Method for Analysis of Front-End

advertisement

Method for Analysis of Front-End

Technology Development Effectivity

by

Thomas P. Courtney

M.S. Mechanical Engineering

Santa Clara University

B.S. Mechanical Engineering

Rochester Institute of Technology

AT THE

MASSACHUSETTS INSTITUTE OF TECHNOLOGY

JANUARY, 2001

@ 2001 Thomas P. Courtney, All rights reserved

The author hereby grants to MIT permission to reproduce and distribute publicly paper

and electronic copies of this thesis document in whole or in part.

Signature of Author

A

J

/Thomas P. Courtney

System Design and Maqagement, January 2001

Certified by

Cliff Whitcomb

Associate Professor Ocean Engineering

Thesis Advisor

Accepted by

Steven C. Graves

LFM/SDM Co-Director

Abraham Sieael Professor of Management

Accepted by

--

Paul A Lagace

M/SDM Co-Director

Professor of Aeronautics & Astronautics and Engineering Systems

MASSACHUSETTS INSTITUTE

OF TECHNOLOGY

AUG 0 1 2002

LIBRARIES

BARKER

This thesis presents a method for analyzing the effectivity of an organization's

fuzzy front-end processes. Several technology development frameworks were

considered as the foundation of the proposed analysis method. Don Clausing's

"An embedded process framework for Total Technology Development" was

selected as the basis for the assessment. From this framework, a behavior

driven questionnaire was developed. The interview format was selected as the

method for obtaining data from the organization. The interview format specified

and detailed questionnaire were developed to be generally applicable to any

organization. The proposed assessment method was applied to one

organization within Xerox Corp. Over 800 data points were gathered,

summarized, sorted and discussed. Xerox uses the TTM (Time to Market)

development process. The proposed assessment method focuses on assessing

the actual processes implemented within the local organization. These

processes may be different than the corporate documented TTM processes. Ten

senior managers at Xerox were interviewed. Data from the interviews was

summarized and sorted. Weaknesses and strengths of the organization were

obtained from the sorted data. Initiatives may then be developed to improve

upon the weaknesses. Strengths are highlighted and communicated to foster a

learning organization. An example is given demonstrating the use of Monte

Carlo analysis to improve upon one of the weaknesses obtained from the Xerox

assessment. Further research into web-based assessment methods is

proposed.

Author:

Advisor:

Title:

Date:

Thomas P. Courtney

Professor Cliff Whitcomb

Method for Analysis of Front-End Technology Effectivity

January 29, 2001

2

I am filled with gratitude to all those who have helped me on this invigorating journey at

MIT these past three years. Through all the ups and downs, so many people have given

so freely of their time, energy, ideas, and spirit. I am so thankful.

First, I would like to thank my dearest companion Karen for her constant love and

support. Her encouragement means so much to me. A warm hug and a loving prayer

from her gave me the enthusiasm and stamina to be the best I could be.

My SDM friends have taught me so much. Much of my learning came from each of you.

I am thrilled to have been in the presence of so many dedicated, creative, energetic,

brilliant and fun individuals.

I would like to thank my incredible parents, Lucille and Richard Courtney, for all the

lessons in life they have taught me. Their examples of dedication to excellence,

compassion for what they do, and a thirst for continuous growth has shaped me into who

I have become.

God is the source of my strength. My travels to MIT provided me much more than an

education. My travels to MIT placed people in my path that profoundly changed my life

forever.

My thanks goes out to all those who participated in the interviews. Thanks to Ken

Altfather, Bob Burkett, Bill Hawkins, Juan Becerra, Terry Coggeshall, Mel Croucher,

Mariano Freire, Louis Isganitus, and Dale Ims. Their candid discussions greatly added to

the quality of this work.

Thanks to my thesis advisor, Cliff Whitcomb. Cliff helped keep my thesis properly

focused and provided valuable advice that greatly improved the quality of this thesis.

Last, but not least, I would like to thank my children Aaron, Robert and Andrew. Your

bright smiles and witty humor helped me over many bumps in the road. I am so pleased

with the growth I have seen in each of you over these past years. Your youthful spirit and

playfulness helped me to learn how to let the youthful child inside of me come out and

play.

3

Table of Contents

Chapter 1 Introduction................................................................................................6

Background ................................

.................................................................................

6

Objectives of this Thesis.............................................................................................

6

The Problem Statement....................................................................................................7

Research M ethod ........................................................................................................

8

Term inology .....................................................................................................................

9

Chapter 2 Total Technology Development Framework

....................

11

Total Technology Development Framework Selection .............................................

11

TTD Framework Overview.........................................................................................

12

Framework Phase 1 - Technology Strategy ...............................................................

12

Framework Phase 2 - Concept Generation and Enhancement

.................

13

Framework Phase 3 - Robustness Development and Analysis .................................

14

Framework Phase 4 - Technology Selection, Transfer, and Integration.................... 15

Comparison to Xerox Time To M arket Process ........................................................

16

Chapter 3 How to Analyze Upstream Technology Development Effectivity.....24

Introduction....................................................................................................................

24

Process used to create the methodology. ...................................................................

24

Applicability to other companies...............................................................................

25

Generation of behavior driven questions ....................................................................

25

Selection of Interviewees...........................................................................................

26

How interviews were conducted................................................................................

27

Chapter 4 Data Summaries and Key Points ..........................................................

28

Introduction ....................................................................................................................

28

Discussion of Lowest scoring behaviors....................................................................

29

Discussion of Highest scoring behaviors....................................................................36

Discussion of behaviors having high standard deviations ........................................

40

Chapter 5 Application of Results.............................................................................43

Chapter 6 Conclusions and Recommendations ......................................................

57

Bibliography and References......................................................................................60

A ppend ix ..........................................................................................................................

62

Appendix 1: Phase 1 Process Steps ..........................................................................

62

Appendix 2: Phase 2 Process Steps ..........................................................................

65

Appendix 3: Phase 3 Process Steps ..........................................................................

69

Appendix 4: Phase 4 Process Steps ..........................................................................

71

Appendix 5 Source Code for Install W ater Loss M onte Carlo Analysis....................72

Appendix 6. Detailed Questionairre Responses.........................................................73

Appendix 7 Questionnaire........................................................................................

75

4

Table of Figures

Figure 1 TTD Framework ..............................................................................................

12

Figure 2 Xerox Business Model.....................................................................................

16

Figure 3 TTD Bubble Portfolio.....................................................................................

18

Figure 4 Market Strategy Allocation Model ..................................................................

19

Figure 5 Newness and Complexity vs Program Configuration..................

22

Figure 6 Total Response Distribution ...........................................................................

28

Figure 7 Market Pull vs Technology Push....................................................................

33

Figure 8 Truncated Normal Distribution.......................................................................

44

Figure 9 Quality Loss Function.....................................................................................

45

Figure 10 Monte Carlo Analysis Example....................................................................

46

Figure 11 Useful Ink Histogram. Monte Carlo Output ................................................

47

Figure 12 Factory % Water Normal Distribution..............................................................

