Nanocontainers with controlled permeability for feedback active coatings

advertisement

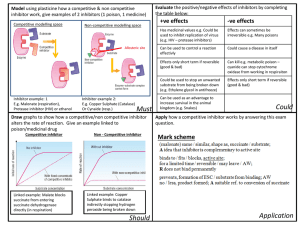

Nanocontainers with controlled permeability for feedback active coatings Contents: 1. Self-healing coatings based on nanocontainers for corrosion protection: - with pH-triggered release, - triggered by mechanic rupture, - with light-triggered release. 2. Polyelectrolyte coatings for corrosion protection: - inhibitor-free coatings, - sandwich-like structures with controlled release of the inhibitor. 3. Ultrasonic fabrication of oil- or gas-filled containers: - gas-filled containers, - oil-filled carriers. 4. Bioactive coatings based on oil-filled containers. Nanocontainer-based coatings To use the nanocontainers loaded with corrosion inhibitors Advantages 9 Reduction of negative effect of the inhibitor on coating Prevention of inhibitor deactivation due to interaction with coating components Controllable release of inhibitor on demand Prevention of the inhibitor leakage 9 9 9 Triggers: pH shift, light, pressure, corrosion products, etc. Shchukin, D.G., Möhwald, H. (2007): SMALL, 3, 926-943. Shchukin, D.G., Möhwald, H. (2007): Hollow Micro- and Nanoscale Containers, "Advanced Materials Research" Ed. by L.V. Basbanes. 2007, Nova Science Publishers, Inc. Andreeva, A.V.; Shchukin, D.G. (2008): Materials Today, 11, 24-30. Corrosion inhibitor (INH) loading into mesoporous containers INH PEI INH INH INH INH Polyelectrolyte shell Skorb, E.V.; Fix, D.; Möhwald, H.; Shchukin, D.G. (2009): Adv. Funct. Mater., in print. PSS Inhibitor release from nanocontainers OH- neutral alkaline OH- OH- Æ controllable permeability of the polyelectrolyte shell Æ the release of the inhibitor starts only after the begin of the corrosion pH-controlled release of the inhibitor from containers in solution Zeta Potential (mV) (A) scheme; (B) changes of zeta potential during the procedure of polyelectrolyte shell formation; % remained INH content mg/1 g of silica Layer number Deposition step Time, min (C) loading of the interior of titania containers with 2-(benzothiazol-2ylsulfanyl)succinic acid under vacuum; (D) the release of inhibitor from nanocontainers at pH=10.1(a), and neutral pH (b) sonication substra te The incorporation of the inhibitor-loaded containers with controlled release curing Coating Precursor Shchukin, D.G., Zheludkevich, M.L., Möhwald, H. (2007): J. Mater. Chem. 16, 4561-4566. Incorporated containers θ=65 R=1,8 Release of the inhibitor from directly-impregnated coatings and coatings with containers. Conditions: under deaerated Milli-Q water (no oxygen, no ions). Coating directly doped with benzotriazole 100 3µm % remained 80 60 40 20 0 0 1 2 3 4 5 Days Coating with the same amount of benzotriazole in nanocontainers with PE shell for controlled release 100 3µm % remained 80 60 40 20 0 0 1 2 Days 3 4 5 Incorporated containers Self-healing effect on coatings with mesoporous containers without containers, 0.5 M NaCl, 14 days inhibitor-loaded containers with polyelectrolyte shell Halloysite nanotubes Structure Dimensions 3 -3 0.3 15 nm 50 nm 0.4 -1 -1 DV [10 cm *Å *g ] 0.5 0.2 Pore size distribution 0.1 1 µm dmax = 17.8 ± 0.7 nm 0.0 0 50 100 150 200 Pore diameter [nm] Lvov, Y.M.; Shchukin, D.G.; Möhwald, H., Price, R.R. (2008): ACS Nano 2, 814-820. Loading of halloysite nanotubes