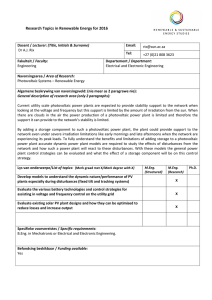

Technological Innovation and

advertisement