48

Figure 13 Transport LogNormal Distribution................................................................48

Figure 14 Evaporation Rate Emperical Table Distribution............................................

48

Figure 15 Storage LogNormal Distribution ..................................................................

49

Figure 16 Rate at Environmental Storage ....................................................................

49

Figure 17 Installation Temperature Emperical Distribution .........................................

49

Figure 18 Humidity Normal Distribution.......................................................................50

Figure 19 Pages/Day LogNormal Distribution .............................................................

50

Figure 20 Sensitivity to Temperature Noise .................................................................

52

Figure 21 Sensitivity to Humidity Noise.......................................................................

53

Figure 22 Sensitivity to Pages printed per day..............................................................

54

Figure 23 Water Evaporation Rate Sensitivity..............................................................

55

5

Chapter 1

Introduction

Background

How does one prosper in this high tech world? There is great leverage in the

Front-End of the product development process. This fertile time is often called the

Technology development phase, or Advanced Development phase. (Clausing, 1998).

This thesis will refer to this process as the Fuzzy Front-End. (Khurana, 1997). This is a

time of great uncertainty. Where is the market going? Which Technologies will become

dominant in the future? Where are our competitors going? How will we make money?

How should we be organized? What is more appropriate, Technology Push or Market

pull? Several heuristics passed down over the centuries capture the importance of this

phase. "The beginning is the most important part of the work." (Plato,

4 th

Century B.C.).

"All the serious mistakes are made in the first day." (Robert Spinrad, 1988). This early

process is often confusing and chaotic. It is an artistic time. No one has the answers.

Some organizations are fortunate to have a great system's thinker.

These system's

thinkers have the uncanny ability to merge and meld a plethora of disjointed and often

confounding issues to create a set of technology elements which when integrated bring

bountiful success to the organization. Most organizations however, do not possess such

an individual. Somehow, ordinary people in ordinary organizations must navigate these

waters and take their best guesses. This thesis suggests a better way.

Objectives of this Thesis

The goal of this thesis is to develop a method for assessing the strengths and

weaknesses of an organization's implemented Front-End Technology Development

process. Carefully note the word 'implemented' in the prior sentence. Many companies

have documented processes and procedures, yet there can be significant differences

between the corporate documented processes and the processes actually implemented

within an organization. This thesis focuses on those processes actually implemented and

practiced within an organization. The process will generate a list of areas for

improvement. Once a list of weaknesses are derived using this method, the organization

can create initiates targeted at improving their actual fuzzy front end processes. Where

would one start to try to improve their actual processes? This thesis provides a

6

methodology for systematically understanding the strengths and weaknesses of an

organization's Fuzzy Front-End Technology Development process. It is NOT the

objective of this thesis to make specific prescriptions, although many prescriptive

solutions are easily inferred from the proposed method. An example showing how the

results can be used to create an initiative is given. Individuals inside or outside the

organization may use the methodology proposed. The main objective is to get focus on

the right problems. Management consultants may find this methodology extremely

beneficial to help them pinpoint dysfunctional or absent processes for their clients.

Different companies use different terminology and practices, therefore, an interview

format for data collection was selected. Details of the interview procedure are given.

Ultimately, people and organizations will use this material to make major changes within

their organizations and reap significant success in their chosen markets.

The Problem Statement

Introduction of immature technologies is a leading source of schedule uncertainty.

(Clausing, 1994). A distinct technology development phase can greatly reduce schedule

uncertainty. (Clausing, 1994). Weak technologies even induce additional problems in

product development programs. (Clausing, 1994) and (Altshuller, 1984). The lack of

technology robustness has to be fixed in elaborate rework cycles during the production

preparation phase and thus quality and time to market become uncertain. (Clausing,

1998). Cooper and Kleinschmidt's research indicated that successful projects spent twice

the amount of money and almost twice the amount in man-days in the front end than did

projects that failed. (Cooper and Kleinschmidt, 1988). Hence, there are many important

reasons for seeking improvement in the fuzzy front end. There are many issues to

consider. Technology Push or Market Pull? Technologists have a notion of what's

possible. Business planners have a notion of what will sell in the marketplace. There

should always be a comfortable tension between these two fields. Often, however, they

live in two separate worlds. Their languages are different. Their motivations are

different. Technologists want to see their latest invention incorporated because they

believe it's the best thing since sliced bread. Product planners, on the other hand, are not

impressed with under the hood wizardry. They are simply looking for features to delight

customers at or below competitor's prices. The proposed methodology seeks to discover

7

and illuminate the most important areas in need of improvement in the fuzzy front end.

How are we to spend this important time and money?

Research Method

An interview/questionnaire was developed to identify areas in need of

improvement in the fuzzy front end. The questionnaire was developed based upon the

Total Technology Development framework proposed by Clausing. (Clausing, 1998). I

will refer to Clausing's Total Technology Development process as the TTD process.

Several frameworks were considered. Other frameworks considered include Xerox's

Time to Market Process, Michael Frauens "Improved Selection of Technically attractive

projects using knowledge management and Net Interactive tools, (Fraeuns, 2000) and

Robert Wirthlin's "Best practices in user needs/requirements generation." (Wirthlin,

2000). A discussion of the selection of Clausing's TTD process is included. Interviews

were conducted with ten senior managers from one organization's division. The interview

consisted of 82 questions. Respondent's scores were collected for each question.

Subjective comments regarding each question were also recorded. Averages and

Standard Deviations were calculated for each question. (Appendix XX). The average

scores were sorted. A discussion of the lowest scored questions and highest standard

deviation questions is given in section XX. Once a list of weaknesses are derived using

this method, the organizaton can create initiates targeted at improving their actual fuzzy

front end processes.

8

Terminology

The following words or phrases show up throughout the thesis. They are given to

help to reader interpret the thesis.

System's Thinking

"A way of thinking about, and a language for describing and understanding, the

forces and interrelationships that shape the behavior of systems. This discipline helps us

see how to change systems more effectively, and to act more in tune with the larger

professes of the natural economic world." (Peter Senge, pp. 6-7).

Technology Push

Technology push can lead to great technical concepts, but they can dismally fail

to meet some important customer needs. (Clausing, 1994).

Market Pull

The opposite of Technology push is market pull. Here, there are major customer

needs and technologists attempt to deliver technologies which lack robustness, leading to

disastrous results. (Clausing, 1994).

Technology

The word Technology derives from the Greek word technologia, meaning

'systematic treatment'. (Websters, 1996) Within this thesis, technology will be defined

as:

'Technology is the structured application of scientific principles and knowledge to

enhance the functional performance of a system. It has an overall structure and

classification. A particular technology contains a body of formalized, transmittable

scientific knowledge and has distinct attributes such as specialist techniques for

investigation, measurement, and application.' (Clausing, 1998).

Technology Readiness

9

Technology Readiness is the point in time in a program when the launch schedule,

product quality and product cost can be estimated with reasonable confidence. It

represents the point in time when a corporation makes a firm commitment of resources

and money to develop and deliver a product. (Xerox TTM Process).

