Role of polymer chemistry in cell encapsulation Role of polymer chemistry

advertisement

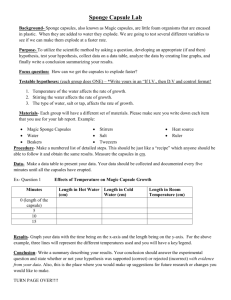

Role of polymer chemistry in cell encapsulation by polyelectrolyte complexation in biomedical and biotechnological applications Igor Lacík Polymer Institute of the Slovak Academy of Sciences Dept. of Special Polymers and Biopolymers Bratislava, Slovakia igor.lacik@savba.sk www.polymer.sav.sk/lacik.html igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 OUTLINE • ENCAPSULATION Why polymer chemist(ry) should enter encapsulation? • POLYMERS IN CAPSULES Polyelectrolytes as a capsule material Case 1: Pros and cons of Alginate-based capsules Case 2: Alternative capsules “PMCG” Process, mechanism, understanding and optimization • APPLICATIONS – Biomedicine & Biotechnology • CONCLUSIONS igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 Why polymer chemist(ry) should enter… Premise of encapsulation: SEMIPERMEABLE MEMBRANE made of POLYMERS • to concentrate encapsulated material • to protect encapsulated material • to release encapsulated material in a controlled way igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 Why polymer chemist(ry) should enter… BIOMEDICINE immunoprotection BIOTECHNOLOGY specifically catalyzed reactions islets of Langerhans diabetes treatment immunocytes glucose, O2, nutrients chemistry food technology pharmaceuticals cosmetics Reactant A SEMIPERMEABLE MEMBRANE therapeutic products (insulin) antibodies •• still still in in development development stage stage •• aa lot lot of of involvement involvement (companies, (companies, universities) universities) igor.lacik@savba.sk Reactant B CELLS (enzymes) Product •• already already as as industrial industrial process process Neuchâtel, Switzerland,,July 6-7 2005 Detour #1: pancreas (whole organ) transplantation USA: Number of organ transplantations in 2002 (24 544) Port et al. Am J Transplant 2004, 4 (Suppl.9): 7-12 0.1% 4.2% Success rate of pancreas transplantation 1996-2001 8.6% 20.6% 59.2% 0.2% <1% 3.7% 1.6% 0.6% 100 90 Success rate (%) Patients with Type 1 Diabetes ~ 200 000 80 70 60 50 40 30 20 10 0 Kidney + 1 pancreas Kidney (14 523) Kidney+pancreas (902) Heart (2 111) Pancreas alone (141) Intestine (44) Heart+Lung (31) Pancreas after kidney (376) Liver (5 060) Lung (1 041) Pancreas after 2 kidney Pancreas 3 1st year - patient 5th year - patient 1st year - pancreas 5th year pancreas C.N.Street et al, Int J Biochem Cell Biol 2004 Problems in this strategy of diabetes treatment: Ødonors Ø major operation Ø cost ? TRANSPLANTANTION OF VIABLE CELLS? igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 Detour #2: Cell therapy in diabetes treatment Method Edmonton protocol Results Drawbacks Shapiro et al. N Engl J Med 2000,343,230 • 100 % of patients: physiolo• cell source (2 donors/1 transplant) • human islets to liver portal gical blood glucose level • immune response (allo-, auto-) vein (11 000/kg) in 7 patients within 1 year • ? long-term effect of immuno• islet isolation protocol!!! • follow-ups: Edmonton & tens of suppressive drugs • selection of immunosuppreother groups USA/Canada/Europe ssive drugs!!! http://www.med.ualberta.ca/islet/ follow up: Bertuzzi et al. Diabetologia 2002,45,77 Stem cells and precursor cells • embryonic cells • adult pancreatic cells • other sources Street et al, Int. J. Biochem Cell Biol 2004, 36,667 • successful experiments in mice • a number of open questions • cell cluster producing insulin Cell encapsulation • autoimmune response • balance between proliferation and insulin production • ? unknown effects (tumors…) deVos et al, Diabetologia 2002, 45, 159 Orive et al, Nature Med 2003, 9, 104 • immunoisolation of donor cells behind semipermeable membrane • immunosuppression-free igor.lacik@savba.sk • clinical test in 1994 • “boom”in 90-ties • allo- and xenotransplanted cells to different recipients • progress??? • definite type and material remains to be answered Neuchâtel, Switzerland,,July 6-7 2005 Why polymer chemist(ry … chemist(ry)) should enter enter… …to designed semipermeable membrane biomedical applications Biological criteria • biocompatibility • resistance to biodegradation • non-cytotoxicity (host & transplanted cells) Physical and chemical criteria • mechanical stability • chemical stability • adjustment size/shape mechanical properties permeability membrane thickness Process criteria • homogeneity • capacity • reproducibility • availability biotechnolog ical aapplications pplications biotechnological igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 Why polymer chemist(ry … chemist(ry)) should enter enter… Semipermeable membrane = polymer Intravascular semipermeable membrane polyacrylates cells ? major surgery / thrombosis / retrieval vein Macrocapsule cells semipermeable membrane ? •modified cellulose •poly(acrylonitrile-co-vinylchloride) hollow fibres •teflon planar membranes •polyesters •macrobeads of polysaccharides diffusion / islet necrosis / mechanical properties hydrogels: • gelling polysaccharides polyelectrolyte complex temperature induced sol-gel process • solvent extraction/ precipitation Microcapsule semipermeable membrane cells ? igor.lacik@savba.sk retrieval Neuchâtel, Switzerland,,July 6-7 2005 OUTLINE • ENCAPSULATION Why polymer chemist(ry) should enter encapsulation? • POLYMERS IN CAPSULES Polyelectrolytes as a capsule material Case 1: Pros and cons of Alginate-based capsules Case 2: Alternative capsules “PMCG” Process, mechanism, understanding and optimization • APPLICATIONS – Biomedicine & Biotechnology • CONCLUSIONS igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 Capsules by polyelectrolyte complexation A- M+ A- M + + A- M + PA + X- B + A-.....B+ X- B + A-.....B+ X- B + A-.....B+ PC = + M + X- Polyanion (PA) and poly- cation (PC) via (predominantly) LONGRANGE COULOMBIC INTERACTIONS between oppositely charged polymers will ALWAYS (!) form polyelectrolyte complex (PEC) PEC Ø Overlapping fields (i) general macromolecular chemistry (ii) specificity of polyelectrolyte chemistry (iii) hydrogels and physically crosslinked networks (iv) membranes. ? CAPSULE with adjustable properties è serving the purpose igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 Polyelectrolyte comlexation: How the cells are encapsulated Polymer Polymer solution solution Cells Cells DROPLETS DROPLETS by: by: Drop Drop formation formation iioonn t t a a t ggiiaat a a ttllee n n e e GG Inotech Inotech Nisco Nisco genialab genialab …or …or In-house In-house made made 100-102 s-1 Mild, Mild, fast, fast, controlled controlled procedure procedure at at physiological physiological conditions conditions è è POLYELECTROLYTE POLYELECTROLYTE COMPLEXATION COMPLEXATION Hydrogel Hydrogel // membrane membrane formation formation igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 Polyelectrolytes - categorization • type of charge – PA vs. PC charge density charge distributon • acid-base characteristics weak vs. strong acids and bases • molecular weight • MWD • chemical distribution (homopolym. vs. copolymers) Many possibilities igor.lacik@savba.sk • hydrophobic groups • H-bonds • gel-formation in the presence of simple electrolytes • origin - synthetic vs. narural vs. modified • chain architecture – linear vs. branched •monomer type - flexible vs rigid ALL FACTORS NEED TO BE CONSIDERED WHEN STATING SUITABILITY OF A GIVEN POLYMER Neuchâtel, Switzerland,,July 6-7 2005 Polyelectrolytes - selection Polyanion vs. Polycation PA – “biocompatible” – not critically toxic – internal polymer INTERNAL POLYMER EXTERNAL POLYMER igor.lacik@savba.sk Sodium alginate Cellulose sulfate Carboxymethyl cellulose Hyaluronic acid Pectates .............. Polyacrylic acid PolyAMPS ……….. PC – decomposition of cell walls – positive charge has to be SATURATED – external polymer Chitosan ………… Poly(L-lysine) Poly(L-ornithine) ................ Poly(methylen-co-guanidine) Poly(vinylamine) Poly(ethylenimine) Poly(DADMAC) Poly (N-vinylpyrrolidone) .............. Neuchâtel, Switzerland,,July 6-7 2005 Polyelectrolytes - selection Polyanion vs. Polycation PA – biocompatible – not critically toxic – internal polymer Sodium alginate Cellulose sulfate Carboxymethyl cellulose Hyaluronic acid Pectates .............. PC – decomposition of cell walls – positive charge has to be SATURATED – external polymer Chitosan ………… Poly(L-lysine) Poly(L-ornithine) INTERNAL ................ POLYMER Polyacrylic acid Poly(methylen-co-guanidine) PEC Poly(vinylamine) PolyAMPS PEC – „non-toxic, biocompatible“ Poly(ethylenimine) ……….. Poly(DADMAC) – stability! is critical Poly (N-vinylpyrrolidone) è multiple layers PA/PC/PA/PC/PA... .............. igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 Polyelectrolytes - selection Charge density AIM → HYDROGEL (polym. conc. → 0 %) - physiological environment for cells - strict selection of PE’s to balance interactions between PA and PC WATER POLYMER STRONG INTERACTIONS → COACERVATE polym. conc. →100 % - lost control over membrane properties Additional factors è polymer concentrations, pH, ionic strength, reaction time… igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 Polyelectrolytes - selection Molecular weight and MWD Critical parameter for → solution rheology → drop and capsule shape and surface topology → mutual diffusion of PA and PC zones (pH, ionic strength) → osmotic pressure → complex stability (biocompatibility and capsule overall performance RECOMMENDATION – internal polymer é M.h. (rigid chain, gelled ionotropically by small ions) 100 – 1000 kDa – external polymer ê M.h. (flexible chain) 5 – 20 kDa – MWD – so far not emphasized Consider in line with other??? parameters – concentration, time of reaction, process parameters... igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 Polyelectrolytes - selection Natural polymers predominantly used as internal polymers - advantage – ionotropically formed gels – diversity – availability and cost - drawbacks – purity – standardization!!! – overcoming these problems ???? Synthetic polymers - advantage – “simply” prepared, modified, purified & characterized - drawbacks – difficult to mimic, by e.g. secondary structure, the advantageous properties of natural polymers igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 OUTLINE • ENCAPSULATION Why polymer chemist(ry) should enter encapsulation? • POLYMERS IN CAPSULES Polyelectrolytes as a capsule material Case 1: Pros and cons of Alginate-based capsules Case 2: Alternative capsules “PMCG” Process, mechanism, understanding and optimization • APPLICATIONS – Biomedicine & Biotechnology • CONCLUSIONS igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 Sodium alginate in microparticle and capsule formation OH COO-Na+ O O OH O OH O OH guluronic acid (if >60% high-G alginates) COO- Na+ + CaCl2 = gel HO O OH O HO mannuronic acid (if >60% high-M alginates) EXTREMELY simple igor.lacik@savba.sk Ca2+ COO-Na+ COO- Na+ HO O O egg-box model may cause a problem if the „polymer nature“ of alginate is underestimated Neuchâtel, Switzerland,,July 6-7 2005 Sodium alginate in microparticle and capsule formation OH COO-Na+ O OH O è è drops drops of of alginate alginate solution solution into into CaCl CaCl22 solution solution O OH O OH guluronic acid (if >60% high-G alginates) COO- Na+ + CaCl2 = gel HO O OH O HO mannuronic acid (if >60% high-M alginates) EXTREMELY simple igor.lacik@savba.sk