% eta ) eth mid y l Dim fo e eth rmam (DMA C) ide Dis yl su (DM (< 4 lf odi 0% um oxide F )( ) For ma salt o (DMS < 40% lde O) fE ) DT Glu (< hyd A( tar e( 10% 40%) a 1 Gly ldehy %) ) cer de i Gu ne (5 (0.5% ani 0% ) d ) Hyd ine H CI rog (6 N-M en pe M) rox eth ide y l Ph (1% osp pyrro ) lido hat Sod eb ne uff (1% ium e r (1 ) az Sod ium ide (1 M) (p H % c 8.2 ) Sod h ) ium loride ( d 5% Sod e ium oxych ) (50 ola ºC) do Sod ium decyl te (5% sul ) hy Sod ium poch fate ( hyp lorite 0.01 Sod M (0. ium och 005 ) hyp lorite Sod %) o ( ium 0.0 chl 2% ori ni Ter te ) (0. g-a trate 1% z ym ) Tri e◆ sb (1% u Tri ffer ( ton 1M ) ) (p X-1 Ure H8 . a ( 00 (0 .00 2) 25% 2 Ult M) ) ras il 1 1( 1% ) chemical compatibility Acids Omega™ Membrane chemical compatibility Ac etic Ac acid etic (5% ) Cit acid (25 ric .5% aci d For ) mic (1%) a c Hyd id (5% roc Hyd hloric ) roc aci Hyd hloric d (0. 1N roc aci at 25 Lac hloric d (0. ºC 1 tic Na aci a t5 ) d( cid Nit 0º 1 Na (5% ric C) t5 aci ) 0º d( Ox C) alic <1 %) Ph acid osp (1% hor ) Su lfu ic ac id ric (1 a Bu tan cid (1 N) ol ( %) 70% Bu tyl ) c Eth ellos olv ano e Iso l (70% (10% pr o ) ) pyl Me rca alcoh o pto Me eth l (25% thy ano l al l (0 ) Am c .1% ine ohol ) (25 s Am %) mo niu Sod m hyd ium r h Sod ydr oxide oxi ium (5% de h ) Sod y (0. 1N ium droxi a d t e hy 25 Sod (0. ºC) 1N ium droxi hyd de (0 at 50 Sod .5N ºC) ium roxi at de h 25 Ali ph ydrox (1N a ºC) ati t2 c & ide ( 5º Bu 1N C) aro tyl at a ma 50 t Eth cetat e ( ic est ºC) yl a 4 ers 0 c % e Iso t pro ate (< ) pyl ace 30%) tat e( 1% ) Ultrafiltration Membrane The membrane or housing is basically unstable and is not recommended for use. - = Insufficient Data Information is not available. Trial testing is recommended. 1.800.521.1520 (USA and Canada) (+)800.PALL.LIFE (Outside USA and Canada) www.pall.com/lab 297