Maximum safety in maintenance Energy Management Suite Instrumentation, Controls & Electrical

advertisement

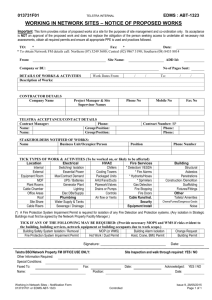

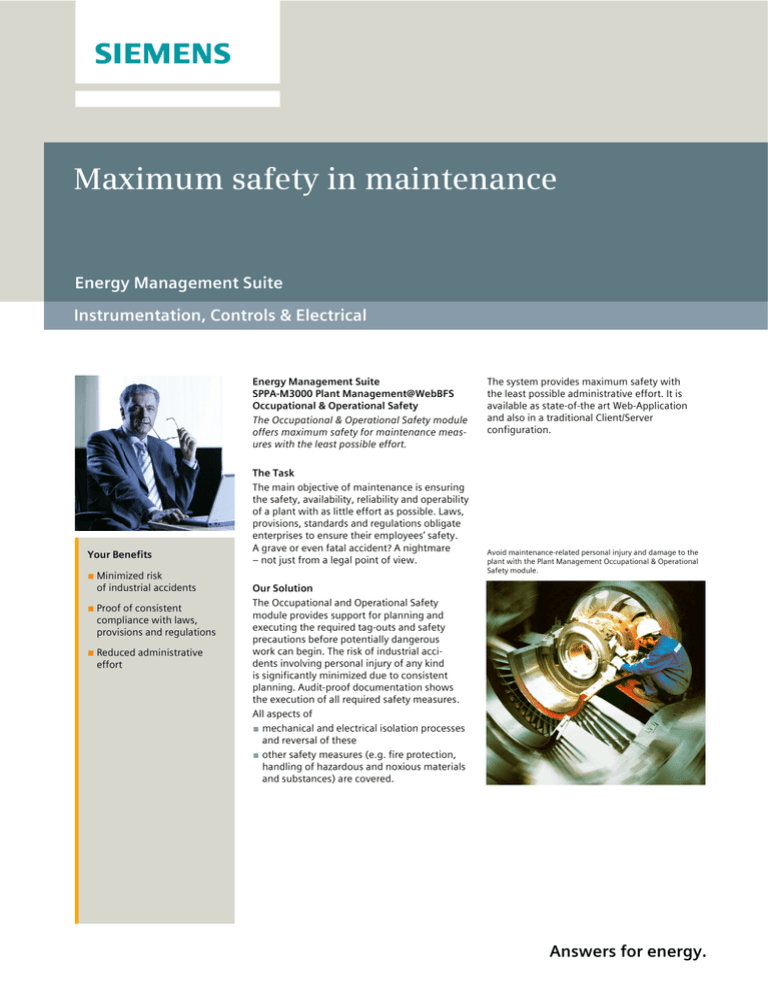

Maximum safety in maintenance Energy Management Suite Instrumentation, Controls & Electrical Energy Management Suite SPPA-M3000 Plant Management@WebBFS Occupational & Operational Safety The Occupational & Operational Safety module offers maximum safety for maintenance measures with the least possible effort. Your Benefits The Task The main objective of maintenance is ensuring the safety, availability, reliability and operability of a plant with as little effort as possible. Laws, provisions, standards and regulations obligate enterprises to ensure their employees’ safety. A grave or even fatal accident? A nightmare – not just from a legal point of view. ■ Minimized risk of industrial accidents ■ Proof of consistent compliance with laws, provisions and regulations ■ Reduced administrative effort The system provides maximum safety with the least possible administrative effort. It is available as state-of-the art Web-Application and also in a traditional Client/Server configuration. Avoid maintenance-related personal injury and damage to the plant with the Plant Management Occupational & Operational Safety module. Our Solution The Occupational and Operational Safety module provides support for planning and executing the required tag-outs and safety precautions before potentially dangerous work can begin. The risk of industrial accidents involving personal injury of any kind is significantly minimized due to consistent planning. Audit-proof documentation shows the execution of all required safety measures. All aspects of ■ mechanical and electrical isolation processes and reversal of these ■ other safety measures (e.g. fire protection, handling of hazardous and noxious materials and substances) are covered. Answers for energy. Functional overview Tag-out (isolation) process To carry out work on process-related or electrical plant items that involves potential danger to persons, the environment or the plant, such plant items need to be isolated, i.e. disconnected from the process. Some of the functions provided by the isolation program: ■ Definition of an isolation process including description of the plant section, operating condition and the period to perform the work ■ List of all plant parts that need to be tagged out (mechanically/ electrically) ■ Assignment of the work to be completed during the respective isolation process ■ Coordination of the tag-out schedule and the work schedule ■ Tag-out list specifying individual switching operations and measures ■ Untagging list specifying the required switching operations and measures ■ If required: specification of switching operations for the trial run ■ Check for conflicts with other isolation processes ■ Tracking the workflow of an isolation process ■ Printout of isolation lists and tags Tag-out overview The program shows all isolation measures currently active and thus also provides a quick overview to the shift. Published by and copyright © 2012: Siemens AG, Energy Sector Freyeslebenstrasse 1 91058 Erlangen, Germany For more information contact sppa-m3000.energy@siemens.com www.siemens.com/energy/sppa-m3000 Siemens Energy, Inc. Instrumentation, Controls, & Electrical 1345 Ridgeland Parkway, Suite 116 Alpharetta, GA 30004, USA The disconnection list of an Isolation as part of a work permit Standard isolation process This can be used as a quality-assured template for certain isolation processes that are used repeatedly. Its structure and contents correspond to a regular isolation process, but no concrete work is assigned and no dates are entered. It can be created by simply duplicating an isolation process that has already been carried out. Safety precautions Particularly hazardous work, involving dangers such as explosion, fire, radiation, poisoning or suffocation, mandates careful planning, execution and maintenance of the requisite safety precautions. Whether such precautions are required and what these precautions are can be specified when planning maintenance M2PM7_FS_Safety_e_V3-0 Order No. E50001-G230-A261-X-4A00 Printed in Germany Dispo 05401, c4bs-Nr. 7465 Printed on elementary chlorine-free bleached paper. work with the Maintenance Management module. In addition, the workflow of the safety precaution is tracked and documented. Work permit and approval program Before carrying out maintenance work, the required safety precautions need to be registered in the system in the form of work permit slips, regardless of whether they are required before, during or after the work. Common safety precautions include precautions for confined-space entry, hot work and work with hazardous materials. Permit slips can be planned for any work order item. Safety precautions frequently used in the same manner may be copied for simple and convenient reuse. All rights reserved. Trademarks mentioned in this document are the property of Siemens AG, its affiliates, or their respective owners. Subject to change without prior notice. The information in this document contains general descriptions of the technical options available, which may not apply in all cases. The required technical options should therefore be specified in the contract.