Ca2+ COO-Na+ COO- Na+ HO O O egg-box model may cause a problem if the „polymer nature“ of alginate is underestimated Neuchâtel, Switzerland,,July 6-7 2005 Sodium alginate ionotropic gels Bead inhomogeneity Na-alginate Na-alginate into into CaCl CaCl22 Gell density across the capsule ? SA concentration in core vs surface Polymer concentration è Crucial for bead/capsule properties SA SA diffusion diffusion towards towards gelling gelling zone zone ?? Inhomogeneous bead in bead Ca2+ SL O W high high Na+ Homogeneous bead original in soltn. alginate conc. FA ST low Ca2+ low Na+ distance igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 Sodium alginate in capsules: history to presence Lim and Sun, Science 210, 908-909,1980 1st step: drops of SA (0.6-0.8%) containing islets of Langerhans (Wistar rats) gelled by Ca2+ ions 3rd step: strengthening the membrane 0.2 % polyethyleneimine solution reaction time ~ 2 - 4 min 2+ solution Ca 1.5%CaCl solution SA /Ca2+- PLL/PEI coated bead 2 SA/Ca2+ bead collection time + gelling time ~ ? + ? min 2nd step: 4th step: Dissolving SA/Ca2+ gel sodium citrate solution ~ 700 – 1000 µm membrane formation 0.02% poly-L-lysine solution reaction time ~ 5 min SA-PLL/PEI hollow capsule reaction time ~ 3-5 min SA/Ca2+-PLL coated bead igor.lacik@savba.sk CELL VIABILITY èfour months in vitro è3 weeks in vivo Neuchâtel, Switzerland,,July 6-7 2005 Sodium alginate in capsules: history to presence Modified protocol of Lim and Sun - till now 1st step: drops of SA (1-3 %) containing islets of Langerhans gelled by Ca2+ ions 3rd step: saturating residual cationic charge by SA layer 0.1 % sodium alginate solution reaction time ~ 5-10 min 2+ solution Ca 1.5%CaCl solution SA/Ca2+-PLL-SA coated bead 2 SA-Ca2+ bead collection time + gelling time ~ 5 + 5 min 2nd step: 4th step: Dissolving SA-Ca2+ gel Sodium citrate solution membrane formation ~ 0.02% poly-L-lysine solution reaction time ~ 5-10 min SA-PLL-SA hollow capsule reaction time ~ 5 - 30 min SA/Ca2+-PLL coated bead igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 Sodium alginate in capsules: history to presence Patrick Soon-Shiong et al (VivoRx): a dominant influence on encapsulation community 1990-1998 purified alginate with high G content (mechanical stability & biocompatibility) ê SA/PLL/SA hollow capsules with 15-20 000 islets/kg (allografts) TX site: peritoneal cavity ê Successful dog trials (1992) ê Successful clinical trial (Lancet 1994) US Patents 1998-1999 Understanding: (i) PEC stability (ii) capsule formation (Trondheim, Norway) Capsule and membrane mechanical & chemical stability • alginate rich in G units • alginate rich in M units for binding to PLL has to be present (multi-layer) • no degelling of core by citrate • stable Ba2+ gelation to Ca2+ • anisotropic distribution of alginate in core • absence of PLL positive charge on surface → macrocapsules Boom in the field 1. dispersed in SA Difficult / impossible to repeat igor.lacik@savba.sk ~0.7mm 2. Ca2+ y.2005: Neuchâtel, Switzerland,,July 6-7 2005 y.2005: clinical clinical trials trials www.amcyte.com www.amcyte.com Sodium alginate in capsules: history to presence MODIFICATIONS & “IMPROVEMENTS” TO SA/PLL/SA CAPSULE → suppress islet necrosis, improve long-term biocompatibility and durability SIZE (diffusion/site of Tx/volume…) ANIMAL MODELS ALGINATE TYPE (chemical composition) MEMBRANE CHEMISTRY (biocompatibility) ??? SITE of Tx (vascularization/explantation/safety…) igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 Sodium alginate in capsules: history to presence MODIFICATIONS & “IMPROVEMENTS” TO SA/PLL/SA CAPSULE • high-M alginate is more suitable than high-G yet biocompatibility → suppress islet necrosis, improve long-term biocompatibility durability is an issue of purity (endotoxins, mitogens,and phenolic compounds) Klöck et al. 1997 • high-M alginate is more suitable than high-G for SA/PLL/SA SIZE capsules due to efficient binding to PLL (diffusion/site Tx/volume…) deVos et al.of(1996-2005) • high-G alginate should be the main constituent SA/PLL/SA ANIMALinMODEL capsules for their stability ALGINATE TYPE Soon-Shiong et al (1998) (chemical composition) • high-G alginate is more suitable than high-M for SA/PLL/SA capsules due to improved mechanical stability Halle et al (1999) ??? MEMBRANE CHEMISTRY • high-G alginate is more suitable than high-M for SA-Ca 2+ beads (biocompatibility) deVos et al. (1996-2005) • high-M alginate is more suitable than high-G for SA-Ba 2+ beads Weir et al. (2001-2005) SITE→ofbiocompatibility Tx • high-G vs high-M is an issue of purity (vascularization/explantation/safety…) Orive et al. (2002) • purity may not be a major issue → for PEC capsules, endotoxins as polyanions are captured by cationic charge of membrane Wandrey (1999) igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 Sodium alginate in capsules: history to presence • replacing PLL by poly-L-ornithine (stable complex with SA) Calafiore et al (1995-presence, clinics) CAPSULE MODIFICATIONS & “IMPROVEMENTS” TO SA/PLL/SA • replacing PLL by aminopropyl (stable complex, sol-gel) → suppress islet necrosis, improve long-term silicate biocompatibility and durability Sakai et al (2001 - presence) • SA (macro)bead containing SA-PLL-SA microcapsules (clinics: www.amcyte.com) SIZE • avoiding PEC – formation of stable SA/Ba2+ (diffusion/sitemembrane of Tx/volume…) beads Weir et al (2001 - presence) ANIMAL MODEL • coating layer based on the PEG chemistry grafting PEG on ALGINATE TYPE PLL Hubbell (1992); presence devoted to PEG chemistry • etc. (chemical composition) MEMBRANE CHEMISTRY (biocompatibility) ??? SITE of Tx (vascularization/explantation/safety…) igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 