Nanotube lumen Molybdate-loaded nanotube Shchukin, D.G., Lvov, Y. (2009): ACS Appl. Mater. and Interfaces, in print. Halloysite-based feedback active anti-corrosive coatings aggressive medium mechanical damage + changed pH locally triggered release of inhibitor ! homogeneous distribution metal Fix, D.; Andreeva, D.V.; Lvov, Y.M.; Shchukin, D.G.; Möhwald, H. (2009): Adv. Funct. Mater., 11, 1720-1727. . Halloysite-based coatings Current density observations (SVET) 12 12 9 9 6 6 6 3 3 3 0 0 0 -3 1 -1 x [m 0 m] -3 0 1 -1 9 1 -1 ] mm [ y 0 min 12 pure sol-gel coating x [m 0 m] 0 1 -1 x [m 0 m] 6 3 3 3 0 0 0 1 x [m 0 m] 0 1 -1 ] mm [ y -3 1 -1 x [m 0 m] ] mm [ y 9 6 -1 1 -1 12 …with inhibitor 9 loaded halloysite 6 -3 0 120 min 12 9 1 -1 ] mm [ y 30 min 12 -3 0 1 -1 ] mm [ y -3 1 -1 x [m 0 m] 0 1 -1 ] mm [ y Halloysite-based coatings Visual observations pure sol-gel coating 10 h in 0.1 NaCl …with inhibitor loaded halloysite 10 h in 0.1 NaCl Light triggered release Kinetics of benzotriazole release from the containers meso-TiO2/(PEI/PSS)2 and meso-TiO2:Ag/(PEI/PSS)2 under pH change and under UV and IR irradiation, respectively. 100 100 1 UV 80 pH=7,2 60 50 40 30 pH=10,1 2 20 0 10 pH=10,1 2 60 50 40 30 pH=7,2 + IR 3 10 pH=7,2 + UV 0 70 20 3 10 IR 80 70 1 pH=7,2 90 remainder, % remainder, % 90 0 20 30 40 50 0 10 20 30 time, min time, min light stimulated release (UV, IR) is much faster in comparison with pH stimulate release of incorporated into the container pore chemicals. Skorb, E.V.; Skirtach, A.; Möhwald, H.; Shchukin, D.G. (2009): ACS Nano, in print. 40 50 Release of the inhibitor by light 0h 0.1 M NaCl corrosion 12 h 1 min UV irradiation UV-healing Benzotriazole-loaded mesoporous TiO2 containers with polyelectrolyte shell in SiOx/ZrOx sol-gel coating on Al E. V. Skorb, D. G. Shchukin, H. Möhwald and D. V. Sviridov, J. Mater. Chem., 2009, 19, 4931 Anticorrosion activity of polyelectrolyte multilayers pH buffering activity Stabilization of pH change Good adhesion to the substrate and sealing the surface defects Carrier for corrosion inhibitor Release of inhibitor on demand Barrier for aggressive ions Regeneration of coating defects Mobility of the swollen polyelectrolyte complex Andreeva, D.V.; Fix, D.; Möhwald, H., Shchukin, D.G. (2008): J. Mater. Chem. 18, 1738-1740. Anticorrosion behavior of PE coating with buffer activity 10 bilayers of weak – strong PE PEI/PSS 0.1 M NaCl 0 hr 1.5 hr 16 hr Loading PE multilayers with corrosion inhibitor PSS Inhibitor 8-hydroxyquinoline PSS • Prevention inhibitor leakage • Release on demand • Reduce negative effect of inhibitor on coatings Surface passivation by 8-hydroxiquinoline Scanning vibration electrode technique, 0.1M NaCl A 0 hr Y, µm 6 hr X, µm Y, µm 16 hr X, µm Y, µm B Andreeva, D.V.; Fix, D.; Möhwald, H., Shchukin, D.G. (2008): Adv. Mater., 20, 2789-2794. X, µm Sealing effect of polyelectrolytes 10 µm Flow of the sealing polyelectrolyte Visual corrosion & stability test in 0.5 M NaCl solution 12hr 4 days 7 days 21 days Power of sonochemistry Frequencies from 20 kHz to 1 GHz; acoustic wavelengths from 10 to 10-4 cm far above molecular and atomic dimensions. Sonochemical effects are derived from acoustic cavitation (negative/positive pressure cycles). The compression of bubbles during cavitation leads to the enormous concentration of energy: ~5200 