Total Technology Development Phase

For this thesis, this phase includes all development activities leading up to the

point of Technology Readiness.

I exclude basic research from this phase.

Independence Axiom

An acceptable design is achieved when the design parameters and functional

requirements are related in a way that a certain design parameter can be adjusted to

satisfy its corresponding requirement without affecting other functional requirements.

(Suh, 1990).

10

Chapter 2

Total Technology Development Framework

This chapter provides an overview of several frameworks that were considered for

the foundation of this thesis. The rationale for selecting the Clausing TTD framework is

discussed. The remainder of this section discusses some of the major differences

between these frameworks and Clausing's TTD framework.

New technologies are the life-blood of thriving companies. Generating and

selecting winning technologies is a very difficult process. A process is needed to

generate and assign these winning technologies to products.

The process of generating and selecting these winning technologies is a very complex

process. A.D. Wheelon stated it nicely: (Rechtin, E. Systems Architecting):

"A System is successful when the natural intersection of technology, politics, and

economics are found."

How does one deal with these layers of complexity? The primary method for dealing

with complexity is to decompose the larger problem into smaller manageable pieces.

Hence, a framework is needed to decompose these activities down to manageable pieces.

Total Technology Development Framework Selection

Several frameworks were considered as the basis of the questionnaire.

Frameworks considered include Clausing's "An embedding process framework for Total

Technology Development" (TTD), (Clausing, 1998), Xerox's Time to Market Process,

Michael Frauens "Improved Selection of Technically attractive projects using knowledge

management and Net Interactive tools, (Fraeuns, 2000) and Robert Wirthlin's "Best

practices in user needs/requirements generation." (Wirthlin, 2000). The Framework

selected is titled, "An Embedding Process Framework For Total Technology

Development," by Armin P. Schulz and Professor Don P. Clausing. They completed this

work at the Center for Innovation in Product Development at MIT during 1998.

Members from the Center for Innovation in Product Development, MIT and the Institute

of Astronautics, Technical University of Munich cooperated on this work. Professor

Clausing is the Xerox Fellow in Competitive Product Development at the Center for

11

Innovation if Product Development at MIT. This work is an enhancement of Clausing's

earlier work in his book Total Quality Development (Clausing, 1994). There are several

advantages for selecting this framework over the others:

1.

The framework is comprehensive, incorporating all-important upstream and

downstream influences.

2.

The framework identifies many tools and techniques and their applications. This

makes the framework very practical and useful.

3.

The framework is flexible. Nearly any technology can benefit from these

practices.

4.

The framework encompasses aspects of human behavior.

5.

The framework seeks to integrate the Voice of the Market with the Voice of

Technology.

6.

The concepts and tools are consistent with the training incorporated within MIT's

System Design and Management curriculum.

TTD Framework Overview

The framework is subdivided into four Phases.

Phase I

Integrated

Technology

Strategy

Phase II

Concept

Generation

and

Enhancement

Z>

Figure

Phase III

Robustness

Development

and Analysis

Phase IV

Technology

Selection,

Transfer and

Integration

1 TTD Framework

12

Framework Phase 1 - Technology Strategy

Phase 1 Overview

Phase 1 systematically builds a solid foundation upon which superior Concepts

are generated. This phase seeks to blend the Voice to the Market with the Voice of

Technology. Phase 1 activities illuminate market and technology trends. Specific tools

help translate market needs into technology parameters. This parameterization is

essential. The parameterization speaks to the technologists in a language they can more

easily understand. This phase also sheds light on the basic technology strengths that will

be required to develop the new technology. One must determine whether these strengths

are present in the company, need to be developed further, or whether outside partners

should be considered. The success of this phase depends heavily on interactions between

the technologists and business planners. (Phase 1 steps are described in Appendix 1)

Framework Phase 2 - Concept Generation and Enhancement

Phase 2 Overview

Phase 2 is comprised of 4 main themes. The first is System Decomposition. This

phase begins with the most important functional outputs determined from Phase 1.

Functions are decomposed in solution neutral space. Triz concepts are applied to select

functional solutions having high ideality. The second step is system re-integration. This

is accomplished using a design structure matrix to aggregate related functions. This is

the step where function is transformed into the form of potential solutions. The third step

is concept enhancement. This is accomplished by defining critical failure modes and

critical system conflicts. This important step uses breadboard testing to assess the

significance of related failure modes. The 4th step is concept evaluation and selection.

The goal of this step is to select the most promising solutions in terms of superiority and

pre-robustness. (Phase 2 steps are described in Appendix 2)

13

Framework Phase 3 - Robustness Development and Analysis

Phase 3 Overview

Once several concepts are selected from Phase 2, the concepts now pass through

robustness development. This phase is composed of two major steps. The first is

robustness analysis and evaluation. The second is robustness design. Robustness

analysis consists of defining metrics to measure robustness, selecting appropriate signalto-noise ratios, identifying critical parameter sets, identifying noise sources, establishing

orthogonal array experiments and performing the experiments. Noises should be loud

enough to cause the system to fail. "Make early prototypes Fail", (Courtney, 1998). It is

only though observations of failures we gain a keen awareness of the system's

robustness.

The second step is robustness design. This phase involves calculating signal-tonoise ratios and selecting the best parameter settings. One major concern during this

phase is how to handle interactions. If certain interactions are expected, a suitable

orthogonal matrix should be used to capture the interaction. Preferably, the concept

selected for robustness development will obey the independence axiom. (Suh, 1990).

This will lead to an independent set of control factors. Independent control factors lead

to independent design factors. This will eliminate the interactions among the control

factors and is crucial for applying the additive model. (Clausing, 1998).

(Phase 3 steps are described in Appendix 3)

14

Framework Phase 4 - Technology Selection, Transfer, and Integration

Phase 4 Overview

Winning technologies must meet four general aspects:

1.

They must be Superior

2.

They must be Robust

3.

They must be Flexible

4.

They must be Mature

Superiority

Superiority implies the satisfaction to cost ratio is higher. Satisfaction is viewed in

light of both the market and technology based requirements defined in Phase 1.

Robustness and Maturity

A superior technology by itself won't guarantee success. A robust technology

will be able to be productized through engineering with less rework cycles. Hence, the

ability to predict schedules of robust technologies is greatly enhanced.

Flexible

Flexible technologies are able to easily adapt to variant products. Robustness

development helps to make the technology more flexible.

This selection criteria is similar to concept selection discussed in Phase 2.

However, there is one distinguishing difference. Concept selection and enhancement

seeks to enhance the concepts rather than to rule them out. Selecting winning

technologies for incorporation into product programs is more heavily constrained in order

to meet all the product program requirements.

(Phase 4 steps are described in Appendix 4)

15

Comparison to Xerox Time To Market Process

The Xerox Business Model is shown below.