Sodium alginate in capsules: history to presence MODIFICATIONS & “IMPROVEMENTS” TO SA/PLL/SA CAPSULE → suppress islet necrosis, improve long-term biocompatibility and durability SIZE (diffusion/site of Tx/volume…) • peritoneal cavity (simple, fast, high capacity, retrieval?) • under capsule kidney (localization, retrievalANIMAL if needed) MODELS • portal vein of liver (safety?) ALGINATE TYPE • spleen vein (safety?) (chemical composition) • subcutaneously (geometry?) •… ??? MEMBRANE CHEMISTRY (biocompatibility) SITE of Tx (vascularization/explantation/safety…) igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 Sodium alginate in capsules: history to presence MODIFICATIONS & “IMPROVEMENTS” TO SA/PLL/SA CAPSULE → suppress islet necrosis, improve long-term biocompatibility and durability SIZE (diffusion/site of Tx/volume…) ANIMAL MODEL Calafiore et Calafiore et al al 1995 1995 –– 2003: 2003: ALGINATE TYPE • medium medium and and conventional conventional size size microcapsules microcapsules (chemical •composition) 600 600 –– 1000 1000 µm µm 400 400 µm µm •• coherent coherent microcapsules microcapsules smaller smaller is is better, better, but but was was not not proven proven for for dogs dogs Halle Halle et et al al 1996 1996 –– 1999: 1999: ??? MEMBRANE CHEMISTRY recommended << 350 recommended size size of of microcapsules microcapsules 350 µm µm (biocompatibility) more more biocompatible biocompatible than than conventional conventional size size deVos deVos et et al al 1996 1996 –– 2002: 2002: large ~~ 800 large diameter diameter 800 µm µm SITE of Tx small ~~ 500 small diameter diameter 500 µm µm (vascularization/explantation/safety…) larger larger is is better better == aa more more adequate adequate islet islet encapsulation encapsulation Strand Strand et et al al 2002: 2002: larger ~~ 500 larger diameter diameter 500 µm µm small ~~ 200 small diameter diameter 200 µm µm islets islets in in vitro vitro == no no difference difference between between sizes sizes of of capsules capsules at at adjusted adjusted conditions conditions for for capsule capsule formation formation igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 Sodium alginate in capsules: history to presence MODIFICATIONS & “IMPROVEMENTS” TO SA/PLL/SA CAPSULE → suppress islet necrosis, improve long-term biocompatibility and durability SIZE (diffusion/site of Tx/volume…) •• typical –– normal typical animal animal donors/hosts donors/hosts normal mice mice NOD NOD ALGINATE TYPE –– rats rats (chemical composition) –– pigs pigs –– dogs dogs •• alloallo- vs. vs. xenotransplantations xenotransplantations MEMBRANE CHEMISTRY (biocompatibility) •• note note that that successful successful “Edmonton “Edmonton protocol” protocol” could could avoid avoid ANIMAL MODEL ??? using using animal animal models models before before the the clinical clinical trials trials SITE of Tx (vascularization/explantation/safety…) igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 Sodium alginate in capsules: history to presence & “IMPROVEMENTS” TO SA/PLL/SA CAPSULE •• smoothness vs. physical smoothnessMODIFICATIONS vs. roughness, roughness, i.e. i.e. physical imperfections imperfections → suppress necrosis, is improve → opinion smoother better → general general opinionislet smoother is betterlong-term biocompatibility and durability → → possibly possibly “just “just rough” rough” is is better better (Prof (Prof Hilborn, Hilborn, Uppsala) Uppsala) è è ??? ??? Quantification Quantification SIZE (diffusion/site of Tx/volume…) 2+ vs 2+ •• Ba Ba2+ vs Ca Ca2+ ANIMAL MODEL → → the the gel/capsule gel/capsule chemical chemical stability stability 2+ ALGINATE TYPE è è ??? ??? Toxicity Toxicity of of Ba Ba2+ (chemical composition) •• homogeneous homogeneous vs. vs. heterogeneous heterogeneous capsule capsule core core → → meet meet both both opinions opinions ??? è è ??? ??? real real evidence evidence MEMBRANE CHEMISTRY (biocompatibility) •• homogeneous homogeneous vs. vs. heterogeneous heterogeneous capsule capsule core core → → meet meet both both opinions opinions SITE of Tx è è ??? ??? real real evidence evidence (vascularization/explantation/safety…) •• difference difference in in modulus modulus of of tissue tissue and and material material è è Prof Prof Hilborn, Hilborn, Uppsala Uppsala •• etc etc igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 Sodium alginate in capsules: history to presence MODIFICATIONS & “IMPROVEMENTS” TO SA/PLL/SA CAPSULE → suppress islet necrosis, improve long-term biocompatibility and durability SIZE (diffusion/site of Tx/volume…) ANIMAL MODEL ALGINATE TYPE (chemical composition) MEMBRANE CHEMISTRY (biocompatibility) ??? SITE of Tx (vascularization/explantation/safety…) CIRCLE OUTCOME: A VERY POOR LEARNING CURVE è struggles for one searching “some degree of exactness” igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 Sodium alginate in capsules: history to presence Enzymatically tailor-made composition of sodium alginate by group of Prof. S. Bræk, Trondheim Group mannuronan C-5 epimerase J Biomed Mater Res 64A, 540-550 (2002) Effect on è chain flexibility è packing density è interactivity Improvement è higher stability è lower permeability è core and coat material → → aa new new hope hope for for alginate-based alginate-based capsules capsules igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 Detour #3: search for exactness (IL’s another field) IUPAC activities (www.iupac.org/projects/2004/2004-034-1-400.html ) Availability and precision of rate coefficients in free-radical polymerization ln kp (L·mol-1·s-1) Arrhenius plot for propagation rate coefficient for methyl methacrylate 9 beginning of 90-ties benchmark benchmark values values based based on on data data from from aa number number of of laboratories laboratories 7 6 5 4 2.6 2.8 3.0 3.2 3.4 3.6 1000 T-1 / K-1 1. 