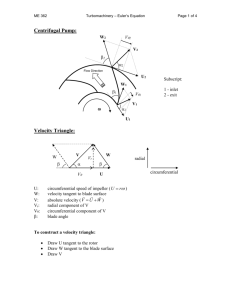

Centrifugal Pump An Experimental Investigation of the Influence of by

advertisement