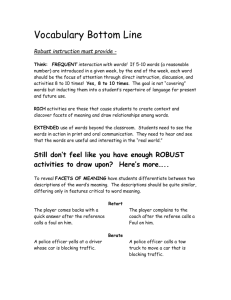

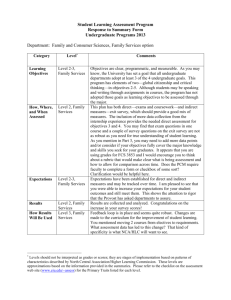

Internalization of Robust Engineering Methods in

advertisement