Xerox

Management

Model

Xerox

Business

Architecture

Tim*e

Ch

2.

eT

IntrastrUCtur6

Time To Market Core Process

-~

Define

MarketAttackt

Dsg

'Define

ein

DeiePrdcProduct Producf Product Customens

e osrt

Dmntae

Deliver

Delight

Teechnnlogy

Figure 2 Xerox Business Model

Xerox's Time to Market Core process is subdivided into 7 Phases.

1.

Market and Product Strategy and Vision

2.

Phase 3.1 Define Market attack Plan and Technology

3.

Phase 3.2 Define Product and Deliver Technology

4.

Phase 3.3 Design Product

5.

Phase 3.4 Demonstrate Product

6.

Phase 3.5 Deliver Product

7.

Phase 3.6 Delight Customers.

This process encompasses all aspects of product and technology creation,

delivery, and service. This thesis focuses on only one aspect of this end to end process,

that being the front end technology development process. Hence, the portions of the

Xerox process that relate to this thesis are only the first three, Market and Product

16

Strategy and Vision, Phase 3.1 Define Market Attack Plan and Technology, and Phase

3.2 Define Product and Deliver Technology. There are many similarities and differences

between the Xerox process and the process proposed by Clausing's TTD process.

Following are descriptions of the first three phases of the Xerox process followed by a

description of the similarities and differences between the Xerox TTM (Time to Market)

process and the processes proposed by Clausing's TTD process.

Many corporations have documented processes. However, this doesn't mean they are

used throughout the company. Whether a company implements its documented processes

depends heavily on the amount of training and management support.

Xerox Market and Product Strategy and Vision

The output of this phase is a document referred to as the MPSV (Market Portfolio

Strategy Vision document.) This document describes the current state of the market,

defines the strategic market opportunities, and identifies vectors of differentiation that

distinguish Xerox from competitors in the mind of the customer. Technology and value

chain capabilities and strategies are identified and a risk assessment is provided. The

details of this process are beyond the scope of this thesis.

Similarities to Clausing's TTD process

Both processes use various charts and graphs to capture the essential business and

technical risks and opportunities. For example, Figure 2 shows Clausing's TTD proposed

Bubble Portfolio Analysis of Market segments and products. Figure 3 shows Xerox's

TTM Market Strategy Allocation Model. They share many similarities. Both indicate

the market or business strength of each product offering. Both also indicate a notion of

the market attractiveness or market growth potential. Both indicate the predicted future

movement of each product. The Clausing TTD graph goes one step further by indicating

the degree of competition for each product.

17

A k

"

*

P3

40

0

*

I-

*

0

Pi: Product i

Size of Circle

represents revenue

contribution.

Arrow indicates

trajectory.

Shading indicates

degree of

competition

0

Weak

below

Avg

Avg above

Avg

Strong

Market Strength

Figure 3 TTD Bubble Portfolio

Figure 4 below describes Xerox's market strategy allocation model. Note the similarity

to Clausing's TTD method.

18

2

4

Weak

Medium

Strong

Business Strength

Figure 4 Market Strategy Allocation Model

In addition to the charts shown above, both Clausing's TTD and Xerox's TTM

process propose similar charts for plotting risk-reward trade-offs. When selecting a new

technology, one must be highly cognizant of the technology risks and they must be

carefully weighed with the potential return on investment. When the technology is very

new or the degree of innovation is new, Utterback suggests completely separating out the

technology development from the organization. (Utterbach, 1991). Clausing also

suggests cycling individuals from mainstream product development teams back into

advanced technology development teams. (Clausing, Total Quality Development, 1994).

This can ease the difficult of NIH, (Not Invented Here) syndrome so common when other

people develop technology and throw it over the wall.

Lowell Steele stated the following misconception:

Misconception: The power of a new technology determines its success.

Reality: The infrastructure required to support it is often the determining factor.

(Steele, Managing Technology, p. 62)

Many of the processes in Phase 3.0 seek to identify technologies and the

underlying infrastructure required to enable the technology to be successful.

19

Management must be highly cognizant of this fact. The technology by itself is useless

without the supporting infrastructure.

Xerox Phase 3.1M

The output of this phase is the Market Attack Plan (MAP). The MAP defines the

market opportunities, defines market driven standards and coherence requirements,

identifies a vector of differentiation, identifies value proposition and family products,

creates a life cycle management plan and again performs risk assessment. Essential to

this phase it the definition of a platform strategy to support a family of products over

time.

The Xerox phase goes into significantly more detail than Clausing's TTD process.

For example, the Xerox process requires documenting where and how customers buy,

and how customers decide to buy.

One common theme is the identification of a Vector of Differentiation (Xerox

Terminology) and identifying Superior technologies (Clausing Terminology.). Each

process seeks to identify the superior technology in customer terms. This is important to

assure technologies are selected for their market strength, not just their technological

strength. This can be problematic, however. Some technologies are so new it is difficult

to obtain accurate market research data simply because the customer is unable to express

or relate to new discontinuous technologies. In these cases, Geoffrey Moore suggests a

need to identify and target niche markets initially. He refers to this as the 'Bowling

Alley.' (Moore, 1995mado). Pins in the bowling alley represent specific niche markets.

As a company is successful knocking down a few of the pins, the others begin to drop as

they hear and learn from the earlier successes. This can be very difficult for large

corporations who tend to listen only to their closest customers. Their closest customers

may NOT represent the best market for the company's new technologies. The disk drive

industry is a good example of how listening to your closest customers can be bad advice.

(Christensen, 1997). Both the Xerox TTM process and Clausing's TTD process should

look carefully at their market definitions to assure they have focused on the best market

segment.

20

There are many similarities between the two processes of this phase. Market

trends are plotted, customer satisfaction targets are established, new technology trends

are assessed, resource requirements are identified, reuse strategy created, cost

assumptions accounted, value chain partners identified, make-buy decisions assessed,

QFD matrix created, Failure modes are predicted. The Xerox process incorporates a

technique known as Input-Output-Constraint charts. The IOC charts clearly define

relationships between the subsystem modules. Clausing's TTD process does not

explicitly define IOC charts, however, he does mention defining constraints and

understanding subsystem dependencies through the interrelations matrix in the QFD

House of Quality.

Xerox Phase 3.1 P

This output of this phase are specific Product proposals, a program economic

case, value chain and channels plans for the program and a team is now chartered to

begin development work.

The elements of this phase are very synergistic with the

Clausing TTD proposal. Some highlights of this phase include technology capability

demonstration for all unproven elements. This is accomplished by charting the trajectory

of critical parameters (Clausing refers to them as Design Parameters). This phase does

NOT guarantee the technologies are Technology Ready. Technology readiness occurs at

the completion of Phase 3.2. One significant difference between Xerox' and Clausing's

TTD process is that Xerox defines newness and complexity ratings to the program.

Depending upon the newness and complexity, the program is categorized as short, midlength, or long. Figure 5 below defines the Xerox newness and complexity configuration

matrix.

