Bachelor of Architecture Department of Architecture by

advertisement

A HOUSING

STUDY

SYSTEM

OF MODULAR-BOX HOUSING UNITS

SYSTEM.

APPLIED TO PULL-UP

By

TONG HONGLADAROMP

Bachelor of Architecture

Chulalongkorn University, Bangkok Thailand.

Submitted in

Partial

Requirements

for The Degree of

Fulfillment

MASTER OF ARCHITECTURE,

of

ADVANCED STUDIES.

At the

MASSACHUSETTS INSTITUTE OF TECHNOLOGY

June, 1973.

Author

Department of Architecture

Certified by

Thesis Advisor

Accepted by

1

1

-%

Chairman, De

rtment

Committee of Graduate Student

&tch

CJ9UL 13 1973

k

May 11, 1973.

Dean William Porter

School of Architecture and Planning

Massachusetts

Institute

of Technology.

Dear Dean Porter

In partial fulfillment of requirements for the degree

of Master of Architecture, Advanced Studies,I hereby

submit this thesis entitled

A

HOUSING SYSTEM: STUDY OF MODULAR-BOX HOUSING UNITS

APPLIED TO PULL-UP

Respectfully,

Tong Hongladaromp.

SYSTEM.

ACKNOWLEDGEMENTS

The author gratefully acknowledge the following people

who assisted in the development of this thesis:

Professor Waclaw P.

Zalewski,

Department of Architecture.

Professor Eduardo Catalano

Department of Architecture

Thesis Advisor.

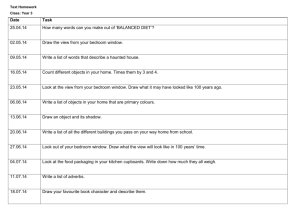

TABLE OF CONTENTS

Title page

Letter of submittal

Acknowledgement

Table of contents

Abstract

Introduction

Housing in high-density urban situation

Design proposal

Advantages of design proposal

Design proposal; Drawing section

Components

Construction sequence

Charactor and detail

Package units and building types

Apartment units

Bibliography

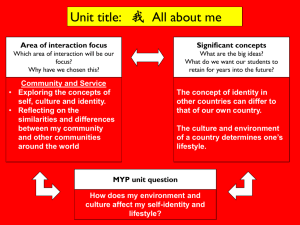

ABSTRACT

A HOUSING SYSTEM: STUDY OF MODULAR-BOX HOUSING UNITS

APPLIED TO PULL-UP SYSTEM.

By

Tong Hongladaromp

Submitted to The Department of Architecture on May 11,

1973 in partial fulfillment of requirements for the

degree of Master of Architecture, Advanced Studies.

This thesis is intented to develop a housing system

based on industrialized technology for high-rise

configuration.

The written section provides a brief overview of

housing in high-density urban situation, potiential

of industrialized housing systems, the constraints

within which the design proposal is developed, and

the advantages of the design proposal.

The design proposal demonstrates how to construct

different components in factories into the box-units,

how to construct those boxes on building site by using

pull-up technique, how boxes composed into different

forms of apartment units, and how the system forms

into vary types of building.

Thesis Supervisor:

Title:

Professor Waclaw Zalewski

Professor of Structures, Department of Architecture.

INTRODUCTION

The demand of housing in high-density urban situation

grows up quickly during this pass decade and is predicted

tobe the same way in the next decade.

There are certain

sources of this demand, one is the slowdown of nation

economy, investors turn against the risk in commercial

and industrial investment and looking toward housing

development or real-estate bussiness, other sources are

the return of U.S. people from abroad is increasing during

this four or five years, the decrease in quality of

existing housing in cities and towns, etc..

This demand turns the mobile-home and many other housing

manufactures to take the important part in construction

industry during this pass decade.

But when taking the

close look at.this industry, one can see that most of

the products emphasize on supplying low-density housing

area,

for example products of mobile-home and wood-boxes

housing units.

No real attempt working toward high-rise

housing or application to housing in cities and towns

area. The reason is that they have to confront to a

lot of building regulation, transportation regulation,

high cost df land, high cost of construction, etc., those

are existing in project developments in towns or cities

area.

But we all realized that the real big market and

demand is

there.

Therefore,

this study is

aiming toward

the application of industrialized housing system in that

area.

