Checklist for Equipment Purchasing and Installation for Grants/Contracts Project Title: PI: Completed by:

advertisement

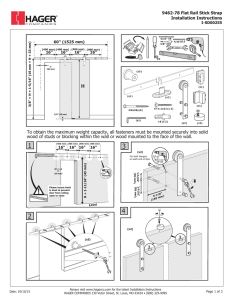

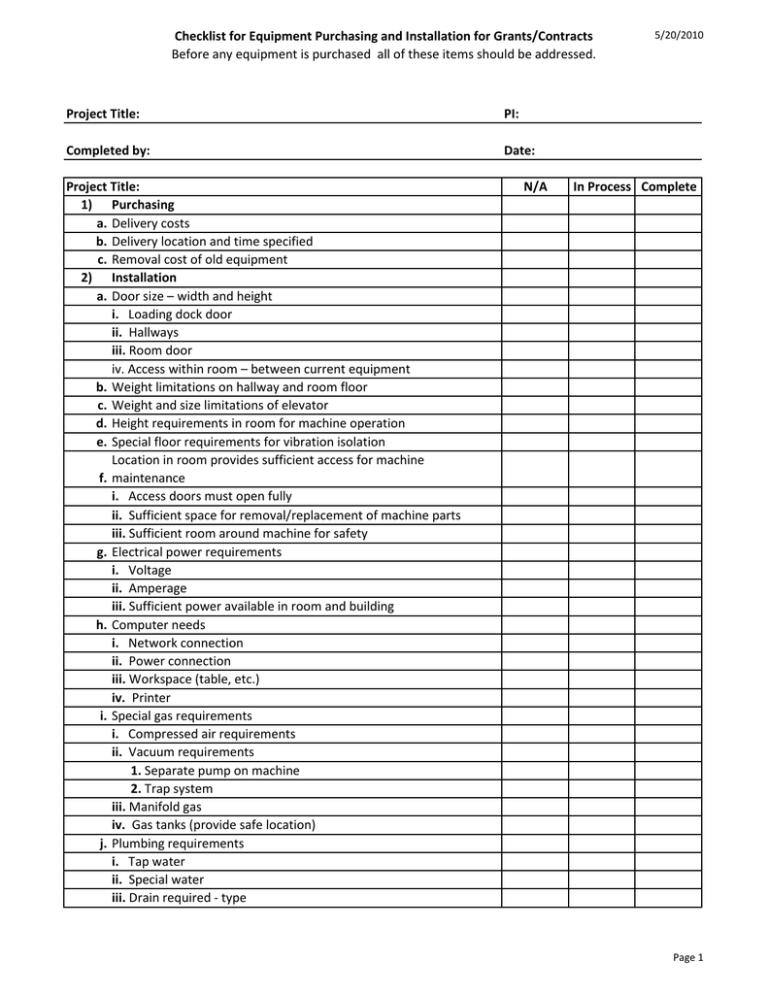

Checklist for Equipment Purchasing and Installation for Grants/Contracts Before any equipment is purchased all of these items should be addressed. Project Title: PI: Completed by: Date: Project Title: 1) Purchasing a. Delivery costs b. Delivery location and time specified c. Removal cost of old equipment 2) Installation a. Door size – width and height i. Loading dock door ii. Hallways iii. Room door iv. Access within room – between current equipment b. Weight limitations on hallway and room floor c. Weight and size limitations of elevator d. Height requirements in room for machine operation e. Special floor requirements for vibration isolation Location in room provides sufficient access for machine f. maintenance i. Access doors must open fully ii. Sufficient space for removal/replacement of machine parts iii. Sufficient room around machine for safety g. Electrical power requirements i. Voltage ii. Amperage iii. Sufficient power available in room and building h. Computer needs i. Network connection ii. Power connection iii. Workspace (table, etc.) iv. Printer i. Special gas requirements i. Compressed air requirements ii. Vacuum requirements 1. Separate pump on machine 2. Trap system iii. Manifold gas iv. Gas tanks (provide safe location) j. Plumbing requirements i. Tap water ii. Special water iii. Drain required - type N/A 5/20/2010 In Process Complete Page 1 Checklist for Equipment Purchasing and Installation for Grants/Contracts Before any equipment is purchased all of these items should be addressed. 5/20/2010 k. Room remodeling i. Special lighting ii. Room temperature requirements iii. Special humidity requirements iv. Ventilation 1. Fume hoods 2. Exhaust fans 3. Ventilation available in room v. Other (specify) 3) Safety issues a. Hazardous materials b. Waste or byproduct disposal issues c. Sound hazards d. Moving or rotating parts in guarded area e. Fumes f. Strong magnetic fields g. High intensity radiation 4) Insurance issues 5) Security requirements a. Special locks on doors b. Surveillance equipment c. Alarm systems 6) Maintenance costs (yearly) a. Maintenance agreements for equipment if required b. Maintenance agreements for software if required c. Estimated operation costs for supplies d. Estimated supplies startup costs e. Calibration costs i. Initial calibration ii. Periodic calibration f. Spare part inventory if necessary 7) Training costs a. Operators b. Maintenance personnel Page 2