Document 10619409

advertisement

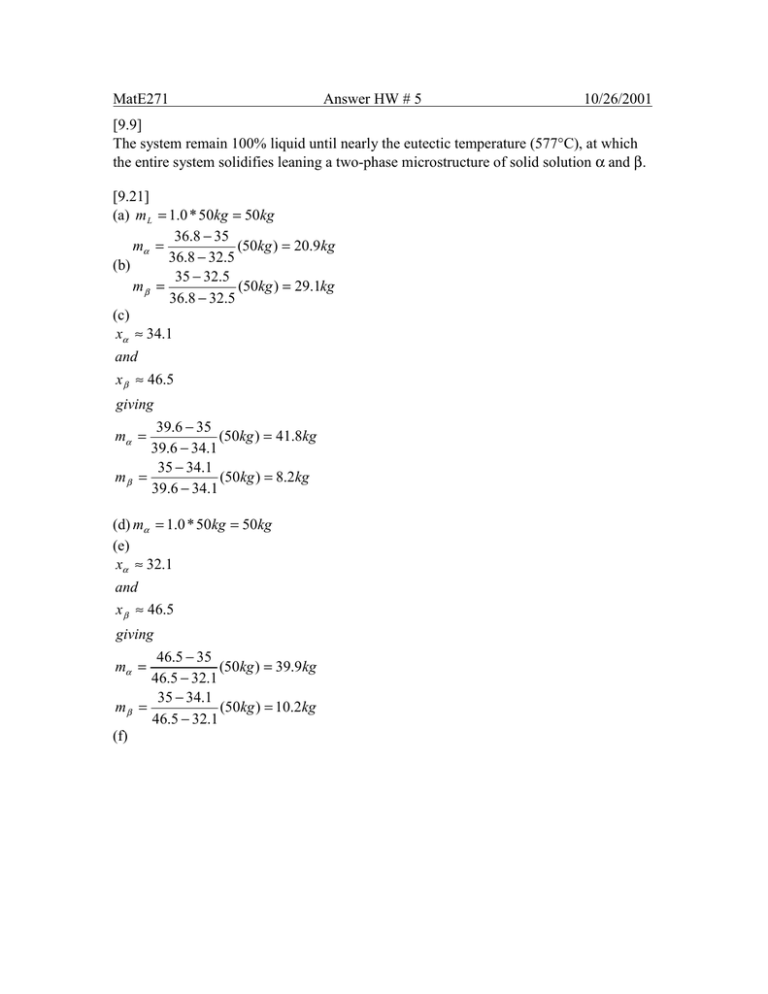

MatE271 Answer HW # 5 10/26/2001 [9.9] The system remain 100% liquid until nearly the eutectic temperature (577°C), at which the entire system solidifies leaning a two-phase microstructure of solid solution α and β. [9.21] (a) m L = 1.0 * 50kg = 50kg 36.8 − 35 mα = (50kg ) = 20.9kg 36.8 − 32.5 (b) 35 − 32.5 mβ = (50kg ) = 29.1kg 36.8 − 32.5 (c) xα ≈ 34.1 and x β ≈ 46.5 giving 39.6 − 35 (50kg ) = 41.8kg 39.6 − 34.1 35 − 34.1 mβ = (50kg ) = 8.2kg 39.6 − 34.1 mα = (d) mα = 1.0 * 50kg = 50kg (e) xα ≈ 32.1 and x β ≈ 46.5 giving 46.5 − 35 (50kg ) = 39.9kg 46.5 − 32.1 35 − 34.1 mβ = (50kg ) = 10.2kg 46.5 − 32.1 (f) mα = xα ≈ 29.2 and x β ≈ 46.5 giving 46.5 − 35 (50kg ) = 33.2kg 46.5 − 29.2 35 − 29.5 mβ = (50kg ) = 16.8kg 46.5 − 29.2 [9.56] (a) ≈ 910°C (b) α , ≈ 30 wt% Zn (c) ≈ 920°C (d) From ≈ 920°C to ≈ 40°C mα = [10.10] (a) This is comparable to the tempering history of figure 10-11 except that some initial fine pearlite formation is allowed at 500 °C (see sample problem 10.3(c) for the initial history). The final microstructure will be : 70% fine pearlite + 30% tempered martensite (b) Figure 10-15 indicate that complete transformation to final pearlite occurs often 5 sec at 500 °C . Subsequent thermal history does not change that. The final microstructure is then: 100% fine pearlie. [10.35 & 10.36] Taking xθ = 53wt %Cu and using Fig 9-27 at various temperatures: 5−0 × 100% = 9.45% At 100 °C , wt % θ = 53 − 0 5 −1 × 100% = 7.69% At 300wt % θ = 53 − 0 5 − 2 .5 × 100% = 4.95% At 400, wt % θ = 53 − 2.5 At 500, wt % θ = 0 × 100% = 0% by inspection Taking x β = 36.1wt %Cu and using Fig 9-28at various temperature: 5−2 × 100% = 8.8% 36.1 − 2 5−3 × 100% = 6.0% At 200 °C , wt% β = 36.1 − 3 5 − 4 .5 × 100% = 1.6% At 250 °C , wt % β = 36.1 − 4.5 At 100 °C , wt % β =