HOUSING IN HIGH-DENSITY URBAN STTUATION

To develop housing projects in high-density area, for

instance in towns or citiesthe most important thing that

has to be carefully considered is the use of land.

The

cost of land is surely very high and one must make the

maximum value out of it.

Low-rise housing or low-income

housing is nearly imposible in such configuration, the

high-rise should be more considered for it respons to

the efficeint use of sites. It is a good idea if

one

can free the low-level of high-rise housing to be used

for commercial area or receation area which will increase

the value of the project.

There are numbers of problems in development in

cities

or towns area which are indicated as follow;

Limitation of Transportation.

To supply building material to the construction sites

in towns or cities, one has to confront transportation

regurations which are different from one state to another.

The maximum size of unit that can be transported on

high-ways is 60'-O" long, 18'-0" high (from road-level),

and 14'-0" wide, some states allow smaller size than this.

The weight of units is also limited, usually not over

30 tons, and more emphasized in city area.

In conventional

construction which most of material supply comes in small

sizes, this reguration is not as big problem as in

modular-box construction.

Building Regulation

Building codes is

always create a lot of problems in

design development of projects in cities or towns, for

example fire-regulation usually requires two hour fire-rating

at out-side facades, corridors, and cover all structural

members those do not have fire-prooving quality.

It

hardly

leaves room for light-weight modular-box construction,

which most of them are constructed of wood or metal. Another

constraint according to building codes or other standards

(for example F.H.A. or M.FH.A. standard) is the standard

sizes of each room, for example 12'-0" width required for

major bedroom, 14'-0" width for living room.

This gives

the difficulty in design of modular-box systems, for

those boxes can not be over 14'-0" or even less in width

according to the transportation reguration.

Citizen Paticipation

Project developments in cities always confront to this

problem and likely to be more everyday.

Many of projects

are blamed of distroying charactor of communities,

increasing traffic, etc..

This indicates that to develop

projects in such area requires good political contract,

relationship with community organizations as well as

good technology.

Construction Labour

Labour workers in this country are organized in form of

unions, especially in construction industry, and those

unions contain a lot of influence over the construction

especially in

big cities.

New technology or systems

which provide decreasing number of labour workers are

strongly opposted by unions.

This is one of the answers

why industrailized housing systems are not well developed

in this country even through the U.S. is farther developed

in technology than other countries.

The unions always

negociate higher labour wages and make the labour-cost

to be the major problem in construction, especially

on-site labour cost.

Limitatiom of Site to Operate Construction.

Construction in

cities or towns lacking of site to

operate is always happen, for example minimum site to

move or install cranes, store building matrial, etc..

Many times one has to rent some area near

by or use

public traffic area for extra site to operate construction,

which means extra more money has to be spent.

Difficulty to Operate Construction on High-level.

The cost of construction per square-foot always higher

if it has to operate at higher level, for it is difficult

ot carry members or material by cranes to work on level

over 100'

( mostly because of wind or bad weather).

Especially in conventional construction which a lot of

activities such as concrete pouring or facade finish

have to be done on high-level, those work is confronted

to the diff iculty of operation and many of times have to

delay.

The rental cost of equipments to operate construction

on level over 130'

to 140' up is very high ( There is

about

50 to 6o% increase of rental cost if one wants the cranes

to work over 140' high and 30 tons load, for working

capacity less than mentioned can be carry out by mobilecranes or hydrolic truck-cranes.)

Financing of Construction Time.

The construction time is

-ment in

is

cities or towns.

the important subject in

develop-

Minimum construction time

always the objective of every project,

for it means

the minimum of financing interest, labour cost, equipment

rental, and many other overhead cost.

Through these problems one can realizes that the technoly

alone cannot fulfill this situation, it surely requires

strong administration, political contract, and assisting

of many other people involved.

This study is carried.

out the attempt of solving some problem mentioned.

DESIGN PROPOSAL

This system begins by factory process of constructing

The

modular-boxes from different standard components,

standard dimensions of boxes are 14'-0" width, 9'-6*

hight and four different lengths 20'-0", 24'-o", 28'-o',

and 32'-0".

Basic structure is steel frames with addition

of light-weight concrete floor and gypsum or asbestos

boards for fire-prooving.

Interior patitions, closets,

and cabinet works are wood construction,

Bath-rooms and

kitchens are installed, H.V.A.C.. plumpling electrical,

and most of final finish are done from factory stage.