21

Platform

Mid-length

Long

Long

Major

Mid-length

Mid-Length

Long

Minor

Short

Mid-Length

Mid-length

e0

Low

Medium

High

Complexity

Figure 5 Newness and Complexity vs Program Configuration

Depending upon the assigned length of the program, benchmarks are defined and

used to assign a time-table to the program. The assignment of program configuration

also determines the number of review cycles required. For example, the Long program

requires a total of 7 reviews while the short program only requires 5 reviews.

Xerox Phase 3.2

There are 5 outputs from this important stage.

1.

Specifications are complete, validated with customers, and under change control.

2.

Value chain and channels plans are complete. Working agreements and contracts

as appropriate have been signed.

3.

The integrated program plan is complete and agreed to by all parties

4.

Program business case is complete, agreed by all participants.

5.

Technology and value chain readiness demonstration is complete and has verified

readiness of the platform architecture and platform system elements for the

program using the unproven elements.

22

Everything above is also included in Clausing's TTD process. Again, both Xerox

and Clausing rely heavily on the use of the QFD House of Quality to track customer

requirements directly to technology requirements. There is great similarity in one

particular aspect, and that is the significance and importance of Technology Readiness.

Both Xerox and Clausing state no Technology should be placed into a Product

Development program until it has been proven, via simulation, experimental rigs, to be at

a significant level of maturity. Clausing states, "The traditional lack of emphasis on

robustness creates great schedule uncertainty during production preparation. The erratic

performance that is caused by lack of robustness leads to many rounds of build-test-fix

rework of product design." (Clausing, Total Quality Development, p 319). Therefore,

Clausing strongly recommends only selecting robust technologies to move into product

programs. Therefore, Clausing emphasizes Robust Design principles (Taguchi methods)

much earlier than the Xerox process. Xerox views robustness development as something

which occurs after Technology Readiness. Clausing believes this is too late.

The Design Structure Matrix is proposed by both Xerox and Clausing to cluster

subsystems based upon their degree of interactions. The Design Structure Matrix also

acts to define the informal network of communications needed within the organization.

In summary, several frameworks for fuzzy front end technology development

have been studied. Clausing's TTD framework was selected for its completeness,

flexibility and inclusion of the latest System Engineering tools. Clausing's TTD

framework provides an excellent basis upon which to build an assessment methodology.

23

Chapter 3

How to Analyze Upstream Technology

Development Effectivity

Introduction

This chapter provides a complete discussion of the thought processes that went

into creating the assessment method. One of the goals of the thesis was to select a

method that would be generic enough to apply to different companies or organizations.

This goal has many implications on the development of this assessment tool. These

issues and their bearing on the proposed assessment method are discussed.

Process used to create the methodology.

First, I researched various Technology development frameworks. I was looking

for a framework with great flexibility. I wanted this work to be applicable to any

company. I also wanted a framework that employed the latest tools and techniques in

System Engineering. Clausing's paper "An embedding process framework for total

technology development" (Clausing, 1998) met these two criteria very well. After

selecting a framework, I needed a method to extract data from an organization seeking to

improve its fuzzy front-end processes. I considered using a written form that could be

mailed to each respondent. This method has the following shortcomings. First and

foremost, the language used within different companies may be different. For example,

one company may call a critical parameter a design parameter. Since the questions are

asking whether or not specific behaviors were present or not present, I was concerned

that respondents might answer they never perform a behavior, simply because they did

not recognize the word or phrase. Second, written questionnaires do not generate any

dialog. Without dialog, it is difficult, if not impossible, to ascertain the motives behind

why a corporate process is not being followed. Hence, a written questionnaire would

have been a poor method for obtaining data. Another method I considered was a

roundtable discussion with all the respondents present. This method would have

generated a great deal of dialog, but has one important shortfall. In a group environment,

individuals may be reluctant to openly share their thoughts and feelings, especially in the

presence of upper management. Hence, this method lacked the ability to get accurate

24

feedback from each individual. The method selected was the interview. This method

overcomes the limitations of the above mentioned methods. The interviews consisted of

82 behavior driven questions. (see Appendix 7).

Applicabilityto other companies

Can this process be used by other companies? Clausing's TTD framework

includes techniques which may not be familiar to all respondents. For example, DSM

(Design Structure Matrix) method was not known by any of the Xerox respondents.

However, the concept of the Design Structure Matrix is easily explained during the

course of the interview. The respondent is asked when they employ any related processes

that achieve the same end result. For example, when creating a task list DSM, some

companies use a Gantt chart to understand the dependencies between tasks. In this case,

the Gantt chart provides for some elements of the task list DSM. Here's another

example. Some companies may not practice the principles of Robust Design. During the

interview, if it clear the respondents are unfamiliar with Robust Design principles, a short

overview of the method, its applicability and the potential benefits can be discussed.

During the interview, the person giving the interview must be knowledgeable about

Robust Design in order to give an overview of its value. This dialog is concluded by

asking the respondent if they see any utility in the method. Positive responses from the

respondents are noted. The value of this dialog is that awareness of the latest System's

Engineering techniques are communicated to the respondents. If the respondents

favorably respond to the techniques, this becomes an excellent starting point for bringing

new initiatives and techniques into the organization. During my interviews with Xerox,

this pattern became obvious. For example, when discussing DSM, all the respondents

said they felt the DSM process was highly valuable and that the organization should try it

out on select projects.

Generation of behavior driven questions

The questionnaire was developed a list of behaviors. The set of questions was

developed with a one to one correspondence to Clausing's TTD process. For tools

unknown to the respondents, I added verbiage to make the process more generic. For

25

example, the behavior surrounding TRIZ I said: TRIZ (or related methods) of conflict

elimination methodology applied. This verbiage seeks to discover if the company utilizes

some other process or technique which embodies the TRIZ principles. Again, the person

conducting the interviews must be well versed in each of the tools and techniques in

order to generate meaningful dialog during the interviews.

The 5 possible responses for each question are:

N- Never

R- Rarely

S - Sometimes

F- Frequently

A- Always

These words were carefully chosen to span the maximum range of behavior space.

Selection of Interviewees

How were the respondents selected? The Xerox organization is a light-weight

matrix organization. Respondents were selected from both the product side and the

functional sides of the matrix. Furthermore, individuals were selected from each of the

functional management teams in order to obtain a good cross section of the entire

organization. One selected individual was not a member of a product team or a member

of a functional department. This individual had a staff job as Technology Strategist. The

ten respondents comprised one Vice President, one Product Manager, one Technology

Strategy manager, four functional department managers, and three Principal technical

contributors.

Selection of individuals from other types of organizations should embody these

principles.

1.

Select managers representing each major subsystem of the product under

development. This assures good homogeneity of the responses across the

organization.

2.

Select managers closest to the market. These individuals may have various titles

such as Product planners, Product managers, Marketing managers.

26

3.

Select a Technology Strategist, if one exists in the organization.

4.

Include the most senior technical individuals. These individuals may have titles

such as Principle Scientist, or Principle Engineer.

