MatE271 ... (a) Metals and ceramics are all crystalline materials. Metals have...

advertisement

MatE271

[1]

Answer HW # 2

9/21/2001

(a) Metals and ceramics are all crystalline materials. Metals have simple

crystalline structures (bcc, fcc and hcp), which favor dislocation mobility

and make them ductile. Metals also have metallic bond, which provides high

electrical conductivity. On the contrary, ceramics have more complex

crystalline structure which prevent dislocation motion and thus rendering

them very brittle. Ceramics also have mix between ionic and covalent

bonding which make them good electrical insulators.

(b) Ceramics have crystalline structure, while glasses have very short order

structure with amorphous (random) arrangements.

[2] See page 73-74, 574

The existence of a central cation atom with a positive charge (Ti+4 ) within the unit cell of

BaTiO3, make it more responsive to the applied electric field and forming dipole by moving

up and down within the unit cell. Such movement manifests itself as expansion or contraction

in the direction of the applied electric field.

[3] Without the applied electric field, the Bravais lattice BaTiO3 crystal is simple cubic. Such

cubic structure is symmetric, and will present isotropic mechanical response to the applied

forces (i.e. will contract or expand with the same amount under the same applied force in a

three perpendicular directions However, once the electric field is applied, the crystal loses its

cubic symmetry and become tetragonal. A tetragonal structure has anisotropic (unequal)

response to the applied load. Therefore the displacement in x-dn is not equal to that in the

y-dn.

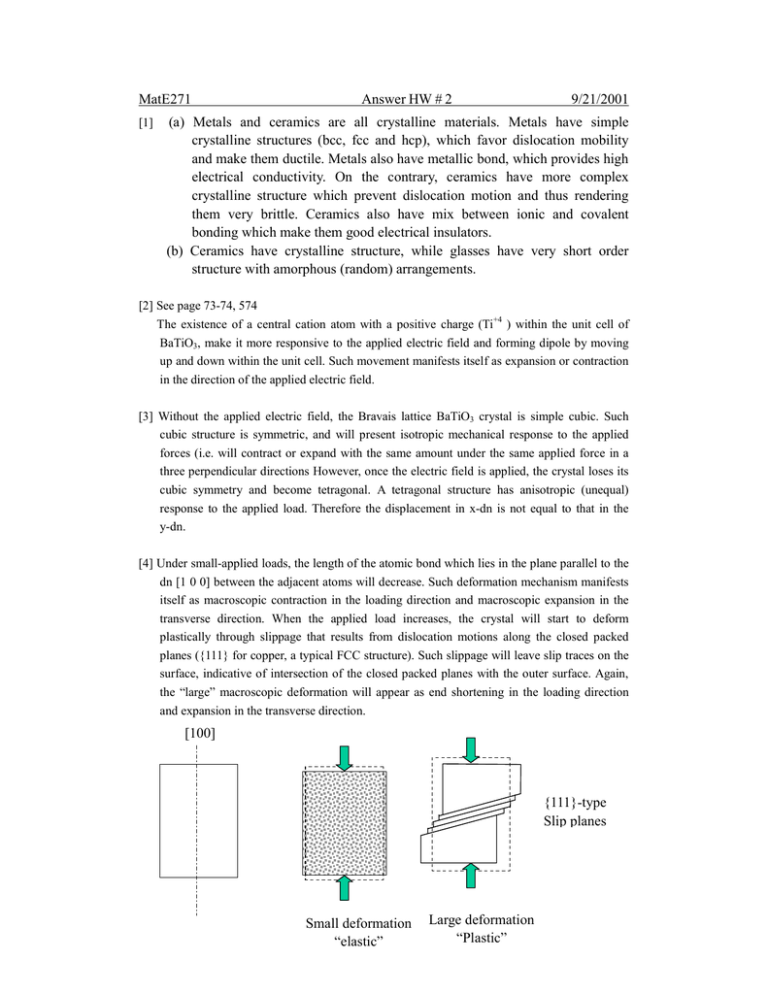

[4] Under small-applied loads, the length of the atomic bond which lies in the plane parallel to the

dn [1 0 0] between the adjacent atoms will decrease. Such deformation mechanism manifests

itself as macroscopic contraction in the loading direction and macroscopic expansion in the

transverse direction. When the applied load increases, the crystal will start to deform

plastically through slippage that results from dislocation motions along the closed packed

planes ({111} for copper, a typical FCC structure). Such slippage will leave slip traces on the

surface, indicative of intersection of the closed packed planes with the outer surface. Again,

the “large” macroscopic deformation will appear as end shortening in the loading direction

and expansion in the transverse direction.

[100]

{111}-type

Slip planes

Small deformation

“elastic”

Large deformation

“Plastic”

z

5) See page 97

The structure of Cr is a typical of BCC, (p. 65 fig 3-4).

From the atomic radii tables (App. 2, P 796)

(111)

a

rCr = 0.125 nm;

4r

a Cr =

= 0.2887 nm;

3

for (111) plane, h = 1; k = 1;l = 1;

a

d 111 =

= 0.0962nm;

2

h + k 2 + l2

x

The planar density canbe either given as percentage fill or as atoms / nm2

h = 2^0.5* a = 0.4082nm;

b = 3^0.5 / 2 * H = 0.3536nm;

1

1

bh =

2 a 3 2 a = 0.0722 nm2 ;

2

2

There is a 1 6 atom at each of the (111) plane corner ,

A 111 =

e je

j

3 x1 6

= 6.93 atom / nm2 ;

A 111

Linear density [1 0 0] = 1atom / a = 3.4641atom / nm;

Planar density =

Linear density [1 0 1] = 1atom / b = 2.4495 atom / nm;

Linear density [1 1 1] = 2 atoms / ( 3 a) = 4.0 atom / nm;

b

y