Document 10549575

advertisement

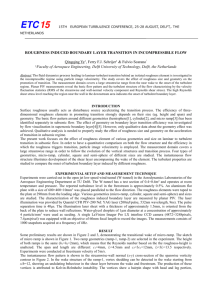

13th Int Symp on Applications of Laser Techniques to Fluid Mechanics Lisbon, Portugal, 26-29 June, 2006 Near wall organization of a turbulent boundary layer over a twodimensional rough wall Lyazid Djenidi1, Robert A. Antonia1, Muriel Amielh2 and Fabien Anselmet2 1 : School of Engineering, University of Newcastle, Newcastle, Australia, lyazid.djenidi@newcastle.edu.au , robert.antonia@newcastle.edu.au 2 : IRPHE, Marseille, France: amielh@irphe.univ-mrs.fr , fabien.anselmet@irphe.univ-mrs.fr Abstract Particle Image Velocimetry (PIV) measurements and Planar Laser Induced Fluorescence (PLIF) visualizations have been made in a turbulent boundary layer over a rough wall. The roughness consists of square bars placed transversely to the flow at a pitch to height ratio of 11. The near wall region flow is dominated by coherent structures associated with the shear layers which originate at the downstream edge of a roughness element and reattach on the wall upstream of the subsequent element. Shear layer vortices shed downstream a roughness elements impact on the consecutive element producing intermittent form drag and strong turbulence production. 1. Introduction The relatively slow progress that has been made, especially in understanding how the roughness affects the turbulence structure, reflects, by and large, the extra parameters involved, by comparison to the smooth wall case, and the general difficulty of making reliable measurements in the vicinity of a rough surface. Nevertheless, there has recently been a renewal of interest in rough wall flows e.g. [1] . Djenidi et al. [2] reported Laser Doppler Velocimetry (LDV) measurements and flow visualizations (with the PLIF technique) for a turbulent boundary layer over a surface consisting of square bars (height = width = k) attached to the wall where the steamwise pitch λ is equal to 2k (λ is the streamwise separation between two consecutive roughness elements, and k the height of the roughness elements). These techniques proved to be quite helpful in gaining insight into the nearwall flow organization. In particular, they confirmed and extended the earlier observations, over the same surface [3]. Direct numerical simulations (DNSs [4, 5]) and large eddy simulations (LESs, [6]) have been carried out for fully developed turbulent channel flows with a rough wall made up of 2D transverse elements (of various cross-sectional geometries). While these studies show that DNS data bases provide much new information, the results remain limited to relatively small Reynolds numbers. This in itself is not too worrisome given that the form drag is the dominant contributor to the total drag under fully rough conditions. However, there is the possibility that differences exist, at least in the outer region, between a channel flow and a boundary layer. It is therefore important to study turbulent boundary layers over 2-D rough walls. The present work is part of a more extensive programme aimed at studying in detail a rough wall -1- 13th Int Symp on Applications of Laser Techniques to Fluid Mechanics Lisbon, Portugal, 26-29 June, 2006 boundary layer with variable λ/k. This paper reports Particle Image Velocimetry (PIV) and PLIF measurements in a turbulent boundary layer over a wall on which two-dimensional square bars are attached with λ/k =11. The main objective is to describe the flow structure and compare it with that previously reported for smaller λ/k. The focus is on the near-wall region of the boundary layer. This work extends that of [2] and [7]. 2. Experimental set up Two complementary experiments were carried out in two different water tunnels, one at Newcastle for the PLIF visualizations, and the other at Marseille for the PIV measurements. PLIF Setup: The PLIF visualizations were made in a constant-head closed circuit vertical water tunnel with a 2 m long square (250mm × 250mm) Perspex test section. One of the working section walls is used as the rough wall. The roughness elements consist of square bars (height k = 3mm) fixed to the wall and spanning the full width of the test section, with a separation between the roughness elements λ equal to 33mm. The boundary layer is tripped with 4.5 mm high pebbles glued over the wall span, 30mm upstream of the first roughness element. The roughness elements extend over a streamwise distance of 1.8m downstream of the trip. Detailed flow visualizations are made at a distance of 1m downstream of the first element; at this location, the boundary layer thickness δ is about 20k. The Reynolds number Rθ based on the momentum thickness θ ( θ is estimated midway between two roughness elements), is approximately 2100. To implement the PLIF method, fluorescein dye is injected through a transverse slit (0.25mm × 240mm) machined flush with the wall at a distance of about 2k downstream of a roughness element. The dye is injected continuously using a small pump at a flow rate low enough to avoid any perturbations to the flow. A 4 W multimode Argon-Ion laser is used as a light source ( ≈ 2 W) for the PLIF. The reflection of the laser beam onto a cylindrical mirror causes the expansion of the beam into a planar light sheet. The 250 µ m thick light sheet was placed either parallel or normal to the wall so as to enable views in either the (x-y) or (x-z) plane (x, y and z are the streamwise, wallnormal and spanwise directions respectively). The flow visualization images are recorded via a CCD camera onto a video tape and then digitized through a video card (256 grey levels). Additional details on the experiment facility can be found in [2]. In the following presentation of the results, the origin x = 0 is chosen to be at the trailing edge of the roughness element located at about 1 m (30 roughness elements) downstream of the trip while y = 0 is at the base of the roughness element along the bottom wall (see Figure 1). PIV Setup: The PIV measurements are carried out in an open water channel. The test section is 8m long, 60 cm wide and 60 cm deep. The 2m long rough wall, which consists of transverse square bars (k = 4mm, and λ/k = 11), commences at a distance of 5m downstream of the contraction. The Reynolds -2- 13th Int Symp on Applications of Laser Techniques to Fluid Mechanics Lisbon, Portugal, 26-29 June, 2006 number Rθ is about 1620 half way through the rough wall where the measurements have been made. The ratio δ/k is about 48. A 200 mJ pulsed Nd:Yag was used to illuminate the flow. The laser sheet was shot from the top through a perspex porthole of about 10 cm diameter. The porthole is flush with the free surface in order not to disturb the flow. A set of cylindrical lenses converted the laser light into a vertical thin sheet located at the mid-plane (z = 0) of the channel. A digital camera (Kodak ES 1.0) was used with a charge-coupled device (CCD) (1008 pixel x 1008 pixel resolution ). The PIV images were post-processed using the adaptive-correlation method (FlowManager 4.30.27; Dantec Dynamics) to obtain the instantaneous velocity fields. Each image was subdivided into 64 pixel x 32 pixel with 50% overlap. The water was seeded with particles (Optimage Ltd) with an average size of 30 microns and a specific gravity of 1.0 ± 0.02. These particles were polycrystalline in structure and provided a high light-scattering efficiency (five times greater than latex spheres which have a similar refractive index).The water level (h = 50 cm) was kept constant. 3. Results 3.1 PLIF Measurements Figure 1 shows an example of instantaneous pictures of the near-wall flow between y λ (a) 0 x Dye injection slot (b (c w k Fig. 1. (x-y) plan view of the near-wall region. The flow is from left to right. The actual ratio λ/k is not respected in this presentation. -3- 13th Int Symp on Applications of Laser Techniques to Fluid Mechanics Lisbon, Portugal, 26-29 June, 2006 consecutive roughness elements. The figure highlights the existence of a shear layer, which develops at the tip of the roughness element. It should be noted that this shear layer develops within a turbulent environment. The interaction between this local shear layer and the overlying flow is still not clearly understood. Associated with the shear layer, there are coherent structures similar to those observed in a plane mixing layer and with a streamwise length scale of the order of the roughness height, k and a wavelength of about 2k. There is a small recirculatory zone (Fig. 1c) immediately upstream of the consecutive element. This recirculatory motion is intermittent due to the flapping of the shear layer. An attempt has been made (see section 3.1) to determine the flapping frequency using the PIV measurements. The flow for λ/k = 11 is quite different from that observed when λ/k = 2 [2], at least in the nearwall region. In this latter case, the recirculatory motion occupies the whole cavity and is only partly destroyed when fluid escapes from the cavity. This leads to the interesting question of whether the structural differences observed in the near-wall region between the two rough surfaces are reflected in the outer region of the boundary layer. Further measurements are required to address this question. z o