STC-GC Siemens standardized integrally geared turbocompressor siemens.com/energy/compression Compression solutions

advertisement

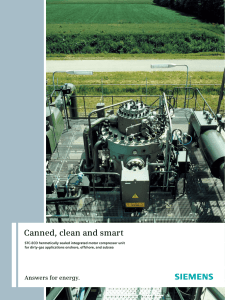

Compression solutions STC-GC Siemens standardized integrally geared turbocompressor The economic solution for high efficient air separation Scan the QR code with the QR code reader in your mobile! siemens.com/energy/compression 2 Main air compressor for an ASU in a steel plant The economic solution for high efficient air separation STC-GC Siemens Turbocompressor – ­Standardized Integrally Geared, Compact Design Siemens integrally geared centrifugal turbocompressors are designed to answer today’s market and technical needs with highest quality standards. The STC-GC product line is the compact and standardized version of the customized integrally geared compressor series STC-GV. Invented more than 60 years ago, the traditional STC-GC compressor series covers volume flows up to 120,000 m³/h. This range of compact integrally geared compressors is also available as high pressure version STC-GC (H). To better meet the requirements of customers in air separation, the existing compressor range has been extended with additional five frame sizes for air volume flows from 120,000–400,000 m3/h capacities. 80% of the machine consists of standard components which results in a smart spare part management: 20% of the machine can be sufficiently adjusted for specific customer process needs. Highlights The perfect match for economic air separation Standardized, compact and reliable design 60 years of experience Fields of application Air separation Process air Plant air Process nitrogen Unique in the market, Siemens is the only compressor manufacturer who also develops and supplies proprietary gear technology, manufacturing compressor and gear out of one hand and at the same location. 3 Economic compressor solution The standardized design of the STC-GC product line combines major advantages such as high efficiency, reliability and compact design with shorter delivery periods and lower investment costs. Several different frame sizes and a wide range of options form the ideal basis to offer a very costeffective integrally geared centrifugal compressor in a compact single-lift unit. More than 150 units of this compressor type are in operation at customers around the globe. Powerful, robust and reliable The STC-GC integrally geared centrifugal compressors feature a multi-shaft arrangement with different speeds. All shafts are mounted in maintenance-free, pressurelubricated sleeve bearings. With up to four compressor stages around a central bull gear, the STC-GC compressor series forms a compact unit for the multi-stage compression of air and nitrogen. Pre-designed gears, highest efficiency impellers, tailored aerodynamics and pre-defined auxiliaries lead to maximum performance. Control Systems Perfect protection and process control via flexible ­Siemens control systems: Anti-surge protection Performance control Fully- or semi-automatic start-up and shutdown sequences exactly matched to your process demands Certified safety systems available STC-GC (10–100) Volume flow: 10,000–120,000m3/h The dynamic environments in the industrial gases market require flexible and sustainable solutions to meet process needs. Whilst plant capacities are permanently growing, there is another trend in increasing standardization of air separation units. Typical outputs are up to 2,000 tpd of oxygen. Siemens reached a step further in customer satisfaction with the introduction of a highly standardized compressor series STC-GC (165–400) of integrally geared machines for main air applications. This extended range of STC-GC compressors, where approx. 80% have standard components and 20% are customized, achieves the same efficiency l­evels as customized integrally geared compressors. This compressor series covers volume flows from 120,000–400,000 m3/h with five casing sizes. 4 STC-GC (165–400) Volume flow: 120,000–400,000m3/h Technical Data STC-GC Volume flow rates from 10,000 to 120,000 m³/h (5,900 to 70,600 cfm) Benefits Compact design Standardized, pre-engineered for economy and reliability Suction pressure up to 1.1 bar (16 psi) Siemens-owned gear technology Pressure ratio up to 20 (machine size 10–50) Highest technical quality standards Pressure ratio up to 7.5 (machine size 63–100) Optimized performance Electric motor drive (fix speed) Short lead times Air and nitrogen Reduced investment costs Short on-site installation Technical Data STC-GC (H) Volume flow rates from 3,600 to 11,000 m³/h (2,100 to 6,500 cfm) Suction pressure up to 5 bar (72.5 psi) Pressure ratio up to 8 Electric motor drive (fix speed) Technical Data Volume flow rates from 120,000 m³/h up to 400,000 m³/h (70,600 to 235,400 cfm) Suction pressure up to 1.013 bar (16 psi) Pressure ratio up to 6.5 Electric motor drive (fix speed, synchronous/asynchronous) Max. coupling power between 12 and 30 MW Air Benefits Highest efficiency through use of well proven flow components Efficiency as high as with customized compressor series STC-GV Maximum cost