1970

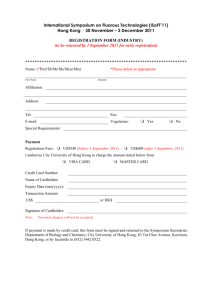

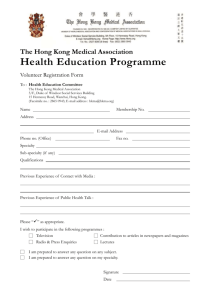

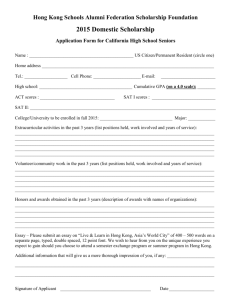

advertisement