w 6k x Fig. 2 (x-z) plan view at a vertical distance of y = k. The flow is from top to bottom The structures associated with the shear layer show a particularly high degree of coherence. The overlying turbulent flow transports these structures without, seemingly, disrupting their evolution. The manner in which these structures interact with the roughness elements is not trivial. The -4- 13th Int Symp on Applications of Laser Techniques to Fluid Mechanics Lisbon, Portugal, 26-29 June, 2006 vertical length scale of the structures is of order k, suggesting that they are likely to dominate the flow in this region. In that respect, they may play an important role in terms of transporting momentum and scalar quantities. These structures are also an additional source of turbulent energy generation which is likely to contribute to the enhancement of the turbulence production near the wall. To our knowledge, no information exists on the interaction between the shear layer and the overlying turbulent boundary layer. This is worthy of further investigation. One may infer from Fig. 1 that the flow in the near-wall region is dominated by two-dimensional structures. However, the (x-z) plane view of Fig. 2 reveals that this is not the case. The dye is concentrated within unsteady localized regions in the spanwise direction near the injection point from where it is entrained downstream. There is a clear demarcation along the spanwise direction in the dye distribution: in the region 0 < x / k ≤ 6 , the dye appears to be concentrated into elongated a b Fig. 3 Velocity vector field (a) and mean velocity iso-contours with streamlines (b). 0 a 0.6 5 10 0.6 b 0.5 0.5 0.4 0.4 U/Ue 1.2 0 10 20 30 40 1.1 0.3 1.1 1 U/Ue 0.2 0.1 0.9 0.8 0.8 0.7 0.7 0.6 0.6 0.5 0.5 0.4 0.4 0.3 0.3 0.2 0.2 0.1 0.1 -0.1 0 0.3 1 0.9 0 0 1.2 0.2 0.1 0 0 10 5 y y/k 20 y 30 40 -0.1 0 10 Fig. 4 Longitudinal variations of U (a) and profiles of U between two roughness elements near the wall (b) within the near wall region; the inset in (b) show the profiles across the boundary layer narrow regions with a spanwise spacing of about 2-3k. In the region x / k ≥ 6 , the dye is patchy, suggesting a strong three-dimensionality of the flow. The demarcation “line” corresponds to the -5- 13th Int Symp on Applications of Laser Techniques to Fluid Mechanics Lisbon, Portugal, 26-29 June, 2006 reattachment line. It is not yet clear whether the elongated streaky structures observed in the region 0 < x / k < 6 are reminiscent of the low-speed streaks observed when λ/k = 2 or of those for a smooth wall. However, flow visualization sequences in the (x-z) plane did not reveal mushroomlike structures, usually interpreted as cross-sectional views of low-speed streaks. This suggests that there is no low-speed streaks when λ/k equals to 11 and supports the idea that the mechanism of turbulence production is different for λ/k = 11 than that when λ/k = 2 and a smooth wall. 3.1 PIV Measurements As noted above, it is of interest to document the shear layer originating at the trailing edge of a roughness element and investigate its interaction with the overlying flow. In this section, we attempt to do this by exploiting the PIV measurements. Figure 3 shows a section of the average velocity field (Fig. 3a), lines of constant streamwise velocity and some streamlines (Fig. 3b). There is a well defined recirculation region behind the roughness, with an extent of about 4-5k in the x direction and about k in the y direction. The centre of this region is at about 2.5k behind the roughness element and at y = k. The flow reattaches at the bottom at a distance of about 6k downstream of the roughness element. This corresponds to the position of the demarcation line observed in the PLIF data. This is in good agreement with the DNS data of Leonardi et al. [4]. Notice the strong deflection of the flow at the leading edge of the roughness indicating not only separation on the top of the element but also a relatively high drag. Leonardi et al. [4] showed that the maximum drag for this type of roughness occurs when the separation between the roughness elements is about 8k. Also, this deflection results in a strong momentum transfer to the outer layer, causing an increase in the turbulence intensity. Despite the clear separation between the steady recirculation region and the overlying flow, the instantaneous flow exhibits strong unsteadiness where the overlying flow interacts with the ‘cavity’ flow between roughness elements. This is illustrated in Fig. 4 which presents the longitudinal variation of the streamwise mean velocity at several vertical