savings through standardization Short delivery time High number of fixed options ensures highest ­flexibility to meet individual project requirements 5 Smart design for optimum performance Design and quality of the pre-engineered STC-GC turbocompressor are in accordance with the world-wide accepted Siemens’ standards. All auxiliaries are according to ASME and PED guidelines. Pre-designing of compressor components is approximately 80%, whilst the remaining 20% is covered by project specific parts. This approach means lean processes, minimizes lead time and reduced costs of the compression system with at the time highest efficiency levels, guarantees the use of well proven components, enhancing plant reliability and availability. The STC-GC features a compression ratio of 6.5 in only three stages, with IGV on the first stage inlet for flow control. The well proven 3D impellers derived from the customized integrally geared compressor series STC-GV. By smartly combining the heat exchangers (interstage and after cooler) their number was reduced significantly, only seven heat exchangers serve to cover the whole line. Standardization principle at a glance Five frame sizes Fixed bull gear / pinion shaft concept Multiple use of equal process gas coolers within up to three frame sizes, in total only seven process gas cooler designs for five frame sizes Concrete foundation, only cast volute casings Vaned diffusers for high stage efficiencies Inlet guide vane unit in front of first stage for stepless compressor control Gear design acc. DIN 3990 and AGMA 6011 leads to Service Factor of at least 1.7 Highlights Only seven heat exchangers for whole compressor line thanks to smart design. Optimized control and safeguard system, SCAUT CPD, guards against faulty operation conditions. Can be operated via customer’s DCS. Inlet guide vane unit in front of first stage for stepless compressor control. 50 Hz and 60 Hz versions. Well proven Hirth connection between impeller and pinion shaft State-of-the-art 3D semi-open 65° and 50° impeller, deriving from customized series STC-GV Pre-designed components (i.e. volutes, gas coolers, oil unit, etc.) Fixed connection coordinates to battery limits – early air separation unit arrangement planning possible – simple assembly concept Compressor train comprising standardized integrally geared turbocompressor and electric motor drive 6 Smart Protection Compact protection device for standardized integrally geared turbocompressors (STC-GC 165-400) To ensure optimum operation and protection of the standardized STC-GC, Siemens has adapted and incorporated the existing compressor automation concept SCAUT. SCAUT CPD (Siemens Compressor AUTomation Compact Protection Device) is a most suitable and cost saving safety device for operation of Siemens pre-designed STC-GC compressor series which allows optionally the control of the compressor process. SCAUT CPD is a module derived from the well proven SCAUT product series based on Simatic S7 hardware. It enables customers to control the entire compression train and ensures a reliable and save operation through a standardized solution with a modular structure. Highlights Protection of compressor against improper operation conditions Benefits Highly efficient protection of compressor against incorrect operation Monitoring possible in customer DCS, additional anti-surge safety device not necessary Suitable for any DCS configuration Reliable IGV control for wide operation range with highest efficiency also for part- and peak load to minimize the operational costs Process control function optionally included without additional dedicated controller leads to reduced overall CAPEX Safeguard and control of anti-surge limit, max. power, max. discharge pressure and minimal IGV position Compressor operation via customer Distributed Control System (DCS) Optional the process control can be done directly via SCAUT CPD SCAUT CPD supports single stage control in case of grid frequency fluctuation Cost saving integration in local junction box with ­operator display Operator’s view on CPD panel Standardized integrally geared main air compressor 7 Published by and copyright © 2013: Siemens AG Energy Sector Freyeslebenstrasse 1 91058 Erlangen, Germany Siemens AG Energy Sector Oil & Gas Division Wolfgang-Reuter-Platz 47053 Duisburg, Germany Siemens Energy Inc. 10730 Telge Road Houston, Texas 77095, USA For more information, please contact our Customer Support Center. Phone: +49 180 524 70 00 Fax: +49 180 524 24 71 (Charges depending on provider) E-mail: support.energy@siemens.com Order No. E50001-G420-A131-V1-4A00 Printed in Germany Dispo 21614, c4bs 7489 K12 130022, P WS 05131. Printed on elementary chlorine-free bleached paper. All rights reserved. Trademarks mentioned in this document are the property of Siemens AG, its affiliates or their respective owners. Subject to change without prior notice. The information in this document contains general descriptions of the technical options available, which may not apply in all cases. The required technical options should therefore be specified in the contract.