2. 3. end of 90-ties 8 3.8 2.8 3.0 3.2 3.4 3.6 3.8 4.0 1000 T-1 / K-1 achieved after recognizing drawbacks and critical discussion and setting consistency criteria difficult topic but seems a simpler problem than capsule formation in encapsulation field, critical discussion might be (is) missing, “ blaming nature” for non-consistency èprimary èprimary principle: principle: consistency consistency igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 Comments on process of capsule formation by PEC (Lim & Sun, 1980) 1st step: drops of SA (0.6-0.8%) containing islets of Langerhans (Wistar rats) gelled by Ca2+ ions SIMPLE è VASTE AMOUNT OF PAPERS è ANYBODY CAN DO IT è ANYBODY CAN REPEAT IT 2+ solution Ca 1.5%CaCl solution 2 SA/Ca2+ bead collection time + gelling time ~ ? + ? min 2nd step: membrane formation 0.02% poly-L-lysine solution reaction time ~ 3-5 min SA/Ca2+-PLL coated bead igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 Comments on process of capsule formation by PEC Polyelectrolyte-based beads and capsules (i) time of droplet collection (ii) time of gel/membrane formation … i.e. discontinuous process take the literature on PEC capsule and find this (logically required) information 50 randomly selected papers (>y.1999) 30% 6% No inormation at all ? igor.lacik@savba.sk 64% Collection time Reaction time • trivial and/or unimportant information? • confidential information? • hard to define? è comparison among the data/groups is questionable Neuchâtel, Switzerland,,July 6-7 2005 Comments on process of capsule formation by PEC collection & reaction times A wrong observation: beads formed by reaction of Ca2+ with sodium alginate in a couple of seconds and a couple of minutes look similar BUT are not identical •Collection time •Reaction time 5 minutes 5 minutes ð Reaction time for individual capsules varies between 5 to 10 minutes Polymer network Øgel density Øeffective molecular weight btw. crosslinks Øgel thickness Øswelling Ø….. Capsule • permeability • mechanical stability • chemical stability • mass transfer • degree of swelling (size) • post-reactions (PLL, coat…) • cell environment •…. Averaged properties a difficult to judge the capsule/cell performance (repeatability; discarded systems) igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 Comments on process of capsule formation by PEC …limitations in SA-PLL-SA (type of) capsule: • capsule inter- and intrabatch homogeneity CaCl2 solution (GELLING REACTION) NaCl solution (WASH & POOL COLLECTED BEADS) PLL solution (MEMBRANE FORMATION) – Ca2+ exchanged by Na + – time dependent Capsule wash ACTIVE STEP (Strand et al 2003) Further exploration for capsule type with: • “independent” adjustment of membrane properties? (mechanical properties, thickness, permeability, smoothness) igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 OUTLINE • ENCAPSULATION Why polymer chemist(ry) should enter encapsulation? • POLYMERS IN CAPSULES Polyelectrolytes as a capsule material Case 1: Pros and cons of Alginate-based capsules Case 2: Alternative capsules “PMCG” Process, mechanism, understanding and optimization • APPLICATIONS – Biomedicine & Biotechnology • CONCLUSIONS igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 “PMCG” microcapsule: basic chemistry Vanderbilt University, TN 5 components interact in one step CH2 Polyanion solution 0.6-1.2 % Polycation solution C NH NH n Poly(methylene-co-guanidine) PMCG Sodium alginate (high M) + CaCl2 0.6-1.2 % NH Sodium cellulose sulfate NaCl 1-2 % 0.6-1.2 % 0.9% Complex stability in PBS (after Ca2+ removal) unstable igor.lacik@savba.sk stable highly stable Neuchâtel, Switzerland,,July 6-7 2005 “PMCG” microcapsule: basic chemistry Polyanion soltn. high viscosity (SA) & cellulose sulfate (CS) ê Polycation soltn. poly(methylene-co-guanidine) & CaCl2 (gelling cation) & NaCl (anti-gelling cation) igor.lacik@savba.sk • SA/CS ratio - specifically interacting polyanions with components of PC solution • CaCl2 - gelling with SA è spherical shape • PMCG - low M.w. (Mn = 4500 g/mol) and high charge density è high mobility and reactivity, strongly interactive with CS • competitive reaction between PMCG and Ca2+ with the anonic sites • anti-gelling Na+ cations tune the gelling reaction • reaction is fast è a few tens of seconds • 1-step process è no changes of membrane introduced between gel bead and membrane formation Neuchâtel, Switzerland,,July 6-7 2005 “PMCG” microcapsule: process of preparation Discontinuous (beaker) collection typically applied to the PEC-made capsules • nominal size of droplets generated at ~ 3000/min by air-stripping. size ~ 0.8 mm • 0.6 % SA + 0.6 % CS in PBS • 2.2 % PMCG, 0.6 % CaCl2, 1.8 % NaCl in H2O Collection time: Reaction time: 30 s + 30 s 0.5 mm igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 “PMCG” microcapsule: process of preparation 1-step CONTINUOUS process Beaker: collect 30’’+ react 30’’ POLYANION (+ cells) AIR air-stripping nozzle Reactor 30’’ POLYCATION drops capsule formation Reactor 60’’ multi-loop reactor Multiloop reactor each capsule is exposed to the same reaction conditions igor.lacik@savba.sk final capsules capsule uniformity (geometry, chemistry) Anilkumar et al Biotechnol. Bioeng. 75, 581 (2001) Neuchâtel, Switzerland,,July 6-7 2005 PMCG capsule: membrane formation & mechanical resistance Conc. (wt.