How interviews were conducted

I contacted each respondent and set up a two hour window. We met either at my

office or at the respondent's office. I began the interview by explaining why I was

conducting the interview, and the goal of the interview was to generate a list of issues

upon which initiatives could be generated to improve the organizations fuzzy front end. I

had a blank copy of the questionnaire available for the respondent to look at. I had

second copy in front of me where I kept the scores. I also jotted interesting comments

next to each question. For behaviors having low scores I would ask the respondents

whether or not they thought the organization could improve its fuzzy front end by

increasing a particular behavior. If the respondent said yes, I made an additional

annotation next to that question. (Future improvements of the questionnaire should

include this directly on the form). The average length of time was 1

interview.

hours per

I also had additional materials with me. For example, when discussing DSM, I

had an simple DSM example with me to show to the respondent if they were unfamiliar

with the method. I also had materials for TRIZ, House of Quality, and Robust Design

available if the respondents were unfamiliar with the methods.

In summary, an interview format for data collection was developed. Specific

recommendations are given to make the process as generic as possible such that the

assessment method could be applicable across many companies and organizations.

27

Chapter 4

Data Summaries and Key Points

Introduction

This chapter provides detailed data summaries of the most relevant findings from

the interviews. First, the cumulative distribution of scores are presented and discussed.

This is followed by discussions of the lowest ranking scores, followed by the highest

ranking scores, followed by the scores having the highest standard deviation.

Figure 6 below is the cumulative distribution of all answers from all respondents.

Total Response Distribution

250

200

*E 150

50

C

\

Figure 6 Total Response Distribution

From Figure 6 above, approximately 4 % of the responses were Never, 26% of the

responses were Rarely, 32% of the responses were Sometimes, 36% of the responses

were Frequently, and 2% of the responses were Always. This result clearly indicates this

organization does not fully embody the behaviors/processes outlined by Clausing, since

only 30% of the responses were Never or Rarely. Assuming the behaviors/processes in

Clausing's model are valid and have benefit, the data indicates there is substantial room

for improvement within this organizations Front-end Technology development.

28

In order to improve the front-end technology development process for this

organization, the following process is employed.

Step 1: Calculate the average response for each question

Step 2: Sort the responses from lowest average to highest average.

Step 3: Eliminate any behaviors having less than 4 responses.

Step 4: Critically assess the respondents verbal responses

Step 5: Discuss the value of implementing the proposed behaviors.

It is beyond the scope of this thesis to discuss all the ramifications of

implementing process changes within an organization. This thesis presents the first step

in that process, to identify beneficial behaviors lacking within the organization.

Discussion of Lowest scoring behaviors.

Lowest Score Behavior #1

PhaseiStep IQ IlndexlRi

21!

61

44A

1R2

1

1R3

1R4

11

1R5

2

1R6

2

1R

3r

R8

1

1R9

2

IR10 I9

1,

1

.6

Apply Design Structure Matrix to re-allocate

system elements and theirfunctions into

modules, that is, highly interrelatedfunctions

allocated into individual modules and work

teams.

Oddly, none of the respondents had ever even heard of or seen a Design Structure Matrix.

During the interviews, the Design Structure Matrix concept was shown to each

individual. Each respondent easily grasped the concept and felt it was an excellent

methodology for mapping the interdependencies within the organization.

One respondent noted the Design Structure Matrix can be utilized to assess the

degree of risk in making certain decisions, or the risk to other subsystems if a decision is

later modified.

29

One respondent commented how some individuals are located in separate

buildings and that the Design Structure Matrix could highlight those groups or

individuals that should be collocated.

Lowest Score Behavior #2

Phs

tpQldx R1R2

1

41 11

221

21

1R3 1R4 1R5

21

21

21

1R6 1R7 1R8 1R9 IR1 0 Avg

21

11

21

11

21

11

1.71

House of Quality builtfor each technology

The respondents all answered this question consistently low. Again, this is a Xerox tool

that is clearly documented in the TTM guide books. Why isn't this organization using

House of Quality? House of Quality has gotten a culturally bad name for itself within

this organization. The reason is because most managers have had to create a House of

Quality to fulfill Xerox Phase gate criteria and have not obtained commensurate value.

The reason is because they are creating the House of Quality too late in the process. The

House of Quality has value during the Concept Phases, not at the completion of a phase.

The House of Quality can be used as a communication vehicle between marketing and

engineering. The cultural stigma from being forced to create a House of Quality to fulfill

the TTM policing function has made it very difficult for anyone to sincerely practice

using this tool.

Another barrier has been the lack of a good House of Quality software tool for the

creation and maintenance of the House. This is now changing. Recently a tool has been

made available from QFD Designer from Qualisoft (see www.Qualisoft.com). This tool

has a good user interface and can be learned quickly.

Lowest Score Behavior #3

Phase Step Q Index R1

R2

2

9 2

58

2

2

8 3

56

2

2

9 1

57

2

R3

R4

2

3

R5

3

4

3

R6

2

1

2

R7

2

R8

2

2

2

R9

R10 Avg

1

1

1.9

2.2

1

1 2.0

30

TRIZ or related methods of conflict

elimination methodology applied.

Inventive problem solving methods such as

ARIZ are applied to break system conflicts.

Conflicts are identified to be eliminated.

These two questions are highly related. At least fifteen individuals in this organization

went through a one week TRIZ training workshop last year. Yet, evidence of TRIZ

usage is nowhere to be found! What went wrong? It appears there was no management

support for TRIZ, other than financing the training. What I found most disturbing

however, is that the concepts embodied within TRIZ have not yet permeated this

organization. This organization focuses greatly on Compromise rather than Conflict

Elimination. Conflict elimination is a way of thinking. It is especially important during

the Concept generation phase. Yet, this organization has not embraced this manner of

thinking. This was highly evident from comments from respondents.

Overall, most respondents agreed Conflict Elimination thinking would be

beneficial to this organization. Their concern was the amount of time necessary to

explore the alternative paths generated.

Lowest Score Behavior #4

IPhaseiStep

2 -621 IQIJndexIRl

451

31

1R2-

1R3 JR4

I-

31

2

1R5

1

1R6

-

JR7

31

1R8

21

3

IR10 JAvg

1R9

-21

I

1 2.21

Great care taken to assure the architecture

has minimal interrelationsbetween modules.

There was greater variance to this behavior from the respondents. Two of the

respondents said the organization Never did this behavior. Four of the respondents said

the organization Sometimes did this behavior. This issue has caused schedule problems

for this organization. The firmware development for the inkjet printer was handed off to

an outside firm. The firmware touches practically every subsystem within the printer.

The interrelations between firmware and other modules is complex. The information

31

transfer requirements between firmware and the modules is high. The information

conduit passed through one individual who tried to keep the firmware and testing

requirements in order. It didn't work. The firmware became the critical path and caused

the program to slip. The quality of the firmware also was in question. The architecture

simply could not handle the two directional information pathways required between the

modules and the firmware. A Design Structure Matrix would have made this obvious.

32

Lowest Score Behavior #5

Phase Step

1

1

1

4

Index R 1Q R2

R3

R4

R5

R6

R7

R8

R9

R10 Avg

1

4

2

3

3

3

3

2

2

2

22.6

23

2

3

2

2

2.3

Market Pull requirements clearly defined.