planes (Fig. 4a) and the profiles of the streamwise component of mean velocity at several positions between two roughness elements (Fig. 4b). Notice in Fig. 4a the sharp drop in U at the top of the roughness, which suggests the presence of a small separation “bubble”, which is consistent with the velocity field of Fig 3a (this was also observed in [4]). The velocity profiles over the region x/k < 6 show similar features to those observed in a turbulent flow over a backward facing step. The instantaneous velocity field (Fig. 5) shows a remarkable similarity to the PLIF data. For example, by comparing figures 1a and 5a, one can discern similar coherent vortical structures. Also notice in Fig 5b the vortices that are preceded by a large outward motion; this is similar to what is pictured in Fig. 1b. The shedding of vortices from the trailing edge of the roughness elements, and the occurrence of outward motions upstream of the roughness, contributing significantly to the form drag, reflects the interaction between the ‘cavity’ and the overlying flow above the roughness elements. -6- 13th Int Symp on Applications of Laser Techniques to Fluid Mechanics Lisbon, Portugal, 26-29 June, 2006 1000 1000 a pix 900 900 800 800 700 700 600 600 500 500 400 400 300 300 200 200 100 100 0 b pix Vector map: Adaptive 64×32 50%, 30×62 vectors (1860), 342 substituted Burst#; rec#: 1; 1 (1), Date: 01/01/1970, Time: 11:00:00:000 Analog inputs: 0 000; 0 000; 0 000; 0 000 Image size: 1008×1018 (0,0), 8-bits Burst#; rec#: 1; 1 (1), Date: 01/01/1970, Time: 11:00:00:000 0 Fig. 5 Examples of instantaneous velocity vectors around a 0roughness element. Analog inputs: 0 000; 0 000; 000; 0 000 0 100 200 300 400 500 600 700 800 900 pix 1000 0 100 200 300 400 500 600 700 800 900 pix 1000 This is illustrated in Fig. 6, where a series of sequential images are shown; the sequence is (a-b-cd). The field of view is larger than in Fig. 5 to encompass two elements. In Fig. 6a, a relatively high 1000 1000 900 900 800 800 700 700 600 600 500 500 400 400 300 300 200 200 100 100 0 1000 Vector map: Adaptive 64×32 50%, 30×62 vectors (1860), 93 substituted Burst#; rec#: 1; 1 (1), Date: 01/01/1970, Time: 11:00:00:000 Analog inputs: 0 000; 0 000; 0 000; 0 000 c pix 900 0 100 200 300 400 500 600 700 800 1000 0 pix 800 700 700 600 600 500 500 400 400 300 300 200 200 100 100 Vector map: Adaptive 64×32 50%, 30×62 vectors (1860), 98 substituted Burst#; rec#: 1; 1 (1), Date: 01/01/1970, Time: 11:00:00:000 Analog inputs: 0 000; 0 000; 0 000; 0 000 Vector map: Adaptive 64×32 50%, 30×62 vectors (1860), 103 substituted Burst#; rec#: 1; 1 (1), Date: 01/01/1970, Time: 11:00:00:000 000; 0 000; 0 000 d 900 Analog inputs: 0 000; 0 900 pix 10000 100 200 800 0 b pix a pix 0 300 400 500 600 700 800 900 pix 1000 Vector map: Adaptive 64×32 50%, 30×62 vectors (1860), 118 substituted Burst#; rec#: 1; 1 (1), Date: 01/01/1970, Time: 11:00:00:000 Fig. 6 Series of instantaneous velocity vectors around element to illustrate the Analog inputs: 0 000; 0 000; 0a 000;roughness 0 000 0 100 200 300 400 500 600 700 800 0 900 pix 1000 100 200 300 400 500 600 700 800 900 pix 1000 interaction of the shear layer with the boundary layer. velocity fluid passes over the element, generates a small vortex (figure 6b) which, while convected -7- 13th Int Symp on Applications of Laser Techniques to Fluid Mechanics Lisbon, Portugal, 26-29 June, 2006 downstream, increases in size (Fig. 6c and 6d). Notice also the large vortex in 6a which is seen to be convected in the subsequent images. This sequence of events confirms the presence of a non stationary shear layer originating at the trailing edge of the roughness element (as clearly seen in Fig. 7). The shear layer, reflecting the interactions between the overlying flow and the flow within the cavities, is created at the interface between the flow issuing from top of the elements and the recirculatory 1000 1000 pix pix 900 900 800 800 700 700 600 600 500 500 400 400 300 300 200 200 100 100 0 -1599-1560-1520-1481-1442-1402-1363-1324-1284-1245-1206-1166-1127-1088-1048-1009-970 -930 -891 -852 -812 0 100 200 300 400 500 600 700 800 0 900 pix 1000 0 -2455-2349-2242-2136-2029-1923-1816-1710-1603-1497-1390-1284-1177-1071 -964 -858 100 200 300 400 500 600 700 800 Fig. 7 Contours of the instantaneous spanwise vorticity illustrating the existence of a shear layer. 