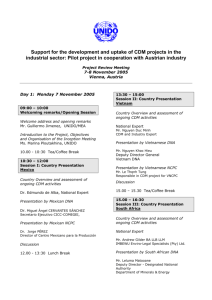

An Assessment of Projects on the Clean Development

advertisement