K, ~1000 atm, heating and cooling rates ~ 1010 K/s Potential of ultrasound: • • • To perform chemistry and physics at high temperature but with a reactor near room temperature. Highly nonequilibrium structures can be made which meets the demands of technology as well as physical sciences. Surface energy is converted into chemical energy and its control can make rapid progress in interfacial science. Shchukin, D.G., Möhwald, H. (2006): Phys. Chem. Chem. Phys. 8, 3496-3506. Surface of the cavitation microbubble ~5200 K ~1900 K Room temperature The work of evolution R(r) of a bubble with a radius r in metastable liquids is (thermodynamic nucleation theory): 4 R (r ) = 4π r 2σ + π r 3 ( P1 − Pv ) + ( μ v − μ1 )mv 3 [ ] The probability of the formation of microbubbles ω n ∝ exp − R (r * ) / k B T , R (r*) ~ σ3 is: For a typical surfactant concentration of cs= 1 mM and d= 10 µm the surfactant density is: cs ⋅ v Θ s = 2 ≈ 1014 mole/cm2 πd A monolayer coverage and hence a reduction of σ may be expected! Surface active materials in the sonicated liquid will result in drastic reduction of the surface tension increasing the efficiency of the ultrasonic treatment. They decrease “surface” component of the evolution work and change the difference of the chemical potentials between liquid and gas phases, which is of special interest for sonochemical reactions. Cavitation microbubbles as templates heating, 45 ºC Intensity, a.u. Polymer/polyelectrolyte air-containing microbubbles Span/Tween Span/Tween H2O PSS 500 1000 PSS 1500 2000 2500 Raman shift, cm Shchukin, D.G., Köhler, K., Möhwald, H., Sukhorukov, G.B.: (2005) Angew. Chem. Int. Ed., 44, 3310-3314. 3000 3500 4000 -1 Raman confocal microscopy spectra from an aircontaining microbubbles (blue) and surrounding water solution (black). Ultrasound in nanocontainer fabrication SiO2 containers Grigoriev, D.; Miller, R.; Shchukin, D.; Möhwald, H. (2007): SMALL, 3, 665-671. Containers with oil core and polymer shell Statistics Graph (1 measurements) 60 US generator ive Act rial te ma I n t e n s ity ( % ) 50 40 30 20 10 0 1 10 100 Size (d.nm) er ym pol Son. LbL Coating General scheme: A. emulsification of active material presenting in oil phase in aqueous polymer solution by ultrasonication; B. shell functionalization (if necessary); C. embedding of nanocontainers into coating film. 1000 10000 Ultrasound in nanocontainer fabrication Oil-filled polymer containers Teng, X.; Shchukin, D.G.; Möhwald, H. (2007): Adv. Funct. Mater., 17, 1273-1278. Containers with oil core and polymer shell Polystyrene shell Polyurithane shell Teng, X.; Shchukin, D.G.; Möhwald, H. (2008): Langmuir,24, 383-389. Protein shell Containers with oil core and polymer shell 5.00 2.50 0 0 2.50 5.00 AFM image of nanocontainers entrapped into polymer film Borodina T., unpublished results. Containers with oil core and polymer shell 20 µm 20 µm 20 µm CLSM of the nanocontainers embedded into polymer coating 1µm 1µm SEM photographs Release profile of VE from bioactive film in H2O/EtOH solution Acknowledgements Max Planck Institute of Colloids and Interfaces: Prof. Dr. Helmuth Möhwald Dr. D. Grigoriev, Dr. X. Teng, Dr. E. Skorb, Dr. D. Andreeva, D. Fix, A. Praast, Dr. I. Dönch, Dr. T. Borodina, Dr. Y.-S. Han, M. Haase, Dr. J. Hartmann Institute for Micromanufacturing, Louisiana Tech: Prof. Dr. Y. Lvov