Technologists and ProductMarketing work

well together defining the best mix of

technologies and markets.

This organization makes decisions primarily based on Technology Push and less

on Market Pull. Respondents were asked to place an 'X' where they thought we were on

the Market Pull vs Technology Push continuum. And to place an '0' where they thought

we should be. The results were unanimous.

Market

0

X

Pull

Technology

Push

Figure 7 Market Pull vs Technology Push

All respondents felt there needed to be more Market Pull and less Technology

Push in decision making. There was fear of creating technologies the market wouldn't

accept. The House of Quality can act as a speaking tool between these two forces. The

left side (Rows) being the 'What' (Market Pull) and the vertical colurns being the 'How'

(Technology Push).

One manager felt having more technical people in the marketing function could

help bridge this gap.

The other major difficulty occurred when partnering with companies having

different views of the market. This creates great confusion and chaos, resulting in

delayed decision making and sometimes reverting decisions later in time. These political

hurdles must be dealt with very early. If the differences in markets being served by the

partners are too vast, highly flexible technology must be developed for the partnership to

survive.

33

Lowest Score Behavior #6

IPhaseiStep IQ indexIJR1

21

61

11

351

1R2

31

1R3

21

1R4

31

IR5 1R6 1R7

21

21

21

1R8

21

IRio tAvg

1R9

21

31

21

2.31

Functions decomposed into sub-functions in

solution-neutralspace, that is, without regard

to any design concept.

The respondents, who responded with 3- Sometimes, said this behavior occurs implicitly

within the minds of the engineer. It isn't an explicit, written down process as suggested

by Clausing. Most respondents were unsure of the value of explicitly performing this

behavior. This process is the backbone of System' s Engineering. The value resides in

the ability to decompose the function down to the essential functional elements prior to

deriving a concept to map function to form. When an individual prematurely establishes

a design concept, the brain tends to take hold of this idea and great energy is required to

move the brain onto other concepts. The value of breaking down the functions to

subfunctions in design neutral space is proposed to prevent the brain from adopting

premature concept selections.

Lowest Score Behavior #7

IPhase-Step IQI~ndexIR1

41741

82

1R2

1R4

jR3

2

jR5

3

1R6 1R7

3

1R8 1R9

31

21

JR10 IAvg

2

2

Promisingtechnologiesnot yet readyfor a

productprogram areplaced back into

robustness development.

Many of the respondents indicated that promising technologies that are not yet ready for

product programs are typically killed, rather than placed back into Robustness

development. This organization does not actively staff resources to enable promising

technologies to cultivate. The organization is so fixated on getting the next product out

that managers are reluctant to place any resources on longer term, potential high gain,

projects. This approach is short sighted. The organization needs to achieve a balance

between getting products out the door, and maintaining a steady technology stream. This

34

is very difficult to achieve, because culturally, Xerox has a tendency to throw resources at

problems. Managers feel constantly in a state of fire fighting. In this mode, all resources

are thrown at the problem of the week to keep the fires from raging out of control. At

this point, a senior manager, or VP needs to step in, assess the total picture, and make an

appropriate judgement regarding allocation of resources.

Lowest Score Behavior #8

IPhase Step IQ In-dex Ri

1

1 131

131

1R2

21

1R3

41

R4 IR5

3

31

R7

R6

2

21

1R8 1R9

2

31

R10 IAvg

2

2 2.5,

Business Impact of technology assessed.

This question generated lots of discussion. Because there is a lack of Market pull

in this organization, technologists feel unsure of the value of their technical

achievements. The business cases for recent product programs had not been shared with

many of the senior managers interviewed. Hence, there was a lack of trust between

technical managers and business planners. Business planners need to openly share their

business models with the technical community. A sound business model can give the

organization the needed motivation and personal security to know their efforts will bear

fruit.

Lowest Score Behavior #9

JRi 3 1R2 3 1R3 4 1R4 2 IR5 2 R6 1R7 1R8 1R9 JR10 IAvgI

I1ndex

PhaseiStep

1

2 IQ5

18

1

4

3

2

1 2.5

Reasonable timeline estimates created.

Most managers agreed that unrealistic schedules are created. It is not clear

whether this is good or bad for the organization. Many managers believe that creating

realistic schedules is a poor idea because it takes the pressure off the people. They argue

aggressive schedules drive and motivate individuals. There is a flip side to this issue. If

schedule pressure is too great, individuals begin making poor decisions. They don't take

35

the time to properly gather the appropriate data for the decision. Excessive schedule

pressure over prolonged periods of time can lead to individual bum-out. This

organization is approaching burn-out stage as it continues to drive multiple parallel

projects, each under aggressive schedule pressure.

Lowest Score Behavior #10

IPhaseiStep IQolindexiR1

2

6

31

461

1R2

21

1R3 1R4

1

31

1R5 1R6 1R7

21

21 -31

1R8

21

1R9

IR1 0IAvg

31

21

42.61

Multiple System Architectures proposed,

rather than keying in early on a single

solution.

Rarely is the first idea the best idea. Yet, respondents said very little time is spent

developing multiple concepts! Pugh concept enhancement is a method proposed by

Clausing which leverages the strengths of each concept to build new concepts. This

behavior is grossly deficient in this organization. Most respondents agreed the

organization should foster a more active concept generation phase.

Discussionof Highest scoring behaviors.

Highest Score Behavior #1

Phase

Step Q Index R1

R2

3

123

69

4

3

122

68

4

R3

R4

4

R5

R7

R6

R8

4

3

2

4

4

4

R9

1

R10 Avg

4

4

Stdev

43.6

0.8

44.0

0.0

Design of Experiments. Environmental noises

selected.

Design of Experiments. Tolerance noises

selected.

36

Most respondents indicated this organization does a good job defining

environmental and tolerance noises. They indicated frequent testing at high and low

temperatures, high and low humidities, and high altitude testing. Tolerance noises were

also selected. This organization has painfully learned from past projects what happens

when a product moves into production and production processes are not able to meet the

tolerances specified. Because of this prior experience, the organization has become

sensitized to discovering tolerance sensitivities early in the development process. There

was one individual who did not agree tolerance noises were selected. This individual felt

tolerance noises were selected, however, they were selected too late in the development

process. Tolerance noises were considered something that could be worked out at a later

stage in the program. Also, note that several respondents did not answer this question.

This was because these individuals were at a higher level in the organization and did not

understand this level of detail within their organization. Is this an indication that upper

management isn't aware of what people lower in the organization are doing? Are these

managers out of touch with the processes being used in their organization? Should these

managers know whether or not environmental and tolerance noises are applied? Upon

further probing in the interview, the respondents indicated they believed these noises

were being applied, they simply didn't know the details of what specific noises were

being applied.