900 pix 10 fluid behind the backward step formed by the element and the bottom wall as illustrated in the Fig. 8. wall Fig. 8 A schematic of the shear layer generation mechanism at the trailing edge of a roughness element. Shear layer vortices are shed and convected downstream of the roughness elements. Examples of such shear layer vortices are seen in Figs. 1 and 6. The non stationary nature of the shear layer stems from the fact that it originates within a turbulent environment. As can be inferred from Fig. 7, the shear layer can flap causing vortex shedding as seen in Figs. 1, -8- 13th Int Symp on Applications of Laser Techniques to Fluid Mechanics Lisbon, Portugal, 26-29 June, 2006 5 and 6. It is likely that pressure fluctuations are responsible for the flapping of the shear layer. The flapping is responsible for the destruction of the vortical motion just behind the roughness. A Strouhal number (St = f k/Ue, where f is the shedding frequency or flapping frequency of the shear layer, and Ue is the freestream velocity) of about 0.045 is estimated from the autocorrelation of the wall-normal velocity fluctuation. This value is not too different from that (0.06) obtained by Le and Moin [8] in a turbulent flow over a backward-facing step. One may argue that the present shear layer has similar structural features to that which occurs over a backward-facing step. However, it is likely that the magnitude of λ/k plays a role in controlling the shear layer. Further studies should be carried out to document the characteristics of the present shear layer and how it is affected by this ratio. 4. Conclusions Particle Image Velocimetry (PIV) measurements and Planar Laser Induced Fluorescence (PLIF) visualizations have been made in a turbulent boundary layer over a rough wall. The wall roughness consists of square bars placed transversely to the flow at a pitch to height ratio λ/k of 11. The visualizations revealed that the flow near the roughness element is dominated by coherent structures The PIV data confirmed the presence of such structures. Furthermore, they also revealed that these structures are associated with non steady shear layers originating at the trailing edge of the roughness elements. The shear layers are created by the interactions between the overlying flow and the recirculation behind the roughness elements. Contrary to the λ/k =2 and smooth wall cases, there appear to be no low-speed streaks over the present surface, indicating that the mechanism for turbulence production is different. It would seem that the shear layers may play an active role in this production. A possible scenario for the turbulence production mechanism may be as follows: shear layer vortices are shed at the trailing edge of the roughness element (Strouhal number of about 0.045) and convected downstream before impacting on the following roughness element. This results in an outward motion, which leads to an intermittent form drag and strong turbulence production. From a practical point of view, this chain of events may suggest that an effective way for reducing the drag of the rough surface might be to control the shear layer in order to reduce or eliminate the shedding of vortices. As an example, a possible control strategy would be to apply a pulsating synthetic jet at the trailing edge of the roughness elements. Such an approach has been tried in a shear layer over a backward- facing step [9]. REFERENCES [1] Jimenez J (2004), Turbulent flows over rough walls. Ann. Rev. Fluid Mech., 36: 173-196 [2] Djenidi L, Elavarasan, E, Antonia, RA (1999) Turbulent boundary layer over transverse square cavities. J Fluid Mech 395:271-294 [3] Townes HW, Sabersky RH (1966) Experiments on the flow over a rough surface. Int J Heat -9- 13th Int Symp on Applications of Laser Techniques to Fluid Mechanics Lisbon, Portugal, 26-29 June, 2006 Mass Transfer 9:729-738 [4] Leonardi S, Orlandi P, Smalley RJ, Djenidi L Antonia RA (2003) Direct numerical simulations of turbulent channel with transverse square bars on one wall. J Fluid Mech 491:229-238 [5] Krosgstad P-A, Anderson HI, Bakken OM, Ashrafian A (2005) An experimental and numerical stydu of channel flow with rough walls. J Fluid Mech 530:327-357 [6] Cui J, Pate VC, Lin C-L (2003) Large-eddy simulation of turbulent flow in a channel with rib roughness, Int J Heat and Fluid Flow 24:372-388 [7] Rehab H, Djenidi L, Antonia RA (1999) LDV and PLIF measurements in a turbulent boundary layer over a rough wall, Proc. 2nd Australian Conference on Laser Diagnostics in Fluid Mechanics and Combustion, Melbourne, 132-137 [8] Le H, Moin, P, 1994 Direct numerical simulation of turbulent flow over a backward-facing step, Standford University Report no TF-58. [9] Pastor M, Noack BR, King R (2006) Spatiotemporal waveform observes and feedback in shear layer control, AIAA paper 2006-1402. - 10 -