This provide maximum finishing work and minimum transport-ation weight to each box-unit.

On site-work, circulation cores with dimensions of

20'x 20',or 20'x 24', or 28'x 28' (depend on which type

of building) are built by slip-form technique.

-machines

Lifting-

are installed on top of cores and hang down

lifting-tendons and lifting-shoes to the ground-level.

On ground-level, modular-boxes are stacked up four storey

high ( Each box is

steel

welded to the boxes near by.)

in

a

truss frame forms a giantic beam called a package

unit. After the first package unit is done with nescessary

finish, it will be pull up along the circulation cores

by lifting-machines on top of cores to the exact location

on high-level, and the supports for the package are

provided to support it

the lifting-shoes.

to the the cores before lowdown

Corridor and ceiling panels are installed after the first

package is already supported, final works such as main

utility, triming, painting, etc. are done at the same time.

Material supply for final finish on first package unit

is carried out by using circulation cores.

By the same

time that activities take place at high-level, on grou-ndnfloor the construction of second package unit begins.

Then carry the same sequence until finish.

For better understanding in design proposal, the drawing

section is

provided in this study.

ADVANTAGES

OF DESI GN PROPOSAL

Less On-site Labour.

Comparing to conventional system, the design provides less

on-site labour approximately about 60 to 70%, for most of

the work are finished from factories.

In

practicing the

cost of on-site labour is 50 to 60% more than labour cost

in factories, and on-site labour requires security insurance

more. Overhead cost in case of delay or strike is less in

factories than in open shop.

Less Construction Time.

As most of the work are done from factories and the standard

Is already provided for design, using the system surely

save a lot of time in construction fields as well as in

design development.

The system provides minimumum high-level

operation which sometimes causes

delay of work as mentioned,

that also means saving of construction time. Using this

system, most of the work are operate on not more than

four storey high level, it surely easier to work or weath-er-proof, even the work on final finish of package units

at high level most of them are operate indoor, very few

work Is left outside.

Free Ground-level

This is the most advantage of the design proposal.

The

system provides free low-level space that can be used as

commercial spaces, traffic or beautiful recreation area,

parking fasilities, etc.. This configuration contributes

services to communities on the sites and increasing the

value of the projects.

DESIGN

DRAWING

PROPOSAL

0

SECTION

COMPONENTS

PLAN.

END OONDITION

FOR

DUCT SPACES

ISOMETRIC

FLOOR

I"

=

COMPONENT

8'- O"*

3"X3"

2X"T-

CH ANNEL

SECTION

I"5 X

I"

L- SECTION

ALUMINUM.

DIFFERENT

END CONDITION.

PLAN.

LOUR

FIRE-RATING

GYMPSUMBOARD WITH FINALCEILING

FINISH.

ISOMETRIC.

CEILING

I" =

COMPONENT.

8 - O"

-

Lc

PLAN.

ELEVATION.

CORRIDOR

SIDE

END-WALL.

G.B. FIRE-WALL

HEATING

OUT SIDE

e

-sr_

.

ELEVATION.

WALL.

34

0"

4

0 9

RADIATOR

o'-I

0-6

14'1-o"

20'-0"

UP TO 32'-o"

STANDA,R

SIDE

WITH OUT-SIDE

WALL

PLAN.

FINISH.

ELEVATION.

WALL COMPONENT

l'= 8'- 0"

BOARD

WITH OUT-SIDE

FINISH

CORRIDOR END-WALL

1I"= 4'- 0 s

L

-

--

--

-

--

- -

--

- -

BATH ROOM COMPONENT.

F-1IEl

[]

C

o0

ool

L --- -..-- :

L-----

00

K00T

loo

00---L=:

=

KITCHEN

A

COMPONENT.

-I,

II

II

Ii

II

'a

'I

II

DOOR

CLOSET

I - ..

k-

INTERIOR

PANEL

INTERIOR COMPONENT.