%): SA/CS = 0.6/0.6, PMCG 1.8 %, CaCl2 1.0 %, NaCl 0.9% Rate of membrane formation ~ tens of second Mechanical stability 0.06 40 30 0.04 rupture load (g) membrane thickness (mm) 0.05 0.03 20 0.02 10 0.01 Alginate / Poly-L-lysine capsule 0.00 0 10 20 30 40 0 0.00 0.01 0.02 0.03 0.04 membrane thickness (mm) reaction time (s) igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 Permeability of PMCG capsule è inverse SEC 1. Capsules used as a column packing 2. Pullulan standards of different molecular weight injected on column è molecular weight cut-off (MWCO) è pore size distribution ~ 20 ml 0.9 % NaCl 0.2 ml/min 1-3 mg/ml 100 µL MWCO 1 0.8 1-KSEC column bed eluent flow rate pullulan conc. inj. volume 0.6 0.4 KSEC = (Vi-V0)/(Vt-V0) 0.2 d(1-KSEC)/d(logM) Brissova et al Analytical Biochem. 242, 104-111, 1996 0 2 3 4 5 6 log M igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 Permeability of PMCG capsule è effect of MW of CS PA: 0.9% SA, 0.9% CS in 0.9% NaCl PC: 1.2% PMCG, 1.0% CaCl2 0.9% NaCl, pH 7 40’’ reaction time, citrate step CS in polyanion composition CS as a coating layer (0.1%, 10 min) 1 1-K SEC 0.8 0.6 760 kDa 36 kDa 360 kDa 41 kDa 190 kDa 1 MWCO MWCO CS CS - 0.8 1-K SEC CS CS 58 kDa 0.4 0.2 0.6 MWCO MWCO 36 kDa 760 kDa 18 kDa 190 kDa 6 kDa 0.4 0.2 0 0 2.5 3 3.5 4 4.5 log M 5 5.5 6 2.5 3 3.5 4 4.5 log M 5 5.5 6 ð effect of the molecular weight of CS is important • network density • coating of primary membrane igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 Permeability of PMCG capsule è internal polymers SA in polyanion composition Polyanion concentration PA: 0.9% SA, 0.9% CS in 0.9% NaCl PC: 1.2% PMCG, 1.0% CaCl2 0.9% NaCl, pH 7 40’’ reaction time, citrate step PC: 1.2% PMCG, 1.0% CaCl2 0.9% NaCl, pH 7 40’’ reaction time, citrate step 1.0 1 PA PA 0.6 SA SA MWCO MWCO 430 kDa 36 kDa 300 kDa 60 kDa 0.8 0.6 1-K SEC 1-K SEC 0.8 MWCO MWCO 0.90/0.90 36 kDa 0.75/0.75 50 kDa 0.60/0.60 80 kDa 0.4 0.4 0.2 0.2 0 0.0 2.5 3 3.5 4 4.5 5 5.5 6 log M ð refer to Wandrey 2003 – more effect of SA chemical composition than MW 2.5 3.0 3.5 4.0 4.5 log M 5.0 5.5 6.0 ð effect on MWCO and pore size distribution ð correlation to years at Vanderbilt? ! MW (and MWD) affects also other properties than MWCO (stability, rheology…) igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 Permeability of PMCG capsule è secondary coating Polyanion Concentration and Secondary Membrane Effects 1.8 wt% PMCG, 1.0 wt% CaCl2, 0.9 wt% NaCl, 1min Rη [nm] 0.6 / 0.6 0.9 / 0.9 0.9 / 0.9 0.9 / 0.9 0.9 / 0.9 0.9 / 0.9 230 120 44 19 13.8 3.2 11.7 8.5 5.1 3.4 2.9 1.4 PROTEINS (globular conformation) [kDa] 1 770 750 200 67 44 6.5 molecular weight cut-off igor.lacik@savba.sk PLL PLL 0.01 0.01 wt.%; wt.%; 33 and and 4.5min 4.5min 1-KSEC DEXTRANS (statistical coil) [kDa] 1-KSEC SA / CS in PA solution (wt.% / wt.%) log Rη (Å) log Rη (Å) PVAm PVAm 0.001 0.001 wt.%; wt.%; 33 min min 0.1 0.1 wt.%; wt.%; 55 min min Neuchâtel, Switzerland,,July 6-7 2005 Mechanism of capsule formation – a kinetics view Lacik et al J Microencapsulation 2001 I) shape relaxation after impact by viscous forces time ~ 10-3 s a surface smoothness, sphericity and permeability BEFORE IMPACT AIR POLYCATION EFFECT OF GELLING CONDITIONS II) AFTER IMPACT IDEAL RECOVERY shape relaxation by osmotic swelling time ~ 10-3 - 100 s EFFECT OF MW, CONCENTRATION, REACTIVITY III) membrane formation time ~ 100 - 102 s a required thickness, mechanical and chemical stability and permeability OVERALL PROCESS AND CHEMISTRY CONDITIONS igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 Shape relaxation by viscous forces COMMON UNDERSTANDING: NaCl provides physiological osmotic pressure ADDITIONAL ROLE: Screening of ionic interactions a effect on kinetics! Drop penetration via air-liquid interface Before impact Air Polycation solution After impact Ideal shape PE complexation Time to reach the “ideal shape” is given by viscous forces R2 t≈ 5ν ~ 0.052 ( cm 2 ) 2 −1 ~ 1 ( cm s ) ≈ 10 −3 s ðEncapsulation process – minimize time needed for shape relaxation: êdrop size, é viscosity ð OK, but limited by process slow-down the rate of gel formation ! Kendal et al. 1989 igor.lacik@savba.sk Antigelling effect of NaCl Neuchâtel, Switzerland,,July 6-7 2005 Shape relaxation è gelling conditions [Na+]/[Ca2+] Optical microscope a) Immediately after membrane formation b) After dissolving of internal gel by citrate a) a) b) b) 0.5 mm without NaCl in cation solution 0.5 mm 0.9 wt.% NaCl in cation solution Positive effect on capsule quality igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 Shape relaxation è gelling conditions [Na+]/[Ca2+] Quantification: AFM 10 x 10 µm LINE PROFILES 0.9 wt% of NaCl 1.0 wt.% of CaCl2 1.0 wt.% of PMCG 4.5 wt% of NaCl 1.0 wt.% of CaCl2 1.0 wt.% of PMCG igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 Shape relaxation è gelling conditions [Na+]/[Ca2+] Effect on permeability SA/CS = 0.6/0.6 (wt% / wt%), poly (methylene-co-guanidine) 1.0 wt% CaCl2 (%) 0.60 0.86 1.00 NaCl (%) 0.9 0.9 0.9 [Ca2+ ]/[Na+ ] exclusion limit [kDa] 0.35 0.49 0.58 97 137 215 ì[Ca2+ ]/[Na+ ] ì MWCO ì[Ca2+ ]/[PMCG] ì MWCO Indication Indication of of the the competition competition processes processes in in the the membrane membrane formation formation Increased Increased NaCl NaCl concentration concentration lowers lowers the the PA PA concentration concentration at at the the drop drop surface surface ð ð homogeneous homogeneous vs. vs. heterogeneous heterogeneous distribution distribution of of polyanions polyanions Extremely Extremely simple simple adjustment adjustment of of MWCO MWCO igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 Shape relaxation è gelling conditions [Na+]/[Ca2+] Lacik et al J Microencapsulation 2001 Increased ratio Na+/Ca2+ leads to smoother surface, but less stable complex Solution: capsules are formed continuously in two steps c2,i c (1 + k ) − c1,i = i k PC1 