JUL 7 1972 Rotch OF SERVICE UNITS of

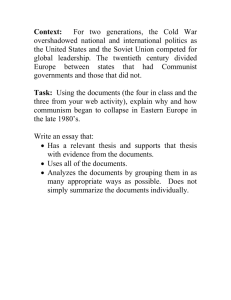

advertisement

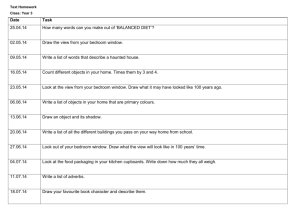

77 SLIP FRAME: A PROCESS FOR UTILIZATION OF SERVICE UNITS BY GEORGE CHARLES WEINER B.S., City College of New York (1967) B. Arch, (1968) City College of New York SUBMITTED IN PARTIAL FULFILLMENT OF THE REQUIREMENTS FOR THE DEGREE OF MASTER OF ARCHITECTURE, ADVANCED STUDIES at the MASSACHUSETTS INSTITUTE OF TECHNOLOGY June, 1972 Author....a... . . . . . . ........ .. ripartment of Arclitecture Certified by. Thesis,-upervisor Chaersia Dprmenta / Accepted by. Chairrdlan, Departmental Committee on Graduate Students Rotch opkss, . JUL 7 1972 LI&RARIEO ii Dean William Porter School of Architecture and Planning Massachusetts Institute of Technology May 1972 Dear Dean Porter, In partial fulfillment of the requirements for the degree of Master of Architecture, Advanced Studies, Slip Frame: A I hereby submit this thesis entitled: Process for Utilization of Service Units. Respectfully, George Charles Weiner -2 iii "Slip Frame: A Process for Utilization of Service Units." by George Charles Weiner "Submitted to the Department of Architecture on May fulfillment of the requirements for 1972,in partial the degree of Master in Architecture, Advanced Studies." ABSTRACT The first part of this thesis provides a brief explanation of a marketing strategy for an industrialized building system utilizing wet modules. A major problem in producing low cost housing is explored: resolution of the conflict involving marketing, delivery and planning. The second part describes through 32 drawings the "slip frame process", a 3 storey box, delivered horizontally which is both an extension of the plumbing chase and a packaging system. The box is capable of expansion in one or two directions to include service modules and other "wet" building components. Thesis Supervisor: Title: Eduardo Catalano Professor of Architecture iv FOREWORD "Start from where you are, not from where you wish you were." Saul Alinsky "Principles of Change" v INTRODUCTION This thesis focuses on the conflict inherent in the production of modular housing: Marketing - volume production, code and labor acceptance Delivery - size, weight and strength constraints Planning - special dimension and flexibility requirements There are many products already produced which are potentially industrializable (e.g., packaged bathrooms and kitchen units) . There are also available many building systems, American and European, all with the common goal of lowering the cost of housing. They all share the common requirement that to lower costs significantly they must have volume production. Clearly, not required are more building systems, but better marketing strategies. The service area of a dwelling (including HVAC, bathroom, kitchen, stairs) has assumed an increasingly disproportionate percentage of the total building cost, compared to the shell. This proposal, the "slip frame", packages this service area in the factory and attempts to maximize application possibilities by the capability to vary in dimension. The idea of expanding modules on site after compliance with road width constraints is not a new one. The "slip frame" approach attempts.to simplify the process and add to the body of knowledge on alternative solutions. With the increasing production of modular housing, limited in dimension by delivery constraints, will come new pressures to explode dimensions imposed by constraints vi other than those of good design practice. This proposal would "factor out" the high cost elements of the dwelling and package them at the factory where maximum savings in labor can be achieved. Perhaps the most significant feature of this approach is that the package is hidden within the shell of the building. The implication here is that acceptance of an industrial- ized building product may be increased since it read as a box or "pre fab" system. A small change in the industrialization of the mechanical of building should result in cost reduction of low cost, does not equipment sector a significant impact on and housing in general. TABLE OF CONTENTS - -- - - -iii . .. - .