11= 81- 0

CONSTRUCTION

COMPONENTS

CONSTRUCTION

OF

BOXES,

CORRIDOR

AND CEILING

I

OF

FINISH (ON-SITE)

= 8 '- 0"

STANDARD MODULAR-BOXES

Box

Dimension in

Length

A

20'-O"

24'-0"

28'-O"

B

20'-O"

24'-O"

28 -O"

C

20'-O"

24'-0#

C1

20'-0"

C2

20'-O

24'-0"

C3

D

20'-0"

24'-0"

E

24'-0"

F

24'-0

F1

20'-0"

24'-O"

F2

20'-O"

24'-0"

F3

28'-O"

28'-O"

24'-0"

G

28'-O"

H

J

K

32'-0"

32'-0"

32 '-0"

20'-0"

24'-0"

28'-.O"

CONSTRUCTION

SEQUENCE

I.

r--n 1

LIFTING - MACHINE

LIFTING - TENDON

CIRCULATION

||

||

PACKAGE

TRUSS

STEEL

LIFTING - SHOES

11000

ALJLJ

I

CORE

I"i = 60'- 0o

IJ

-

CIRCULATION CORES

ARE BUILT BY SLIP-FORM TECHNIQUE,

BRACINGS ARE PLACED

AMONG CORES.

-

INSTALL

-

START CONSTRUCTING 4-STOREY-HIGH PACKAGE UNIT,

MACHINE ROOMS ARE BUILT

IF REQUIRED.

LIFTING -MACHINE

ON TOP OF CORES,

TEMPORALY-

PLACE LIFTIN G-TENDON & SHOES

PENHOUSE

CONSTRUCTION

OR

SEQUENCE

2.

LIFTING- TENDON

BUILDING

TN

PACKAGE

LIFTING - SHOE

I" = 60'- 0"

--------

L----

- LIFT THE FIRST PACKAGE,

REMOVE TEMPORALY BRACINGS DURING

THE PERIOD OF LIFTING AND REPLACE THEM AFTER IF NESCESSARY

CONSTRUCTION

SEQUENCE

3.

""ill

rzLT

I

-N

IN = 60'-O"'

L

I

_I

:

-

SUPPORT

- SHOE S

-

START

-

START CONSTRUCTING

CORRIDORS , INSTALL NESCESSARY

UTILITY, AND

-START FINISHING CEILINGS AND TRIMMING

ON THE FIRST PACKAGE-

THE

BUILDING

FIRST PACKAGE

THE

SECOND

AT

HIGH-LEVEL, LOW DOWN

LIFTING-

PACKAGE

CONSTRUCTION

SEQUENCE

4.

IIIZ::2

Uo

LUiLI"

-

LIFT

THE

SECOND

60'-O"

PACKAGE

CONSTRUCTION

SEQUENCE

5.

m~

PAK4W --INI I

-

csan

L -- - - - -1

-

CONTINUE

THE

L..

SAME

Io=

60'-Oo

.1

SEQUENCE

CONSTRUCTION SEQUENCE

6.

FY11LIZ]

6 0

FINISH

LIFTING -SEQUENCE

REQUIREMENT

ON

LSTART

BUILDING

'- o

NESCESSARY

LOW-LEVEL

CONSTRUCTION

SEQUENCE

CHARACTOR

AND DETAIL

ISOMETRIC

1i"

OF PACKAGE

30'- 0"

UNITS

DETAIL OF STEEL TRUSS

FRAMED AROUND CORE

I"- I0'- O"

DETAIL AFTER

FINISH WITH R.C. PANEL

1 = 10 '- O"

I"

TENDON

INSULATION

HEATER

UP

ROOF

FLASHING

DETAIL OF FINISHING

BOXES WITH FRAME

1"

= 3'- O"

C IBCUCLATORE

-BEAM SLIDED

CORE

SUPPORTliG

OUT FROM

51"_8

CHANNEL

RAIL _2LANNEL

4VD__ W HEE L_-

-GUIDE

5"x 8" VERTICAL MEMBER _

Itt" CONCRETE

PANEL

5"x 8" CHANNEL

03" LIFTING -TENDON

10" x 10" VERTICAL

MEMBER

P L A N.

LIFTING-TENDON

IO"x 10" VERTICAL

R.C. CIRCULATION

GUIDE

RAIL

GUIDE

WHEEL

MEMBER

CO RE

*"x 8" CHANNEL

FINISHING

PANEL

5"x 6"

CHANNEL

ax 8"

CHANNEL

PANEL SLIDED FROM CORE

SUPPORT PACKAGE UNITS

0

TO

1/3" BOLT

ISOMETRIC

DETAIL AT CONER

I" = 2'-O"

OF CORE

.

ill

STEEL

MEMBER

FINAL

INTERIOR

OF WALL

FINISH

BOARD

GYPSUM

LOW-MEMBER OF WALL

~m~h

~ ~

I1keI

F!