Highest Score Behavior #2

R2

Phase Step Q Index R1

1

1 1

1

1 8

R3

R4

R5

R6

R7

R8

R10 Avg

R9

Stdev

10

4

4

5

3

4

4

2

4

3

4

3.7

0.8

8

3

3

4

4

4

4

4

4

4

43.8

0.4

Provide a technology perspective for a

decision on which technologies to focus on.

Technology Trends plotted.

The respondents unanimously agreed that a very thorough technology perspective

is used for decision making. Technology perspectives include benchmarking of

37

competitive technologies, studying patent literature, and in-depth technology risk

assessment. However, the respondents felt that decision making was too focused on the

technology perspective, and too weak on the market perspective, as discussed earlier

(ref.Questionnaire Index #1). This organization is too heavily focused on technology

push and lacks the market pull factors in decision making.

Highest Score Behavior #3

Phase Step Q Index R1

R2

R3 R4 R5 R6 R7 R8 R9 R10 Avg Stdev

2

6 1

37

4

4

4

4

3

4

4

3

3

4 3.7

0.5

2

6 6

42

4

4

4

4

5

4

3

3

4 3.9

0.6

Target values establishedfor each design

parameter.

Appropriate design parametersdetermined for

each subfunction.

This question required some clarification during the interview. Xerox refers to

Clausing's design parameters as critical parameters. This Xerox organization has been

trained to apply Critical parameters to the design process. Management has supported

and fostered the deployment of critical parameters throughout this organization. Note the

consistent high scores across the organization. This is a good indication that training and

management support has been effective at instilling the critical parameter design process.

One of the lower scores came from an individual who worked in an area where it has

simply been too difficult to define appropriate critical parameters. Many of the design

practices in this group are driven by heuristics rather than strict critical parameter

determination for each function. Attempts have been made to seek out the critical

parameters and link them to function, yet the technology itself has been too difficult, even

for senior level scientists, to extract the relevant critical parameters. Because of the lack

of scientific knowledge linking critical parameters to function, they have had to rely on

lots and lots of empirical testing to assure the design functions could be met.

Highest Score Behavior #4

38

MPhase1 Step11 IQI11ndexIJRl

31

31

5

1R2

4

1R3

1R44

IR5

R6

4

1R7

4

1R8

1R9

51

IRl

41

ivg3. Idev09

21

Each competitor is well characterizedin the

market.

The scores were very high on this question, with only one major dissenter. Charts

and graphs are frequently created showing the competitive strengths of each competitor.

A competitive lab has even been established. This is a room dedicated exclusively to

competitive products. The room was created to raise the awareness of the competition.

Individuals within the organization are encouraged to visit the room and actually use the

competitive products. Individuals may also "check out" competitive products for several

weeks to use at their desktops. A great deal of analytic data is also collected from the

competitive products. The one dissenter commented that he believe competitive

information was collected, however, he felt it was not disseminated throughout the

organization, and that only select individuals actually had access to the data. This

individual happened to be located in another building. It appeared this was an example of

how geographic location had left this individual out the mainstream flow of information.

Again, the interview format was necessary to bring out this level of understanding. A

strict questionnaire would not have elucidated this important insight.

Highest Score Behavior #5

R2

Phase Step Q Index R1

4

54

1

8

2

4

48

8 1

2

4

4

4

4

3

3

R8

R7

R6

R5

R4

R3

4

4

3

3

R10

R9

4

4

4

4

Avg Stdev

0.5

3.8

0.5

3.8

FailureModes predicted.

Lab experiments performed to assess failure

mode impacts on System Performance.

These scores were consistently high. Why? When this organization first builds a

prototype, they have a test called the FMIT. This stands for Failure Mode Identification

Test. The name itself assures failure modes will be found! This organization has

39

delivered two generations or products from their core technology set. They have learned

through experience what important failure modes are necessary to evaluate. The

organization does a good job of looking at failure modes both at a subsystem level and at

the system level.

Discussion of behaviors having high standard deviations

Highest Standard Deviation Behavior #1

IPhase Step IQ Index Ri 1R2 1R3 1R4 IR5 1R6 1R7

1

241

171

51

41

31

41

4

5

1R8 1R9

41

R1 0 Avg IStdev

2

2

3.71

1.1

Resource Requirements determined.

Very interesting results. The two lowest scores came from the technical function

management level, where the two highest scores came from the managers responsible for

resource planning! This implies the people responsible for resource planning feel like it's

being done, yet the people who carry out the plans (the functional managers) don't feel

like it's done, or they don't feel it is done well. During the interview, the functional

managers asked whether the question meant whether resource requirements were

'accurately' determined. They believed resources were determined, however, they felt

the resource requirements were not accurate, implying they are asked to do more with

less people.

Highest Standard Deviation Behavior #2

Phase Step Q Index R1

R2 R3

R4 R5 R6 R7 R8 R9 R10 Avg Stdev

1

2 6

19

4

4

4

2

2

4

4

4

2

2 3.2

1.0

1

2 5

18

3

3

4

2

2

1

4

3

2

1 2.5

1.1

Timeline estimates created.

Budget requirements created.

Each respondent asked this question. "Do you mean 'realistic' timelines are

estimated?" The cynical tone of their voices indicated they believed timeline estimates

40

are created, however, most of the respondents indicated the estimates were not realistic.

For consistency sake, I appended the word realistic to this question for each interviewee.

During the interview two points of view on schedule creation emerged. One point of

view was that schedules should be created more realistically, that is, add more time to the

proposed schedules. They felt the organization had a better chance of hitting the

schedule if was created more realistically. The other point of view was to create

schedules that are more aggressive. They felt the same amount of slip would occur with

either schedule! They felt a certain amount of schedule pressure was necessary to keep

the organization pressured to deliver. This organization hadn't directly felt the impact of

schedule slips in the past, so a cultural norm exists within the organization that tolerates

schedule slips. Responses to budget requirements were similar to schedule requirements.

A large portion of this organization's budget is engineering labor, therefore, schedule and

budget estimates are linked.

Highest Standard Deviation Behavior #3

Phase Step

1

1

1R2

indexiR1

4

4

3

1R3

3

IR5

1R4

2

4

1R6

2

1R7

3

1R8

4

R10 Avg Stdev

1R9

5

3

2

1.0

3.1

Key customer satisfactionparametersare

identified for each market segment.

The respondents giving low scores say management gives diverse answers as to

what the markets are and what will succeed in each market. Why is there so much

diversity of opinion? This organization has an alliance with another company. This

partner is from another country and often has different opinions of the market and what

the appropriate satisfaction parameters are for those markets. Having a partner with a

different view of the market has destabilized this organization. They lack a consistent

focus on which market they are attacking. This has created confusion as evidenced by

the wide range of responses from Rarely to Always.

In summary, 820 data points have been summarized, sorted and discussed. From

these summaries, the organization has obtained a list of it's weaknesses and strengths.

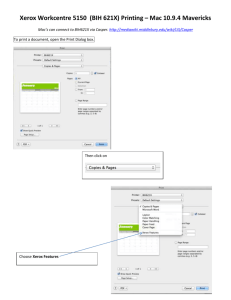

41