high [Na+] Mixing Capsules PC1 & PC2 & PC1 PC2 low [Na+] k is the flow rate ratio V2/V1 of PC2 and PC1 aCapsules of different surface quality igor.lacik@savba.sk smooth surface < 5s Capsules & PC of composition for membrane at physiological NaCl stable membrane tens of seconds Neuchâtel, Switzerland,,July 6-7 2005 Mechanism of capsule formation – a chemistry view interactions – dilute solution composition – real conditions capsules are made by interactions between: PMCG + SA PMCG + (SA-Ca2+) PMCG + CS PMCG + SA/CS PMCG + (SA/CS-Ca2+) Questions: • what do we know about interactions? • can the information on interactions help? igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 Interactions in dilute solution viscometry (Ubelohde viscometer) at 25ºC + + HO -[ CH2 – NH – C – NH –]n- H relative viscosity +NH Mmonmol = 107 g/mol 3.0 charge / unit ? CH2-OSO3 O O HO O3SO Mmonmol = 341 g/mol 1.7 charge / unit COO equilibrium (electroneutral) composition 0 1 addition of PE 1 to PE 2 O O HO HO Mmonmol = 198 g/mol 1.0 charge / unit expected??? è è è igor.lacik@savba.sk molecular weight concentration ionic strength PMCG : CS ~ 1 : 2 (xPMCG ~ 0.33) PMCG : SA ~ 1 : 3 (xPMCG ~ 0.25) Neuchâtel, Switzerland,,July 6-7 2005 Interactions in dilute solution: PMCG - CS IONIC STRENGTH (both polymers 0.01wt.%) water 0.001M NaCl 0.1M NaCl Relative viscosity 1.4 1.3 PMCG e cha e v i t c ffe 2+ 3+ 1.2 rg e 1+ PMCG : CS 4:1 1.1 1.0 0 20 40 60 80 100 PMCG (mol %) igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 Interactions in dilute solution: PMCG - SA POLYM. CONCENTRATION (in 0.01 M NaCl) IONIC STRENGTH (both polymers 0.008 wt.%) Relative viscosity 1.7 1.6 1.5 1.4 1+ 3+ PMCG : SA 4 :1 1.3 1.2 1.20 Relative viscosity water 0.001M NaCl 0.01M NaCl 0.1M NaCl 1.8 0.010 wt.% 0.008 wt.% 0.005 wt.% 1.15 1.10 PMCG : SA 4 :1 1.05 1.1 1.00 1.0 0 20 40 60 PMCG (mol %) igor.lacik@savba.sk 80 100 0 20 40 60 80 100 PMCG (mol %) Neuchâtel, Switzerland,,July 6-7 2005 Outcomes from studies of interactions in dilute solution • PMCG is less (electrostaticaly) interactive than assumed (PMCG effective charge?) • PMCG content in complex is higher than stechiometrical. • Other than (only) ionic interactions are responsible for complex formation? • similar PMCG interactivity to both SA and CS SA + Ca2+ CS + PMCG SA + PMCG è Question: complex composition under REAL conditions? igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 Membrane formation under real conditions igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 Confocal laser scanning microscopy in membrane characterization Multi-spectral confocal microscope Zeiss LSM 510-META+Axiovert 200 Mot Two fluorescence/reflection channels One transmission channel 32-channel polychromatic detector 488 nm laser line and emission bands 435-485 nm (reflection) and 535-590 (fluorescence) igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 Confocal laser scanning microscopy in membrane characterization Fluorescence labels è non-covalent labeling probes after capsule formation (10-7 mol/L) [ ] HO - CH2 – NH – C – NH – n- H NH selected cation probes (visualisation of negatively-charged polymers) selected anion probes (visualisation of positively-charged polymer) Sensitive Sensitive to to (free, (free, unbound) unbound) charged charged polymer polymer groups groups igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 CLSM characterization of microcapsule wall – anionic probes PA: 0.9% SA, 0.9% CS in 0.9% NaCl, PC: 1.2% PMCG, 1.0% CaCl2 0.9% NaCl, pH 7 , 40’’ reaction time, citrate step Reflection è “inner” membrane A) transmission, B) reflection, C) fluorescence, D) cross-sections (across white line in B,C) igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 CLSM characterization of microcapsule wall – cationic probes PA: 0.9% SA, 0.9% CS in 0.9% NaCl, PC: 1.2% PMCG, 1.0% CaCl2 0.9% NaCl, pH 7 , 40’’ reaction time, citrate step Reflection & fluorescence for non-bulky probes è “inner” membrane (of anionic nature) A) transmission, B) reflection, C) fluorescence, D) cross-sections (across white line in B,C) igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 Dilemma between 1- and 2-step processes 1 – step ð capsular membrane SA/CS – PMCG is made in one step (by using loop-reactor) ð intra- and inter-batch homogeneity (geometry and chemistry) ð 1st step: 2nd step: 2 – step SA/CS – Ca2+ beads (step consisted of collection + reaction) exposure to PMCG ð easy control of membrane thickness and shape ð may arise a problem with intra- and inter-batch homogeneity (an issue for large batches!) due to: Ø differences in collection and reaction times Ø diffusion of CS between 1st and 2nd steps (CS is not bound by Ca2+) Ø duration of washing steps …what can CLSM see? igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 CLSM characterization of microcapsule wall: non-covalent labeling 2-step 2-step process process 1-step 1-step process process PA: 0.9% SA, 0.9% CS in 0.9% NaCl, PC: 1.2% PMCG, 1.0% CaCl2 0.9% NaCl, pH 7 40’’ reaction time Rhodamine 123 Eosin Y PA: 0.9% SA, 0.9% CS in 0.9% NaCl, Step 1: 1.0% CaCl2 0.9% NaCl, pH 7, 40’’ reaction time, Step 2: 1.2% PMCG, 0.9% NaCl, pH 7, 40’’ reaction time Rhodamine 123 Eosin Y Intensity Intensity label Intensity reflection reflection label label Intensity label reflection reflection Distance Distance Distance Distance è CLSM identifies membrane composition and suggests mechanism of capsule formation igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 Permeability by inverse SEC è 1- vs. 2-step process PA: 0.9% SA, 0.9% CS in 0.9% NaCl 1-step capsule: 1.2% PMCG, 2.0% CaCl2 0.9% NaCl, pH 7, 40’’ reaction time, citrate step 2-step capsule: 1st step: 2nd