I1I

ueu

I.Ifeuadm

-AIJ

TOP MEMBER

OF FLOOR

LIGHT-WEIGHT

CONCRETE

METAL DECK

FLOOR

-_--

-1

3s x 3

BOTTOM MEMBER OF FLOOR

0 I" GUIDE PIN

T.ECTION

air duet

;

n

I

1

p%~

A

~'

-~

~'

'

1

(~-

If

FLOOR STRUCTURE

FRAME

ELECTRIC PIPE

EEL FRAME

L

E

I"x I'ALUMINUM

MEMBER

[ILl

-V

inside bcxI

Inside box

,

I

hFlh1naSImMEUIA

*m

-

:.

0:

-

M -

U

nW

REINFORCEMENT

VERTICAL

PIPE

~E1~

MEMBER

GUIDE PIN

WELDED TO MAIN

TRUSS

STEEL

BOTTOM-CORD

5"x em

L- SECTION

3" x 3" CHANN{EL

FINAL FINISHING

bottom

cord

of

main truss

SECTION

I" = 10"

PANEL

I

I

I

I

FINAL FINISH AT CORRIDOR

GYPSUM BOARD

-F,

-

1e

I

ool

:giiii

I

K

-

MEMBER

METAL

FLOOR DECK

2"x 2"

L- SECTION

OF WALL

METAL FLOOR DECK

FLOOR STEEL FRAME

STEEL MEMBER OF TRUSS

PIPING SPACE AT CORRIDOR

ee'(D

.11

I.

CEILING STEEL FRAME

GEILING PANEL, CORRIDOR

I-.

L

STEEL

CEILING

m

la

FINISH

MAIN TRUSS

MEMBER

FIRE-COVERING

MAIN PIPING SPACE

BELOW IST. LEVEL

BOX WELDED TO MAIN TRUSS

5"x S"

L-SECTION

5 x 8"

L- SECTION

2 x2"

L- SECTION

3"x 3"

CHANNEL

MEMBER

SECTION

"

i" = 10

COR RI DOR

PLAN

20'x24'

D.

-

DUCT

T.

-

TRASH

J.

-

JANITOR

S.

-

SPACE

SPACE

STORAGE

STORAGE

0r

0

0

0

.

PLAN

20' x 24'

STAIR-CORE

CIRCULATION

1" = 10'- 0i

CORE

CORRIDOR

PLAN

20'x 20'

BO x

I~i

AN

D. - DUCT

SPACE

T. - TRASH

SPA CE

J. -JAN

ITOI R STORAGE

T.K T

Flu-i

IIJ.

-

h~

.

0

PLAN

20'x 20'

Box

STAIR-CORE

CIRCULATION

i" = 10'-O'-

CORE

------------

UNIT

UNIT

IELE.I

PLAN

ALTERNATIVE

C O R R I D O R

------------

----------

20'x 24'

TWO

FOR

ELEVATORS

rT

0

0

0

PLAN

20'x 24'

ALTERNATIVE

FOR

THREE ELEVATOR

ELEVATOR

CORE

CIRCULATION CORE.

I" = 10 - o"

PLAN

20'x 20'

C 0 RR I DO R

I

BOX

ELE.

LOBBY

E LE.

I

0c

0

0

0

PLAN

B0x

20'x 20'

ELEVATION

CORE

CIRCULATION CORE

I"

10'- 0"

i

-

--- -------I

ELE.

BOX

BOX

LOBBY

ELE.

II

h

I

PLAN

2

20'x 20'

C 0 RR I DO R

m

-om

a:

0

0

a:

0o

PLAN

20'x 20'

ELEVATION

CORE

CIRCULATION CORE

I" =

10'-0"

PACKAGE UNIT

& BUILDING TYPES

ES.

SI.

MS.

M.S.

E. S.

El.I

24'-

L4H

PACKAGE

E.S.

E.S.

SI.

M.S.

M. S.

I2.

M.S.

M.S.

8

20

28'

A.

E.S.

El.

PACKAGE

A.