- - - -- . .. . .. . ABSTRACT................. . . . . .. . . .. FOREWORD................. . . . . .. . INTRODUCTION............. . . . . .. . - . ... iv V DRAWINGS Ca o l f oJ% STe r1 i0 vL cen i 1-5 s0. ..6 Application... .. 8 Planning...... ........... 0 .15 Frame Unit.... Structure..... .. 0 . .. . .16 . .18 Mechanical.... .. 0 . .. . . .19 Process....... ............ 0 .20 Package ..... .. 0 . .. . . Delivery...... .25 Expansion..... .26 Erection...... .27 Building Types /Application .28 PHQTOGRAPHS - WET MODULE Horizontal/Expanded...... . . Tilted to Vertical....... . . BIBLIOGRAPHY ............... .. 0 . . . . . . .33 . . . . . . .34 ........................... 35 May 18, 1972 Institute Archivist Massachusetts Institute of Technology Dear sir: This is to acknowledge that the drawings of this thesis do not conform to the standard format set by the Institute. The author assumes all responsibility for any damages occurring during the binding process. Yours truly, George C. Weiner THESIS SUPERVISOR MARKETING DELIVERY PLANNING 8'-0"1 12'-0"1+ CONFLICT 1 4 E-1BR K1 Bl L S 'IL i1-2BR K2 B2I 3-4BR K3 B3 3'" C1- CDI 4-BR PLAN K4 iB4 2'-6" C2,3 EMqM ELEVATION B SERVICE UNITS K KITCHEN 2 B K BATHROOM UTILITY SERVICE UNITS /CODE K3 0011 Ki oo L__JLI Bi LOCATION WITHIN PLANNING MODULE A ~f1001 CATALOG /-POSITION 4 L -C2 K4I --.---. -- B4 _ATA__ /_PITIOC3 CATALOG /POSITION 2B1 ____ GlD CAT ALO 6 SELF SUPPORTING COLUMNS OF SERVICE MODULE ARE STRUCTURAL AND REDUCE IN DIMENSION WITH INCREASING HEIGHT CORRIDOR SUPPORTE BY UNITS SERVICE MODULES CROSS WALL'. FLAT PLATE SERVICE MODULES LATERALLY SUPPORTED EVERY 3RD FLOOR CORRIDOR SPANS LATERALLY BETWEEN WALLS APPLICAT[ON PRESTRESSED CONCRETE SERVICE MODULES LATERALLY SUPPORTED EVERY 3RD FLOOR STAGGERED TRUSS SERVICE MODULES CONNECTED TO MAIN STRUCTURE FOR INCREASED STABILITY ............ ............ 11 APPLICATION 8 EFFICIENCY PLIN 9 Ej El 1 BEDROOM PLAN 0 rlI LI BEDROOM IIILI m1 0m0 CORNER 2 BEDROOM PLAN '111 -2nd FLOOR DUPLEX 2 BEDROOM PLAN 2 CORNER 3 BEDROOM PLA N 13 3 BEDROOM PLAN 14 D CORNER 4 BEDROOM lIZ PLAN --4 aE" / S / U1 16 SERVICE UNIT I ~Afl --------------- 4 1-i F TT 7 TAVT STEEL DECKING I. 171:, I. -WELDED TO FRAME II~ PLAN FINISHED FLOOR LEVEL ~~fT m m ri rr-1 2-~P SERVICE UNIT zt c:) cn ELEVATION STRUCTURE 17 PLAN COLUMN DETAIL HR. FIREPROOFING I BOLTS -' FINAL POSITION 3/4 DIA. BOLT WELDED TO COLUMN CAP PLATEATCRIO PECOST PAI BOX CONNECTION DETAIL ELEVATION DETAILS 18 BRONZE FLEXIBLE HOSE VENT PIPE ADJUSTABLE LENGTH COPPER OR PVC PLASTIC WATER PIPE PIPING CONNECTION DETAIL AT CEILING MECHANICA E 19 CLOSETS, DOORS, WALLS ADDED AFTER SERVICE MODULE IS POSITIONED PROCESS PLAN 20 Ii I, I L I ~-~Z~z~-,J ALTERNATE CHASE LOCATION FRAME UNIT SERVICE MODULE ..................... ................. ................ .. . ELEVATION PACKAGE PLAN1 21 0 B ALTERNATE LOCATION OF CHASE FRAME UNIT SERVICE MODULE ELEVATION PACKAGE PLAN 22 B PLAN FRAME UNIT SERVI CE UNIT (FIBRE GLASS) ELEVATION PACKAGE PLAN 23 DOUBLE UNIT - SHARED CHASE 2B1I Do PACKAGE PLUN 24 PACKAGE PLAN 25 IF PACKAGE REMAINS WITHIN CRITICAL AREA SHOWN THERE ARE NO DELIVERY CONSTRAINTS CRITICAL DIMENSIONS FOR DELIVERY TELESCOPING TRAILER I DELIVERY 26 -v TOP BY STAGES -9 SIDE EXPANSION POTENTIAL EXPANSION 27 CRITICAL HEIGHT (13'-6") M, FOR THIS STUDY = 12'-0" A STAGES AT SITE -EXPANSION TIGHTEN BOLTS WELD DECKING -PRETEST PLUMBING -REMOVE BRACING -LIFT TO POSITION, ALIGN AND LEVEL -FIREPROOF THE STEEL -TILT TO VERTICAL -FINAL CONNECTION AND FINISHING ERECTION 28 LOW RISE Eq TOWER SINGLE LOADED DOUBLE LOADED ---- TOWER r PINWHEEL SERVICE UNITS ALTERNATE CONNECT ION E BUILDING TYPE 29 PLAN _____________________ I I _____________________ ELEVATION ________ HIGH/LOW MIE 30 PLAN HIGH RISE FIZFZI I LA I - 1mmI N- U a ELEnA"LLON__ TOWER COMBINATIONS 31 I SERVICE UNIT INSERTED DOUBLE-LOADED TOWER 32 SERVICE UNIT INSERTED I I / I / I I 1 I / -/ / / / I I / I I I / PINWHEEL TOWER \ y 35 BIBLIOGRAPHY 1. Industrialization Forum Cornell University 2. The New Building Block 3. Crane Report Dec '68 logical Innovation 2173 - Application of Techno- HUD 4. The Architecture of the Well Tempered Environment Reyner Banham 5. Transportation Breakthrough Pre-Fab Transit Co. 6. Steel in Hi Rise Construction 7. Staggered Truss System M.I.T. M.I.T. 8. Industrialized Builders Handbook R.J. Lytle