step: citrate 2.0% CaCl2, 0.9% NaCl 1.2% PMCG, 0.9% NaCl 40’’ 40’’ 1.0 1 -K S E C 0.8 process MWCO 0.6 1-step 52 kDa 2-step 29 kDa 0.4 0.2 0.0 2 2.5 3 3.5 4 4.5 5 5.5 6 log M MWCO shows a denser network in 2-step process ? a higher CS concentration towards surface ? igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 CLSM characterization of microcapsule wall – covalent labeling PA: 0.9% SA, 0.9% CS in 0.9% NaCl, PC: 1.2% PMCG, 1.0% CaCl2 0.9% NaCl, pH 7 , 40’’ reaction time PMCG PMCG –– rhodamineB-isothiocyanate rhodamineB-isothiocyanate igor.lacik@savba.sk SA SA –– fluorescein fluorescein amine amine Neuchâtel, Switzerland,,July 6-7 2005 CLSM characterization of microcapsule wall • extremely useful tool for membrane and capsule characterization • understanding mechanism and, hence, control of capsule formation • specifically bound labels provide sufficient primary information; covalently bound labels provide a rigorous information • cooperation among devoted people is needed • future: also for viability studies of encapsulated cells igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 OUTLINE • ENCAPSULATION Why polymer chemist(ry) should enter encapsulation? • POLYMERS IN CAPSULES Polyelectrolytes as a capsule material Case 1: Pros and cons of Alginate-based capsules Case 2: Alternative capsules “PMCG” Process, mechanism, understanding and optimization • APPLICATIONS – Biomedicine & Biotechnology • CONCLUSIONS igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 PMCG capsule for encapsulation of islets of Langerhans Released insulin (pM/100 cell/min) Capsules with rat islets 900 freshly isolated islets freshly isolated islets after encapsulation encapsulated islets explanted after 9 months 800 700 stimulation stimulation 600 500 400 300 200 100 0 0 20 40 60 80 100 120 Perifusion time (min) Capsules Capsules before before Tx Tx to to C57 C57 mice mice (A) (A) and and explanted explanted after after ~~ 99 months months (B) (B) Perifusion in glucose medium capsules seem to be biocompatible and cells remain viable igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 PMCG capsule for encapsulation of islets of Langerhans ~ 1000 islets of Langerhans / mouse model intraperitoneally capsule: 800 µm, membrane ~ 70 µm, MWCO towards dextrans Neonatal pig islets NOD mice MWCO 100 kDa 500 400 300 200 100 (16) (10) (11) (15) (8) 0 -20 0 20 40 60 80 100 Time after transplantation (days) 120 Glucose concentration (mg/dL) Glucose concentration (mg/dL) Sprague-Dawley rat islets C57 mice 200 mg STZ/kg MWCO 100-230 kDa 500 400 300 200 100 (9) (7) (6) (5) (2) 0 -20 0 20 40 60 80 100 Time after transplantation (days) The same for NOD mice with rat islets igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 PMCG capsule used in biotechnology Immobilization of enzymes and whole cells as catalysts for biotransformation Nocardia tartaricans whole cells with cis-epoxysuccinate hydrolase acitvity O O ONa ONa H2O cESH COONa H HO OH H COONa O cis-epoxysuccinate L-(+)-tartrate Bucko Bucko et et al al EMT, EMT, 2005, 2005, 36/1, 36/1, 118, 118, 2005 2005 SA-CS/PMCG capsule vs. typical calcium pectate beads) Operational stability 140 250 6 200 120 activity 150 (U/mg) 100 time (h) 3 50 2 relative activity (%) 5 4 encapsulated cells 100 80 60 40 1 0 SA-CS/PMCG CPG free cells 20 0 SA-CS/PMCG Storage stability after 35 days CPG Time for complete bioconversion 0 0 1 2 3 4 5 6 7 8 9 10 11 cycle number igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 Conclusion remarks to polymers used in encapsulation of biological substances BIOTECHNOLOGY • industrially utilized process using mainly “simple” encapsulation systems (alginates, pectates, PVA) • ? effect of tight-controlled parameters on efficiency vs. cost • a “simple” problem compared to biomedicine igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 Conclusion remarks to polymers used in encapsulation of biological substances BIOMEDICINE long-term biocompatibility – capsules tested and tailored in vitro, the in vivo performance = black-box • inter-laboratory repeatability is poor • polymers – lacking characteristics, purity, and standardization (and fate in vivo after losing performance) • locus of transplantation? • final composition of polymeric material? (microsphere = gelled SA?; microcapsule = ???) • “academic” approaches – change them to the applicationdriven activities (+ 5 years time…?) igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 Concluding message è whether success or failure, always (for understanding the topic of immobilization of biological substances) 1. THINK OF POLYMERS AND PROCESS, and 2. SEARCH FOR MESSAGES FROM POLYMER CHEMISTRY ©2004, ©2004, www.cavalier.sk www.cavalier.sk igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 Acknowledgement Polymer Institute SAS, Bratislava (polymers) G. Kolláriková, M. Danko, E. Hipka, S. Hanzelova, M.Stach, A. Durisova International laser center, Bratislava (AFM, CLSM, SIMS) D.Chorvát, Jr., J. Podskočová Institute of Chemistry SAS, Bratislava (enzyme engineering) P. Gemeiner, M. Bučko, A. Vikartovská, J. Nahalka Institute of experimental endocrinology, Bratislava (islets) V. Štrbák, J. Benický, M. Najvirtová, Z. Bačová Slovak grant agency for support of science and technology APVT, BASF Ludwigshafen, Slovak Grant Agency VEGA, COST 840 igor.lacik@savba.sk Neuchâtel, Switzerland,,July 6-7 2005 Acknowledgement Nashville Cell Encapsulation Team, Vanderbilt Uni (NASA, NIH, NSF) T. G. Wang A. V. Anilkumar M. Brissova D. Hunkeler A. Prokop A. Powers K. Xu igor.lacik@savba.sk PI reactor design capsule design, permeability capsule design capsule design medical center AFM Neuchâtel, Switzerland,,July 6-7 2005