PACKAGE

a.

E.S.

E2.

E.S.

M.S.

-

END SECTION

MIDDLE SECTION

SI.

-

STAIR CORE

20' x 24'

82.

-

STAIR CORE

20'x 20 '

El.

-

ELEVATOR

CORE

20 x 2'

20

E2.

SINGLE CORE

d 120'

44'

-

ELFVATOR CORE

20 x 20

PACKAGE

20' 8'

PACKAGE

1" =60'-0

UNITS

TWO-WAY

COMPLEX

I" = 100'- 0"

TWO

PACKAGE

PACKAGE A. AND

T WO

DOUBLE-LOAD

I" =

60'-

0"

CORRIDOR

A.

B.

PACKAGE S.

TOWERS

incline member.

----- --

~~N

C)

[

9

3

S

Ar v

Incline

-

----------

member

TRU SS

-1

c

K..

e

0)

3

3

--

incline member

-=

I -

S

K'

incline member

TRUSS

--

TRUSS

----------

ncneincline

--

member

TRUSS

- - _- _--

incline

incline member

member

-- - -- -- - - - - -- -J

STRUCTURE

TOWER

=

FLOOR PLAN

TYPE

161 - 0"

ISOMETRIC

STRUCTURE

OF TOWER

I" =

FRAME

PACKAGE

30'- 0"

APARTMENT

UNITS

FLOOR

CENTER

I"

=

CORE

16'- 0"

PLAN

TOWER

28' B.

24' C.

ONE BEDROOM UNIT

28'D.

20'A.

RI

PACKAGE

SECTION

1" = 8'-

ONE BEDROOM

B., MIDDLE

FIRST LEVEL

"l

0

UNIT

28' 81.

'-A

EFFICEINCY

UNIT

24'E

24'1 F

TWO - BEDROOM

PACKAGE

FIRST

B., MIDDLE

LEVEL

UNIT

SECTION

I" =

8' - 0"

-0~

24'8

---

A

20' e.

ONE BEDROOM

UNIT

ONE BEDROOM

UNIT

MIDDLE SECTION

PACKAGE

B.,

SECOND

LEVEL

I" =

'

28' B

20' C

ONE

BEDROOM

UNIT

20'C

28'8

ONE

PACKAGE

THIRD

B.,

LEVEL

MIDDLE

BEDROOM

SECTION

i"l = 81-Of

UNIT

U

28' D1.

EFFICEINCY

UNIT

20' E

20' F.

2 8'B

TWO

PACKAGE

THIRD

B.,MIDDLE

LEVEL

BEDROOM

UNIT

SECTION

I"=

8'-d'

20' B

ONE

20' Fl.

BEDROOM

UNIT

_ONE BEDROOM

UNIT

24' E.

24' B.

a

PACKAGE

FOURTH

B.,

LEVEL

I IDDLE

SECTION

I"

8'- 0"

28' B.

20' C.

20' J.

TWO

PACKAGE

FIRST

B.,

LEVEL

BEDROOM

END

UNIT

SECTION

I"

= 8'-O"

20' B.

20' C2.

TWO

28' K

PACKAGE

SECOND

B., END

LEVEL

BEDROOM

SECTION

1"

= 8'-d '

UNIT.

K

20' A .

24' F3.

28' G.

THREE

PACKAGE

THIRD

B.,

LEVEL

BEDROOM

END

UNIT

SECTION

I"I

= 8' - O"

0

24'A.

24'

F3.

28' G.

THREE

PACKAGE

FOURTH

B.,

BEDROOM

END

LEVEL

APARTMENT.

SECTION

1l"= 8'-o

I

EFFICEINCY

28 BI.

24'A

24'E.

24' F

28'F

24'E.

28R.

24'A

UNIT

BR.

UNIT

I

24'El

I BR. UNIT

28'D

UNIT

24'F.

24'8

24'A[

2 BR.

24'F

24' C.

IBR. UNIT

24'S.

FIRST

LEVEL

28R. UNIT.

24'A..

SECOND

PA CKAGE A., MIDDLE

= 1'- 0"i

Ii

LEVEL

SECTION

24'B

24 'F.

24'E

2 BR. UNIT

2 BR. UNIT

]IBR.UNIT

I BR. UNIT

24'F

24 'B.

24' E in

24'F.

2 4'B.

21R. UNIT

THIRD

LEVEL

2 BR. UNIT

FOURTH

PACKAGE A.

1I" 8'- O"

LEVEL

,

MIDDLE SECTION

a

24'A.

24' C3.1

IBR.

UNIT

24'C 3

24'A

IBR.

UNIT.

PACKAGE A., M IDDLE SECTION

FIRST

LEVEL

I"I = 8'- 0"

28'B1.

EFFICEINCY

UNIT

24'E.

2 8'F

24' A

2 BR.

PACKAGE

FIRST

A.,

LEVEL

UNIT

MIDDLE

I" =

SECTION

8-O"1

28'B.

24' C

UNIT

I BR.

24'C.

I!

24' B

PACKAGE

SECOND

A.,

I BR.

UNIT

M IIDDL E SECTION

LEVEL

I" =

8

28' 81.

EFFICEINCY

UNIT

24' E

24'1 F.

TWO

24'B.

BEDROOM UNIT

a

PACKA G E

SECOND

A.,

LEVEL

MIDDL E

I I=

SECTION

8 '-O"

a

a

28' B

IBR.

24' C

UNIT

24'C

28'B

I BR.

:=1

UNIT

a

PACKAGE

THIRD

A. , MIDDLE

LEVEL

I"

SECTION

=8'-O"'

28' Bl.

EFFICEINCY

UNIT

24'E

24'F

24 'A

2BR.

a

PACKAGE A., MIDDLE

111=

LEVEL

THIRD

UNIT

SECTION

1

8'-O"

0

24' A.

24' C3.

IBR.

UN IT.

24' C

2 8'S

I BR.

UNIT

u

PACKAGE

FORTH

A. , MIDDLE

LEVEL

Ii

SECTION

= 8'-o"1

2BR.

UNIT

24'A

III

24'F

24'E

EFFICEINCY UNIT

28'B I.

PACKAGE

A.,

FOURTH

LEVEL

MIDDLE

I"

SECTION

=

-O

0

32'A

24 'C

24'K

PACKAGE

FIRST

UNIT A., END SECTION

LEVEL

1" = 8- 0"

U

24'B.

24'F .

32'G.

3BR.

PACKAGE

SECOND

UNIT

A., END

LEVEL

SECTION

Il"= 8 Lo

I BR.

UNIT

24'8

24'C

32'H

I

a

EFFICEINCY

PACKAGE

A.)

SECOND

LEVEL=

END

UNIT

SECTION

1" = 8 '- 0"1

24'A.

24' F1

[i

L

0

32'G.

38R.

PACKAGE A. , END

THIRD LEVEL

UNIT

SECTION

I" = 8'-O"

UNIT

24' A .

2 8' D.

3 2' H

EFFICEINCY

PACKAGE A. ,

THIRD

LEVEL

UNIT

END SECTION

I"

=

8'-d'

a

U

a

24'A

28'F

32'G

3BR.

UNIT

PACKAGE A., END SECTION

FOURTH LEVEL

I"= 8'-O"

24'A

2 8'D

I BR.

UNIT

32'H

EFFICEINCY

PACKAGE

FOURTH

A., END

LEVEL

UNIT

SECTION

I"= 8'-O"

BIBLIOGRAPHY

1, Cornell University, "The New Building Block",

Ithaca, New York: Cornell, Press 1969.

2, M.I.T., 1971 Department of Architecture Master's Class

with Professor Eduardo Catalano, "Housing Systems;

Seven Studies for Factory Produced Concrete and Steel

Modular Units", Limited Published Master's Thesis, M.I.T.

3, M.I.T., Department of Architecture and Civil-Engineering,

"Economic Study of Pull-up System" and "Guide to The Use

of Pull-up System*

4, Daniel Quinn Mills, "Industrial Relation and Manpower

in Construction".

5, Richard H. Clough, "Construction Contracting"

6, 1971, The Construction Engineering Research Laboratory

(CERL) of U.S. Department of Army, "The Study on Potential

of Industrialized Building for The Department of Army"

7,

*Building Construction Cost Data" ,1973.

8, M.I.T., Master of Architecture, Advanced Studies' Thesis

Duane A. Kell, Craig E. Rafferty, "A Housing System; A

Study Based on The Production Capabilities of The

Mobile Home Industry", 1972.